Ventilation system for clean rooms

A technology for ventilation systems and clean rooms, applied in the field of ventilation systems, can solve problems such as large power consumption, and achieve the effects of saving power, reducing air intake, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

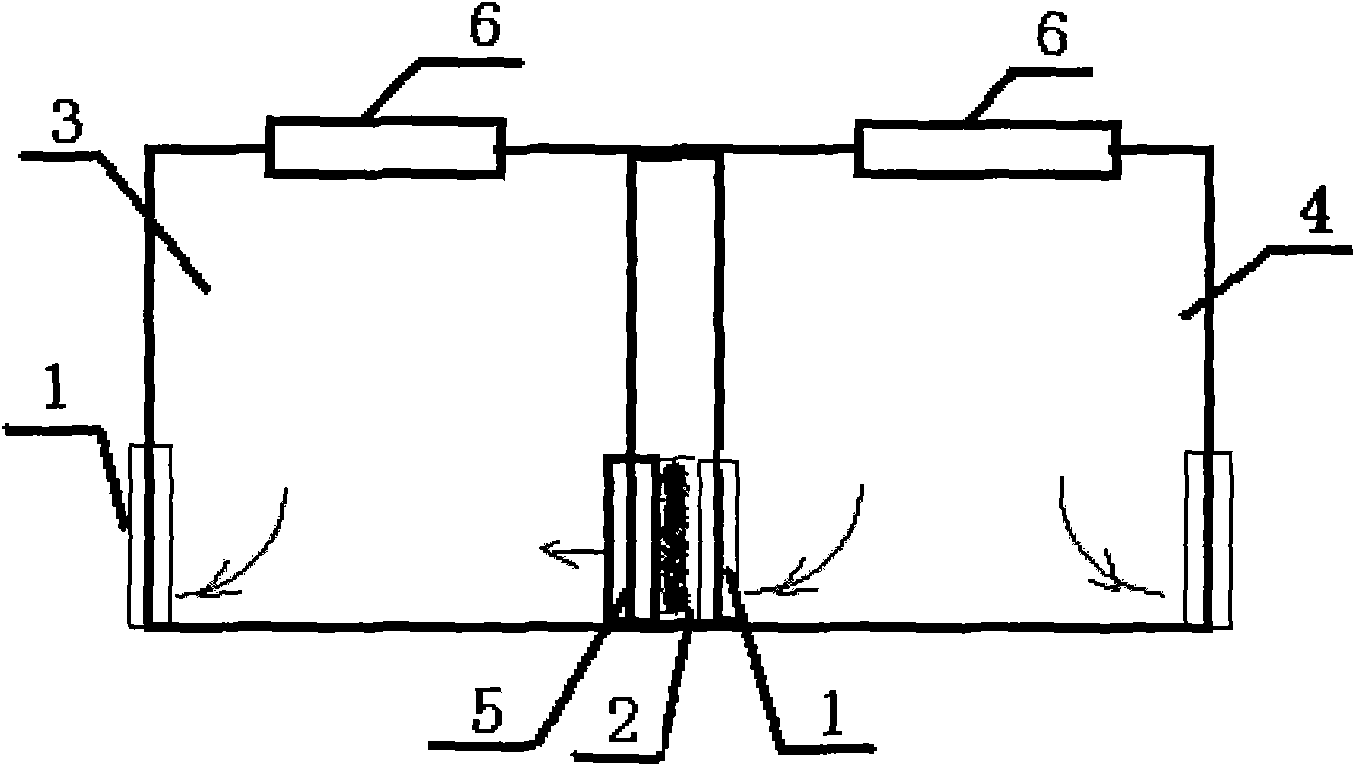

[0011] The present invention will be further described below in conjunction with the accompanying drawings: the lower clean room 3 of the clean level is provided with a supplementary air outlet 5, and the supplementary air outlet 5 is connected with the air inlet unit 6 of the clean room, and the cleanliness level adjacent to it is higher The air outlet unit 1 of the clean room 4 is connected, and a filter 2 is arranged in the middle. The aperture of the filter 2 is different between different clean levels, and the air intake unit 6 of the clean room 3 with a lower clean level is adjusted according to the amount of supplementary air. The air intake volume does not affect the air volume of the air outlet unit 1. By analogy, the air outlet from the clean room with the highest cleanliness level is used as the initial supplementary air source until the air outlet unit 1 with the lowest cleanliness level completes the air outlet.

[0012] Applying the present invention to a clean ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com