Solderless circuit chip carrier socket

A circuit chip and socket technology is applied in the field of solder-free circuit chip sockets, which can solve the problems of easily damaged printed boards, scrapped printed boards, and easy damage of printed boards and chips, and achieves the effect of reliable connection and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment accompanying drawing, the present invention is described in further detail:

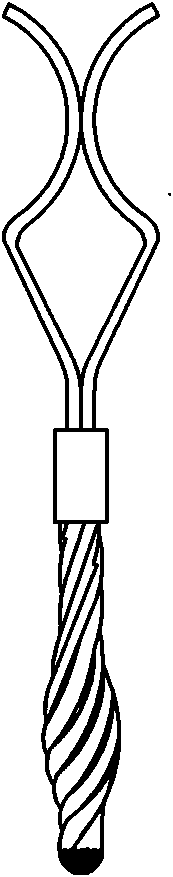

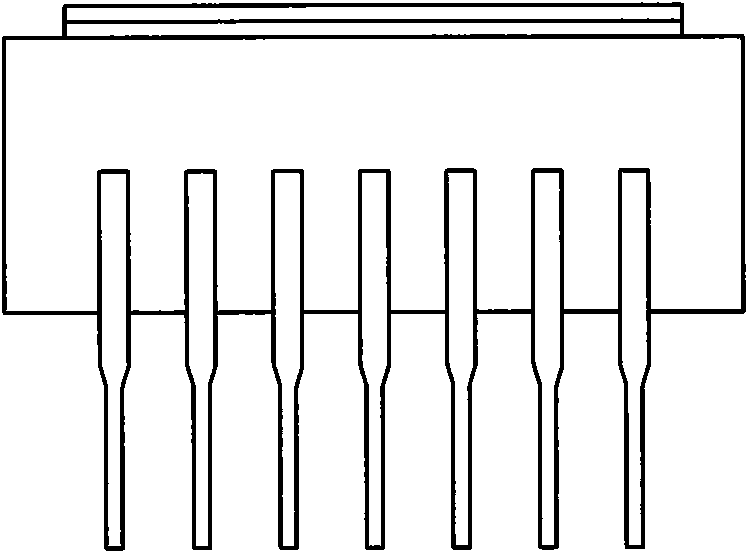

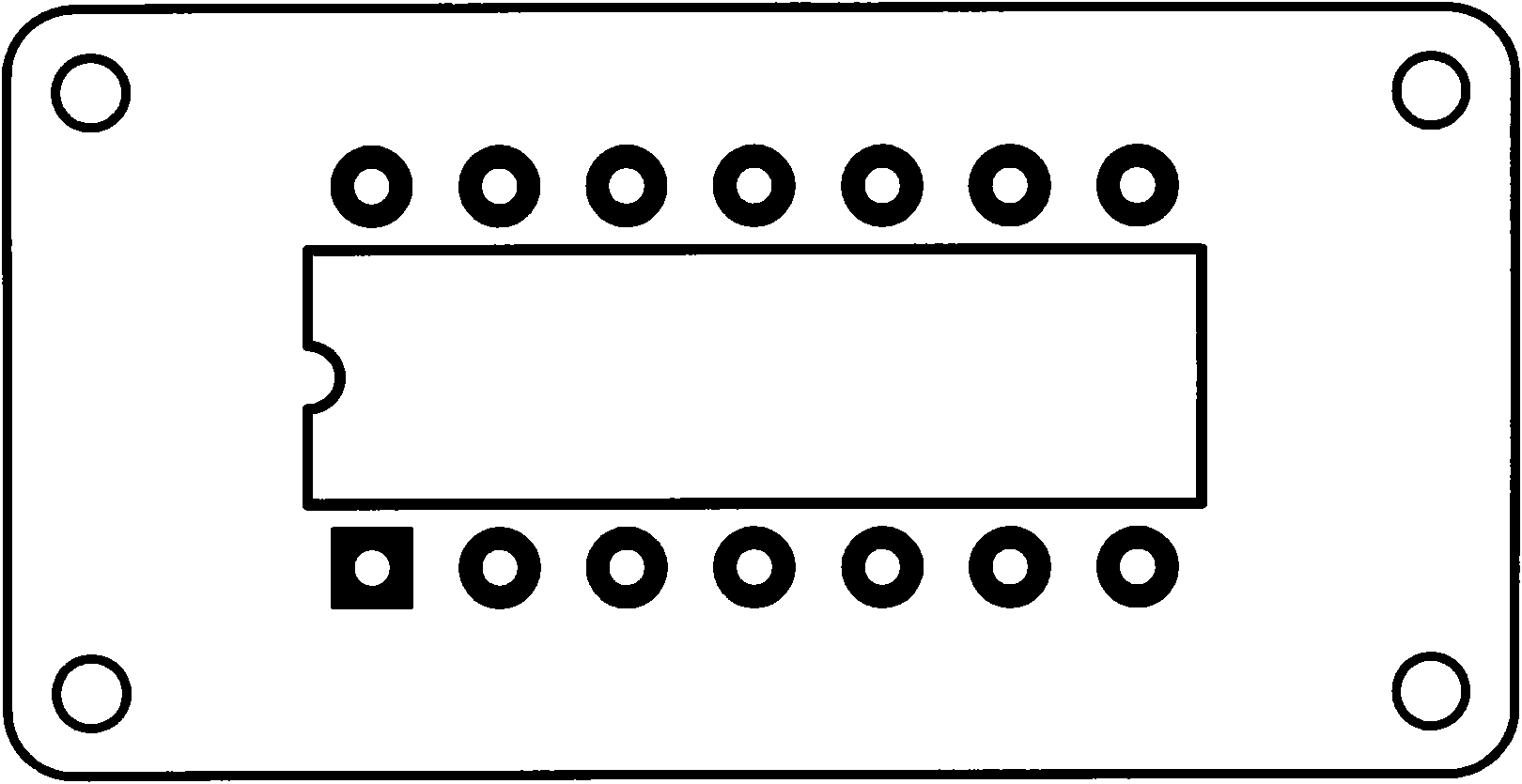

[0021] A solder-free circuit chip socket includes a twist needle reed assembly 1 and a plastic base 2 . First install the twist needle reed assembly 1 on the plastic base 2, install a twist needle reed assembly 1 in each hole on the plastic base 2, and then fix the two together with glue to form a whole. Form a solderless circuit chip socket.

[0022] Insert the twist needle of the twist needle reed assembly 1 into the hole on the printed board 3. Since the hole on the printed board 3 is smaller than the fat point of the twist needle, the solderless circuit chip socket and the printed board 3 are reliable. connect. Insert the circuit chip 4 from the solder-free circuit chip socket again, the pins of the circuit chip 4 will be inserted into the middle of the twist needle reed assembly 1, at this time, the circuit chip 4 elastically contacts with the twist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com