Image forming apparatus

An image and equipment technology, applied in the field of image forming equipment, can solve problems such as the position limitation of the laser scanning unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

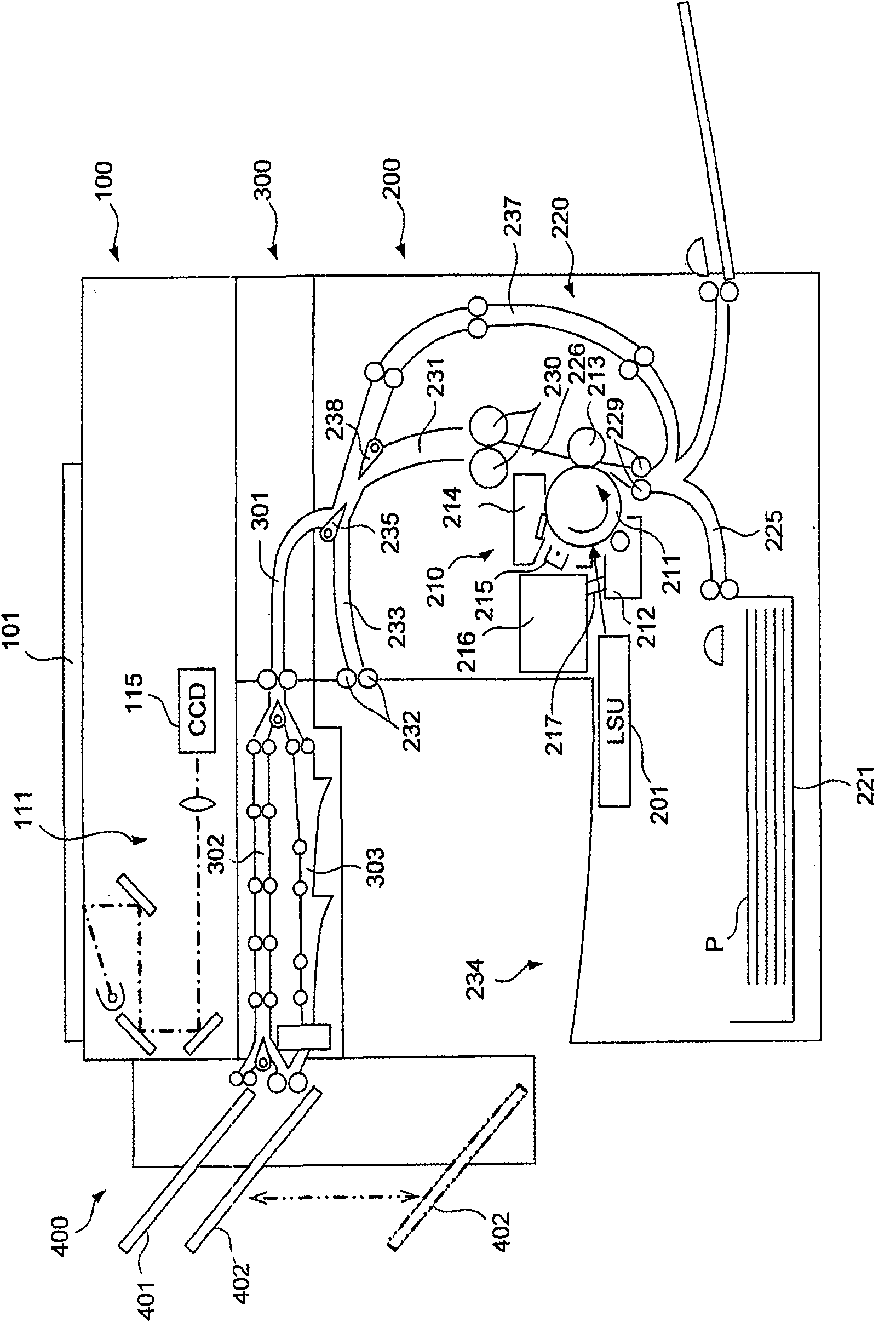

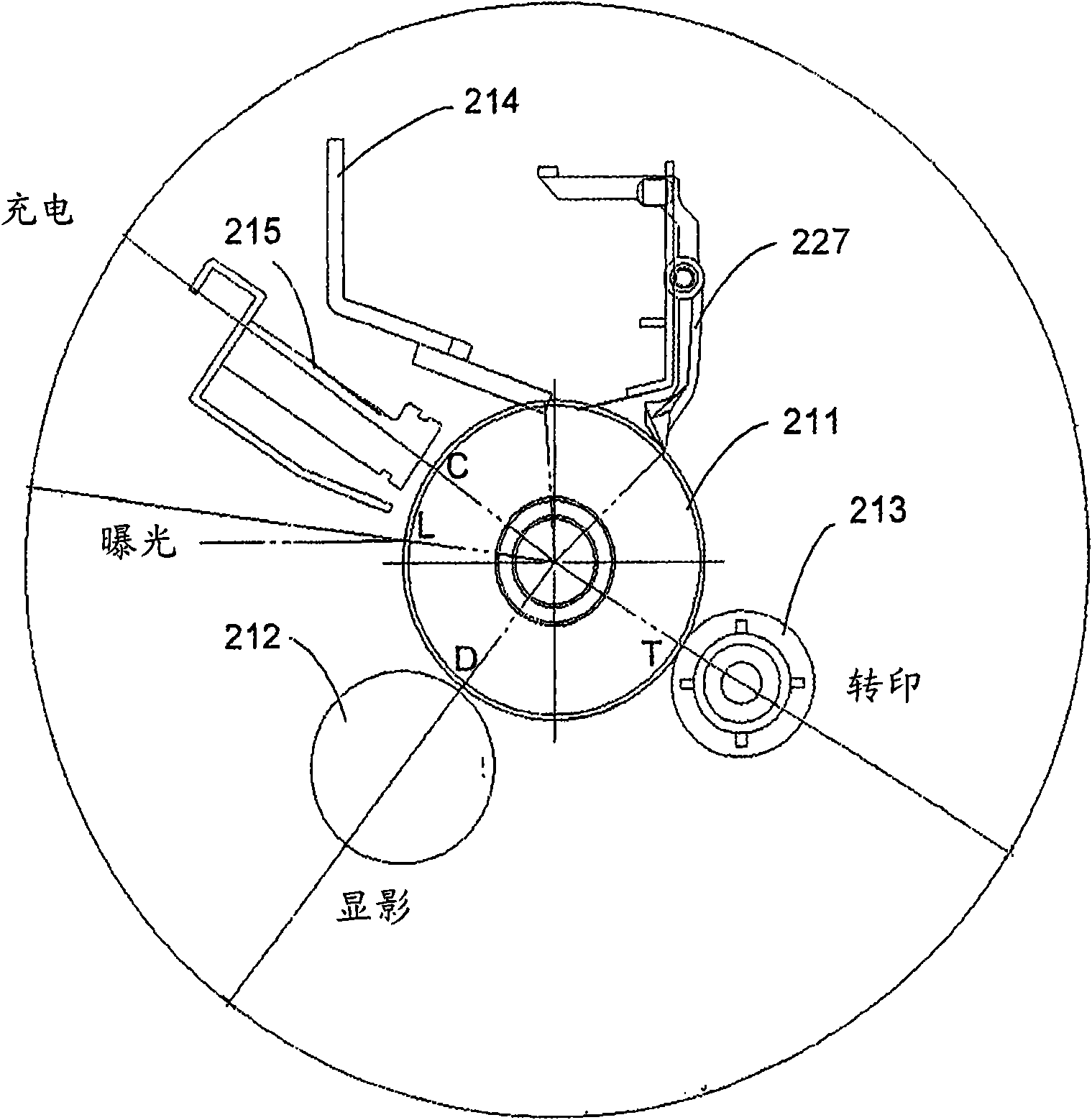

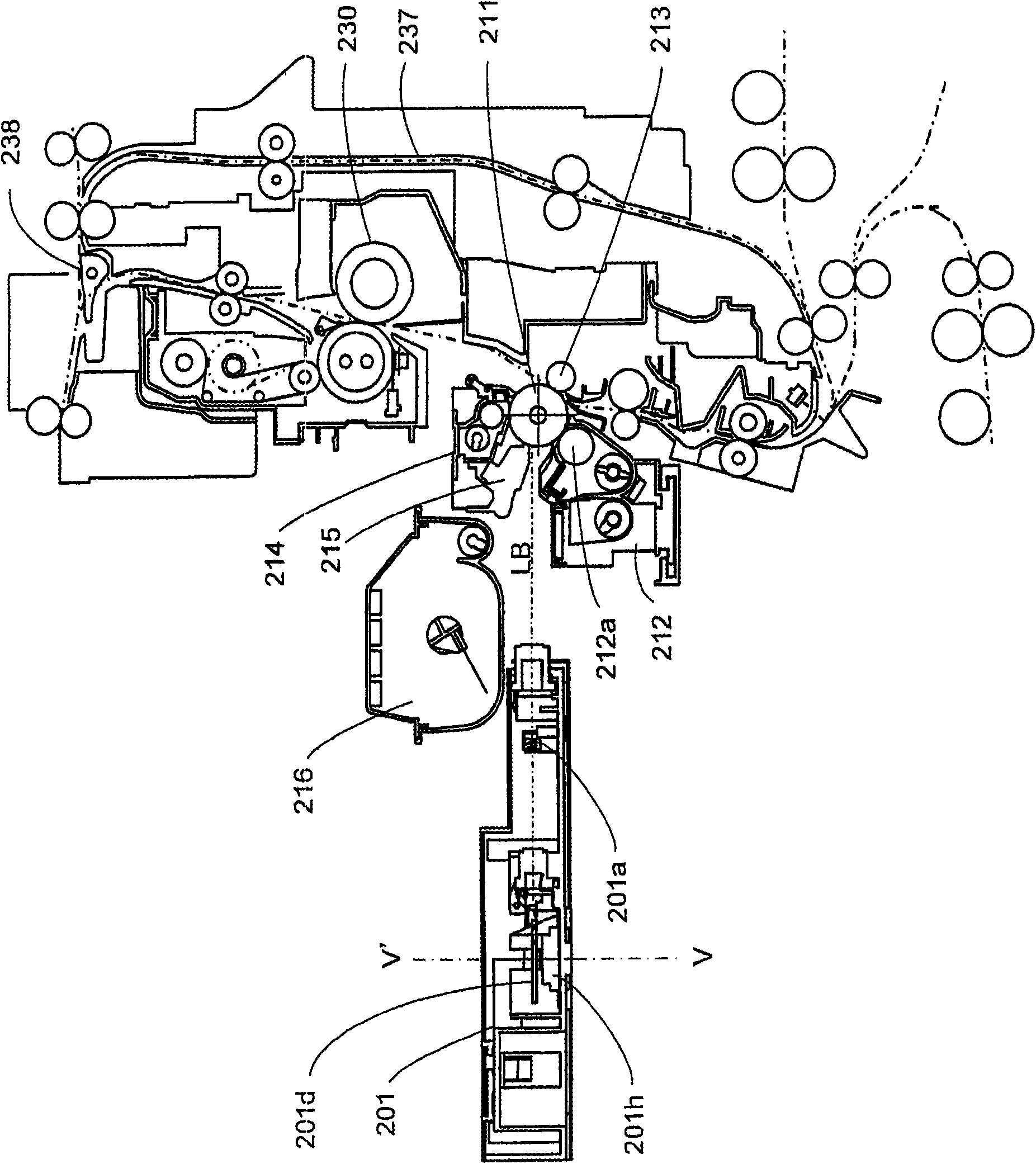

[0021] In the present invention, the light guide is cylindrical in shape. In electrophotographic processing the photoconductor is rotated about an axis while forming an image. Further, the material and physical properties of the photoconductor are not particularly limited as long as the material and physical properties are suitable for electrophotographic processing. When forming an image, the peripheral surface of the photoconductor moves in a single direction (in the second scanning direction). In the case of a drum-shaped photoconductor, the peripheral surface moves in response to the rotation of the drum.

[0022] The laser scanning section performs laser beam scanning on the outer peripheral surface in its moving direction and also in a direction perpendicular thereto (first scanning direction), and exposes the outer peripheral surface to the laser beam. The laser scanning section reflects and deflects a laser beam emitted from a fixed laser source on a side surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com