Hinged pressure-proof water tight door

A hinged, watertight door technology, applied to the layout of watertight doors, ships, etc., can solve the problems of increasing production costs and increasing the thickness of door panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

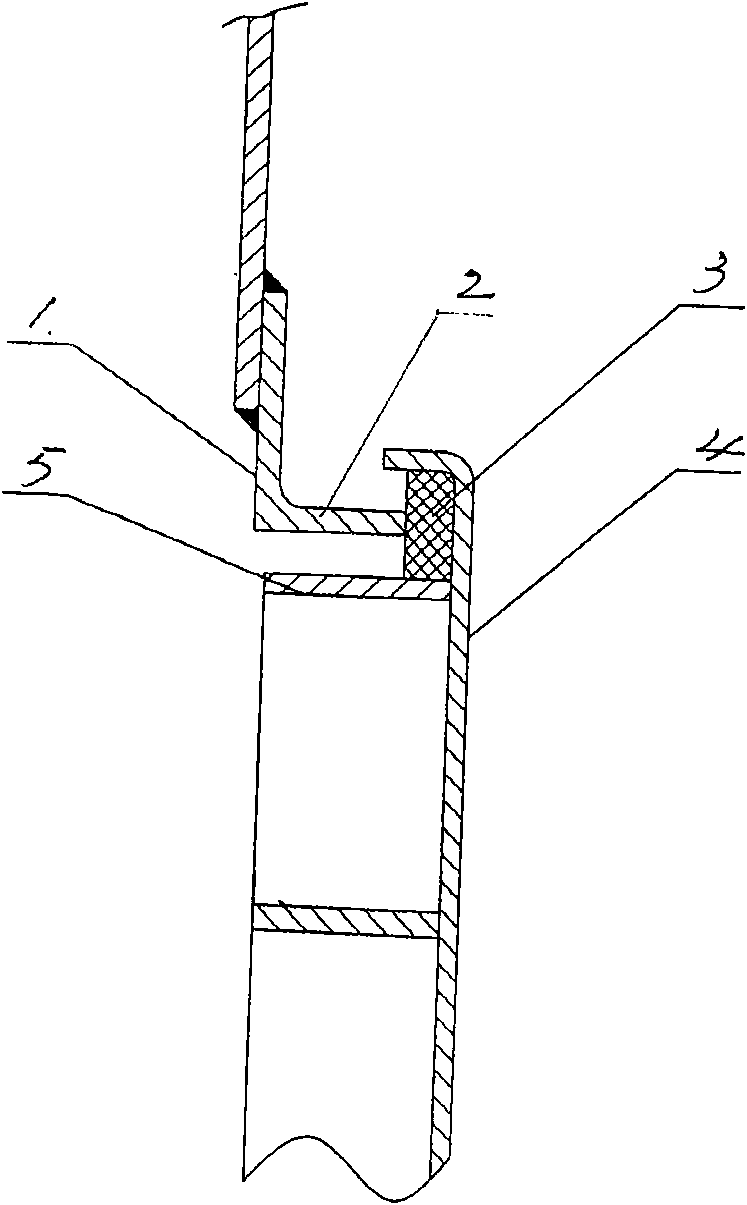

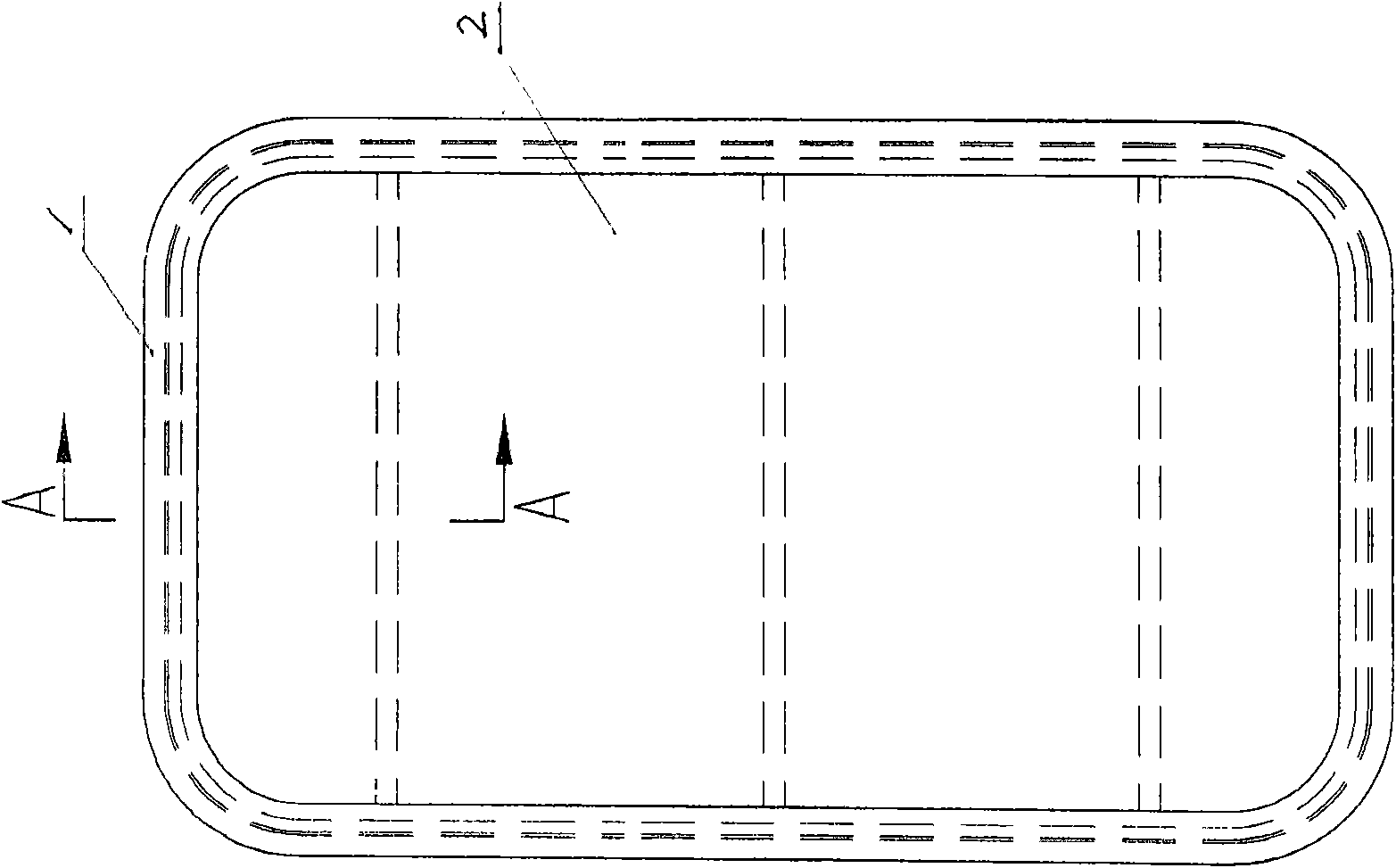

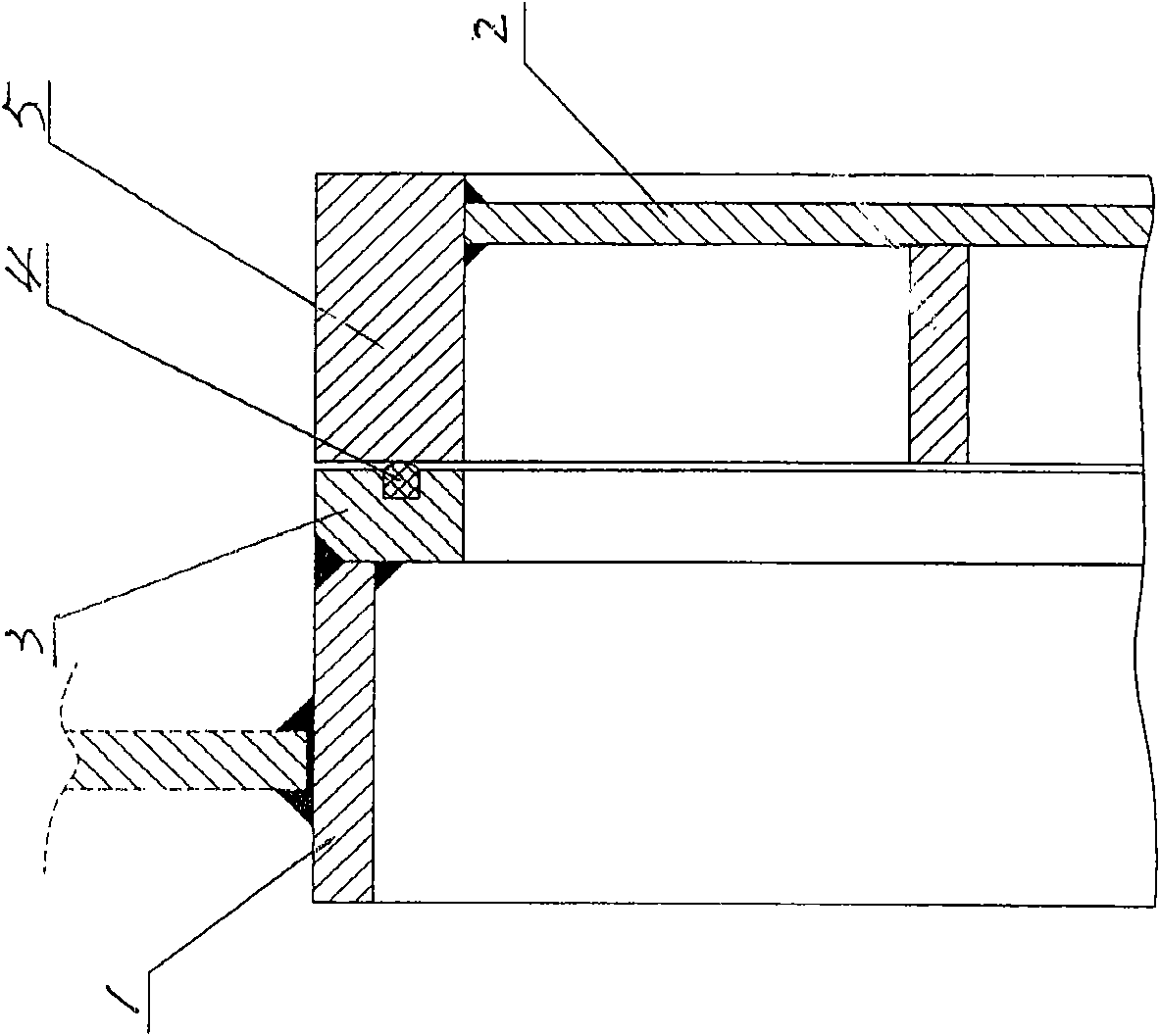

[0013] like figure 2 and image 3 As shown, the hinged pressure-resistant watertight door of the present invention includes a door frame 1 and a door panel 2, and one side of the door frame 1 and the door panel 2 is hinged together by means of a hinge. An inner convex edge 3 is processed around the outer edge of the door frame 1 , and the inner convex edge is formed by welding metal plates, and its thickness is greater than that of the door frame 1 . A frame is welded around the door panel 2 , and the perimeter of the frame protrudes outside the inside of the door panel 2 , so that an inward protrusion 5 is formed around the door panel 2 . The thickness of the inward protrusion 5 is equal to the thickness of the inner flange 3 of the door frame 1 .

[0014] A circumferential groove is processed on the outer surface of the inner flange 3 of the door frame 1, and a sealing strip 4 is embedded in the circumferential groove, and the sealing strip 4 protrudes outside the circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com