Oxidation/absorption/ filtration Integral drinking water arsenic removal system

A technology for oxidation adsorption filtration and drinking water, which is applied in the direction of adsorption water/sewage treatment, oxidized water/sewage treatment, water/sewage treatment, etc. It can solve the problems of poor arsenic removal effect, ensure water quality, reduce investment and operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

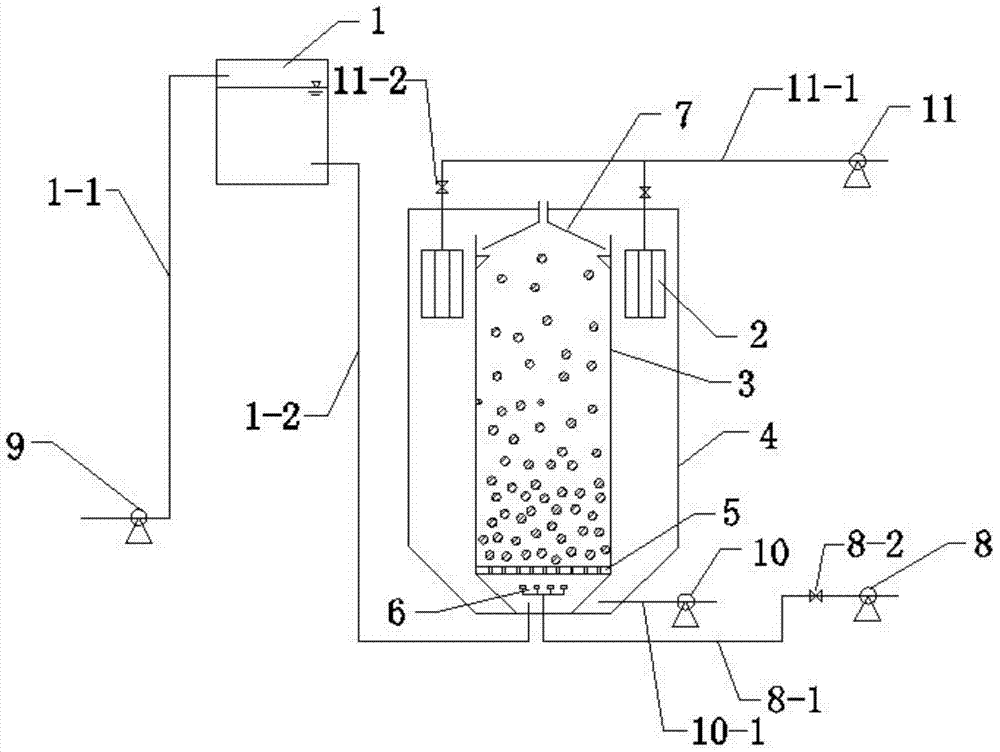

[0012] Specific Embodiment 1: In this embodiment, the oxidation adsorption filtration integrated drinking water arsenic removal system includes an arsenic removal device, a membrane module 2, a high-level water tank 1, a lift pump 9, a suction pump 11, a sludge pump 10 and an air compressor 8, Wherein the arsenic removal device is composed of an inner cylinder 3 and an outer cylinder 4, the inner cylinder 3 is set in the middle of the outer cylinder 4, the bottom of the inner cylinder 3 is provided with a porous support layer 5, and the porous support layer 5 in the inner cylinder 3 The top is filled with adsorbent, the top of the inner cylinder 3 is equipped with a three-phase separator 7, and the bottom of the inner cylinder is provided with a water inlet. The water outlet of the lift pump 9 is connected with the high-level water tank 1 through the water pipe 1-1. The water outlet is connected to the water inlet at the bottom of the inner cylinder 3 through the water inlet pi...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that the adsorbent filled above the porous supporting layer 5 in the inner tube 3 is Mg / Al hydrotalcite adsorbent.

[0024] The Mg / Al hydrotalcite adsorbent in this embodiment is in a fluidized state in the inner cylinder, and the selected Mg / Al hydrotalcite belongs to double-layer metal oxides (LDHs). Anions have good adsorption properties.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 1 in that the particle size of the Mg / Al hydrotalcite adsorbent is 20-450 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com