Electro-heat equipment of electric heater

A heating device, electric heater technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as inability to achieve boiling water, inability to heat water to complete boiling, and inability to discharge a large amount of water vapor. The effect of water safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

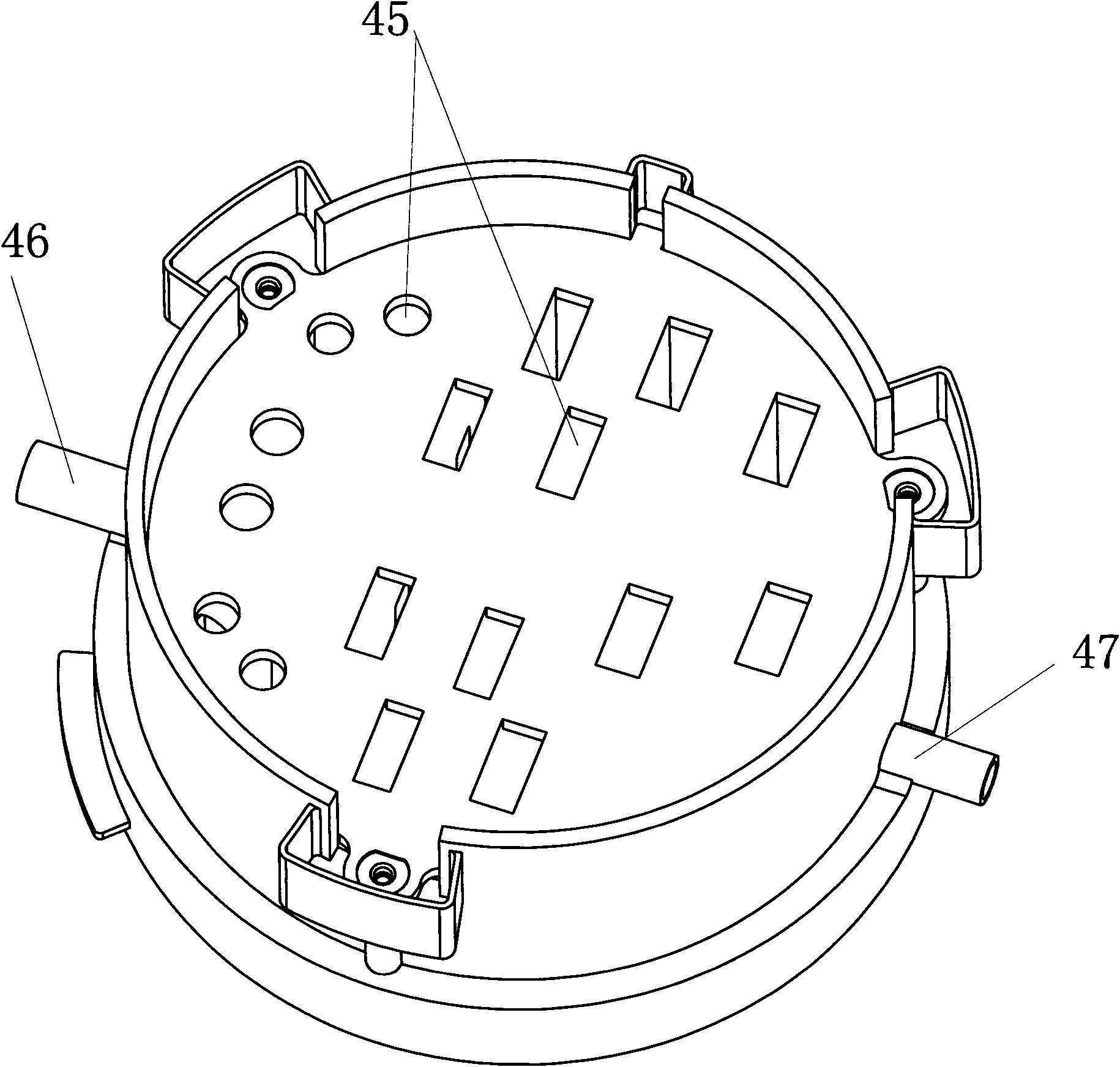

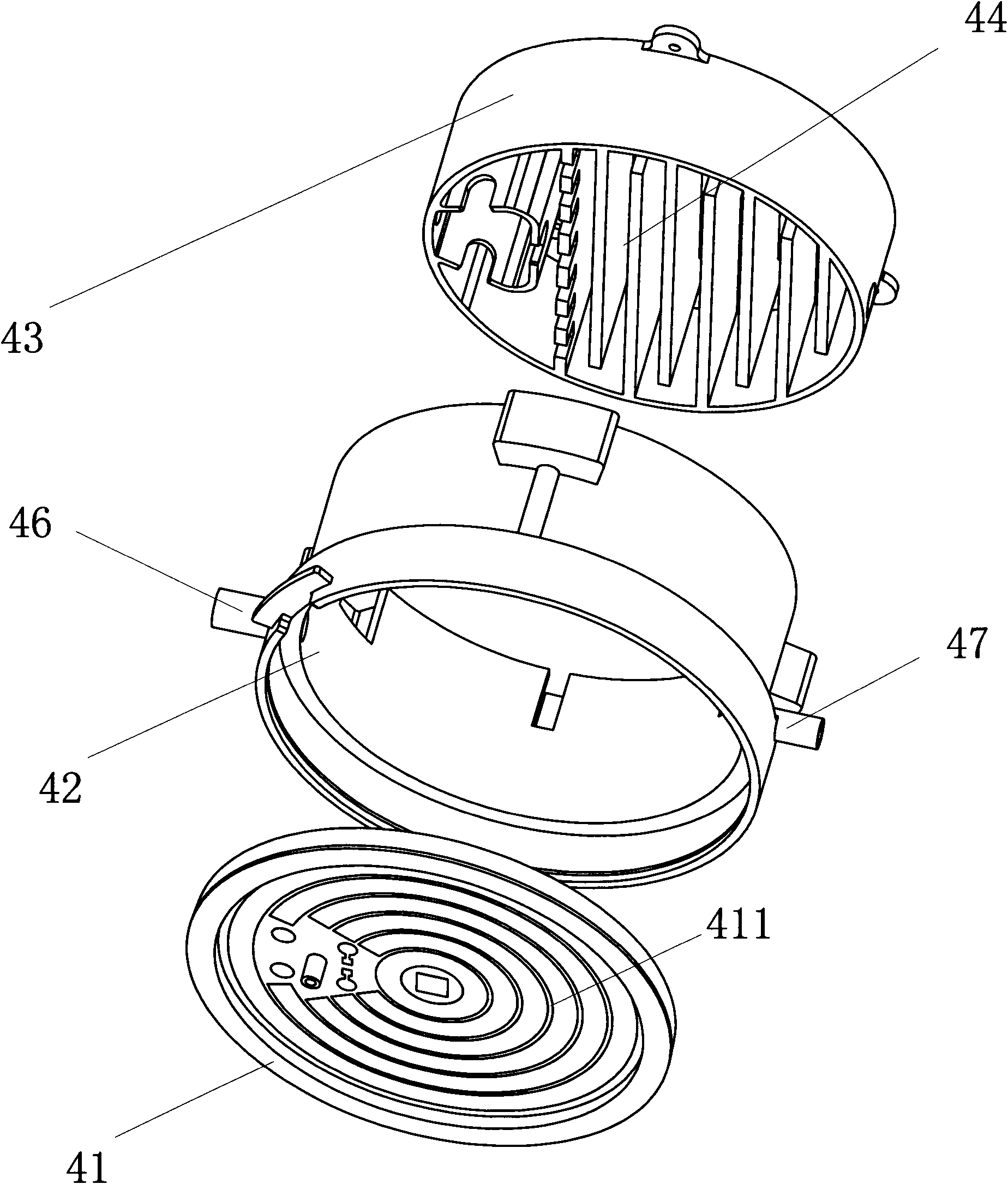

[0020] Such as figure 2 , image 3 As shown, the present invention includes a container body 42, and the bottom of the container body 42 is provided with a thick-film heater 41 composed of a heating resistance element 411. The thick-film heater 41 and the container body 42 are connected and fixed together by a sealing ring, forming a A water container, the periphery of the container body 42 is provided with a water inlet 46 and a water outlet 47, and the heating resistance element 411 is directly screen-printed on the thick film heater 41; It is formed after matching with the container body 42 figure 2 The overall structure of the heating device shown; a plurality of side-by-side partitions 44 are arranged in the deflector 43, and one end of all the partitions 44 is sealed and fixed on the inner surface of the container body 42, and the other end is a free end, and all the partitions 44 are divided into There are two sets of spacers, and the free ends of the two sets of pa...

Embodiment 2

[0023] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the container body 42 and the thick film heater 41 are integral parts, that is, the thick film heater 41 and the container body 42 are made into an integral part, and made into a whole The biggest advantage is that you don't need to consider the problem of water sealing, but the cost may be higher.

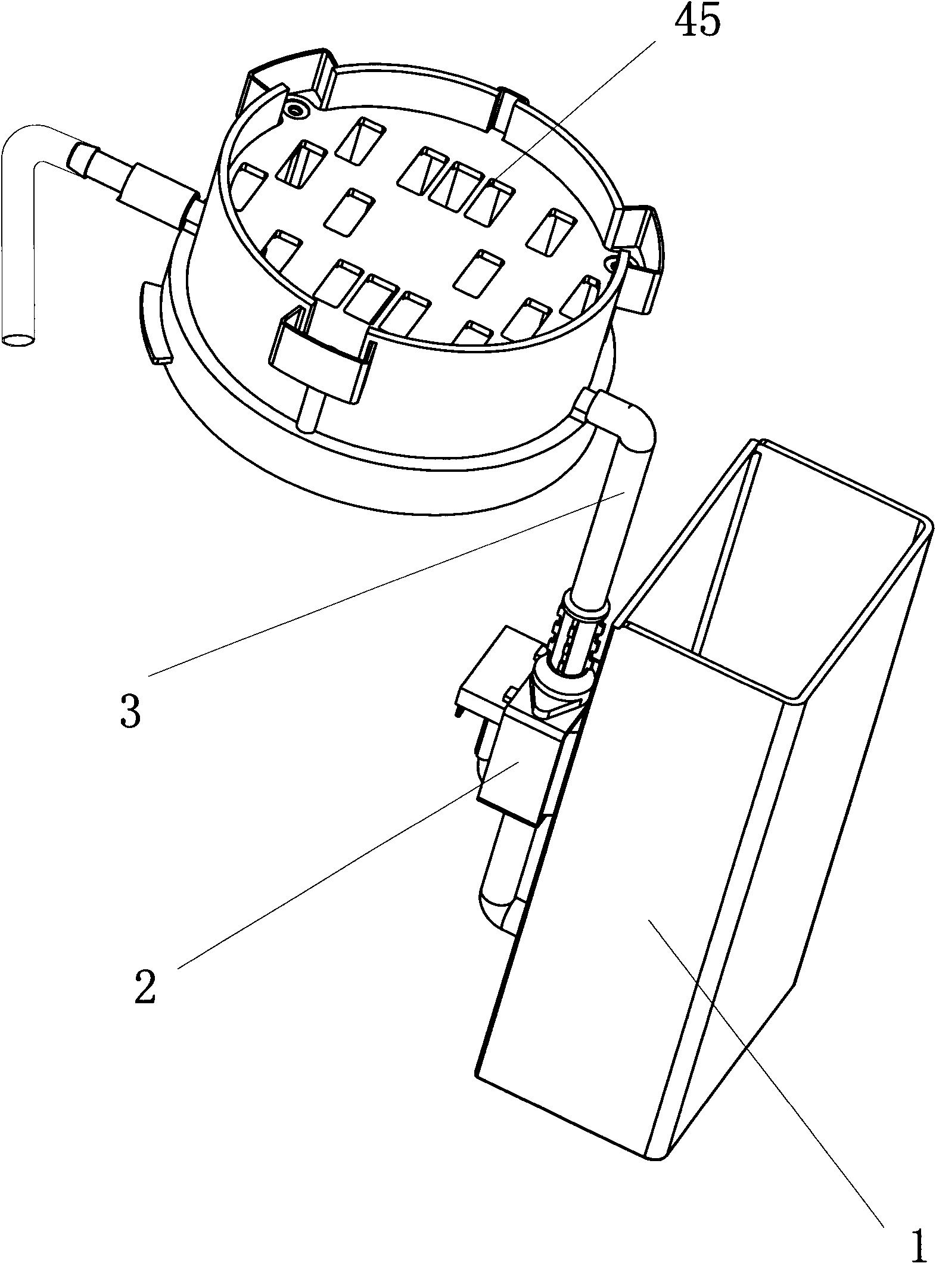

[0024] When the present invention is used, as figure 1 As shown, the water inlet 46 communicates with the water storage tank 1 attached with the water pump 2 . During work, after the water pump 2 pumps water to the heating device of the present invention through the pipeline 3, the water flows slowly in the flow channel in the heating device, and the heating resistance element 411 starts heating at this time, and the flowing water is continuously heated until it boils. The water produces a large amount of water vapor, and more steam is generated at the water outlet 47...

Embodiment 3

[0026] Such as Figure 5 , Figure 6 As shown, the difference between this embodiment and Embodiment 2 is that: the water inlet 46 of the heating device is arranged on the container body 42 , and the water outlet 47 is arranged on the thick film heater 41 .

[0027] Of course, it is also conceivable to arrange both the water inlet 46 and the water outlet 47 on the thick film heater.

[0028] The heating device of the invention can be widely used in products such as electric water heaters and electric kettles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com