Plate type heat exchanging element for evaporation and condensation

A plate heat exchange and evaporative condensation technology, applied in the field of plate heat exchange elements and evaporative condensation plate heat exchange elements, can solve the problems of poor mechanical sealing, low heat transfer coefficient, blockage of the liquid distributor, etc. The effect of increasing the heat transfer area and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

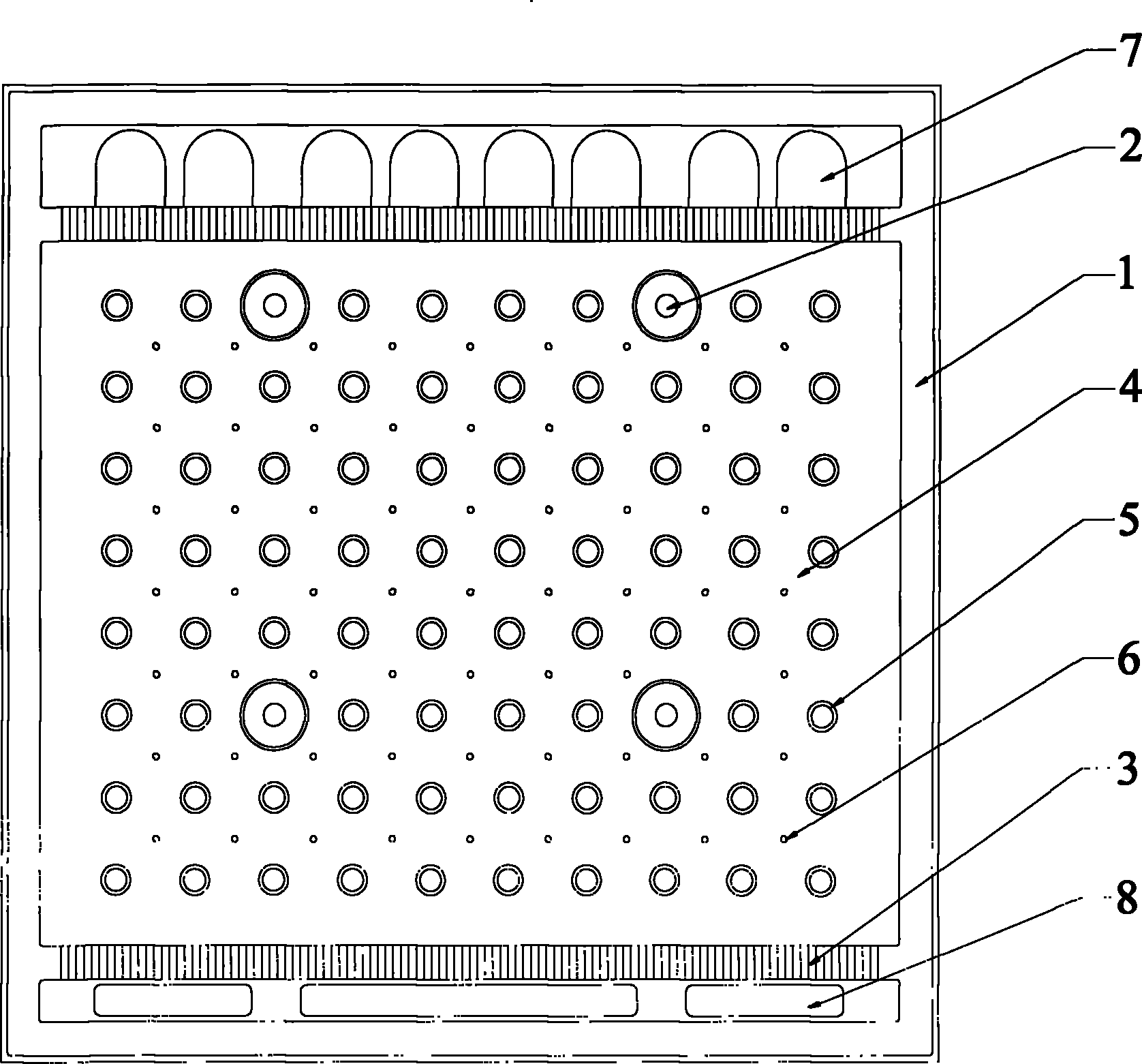

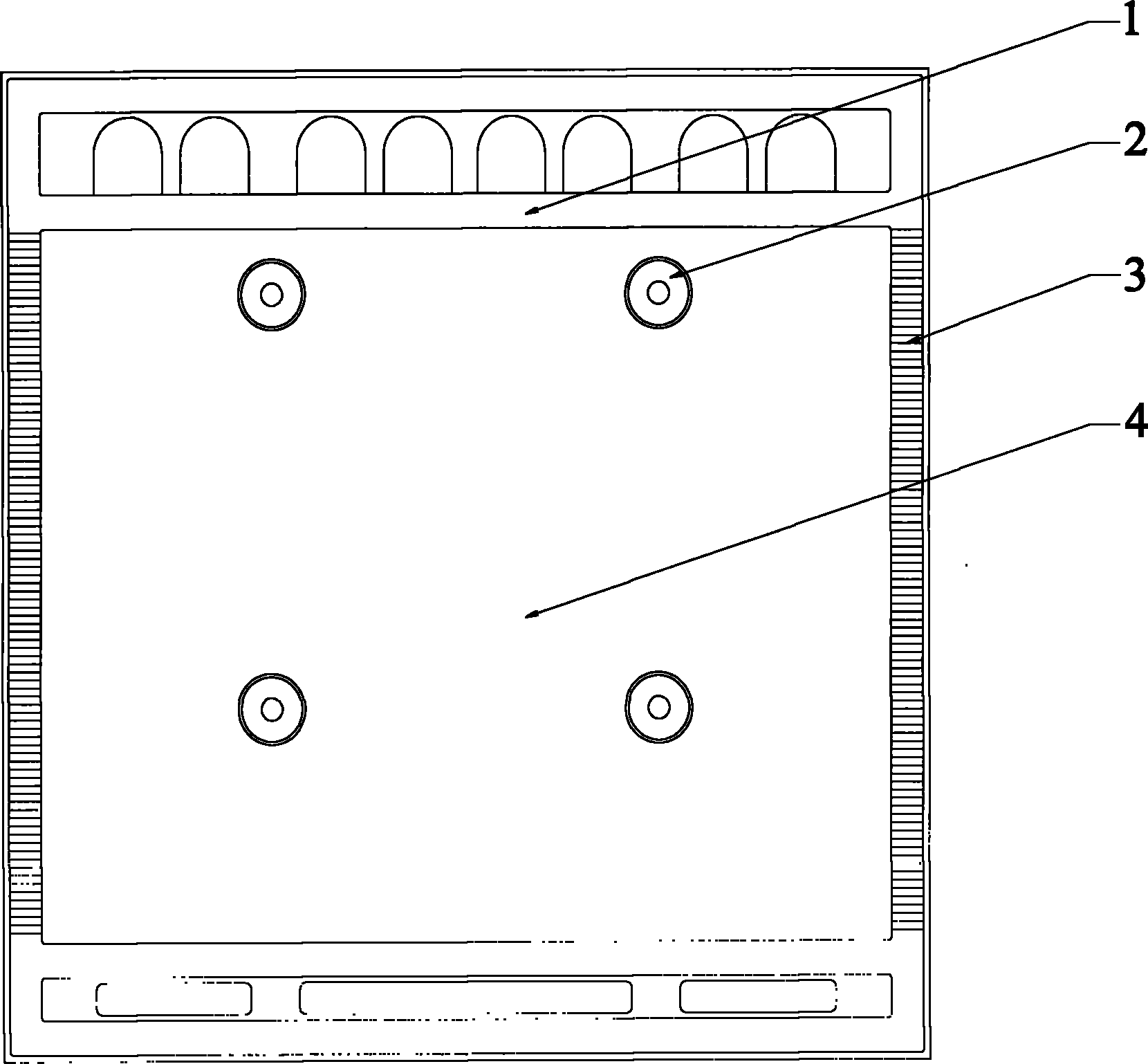

[0018] In a small seawater desalination device developed by the Institute of Chemical Engineering of Dalian University of Technology, the plate heat exchange element provided by the present invention is used to form evaporation and condensation equipment. figure 1 Shown is the structural diagram of plate A, which is made of 316L stainless steel sheet, consisting of 1 steam inlet, 2 positioning holes, 3 sealing gasket installation area, 4 heat exchange area, 5 evaporating side strengthening structure, 6 condensing side strengthening structure, It consists of 7 support bar installation areas and 8 condensate outlets. Among them, the reinforced structure on the condensing side is a hemispherical structure with a diameter of 1.5mm and protruding toward the back of the paper. 5 The enlarged view of the strengthening structure on the evaporation side is shown in Fig. 5. In this embodiment, the structure is a circular frustum with a height of 1.5 mm and a diameter of 7 mm. The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com