Combined steel casing and construction method of waterborne drilled pile based on same

A construction method and technology for steel casings, which are applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of large amount of steel, high cost, and steel casings cannot be used repeatedly, so as to reduce the amount of materials and reduce the cost of steel casings. The effect of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] This embodiment is used to explain the claims of the invention, and the protection scope of the invention is not limited to the structures described below. Those skilled in the art make structural changes different from the following in the technical solution of the present invention, all of which belong to the protection scope of the present invention.

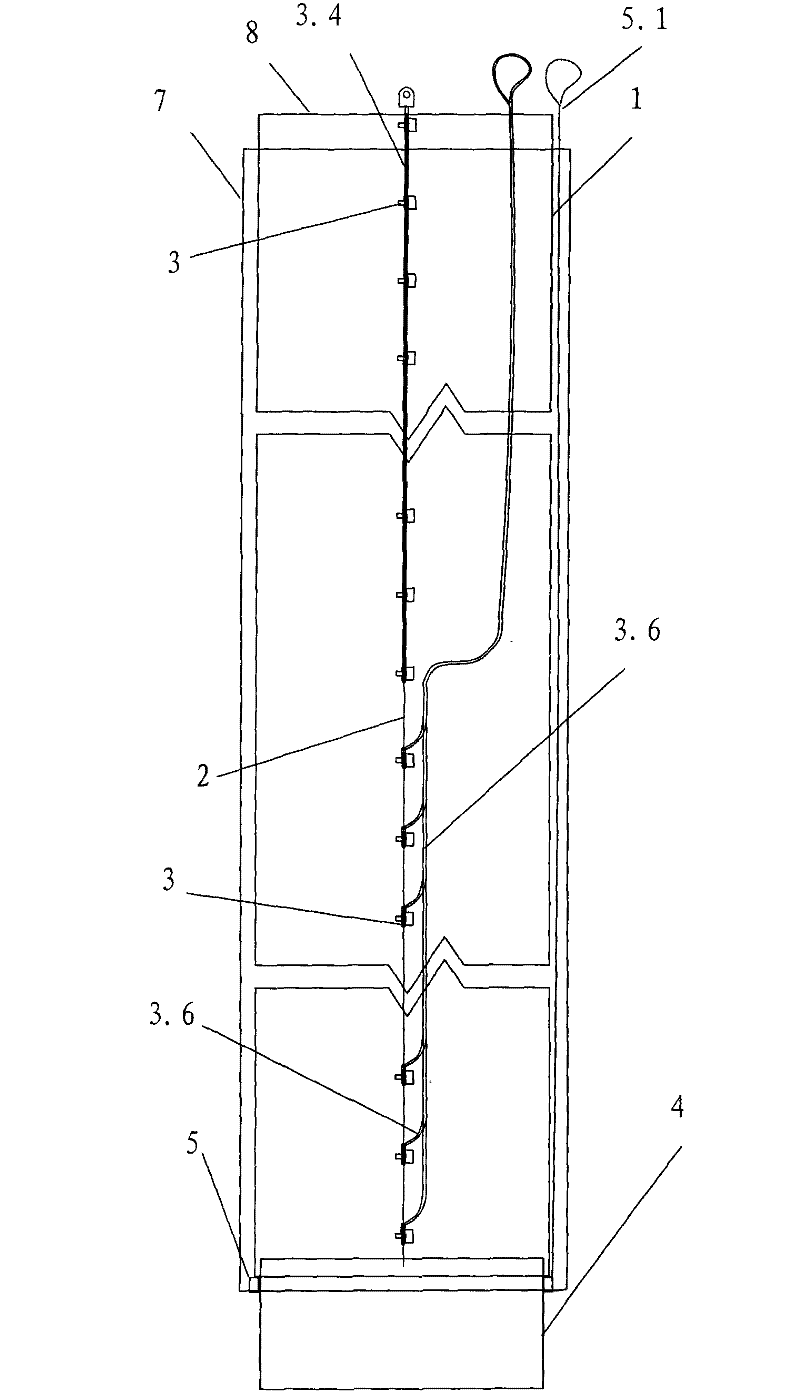

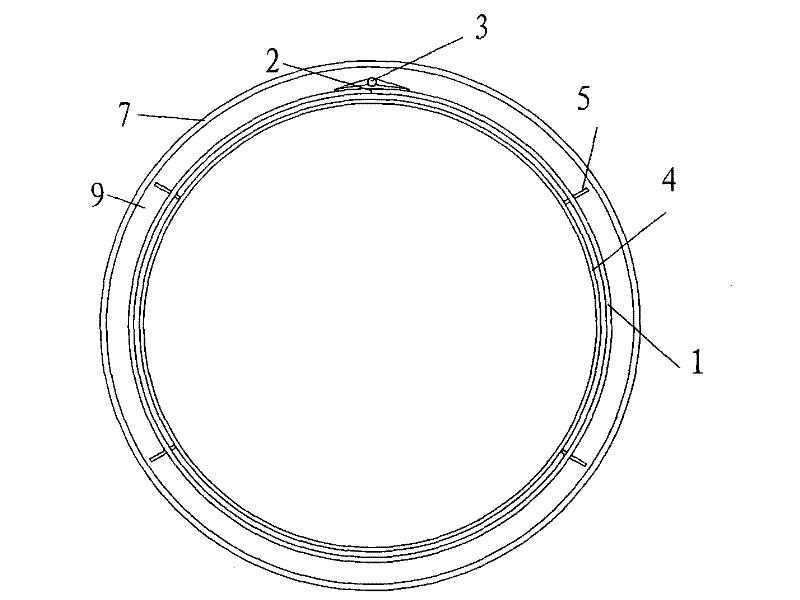

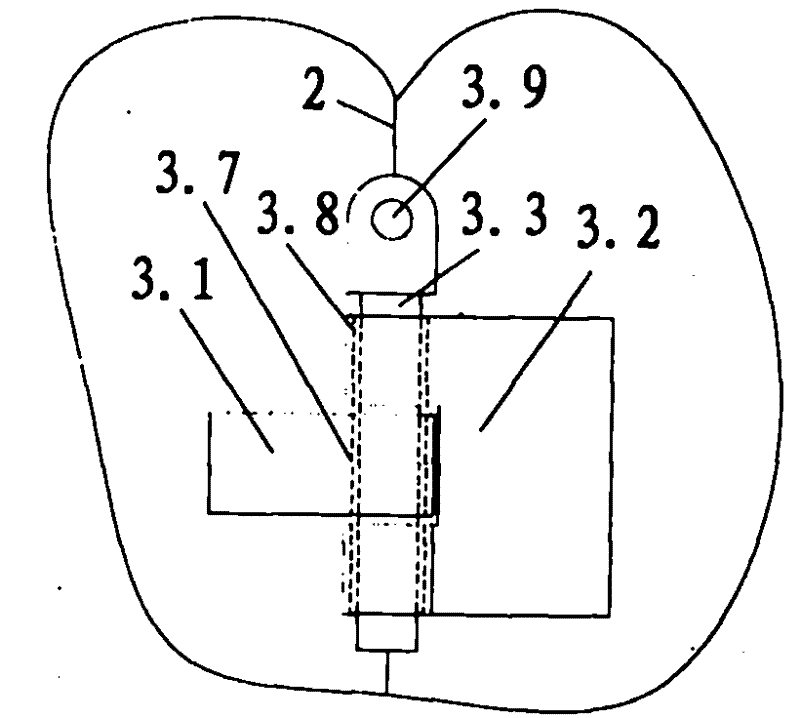

[0018] Such as figure 1 As shown, the outer steel casing 7 is welded into an integral steel casing, which is identical in structure with the existing steel casing. The outer steel casing 7 is provided with an inner steel casing 8 , and there is a gap 9 between the inner steel casing 8 and the outer steel casing 7 . The inner steel casing 8 includes a steel casing body 1 which is rolled from a thin steel plate. The wall of the steel casing is provided with an opening contact seam 2 along the axial direction, and the gap between the opening contact seam 2 is 0-5 mm. The cylinder walls on both sides of the open seam are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com