Compression-absorption type refrigerating machine

An absorption refrigeration and compressor technology, applied in refrigerators, refrigeration and liquefaction, machines using waste heat, etc., can solve problems such as large cooling water volume, low performance index, and complex systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings.

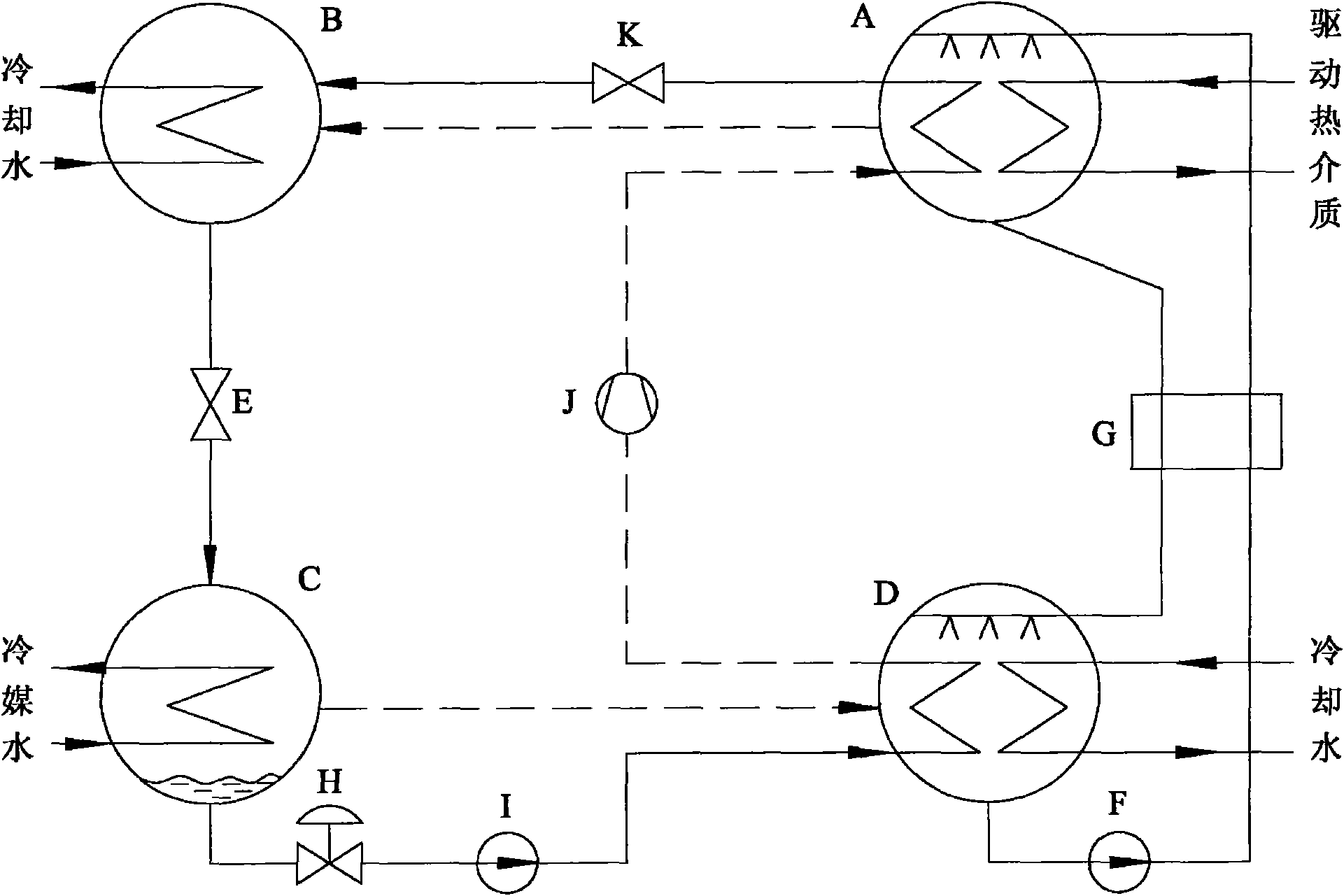

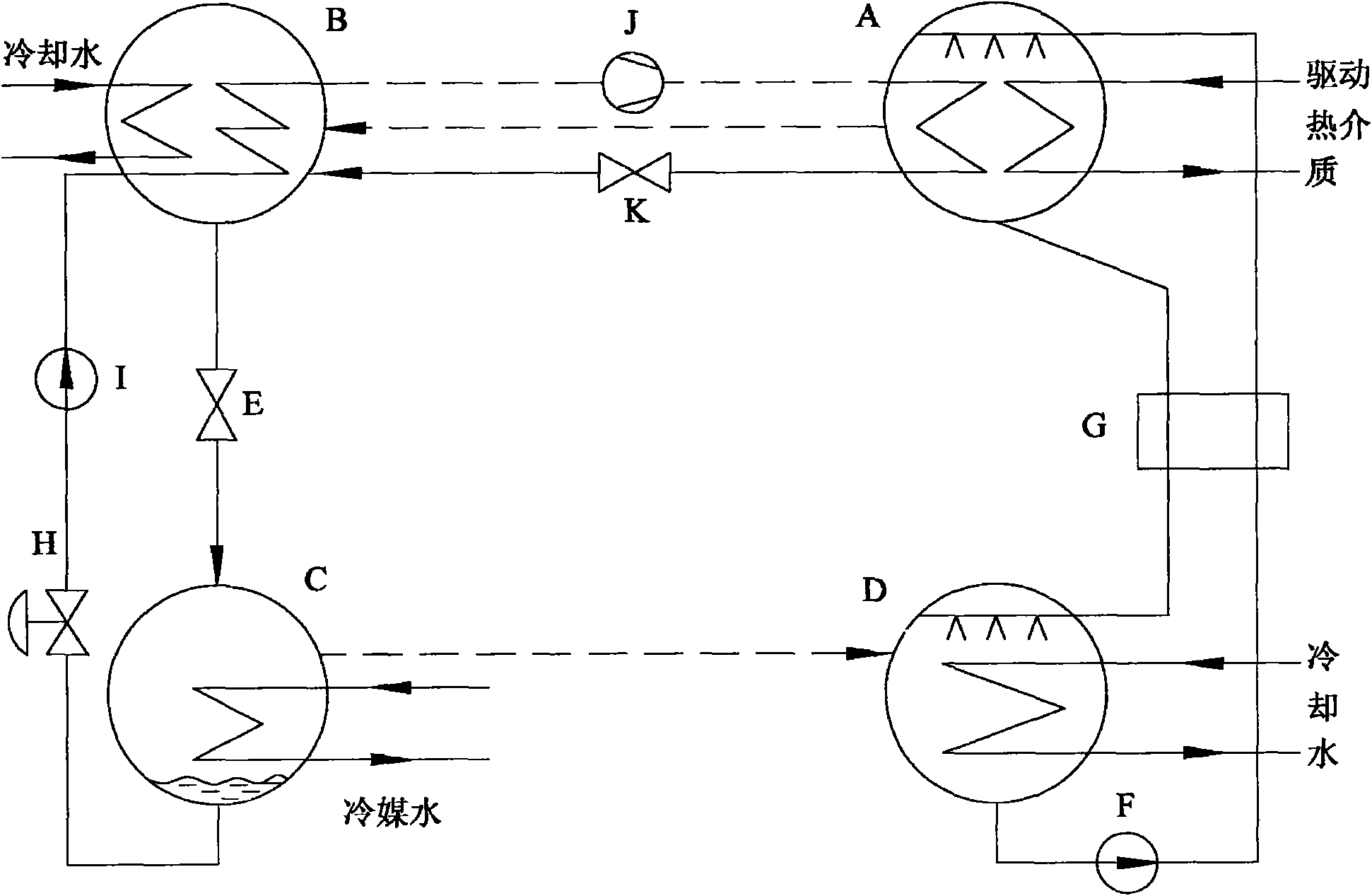

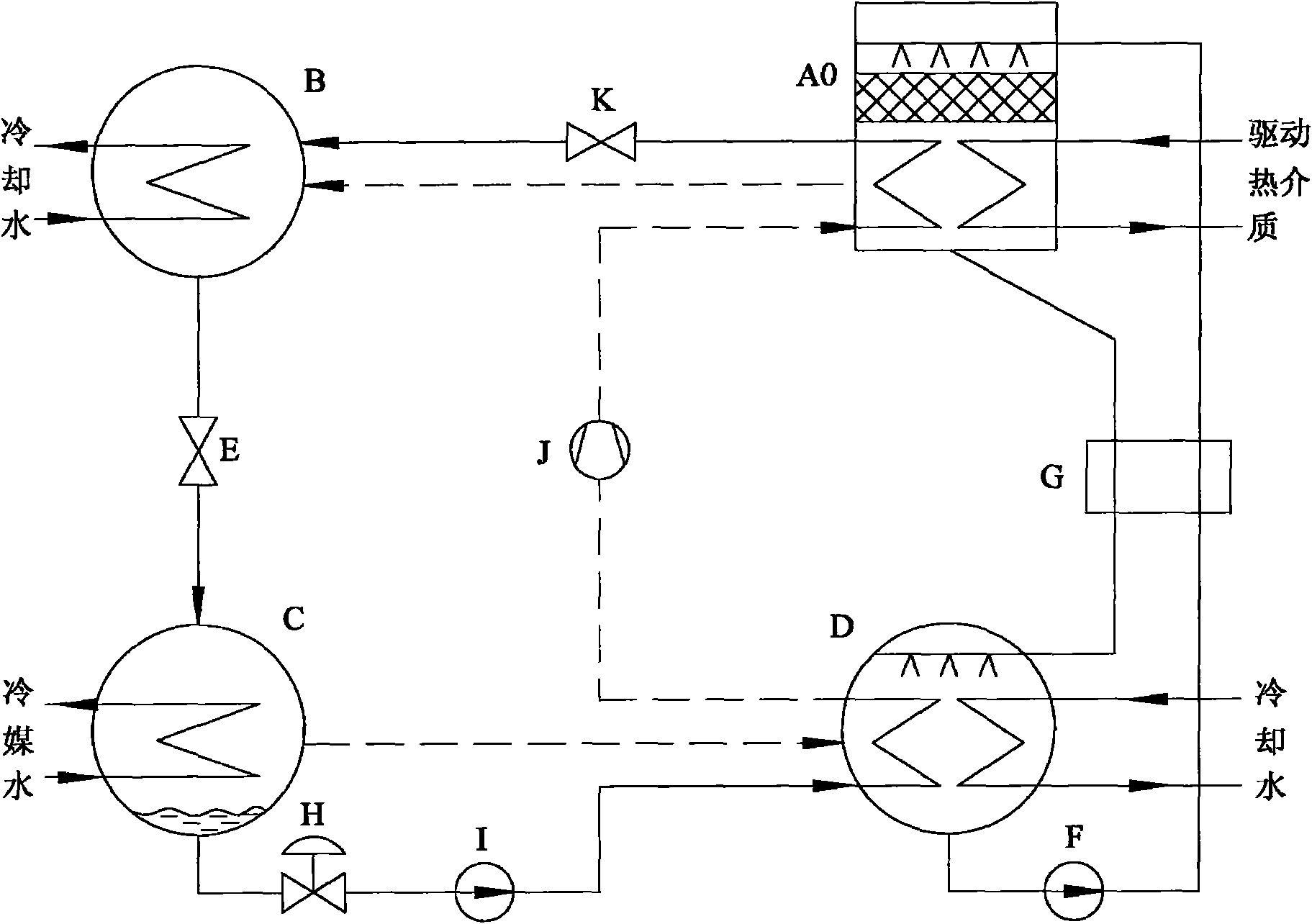

[0011] Such as figure 1 As shown, the purpose of the present invention is achieved in this way: in the single-stage first stage composed of generator A, condenser B, evaporator C, absorber D, throttle valve E, solution pump F and solution heat exchanger G A type of absorption refrigerator - the refrigerant vapor from the evaporator C enters the absorber D, is absorbed by the concentrated solution from the generator A, enters the absorber D through the solution heat exchanger G, becomes a dilute solution, and then goes through The solution pump F and the solution heat exchanger G enter the generator A, and under the action of the driving heat source, the refrigerant vapor is re-released to the condenser B. The condensed refrigerant vapor becomes the refrigerant liquid, and the refrigerant liquid is throttled The valve E enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com