Angle grinder

A technology of angle grinder and rotor, which is applied in the direction of grinding machine, portable grinding machine, grinding/polishing equipment, etc. It can solve the problems of reducing the service life of bearings, low service life of bearings, and easy leakage of lubricating oil, so as to improve the durability of gears Degree, improve gear durability, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

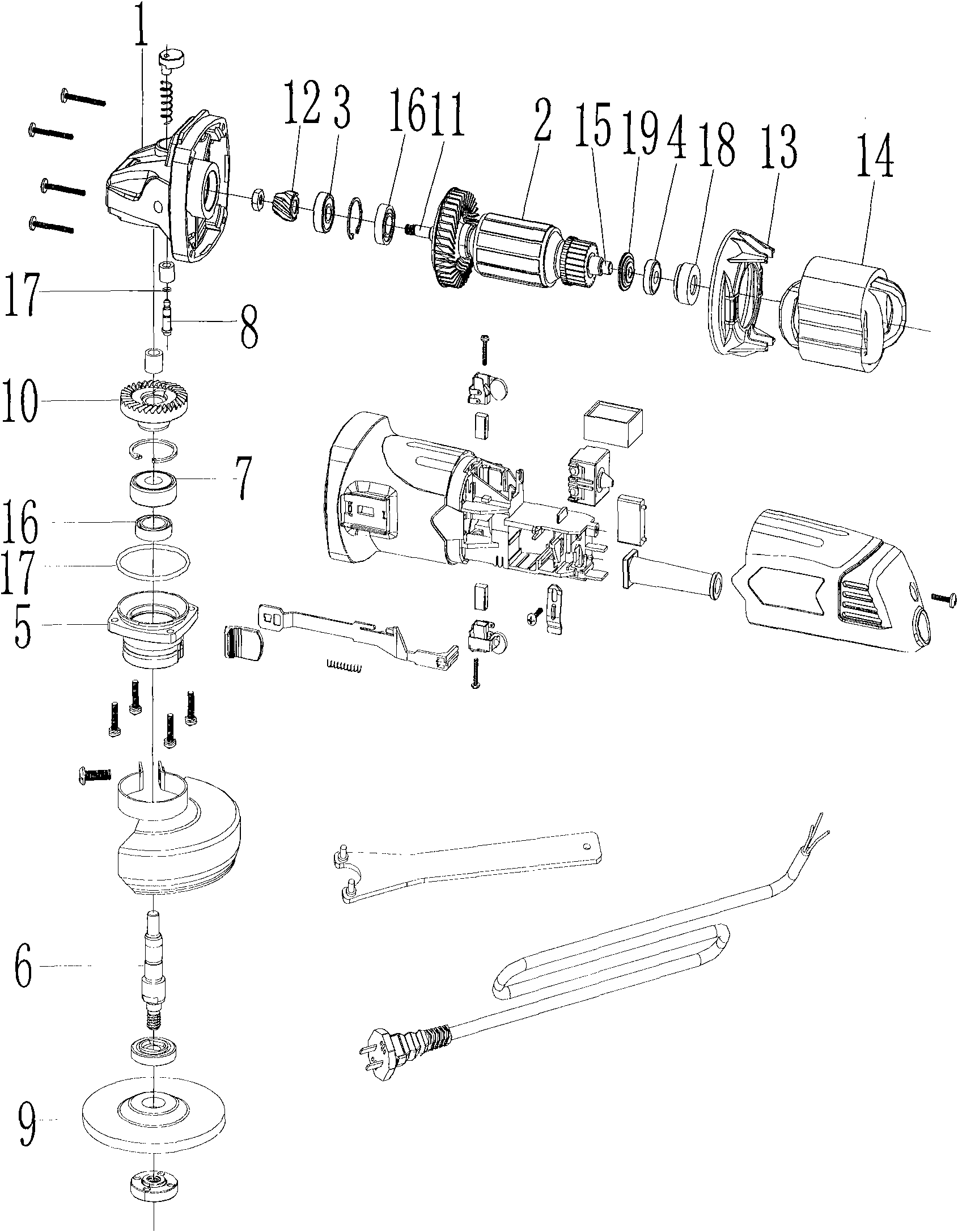

[0013] Such as figure 1 and figure 2 As shown, the angle grinder of the present invention includes a gearbox 1, a rotor 2, a rotor front bearing 3, a rotor rear bearing 4, a bearing housing 5, an output shaft 6, an output shaft bearing 7 and a lock pin 8, and the output shaft 6 One end passes through the bearing box 5 and is fixedly connected to the angle grinder grinding wheel 9, and the other end is fixedly connected to the large gear 10. The large gear 10 meshes with the pinion 12 fixed on the rotor front shaft 11. The outer side of the rotor rear bearing 4 A windshield 13 and a stator 14 are connected, and the windshield 13 and the stator 14 are both sleeved on the rotor rear end shaft 15; between the rotor front bearing 3 and the rotor front end shaft 11 and between the output shaft bearing 7 and the output shaft 6 Elastic oil seals 16 are installed between them, and O-rings 17 are installed on the lock pin 8 of the gear box 1 and the end cover opening of the bearing bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com