Prickling needle

A needle and needle body technology, applied in the field of woven fabric production equipment, can solve the problems of large sliding resistance, increase fiber sliding resistance, reduce friction, etc., reduce the possibility of broken needles, reduce the possibility of broken needles, extend the The effect of service life

Active Publication Date: 2011-01-05

青岛锦钻针业有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. As a result, the sliding resistance of the fibers between the barbed hooks will be increased, and the resistance of the needles during the weaving process will be increased, resulting in excessive broken needles

2. Because the sliding resistance of the fibers between the barbed hooks is large, the direct contact with the high-speed moving fibers at right angles will generate force, which will cause fiber damage and breakage, resulting in uneven surface of the woven product, reduced fiber entanglement, and vertical and horizontal fabric. Reduced pulling force, which eventually renders the product useless

3. Because the hook part of the traditional lancet is used to transfer fibers, when the hook holds the fiber at high speed, due to the large contact surface between the hook and the fiber and the large resistance, a large amount of friction will be generated when the fiber and the hook move and rub against each other at high speed. Heat, when the heat reaches a certain level, will lead to the decomposition of low-melting chemical fiber tissue components and reduce the initial hardness of the hook part, resulting in a decrease in the physical and chemical indicators of the chemical fiber and premature wear and failure of the needle

There are also arc-shaped structures, such as the Chinese patent authorized and announced on February 1, 2006. The announcement number is CN2755134Y, which discloses a high-efficiency non-woven needle, which is made of a needle bar, a middle needle bar and a triangular hook. At least one of the alveolar surface and the lower cut angle surface of each barb in the barbed needle body is convex arc-shaped, which correspondingly improves the breaking resistance of the non-woven needle and prolongs the service life. There are great deficiencies in overcoming heat dissipation and reducing friction

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

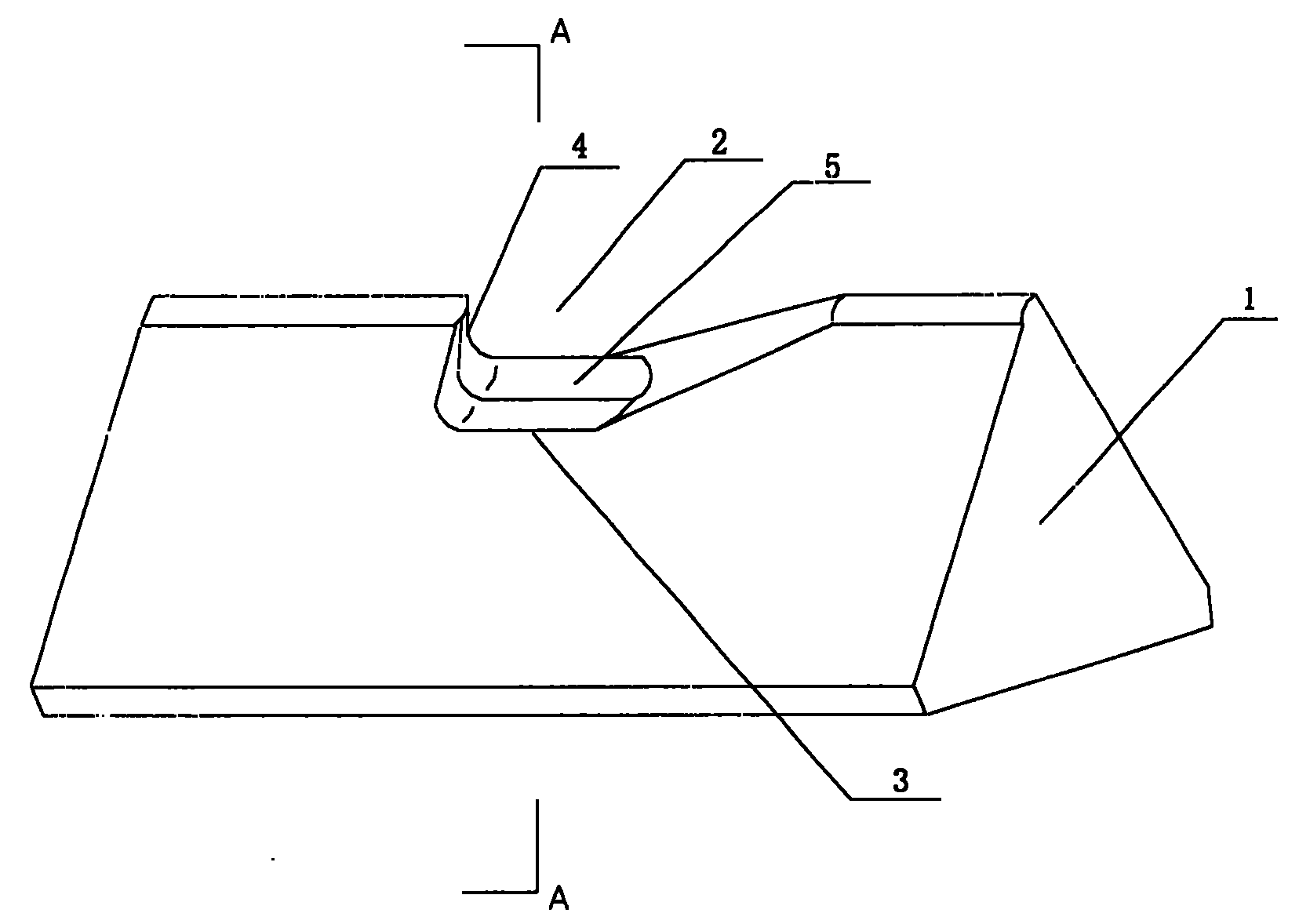

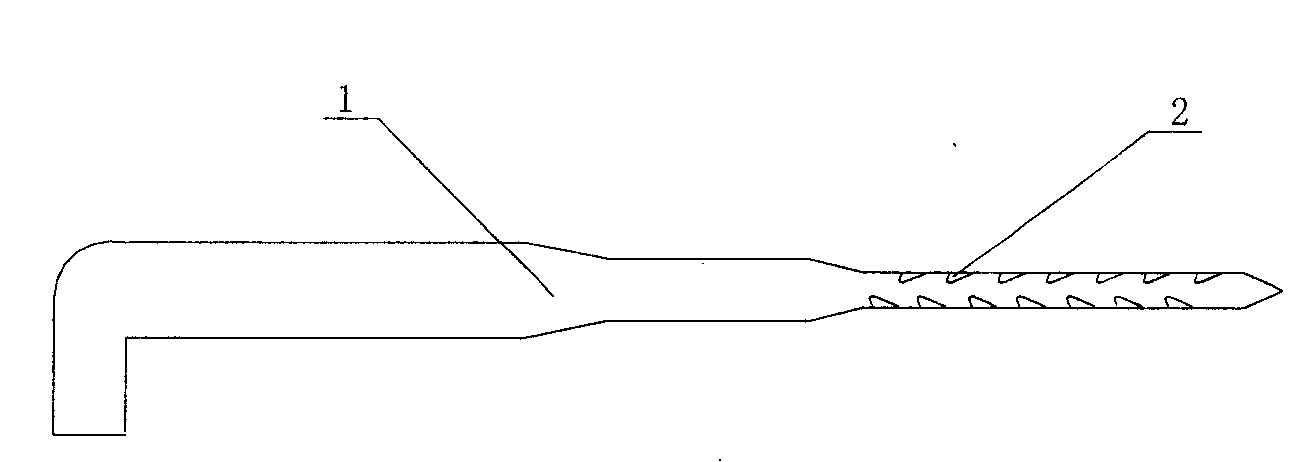

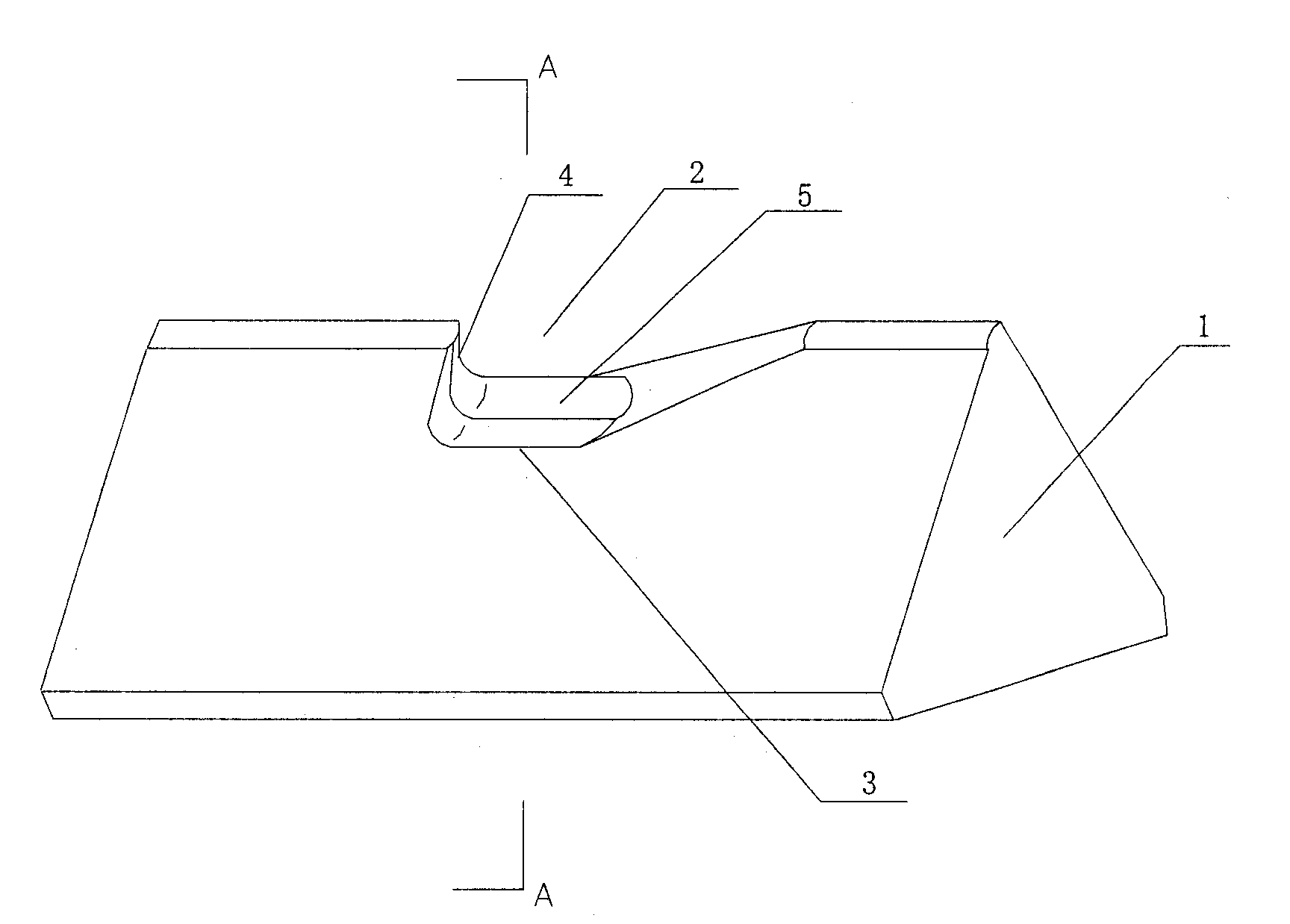

The invention relates to equipment for producing woven fabrics, in particular to a component of a needling machine. A prickling needle comprises a needle body, wherein the needle body is provided with prickling hooks at intervals; each prickling hook comprises a hook slot and a hook prickle; the hook prickle cuts into the needle body and then contacts with the hook slot; and the hook slot is at least provided with two convex cambered surfaces. The prickling needle greatly reduces the possibility of needle breakage, and prolongs the service life of the prickling needle.

Description

Lancet technical field The invention relates to a device for producing woven cloth, in particular to a part of a needling machine. Background technique The hook teeth on the traditional lancets are impacted and pressed by a tool similar to a chisel. The hooks produced inevitably have right angles, acute angles, and planes. These right angles, acute angles, and planes have the following defects on the fibers that are hooked: 1. As a result, the sliding resistance of the fibers between the barbed hooks will be increased, and the resistance of the needles during the weaving process will be increased, resulting in excessive broken needles. 2. Because the sliding resistance of the fibers between the barbed hooks is large, the direct contact with the high-speed moving fibers at right angles will generate force, which will cause fiber damage and breakage, resulting in uneven surface of the woven product, reduced fiber entanglement, and vertical and horizontal fabric. The pulli...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D04H18/00D04H18/02

Inventor 薛同乐薛淞

Owner 青岛锦钻针业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com