Flexible air-bag type controlled atmosphere device

A flexible airbag and atmosphere technology, applied in coating, chemical/physical/physicochemical process, metal material coating process, etc., can solve the problems of high cost of vacuuming, long pumping time, etc., and achieve simple and light structure, pumping Gas equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0038] The invention adopts the characteristics of flexible materials to produce flexible airbags. Then design a cavity that is rigid, capable of supporting, and has a certain strength. After the flexible airbag is sealed and connected with the cavity, the space formed by the sealing connection between the flexible airbag and the cavity is pumped using the principle of negative pressure. / Inflation, thereby providing a simple flexible airbag-type controlled atmosphere device for metal parts processing under very low pressure. The low-cost material selected for the flexible air bag belongs to plastic.

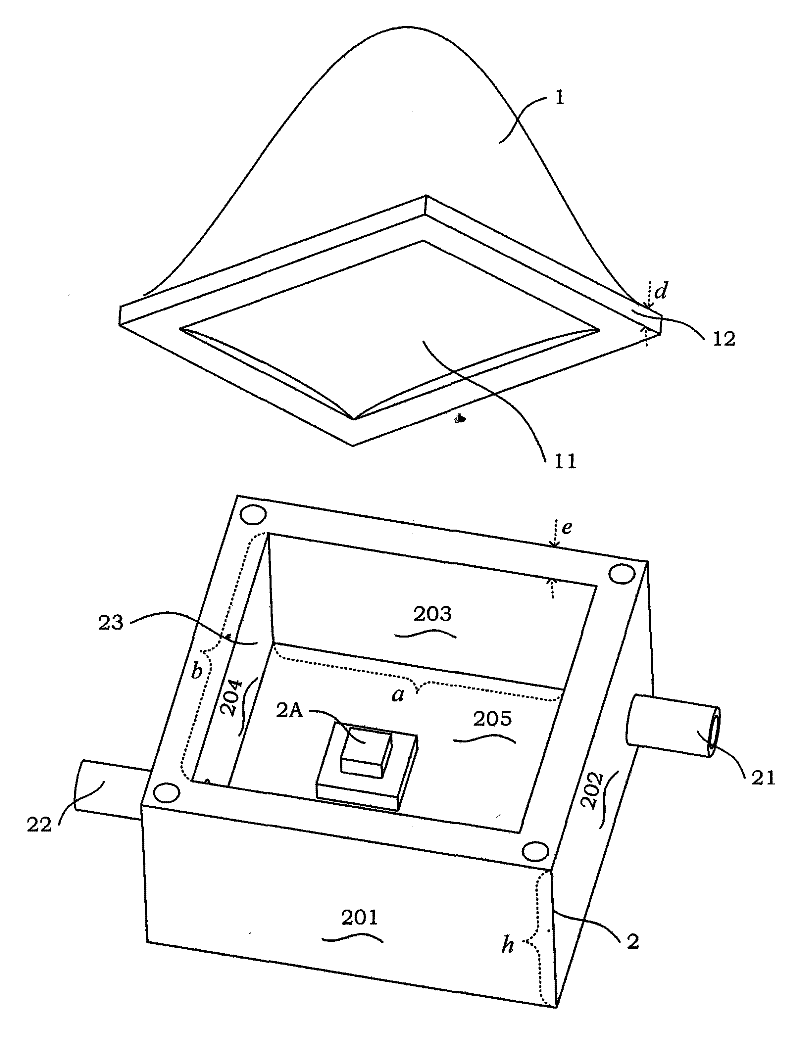

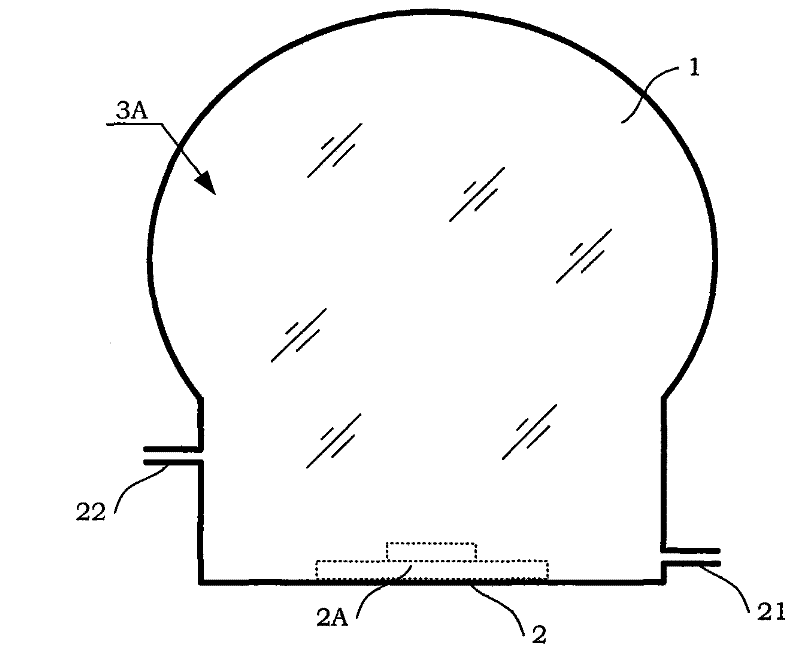

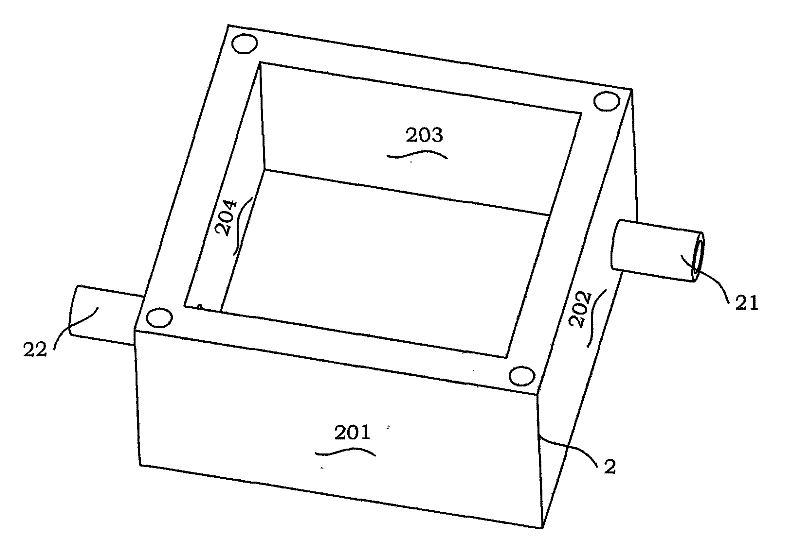

[0039] see figure 1 , Figure 1A ~ Figure 1F As shown, a flexible airbag-type controllable atmosphere device of the present invention is composed of a flexible airbag 1 and a cavity 2, the A opening end 11 of the flexible airbag 1 is sealed and connected w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com