Optical fiber drawing heating furnace

A heating furnace and optical fiber technology, applied in the field of optical fiber production, can solve the problems of uneven size control and low manufacturing efficiency, and achieve the effect of ensuring stability and size control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

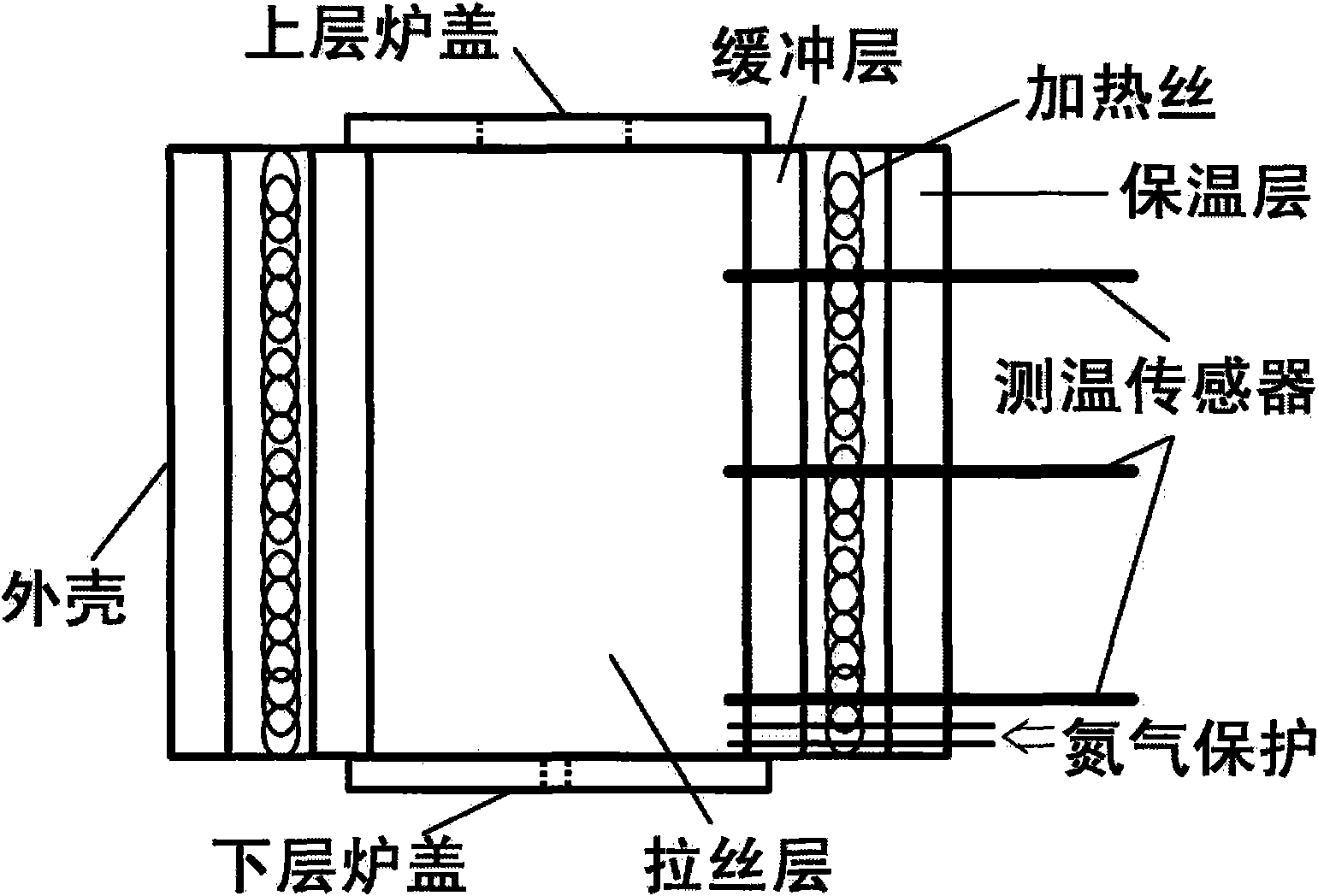

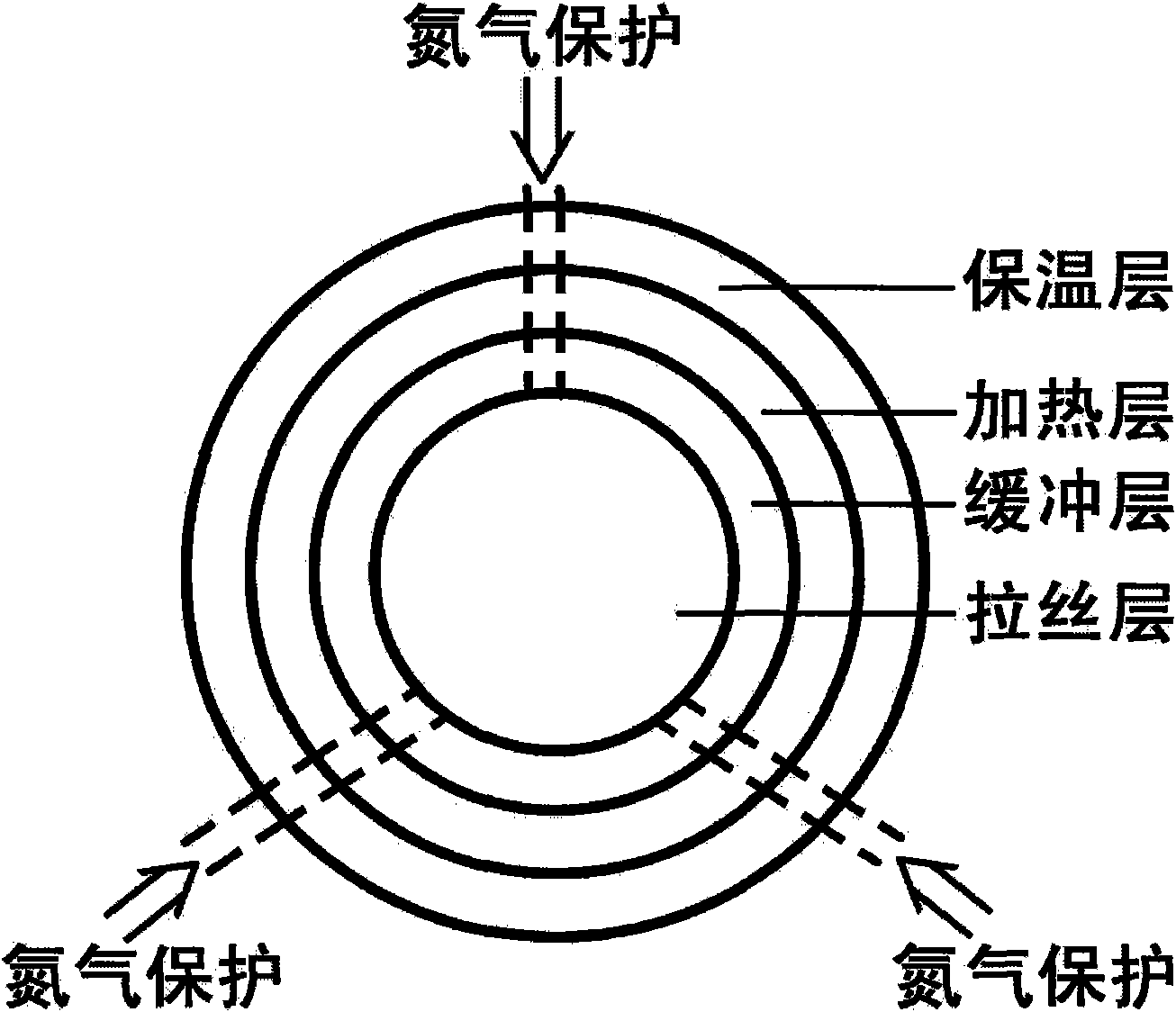

[0019] figure 1 The overall structure of the optical fiber heating furnace of the present invention is shown. The heating furnace is generally a cylindrical structure, which is divided into 5 layers from outside to inside: outer shell, insulation layer, heating wire, buffer layer, and wire drawing layer. And equipped with three sets of temperature sensors, three sets of protective gas ventilation devices ( figure 1 , figure 2 The position pointed to by "nitrogen protection" in the middle), and the upper and lower furnace covers. Among them, three sets of temperature sensors are perpendicular to the above-mentioned 5 layers (i.e. shell, insulation layer, heating wire, buffer layer, drawing layer), that is, perpendicular to the central axis of the cylindrical structure, and run through the above-mentioned 5 layers (i.e. inserted from the shell, until inserted into the brushed layer). Among them, the three sets of protective gas ventilation devices are also perpendicular to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com