Biomedical electrode with surface micro-structure array and manufacturing method thereof

A microstructure array, biomedical technology, applied in applications, medical science, sensors, etc., can solve the problems of poor repeatability, inaccurate measurement results, unsuitable for long-term use, etc., achieve moderate production costs, expand the scope of use, and process Effects with low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

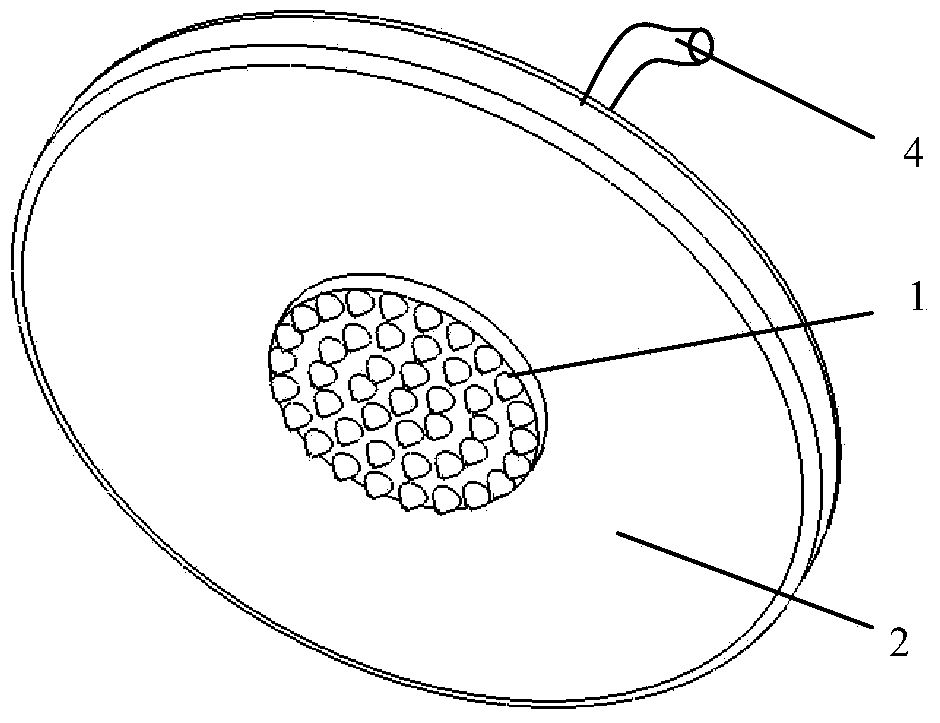

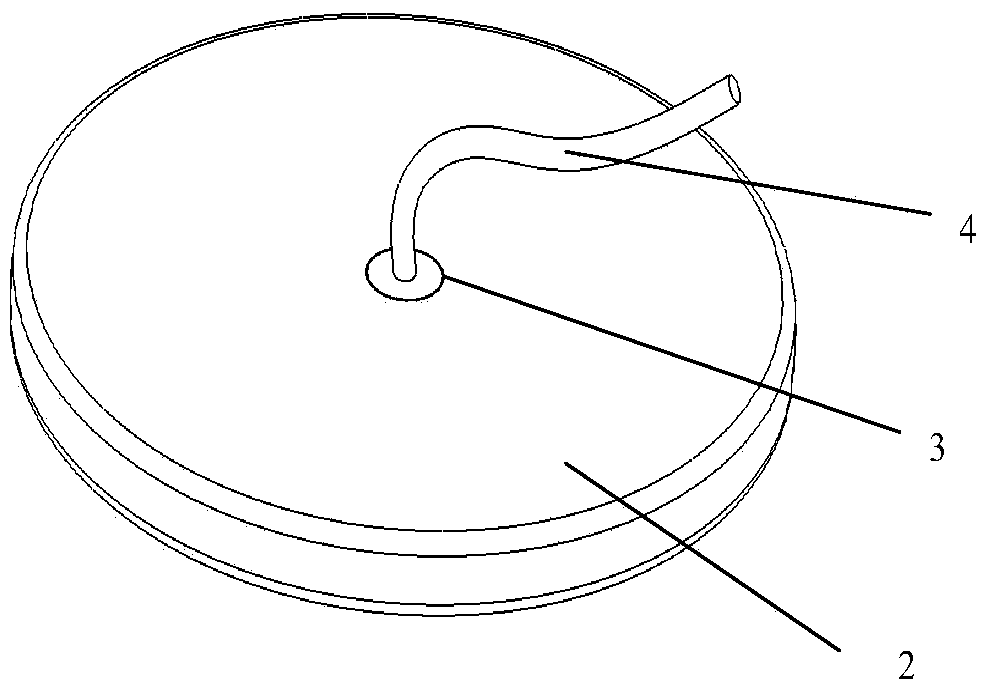

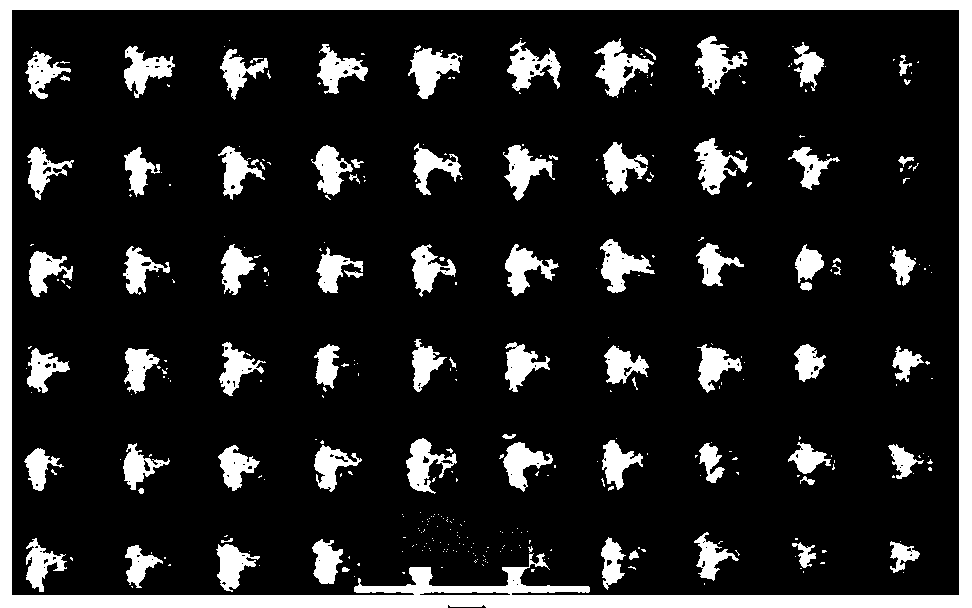

[0027] Such as Figure 1~3 As shown, a biomedical electrode with surface microstructure array characteristics includes four parts: metal electrode core 1 , foam material backing 2 , conductive silver glue 3 and shielding wire 4 . The metal electrode core 1 is pasted on the other side of the foam material backing 2, such as figure 1 shown. The foam backing material 2 and the shielded wire 4 realize the solderless connection through the conductive silver glue 3, such as figure 2 shown. The surface of the metal electrode core has surface cone-like microstructure array features, such as image 3 shown.

[0028] The manufacturing process method includes the following steps:

[0029] The first step is laser processing. Copper metal flakes are selected as the raw material of the metal electrode core. By designing the laser processing route and using laser micromachining technology, a linear array with a vertical and horizontal spacing of 0.1mm×0.1mm conical surface microstruct...

Embodiment 2

[0036] The raw material of the electrode core in the first step can be selected as a metal aluminum sheet material, and a linear array of columnar microstructures with a vertical and horizontal spacing of 0.2mm×0.2mm can be formed by laser processing. Others are the same as in Example 1.

Embodiment 3

[0038] The raw material of the electrode core in the first step can be selected as a stainless steel sheet material, and a linear array of circular microstructures with a vertical and horizontal spacing of 0.3mm×0.3mm can be formed by laser processing. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com