Direct-push unloading type bucket of battery forklift truck

A battery and forklift technology, which is applied to earth movers/excavators, construction, etc., can solve problems such as insufficient power, potential safety hazards, and high consumption of battery forklifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

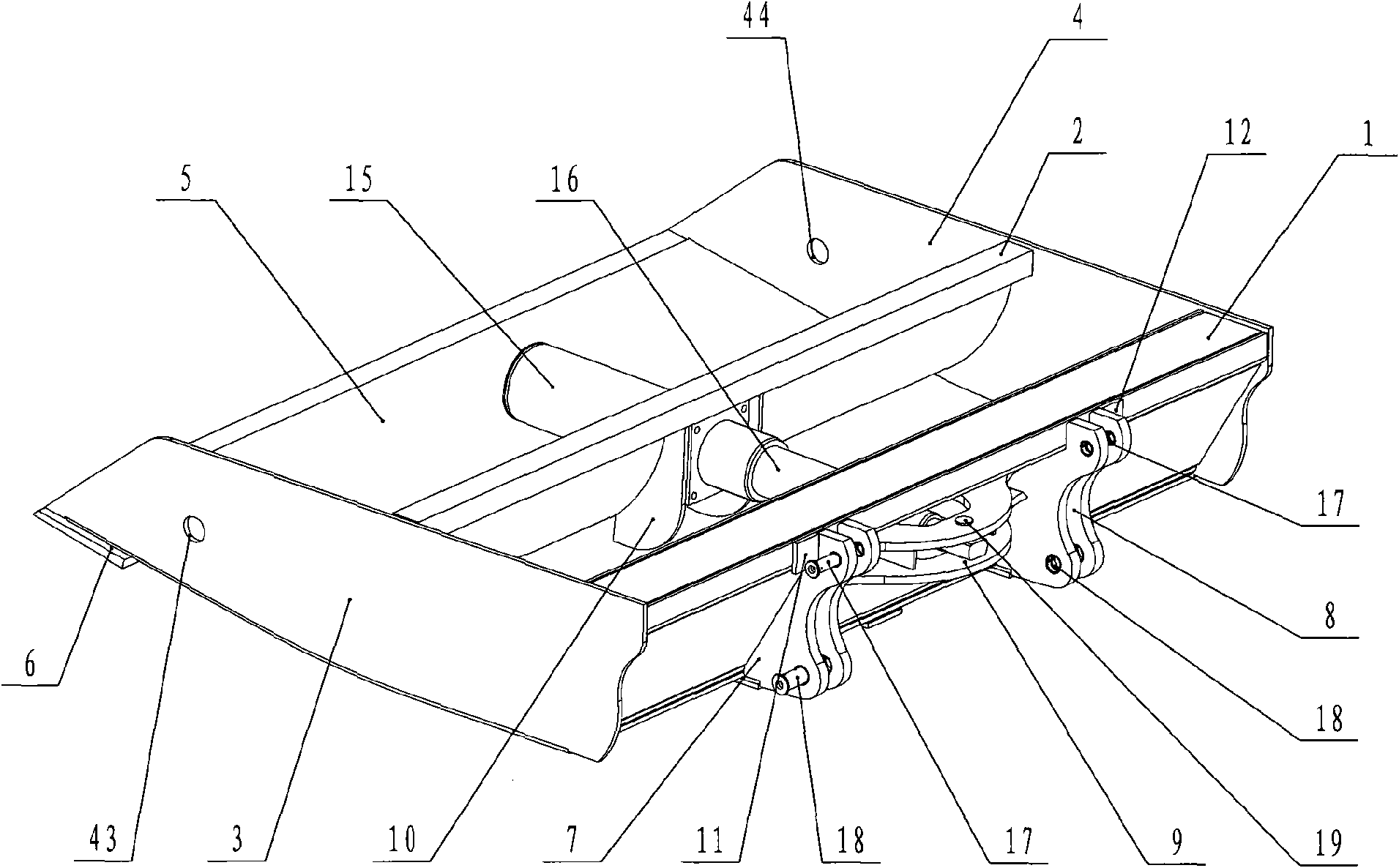

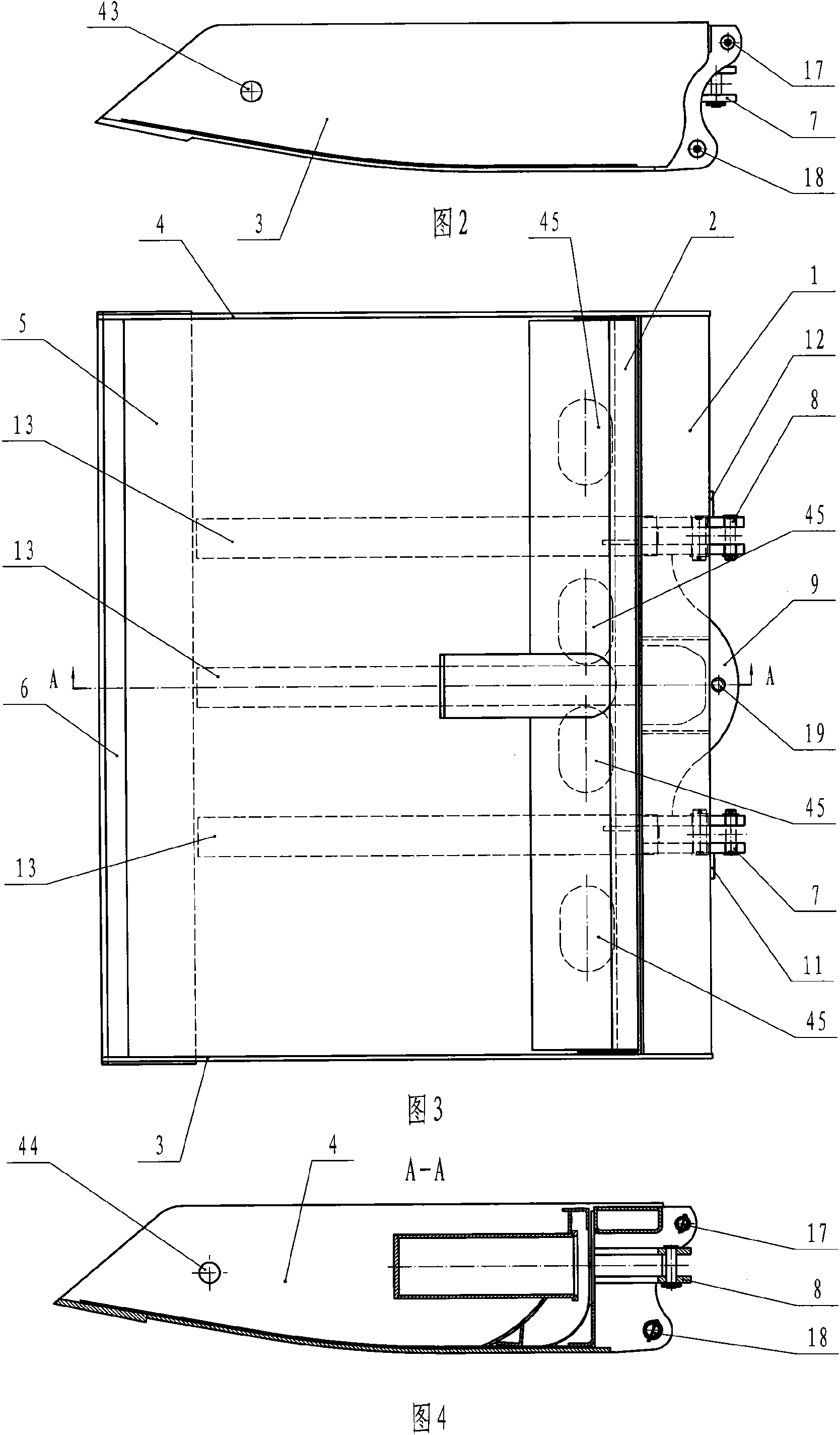

[0020] figure 1 , 2 , 3, and 4 show the overall structure of the bucket. The positions and connections of each part must be correct and the installation should be firm.

[0021] The bucket as a whole is a welded structure, which must have good strength, high hardness, and impact resistance. It must be made of alloy structural steel and hardened.

[0022] The hinged plate, hinged seat and the lifting mechanism of the battery forklift should be installed and fixed firmly to ensure safety.

[0023] The coal pusher, coal pusher, and coal pusher cylinder should be used together, with continuous movement, stable forward and backward movement, and coordinated movements.

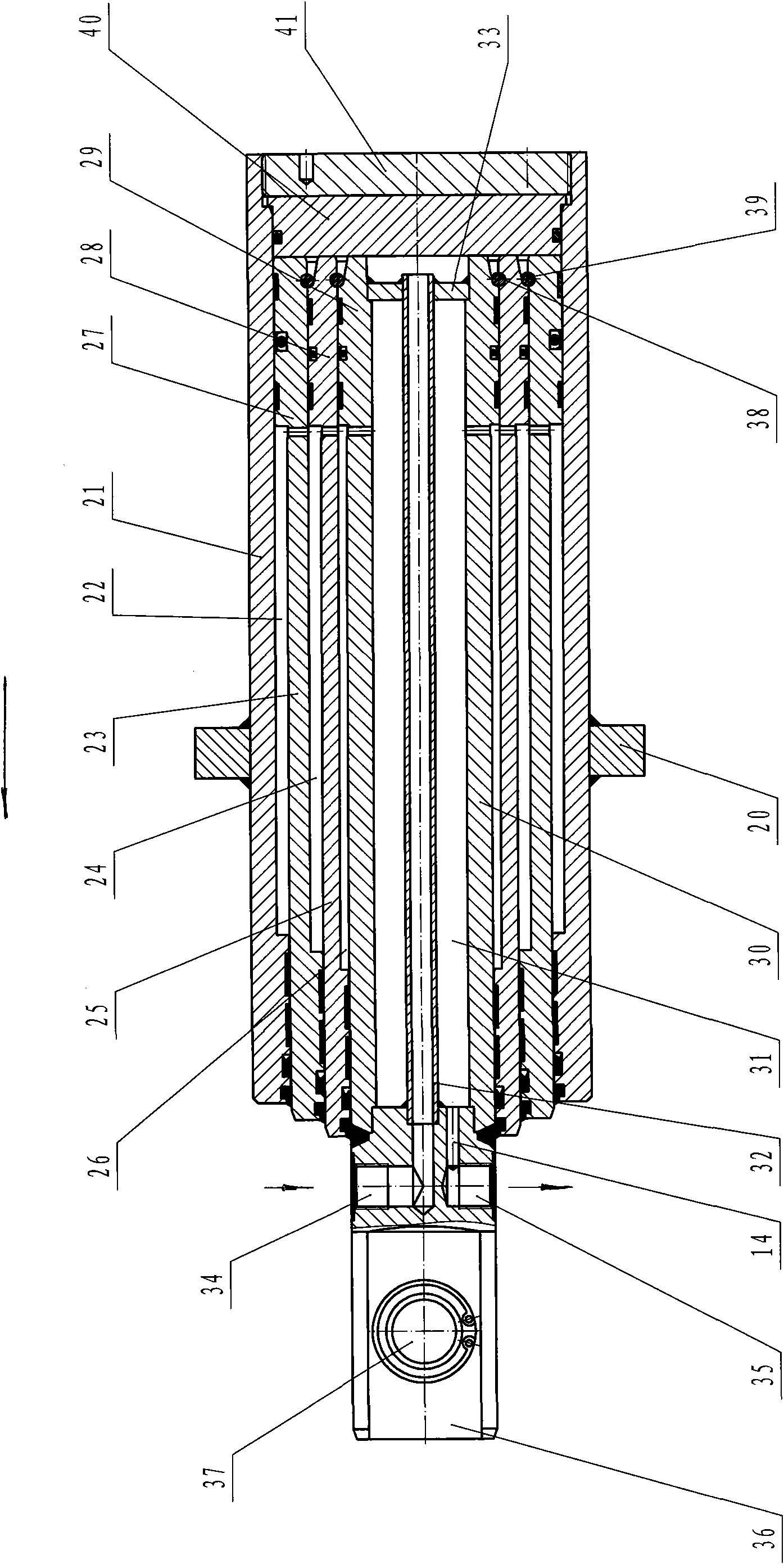

[0024] Figure 5 , 6 As shown, it is a structural diagram of three telescopic push coal cylinders, consisting of an outer cylinder, a middle cylinder, an inner cylinder, an outer piston, a middle piston, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com