Pneumatic weight press

A technology of heavy weights and presses, which is applied to weapon accessories, ammunition, offensive equipment, etc. It can solve the problems of lever knife edge wear, inconsistent pressing speed, poor consistency, etc., and achieve the effect of fast return speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

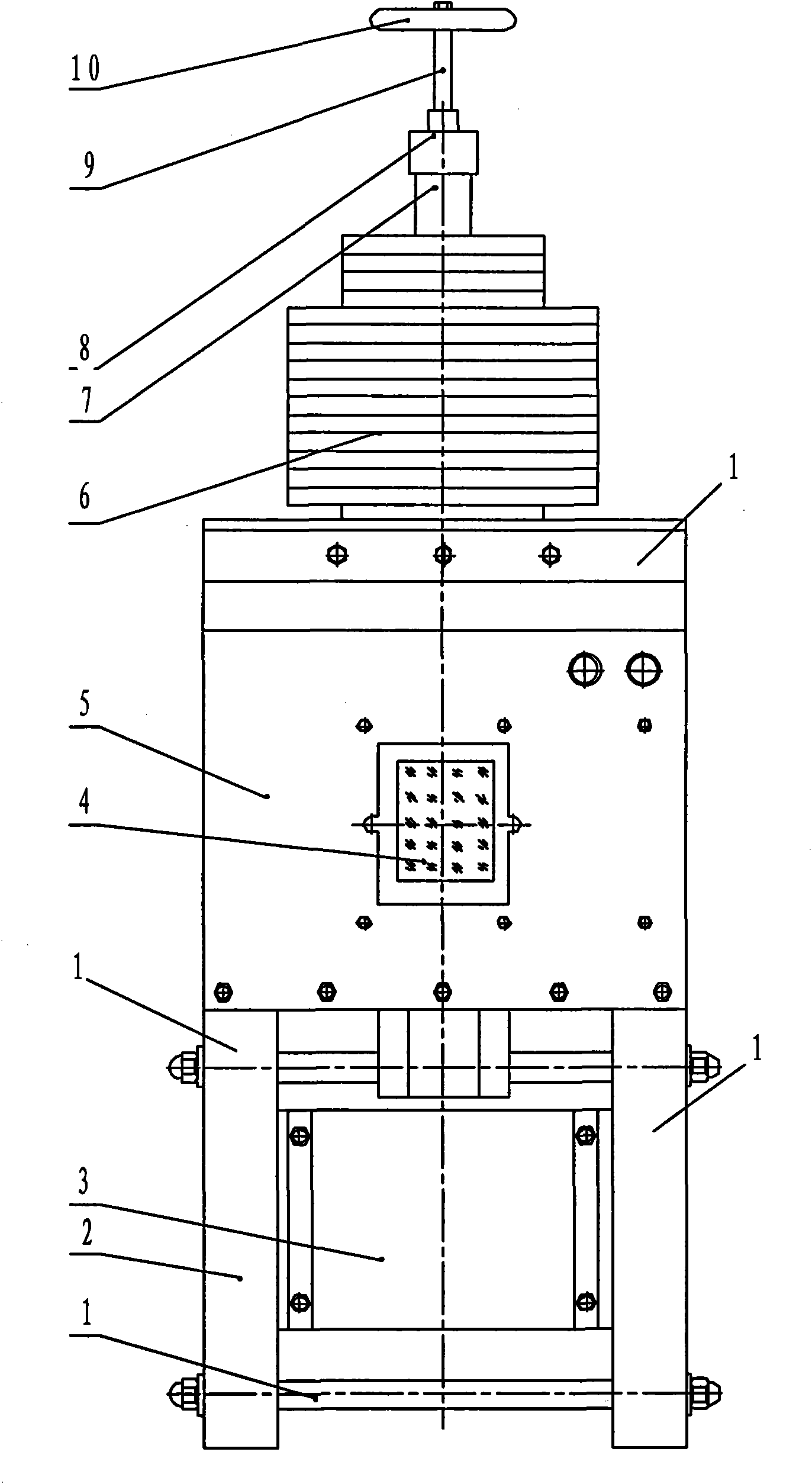

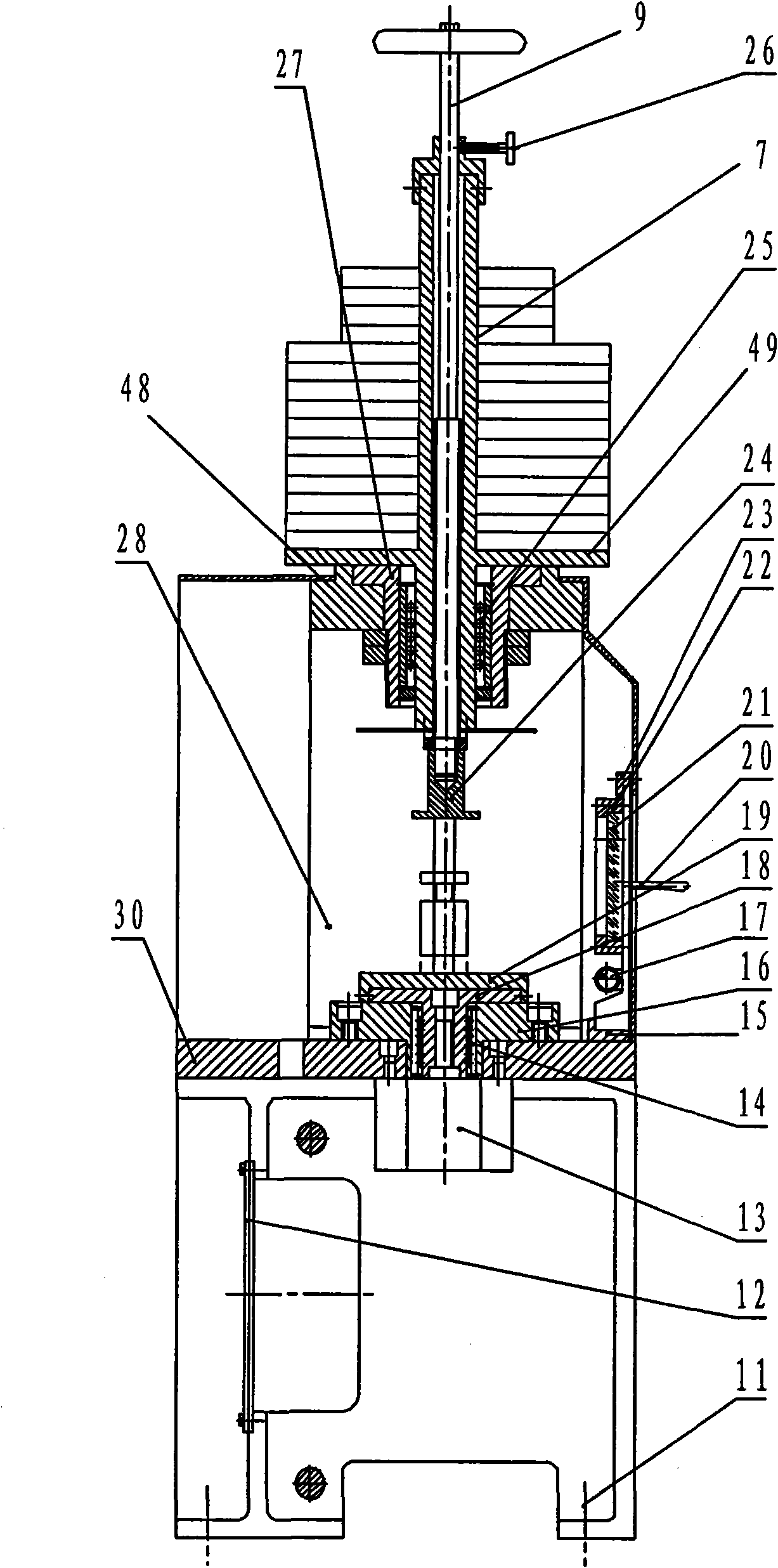

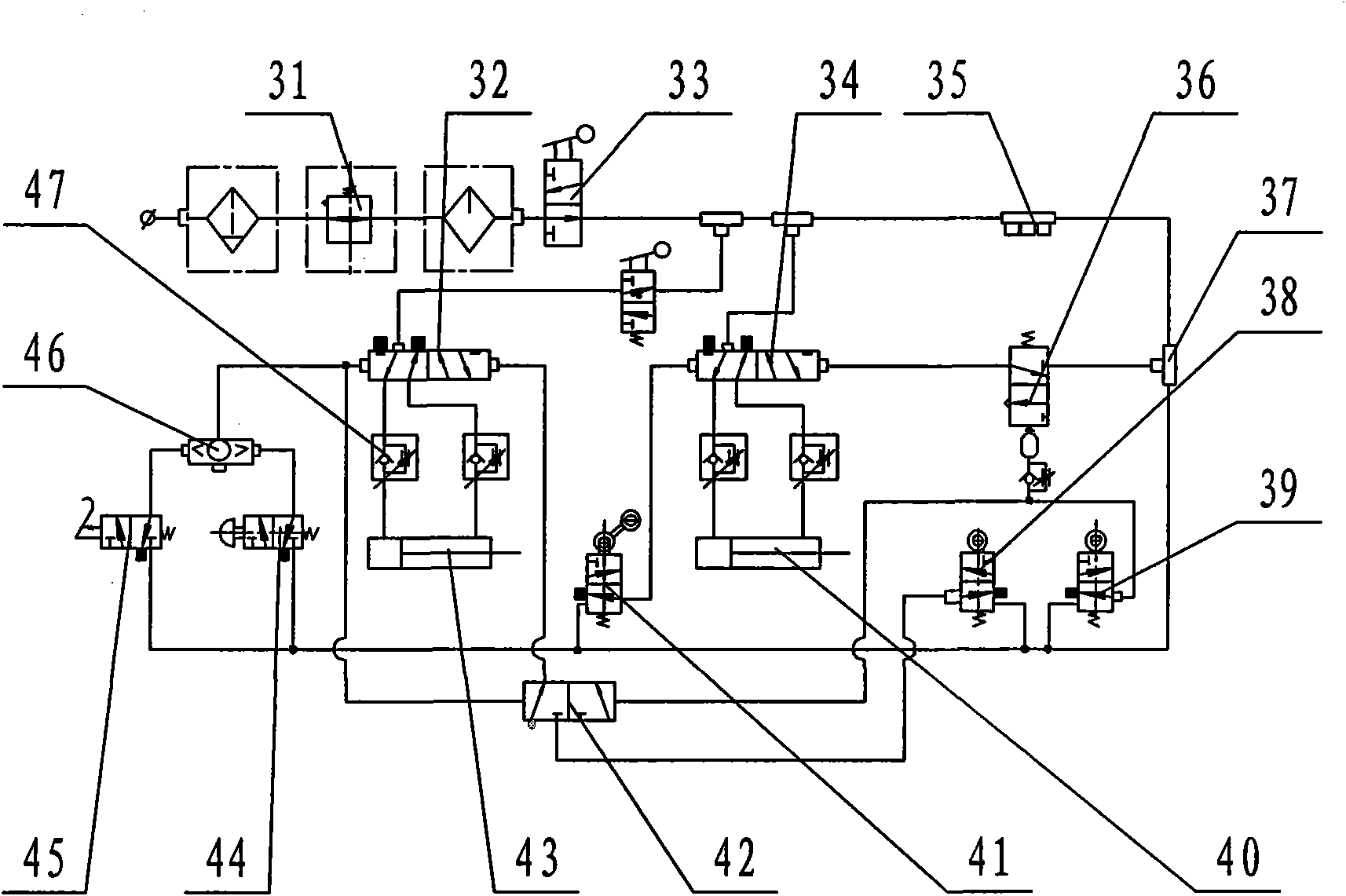

[0022] see figure 1 and figure 2 , is a structural diagram of the present invention, the top of the horizontal platform 30 is a frame top plate 48, the frame top plate 48 is fixedly connected with the horizontal platform 30 through the support 28, and the gap between the frame top plate 48 and the horizontal platform 30 The working cavity is formed by wrapping the protective cover 5, and the central axis of the top plate 48 of the frame is provided with a top plate through hole, and the top plate through hole is inserted with a weight support tube 7, and the outer wall of the weight support tube 7 is provided with The weight is placed on the plate 49, the weight support tube 7 is inserted with a screw 9, the screw 9 axially passes through the weight support tube 7 and extends into the working cavity, and the end of the screw 9 extending into the working cavity is pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap