Integrated cement-casting slow-filtering basin

An integrated, slow filter technology, applied in the field of slow filter, can solve the problems of poor water quality and inapplicability, achieve the effect of thin structure, easy construction and optimized purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

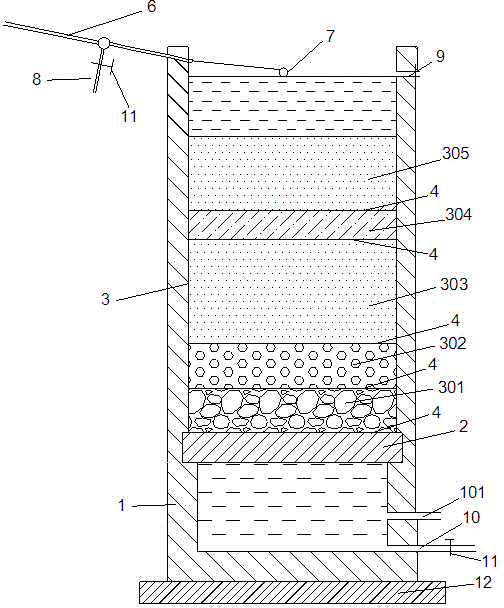

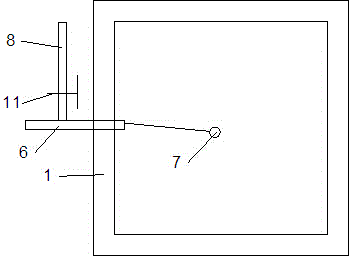

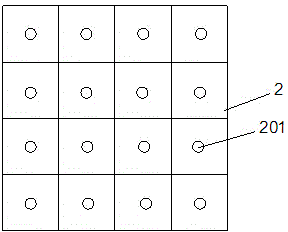

[0020] combine figure 1 , figure 2 and image 3 , the one-piece cement pouring slow filter used in the rocky desertification area described in this embodiment includes:

[0021] Pool body 1, dividing plate 2 and filter layer 3, the bottom of pool body 1 is provided with pool base 12, and dividing plate 2 is horizontally arranged in the pool body 1, and the sidewall thickness of the pool body 1 below dividing plate 2 is 10cm, and dividing plate 2. The side wall thickness of the upper pool body 1 is 7cm, and the lower end wall thickness of the pool body 1 is thicker, which increases the overall stability of the pool body. A water filter hole 201 is provided on the partition plate 2, and the filter layer 3 is arranged on the partition plate 2. A water outlet pipe 101 passing through the pool body 1 is provided on the side wall of the pool body 1 below the partition plate 2, a water inlet pipe 6 is introduced into the pool body 1 above the partition plate 2, and a floating wate...

Embodiment 2

[0024] combine figure 1 , figure 2 and image 3 , the one-piece cement pouring slow filter used in the rocky desertification area described in this embodiment includes:

[0025] Pool body 1, dividing plate 2 and filter layer 3, the bottom of pool body 1 is provided with pool base 12, and dividing plate 2 is horizontally arranged in the pool body 1, and the thickness of the side wall of pool body 1 below dividing plate 2 is 9cm, and dividing plate 2 The thickness of the side wall of the upper pool body 1 is 6cm, and the lower end wall thickness of the pool body 1 is thicker to increase the overall stability of the pool body. The partition plate 2 is provided with a water filter hole 201, and the filter layer 3 is arranged on the partition plate 2. A water outlet pipe 101 passing through the pool body 1 is provided on the side wall of the pool body 1 below the partition plate 2, a water inlet pipe 6 is introduced into the pool body 1 above the partition plate 2, and a floatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com