Power semiconductor module

A technology of power semiconductors and conductor rails, applied in the field of power semiconductor modules, which can solve the problems of reduced lifespan, unreliable elimination of cracks, and reduced breakdown strength of power semiconductor modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

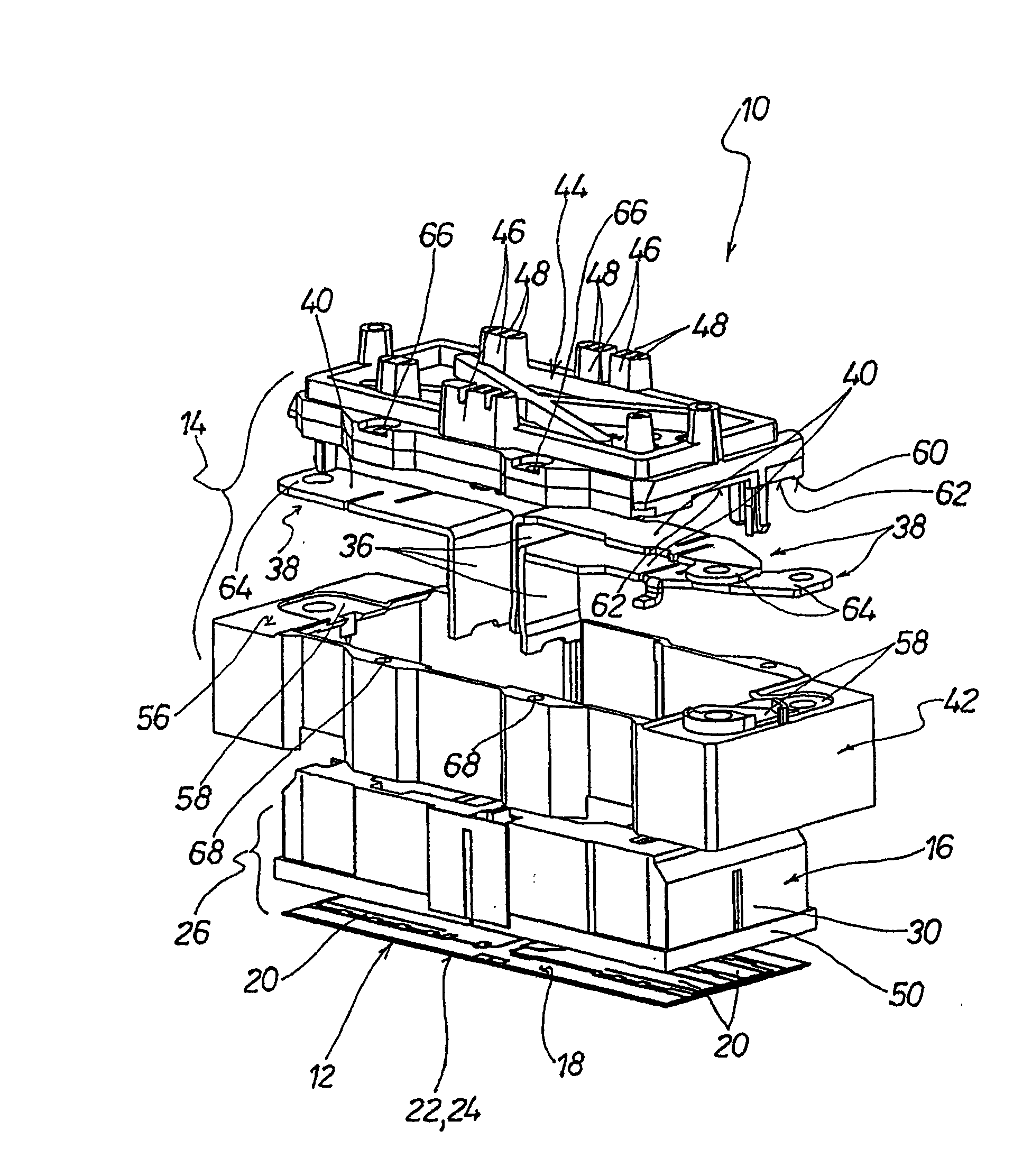

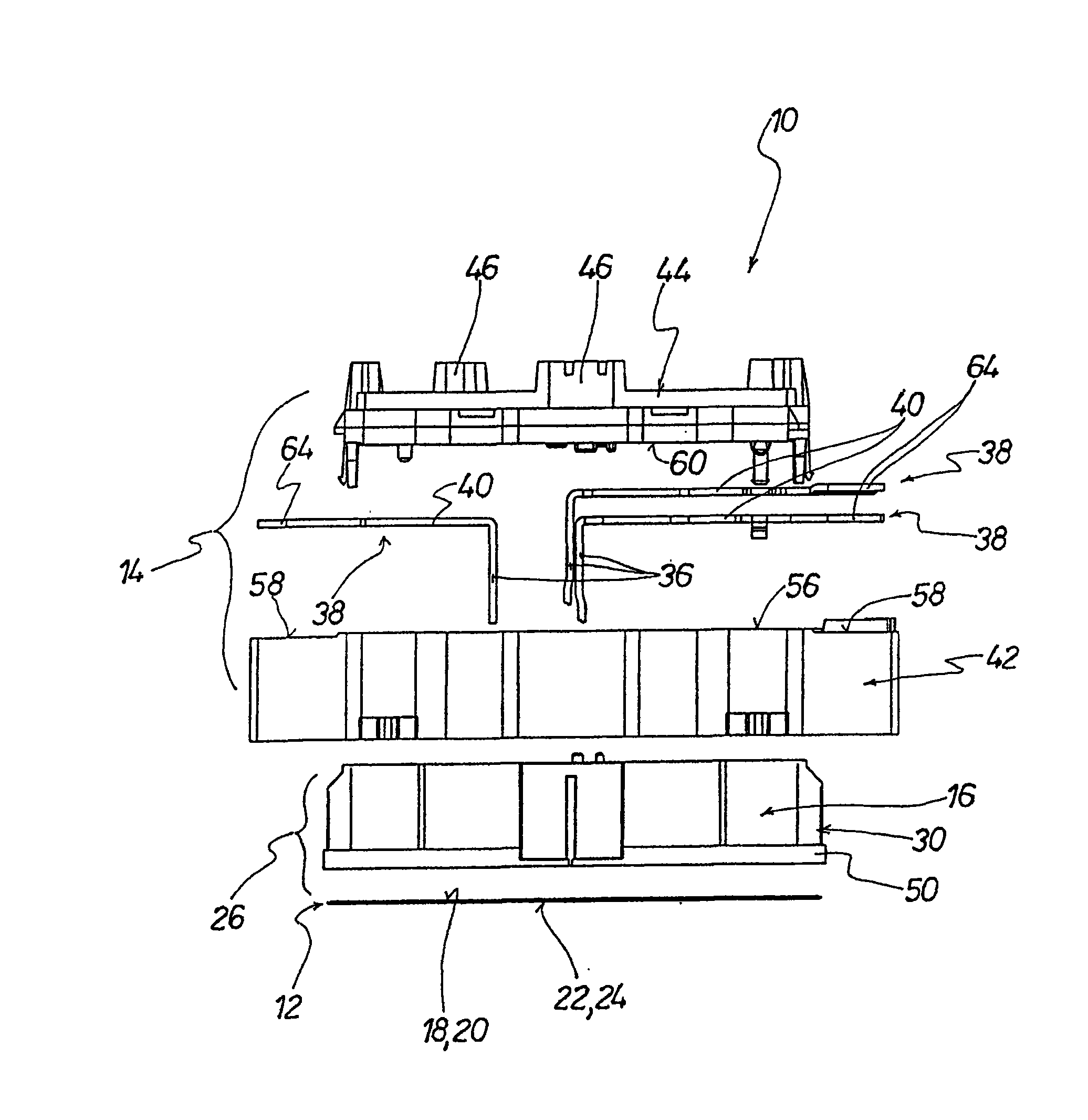

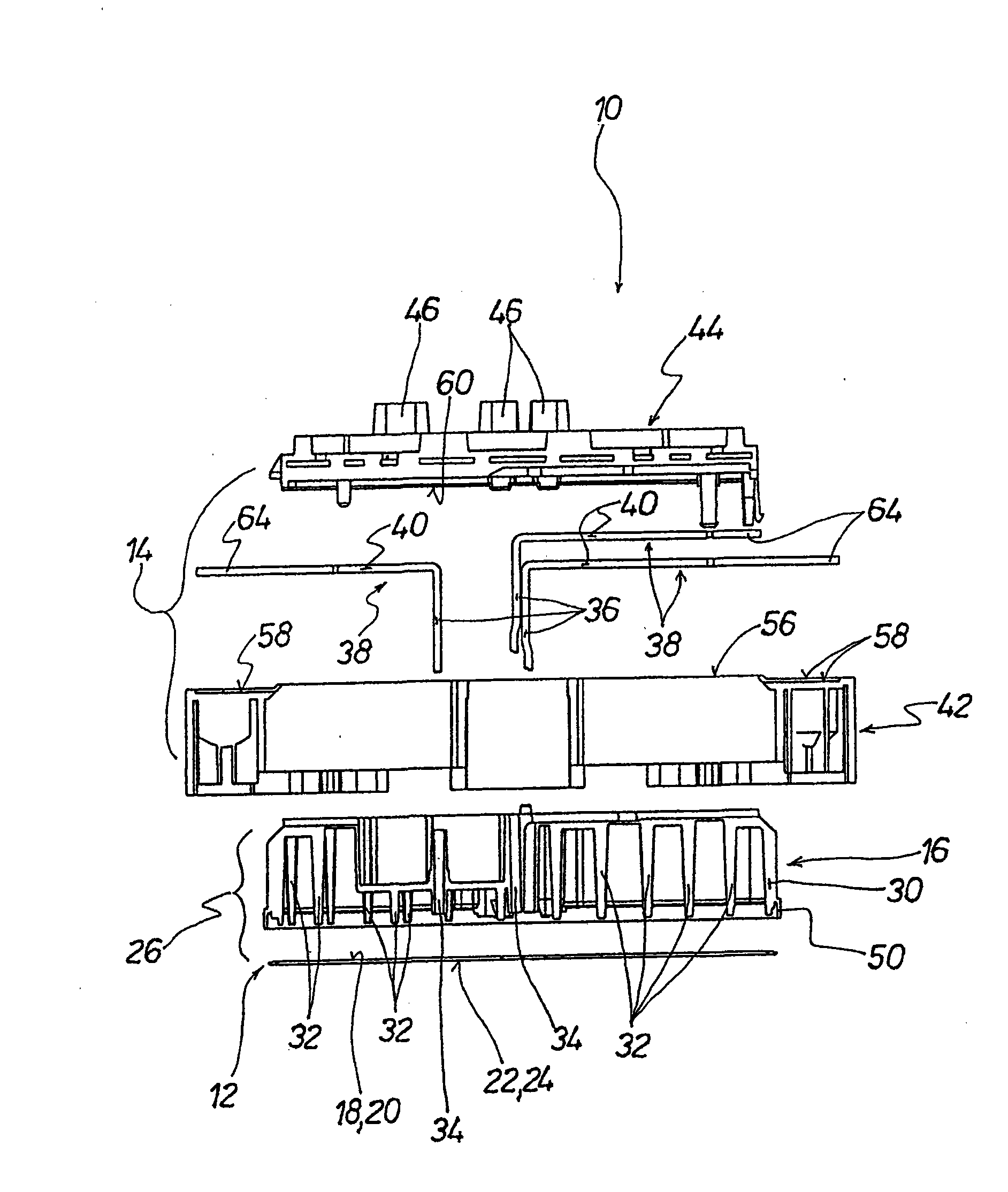

[0018] figure 1 An embodiment of a power semiconductor module 10 is shown, which has a substrate 12 , a housing 14 and a bridge element 16 . as by Figure 4 It can be seen that the substrate 12 has conductor tracks 20 and power semiconductor components (not shown) on the first main surface 18 and a metal layer 24 on the opposite second main surface 22 . A metal layer 24 is provided for dissipating heat to cooling structures (not shown).

[0019] The substrate 12 together with the bridge element 16 forms a structural unit 26 which is movable in a restricted manner in all transverse directions parallel to the first main body surface 18 and the second main body surface 22 in the housing 14 . restricted mobility in Figure 4 is represented by double arrow 28 . Furthermore, movement in a direction perpendicular to said transverse direction is also possible.

[0020] as by image 3 It can be seen that the bridge element 16 is configured in the shape of a cap with an annular si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com