Corrugated board and corrugated carton production process

A corrugated cardboard and corrugated box technology, applied in paper/cardboard layered products, special paper, paper/cardboard containers, etc., can solve the problems that it is difficult to coat the corrugated body with a waterproof coating and the defective rate of corrugated cardboard is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

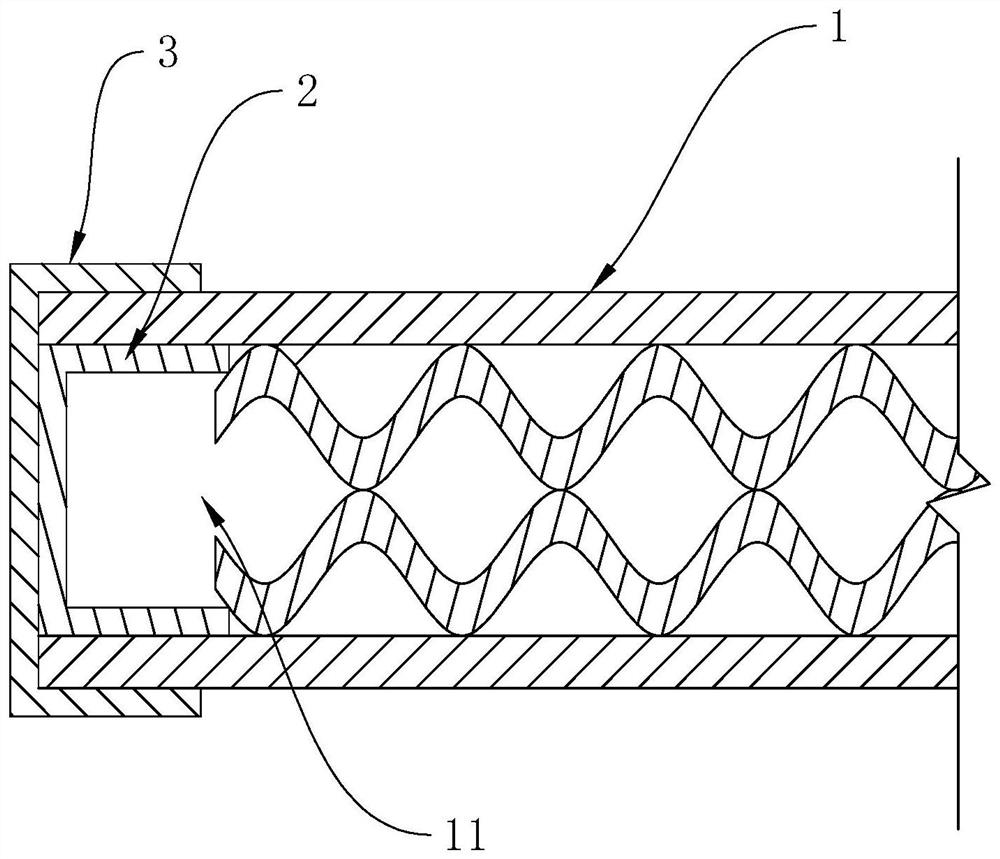

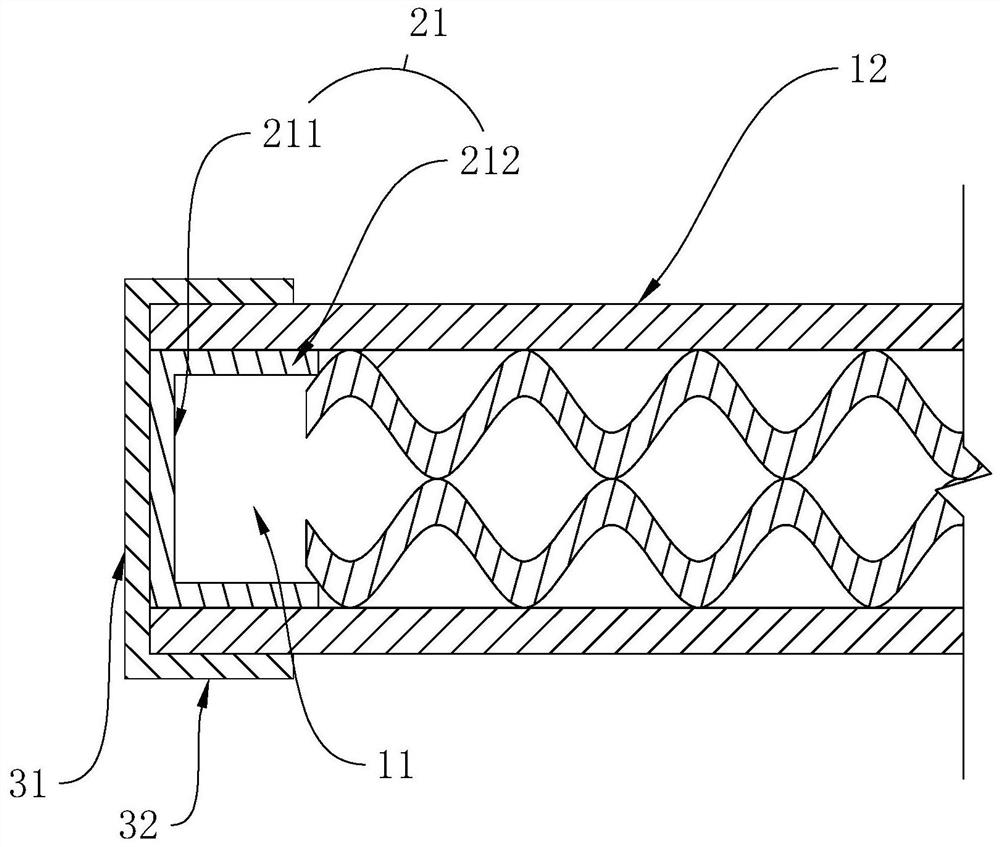

[0042] The embodiment of the application discloses a corrugated cardboard. refer to figure 1, the corrugated cardboard includes a corrugated cardboard body 1 and a sealing filler 2; wherein, a filling groove 11 around the corrugated cardboard body 1 is provided on the side wall of the corrugated cardboard body 1, and the sealing filler 2 is installed in the filling groove 11, And the end of the sealing filler 2 is connected.

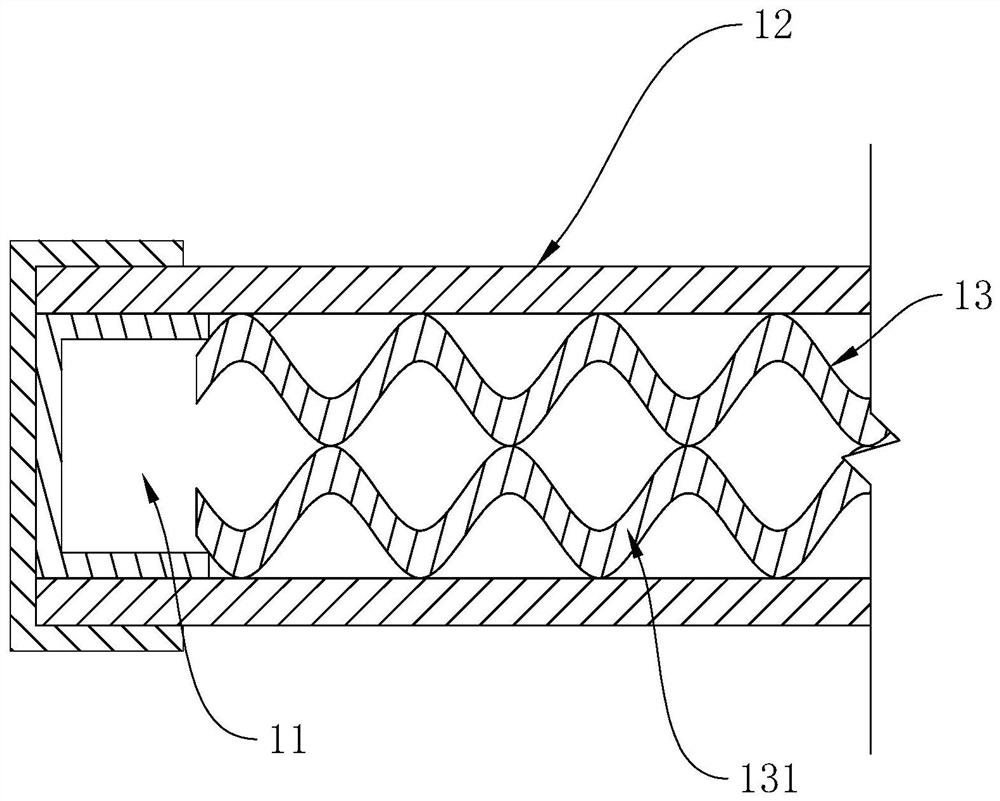

[0043] refer to figure 2 The corrugated cardboard body 1 includes a surface paper 12 and a corrugated body 13. There are two surface papers 12, and the two surface papers 12 are respectively arranged on both sides of the corrugated body 13, and the two surface papers 12 are arranged on the opposite side. Both are coated with a waterproof coating (not shown in the drawings) for preventing water vapor from directly intruding into the corrugated cardboard body 1; wherein, each peripheral side of the surface paper 12 protrudes outside the corrugated body ...

Embodiment 2

[0049] refer to Figure 4 The difference between this embodiment and Embodiment 1 is that the sealing filler 2 is set as a waterproof sealing strip 22, and the side of the waterproof sealing strip 22 away from the corrugated body 13 is on the same plane as the side wall of the corrugated cardboard body 1 .

[0050] The implementation principle of embodiment 2 is:

[0051] The cross-section of the waterproof sealing strip 22 is set in a rectangular shape, and the waterproof sealing strip 22 can be prefabricated in advance. Apply glue inside, and finally install each section of sealing and waterproof adhesive strips into the filling tank 11 , and use glue to bond and fix each section of sealing glue 231 in the filling tank 11 .

[0052] The waterproof sealant strip 22 can also be directly filled into the filling groove 11 with the waterproof sealant 231 , and the waterproof sealant strip 22 can be formed after the waterproof sealant 231 is solidified and formed.

Embodiment 3

[0054] refer to Figure 5 , the sealing filler 2 is set as a waterproof bundle 23, and the waterproof bundle 23 is formed by kneading several pieces of waterproof paper or waterproof thread into a round strip, and the sealing filler 2 also includes a water-proof bundle filled between the waterproof bundle 23 and the filling groove 11. Sealant 231.

[0055] The implementation principle of embodiment 3 is:

[0056] The waterproof bundle 23 formed by kneading waterproof paper or waterproof thread can be bonded and fixed in the filling groove 11 by using the sealant 231, and the waterproof bundle 23 can be wrapped by the sealant 231, thereby ensuring the overall waterproof ability of the waterproof bundle 23. The sealant 231 can also fill the gap between the waterproof bundle 23 and the filling groove 11 to ensure the sealing effect of the waterproof bundle 23 on the filling groove 11 .

[0057] The embodiment of the present application also discloses a corrugated box production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com