Dual-roller dual-cavity three-impact crusher

A crusher and crushing roller technology, applied in grain processing and other directions, can solve the problems of rapid wear and consumption of the wearing parts of the hammer head, the difficulty of crushing and processing operations, and the influence of production work order, etc. The effect of improving adaptive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

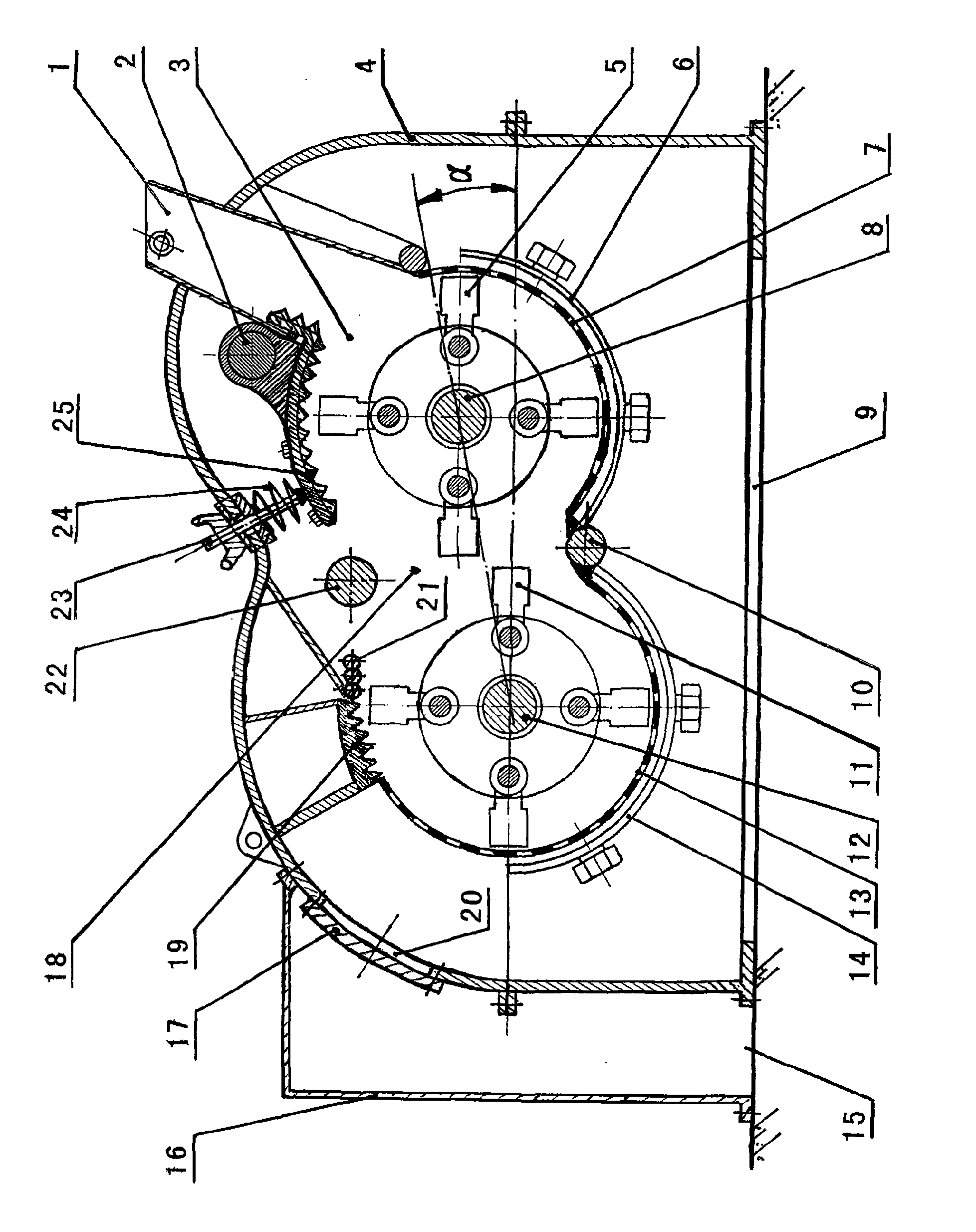

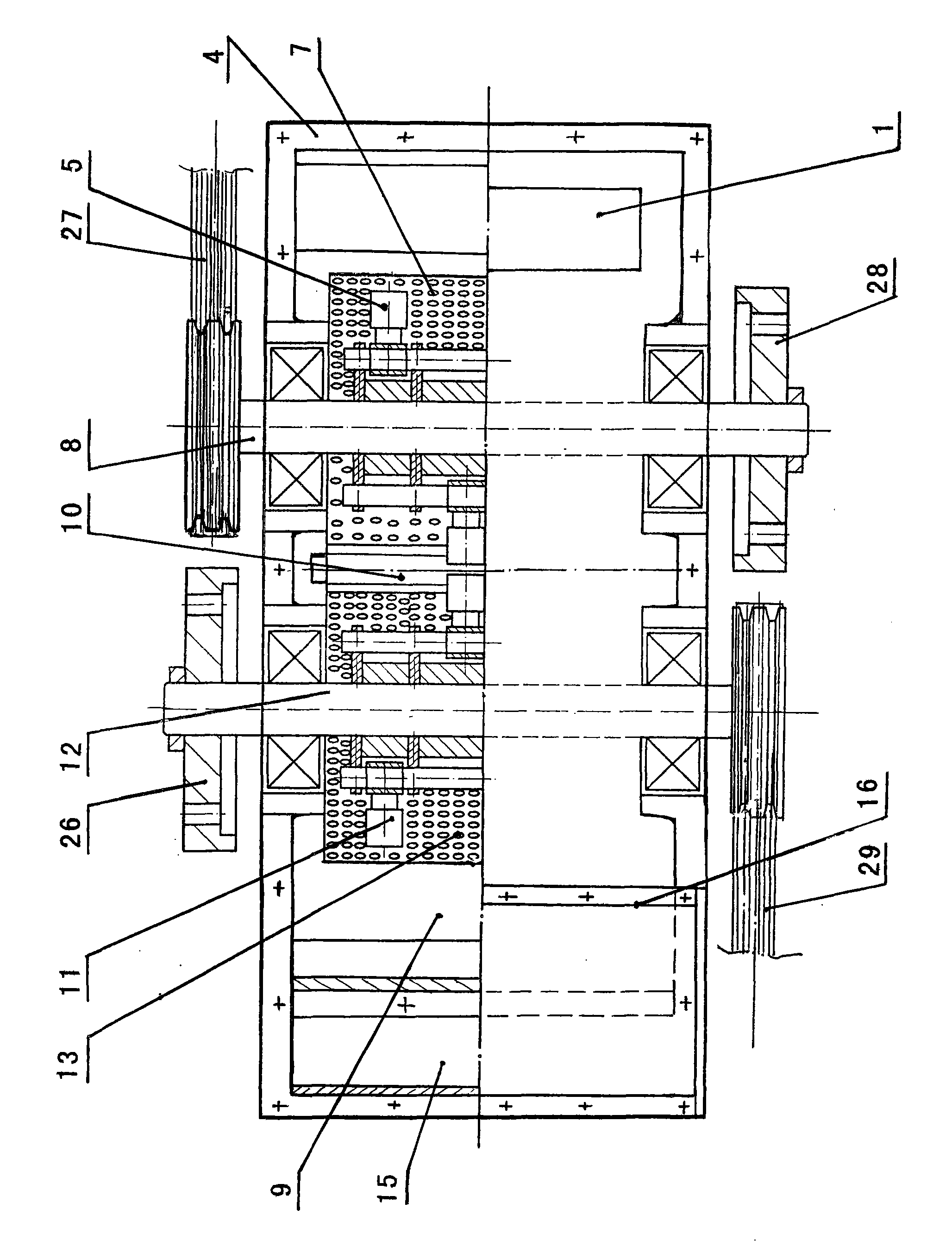

[0016] The following describes the embodiment of the double-roller double-cavity triple-strike crusher proposed by the present invention in conjunction with the accompanying drawings:

[0017] A double-roller, double-cavity, three-strike crusher, which is mainly composed of a feed hopper 1, a chassis shell 4, a movable tooth plate 25, a fixed tooth plate 19, an impact bar 21 and a crushing roller shaft 8 and a fine crushing roller shaft respectively. 12 broken hammer head 5, broken flywheel 28 and finely crushed hammer head 11, finely crushed flywheel 26 are composed of broken material sieve 7, finely crushed material sieve 13 and a group of detachable Type brackets 6, 14 are hinged at the upper position of the crushing roller shaft 8 by a pin shaft 2 and equipped with a movable tooth plate 25 to form a crushing working chamber 3. The movable tooth plate 25 is equipped with a spring 24 and a screw rod 23. The adjusting device can easily adjust the position of the movable tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com