Improved microchannel high-efficiency water cooling exchanger

An exchanger and micro-channel technology, applied in the field of improved micro-channel high-efficiency water-cooling exchangers, can solve the problems of limited heat dissipation area of water channels and poor heat exchange effect, and achieve good heat exchange effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

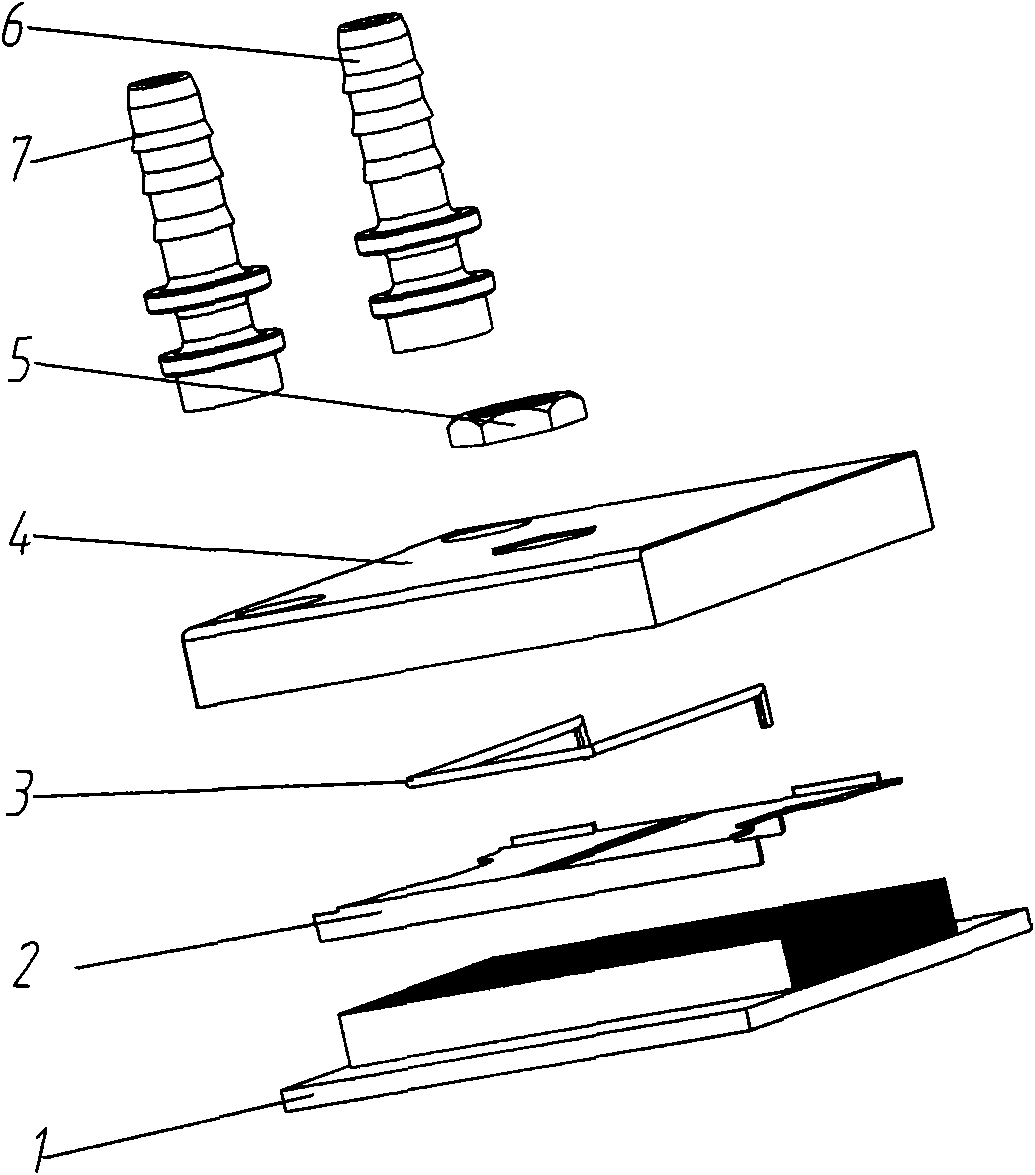

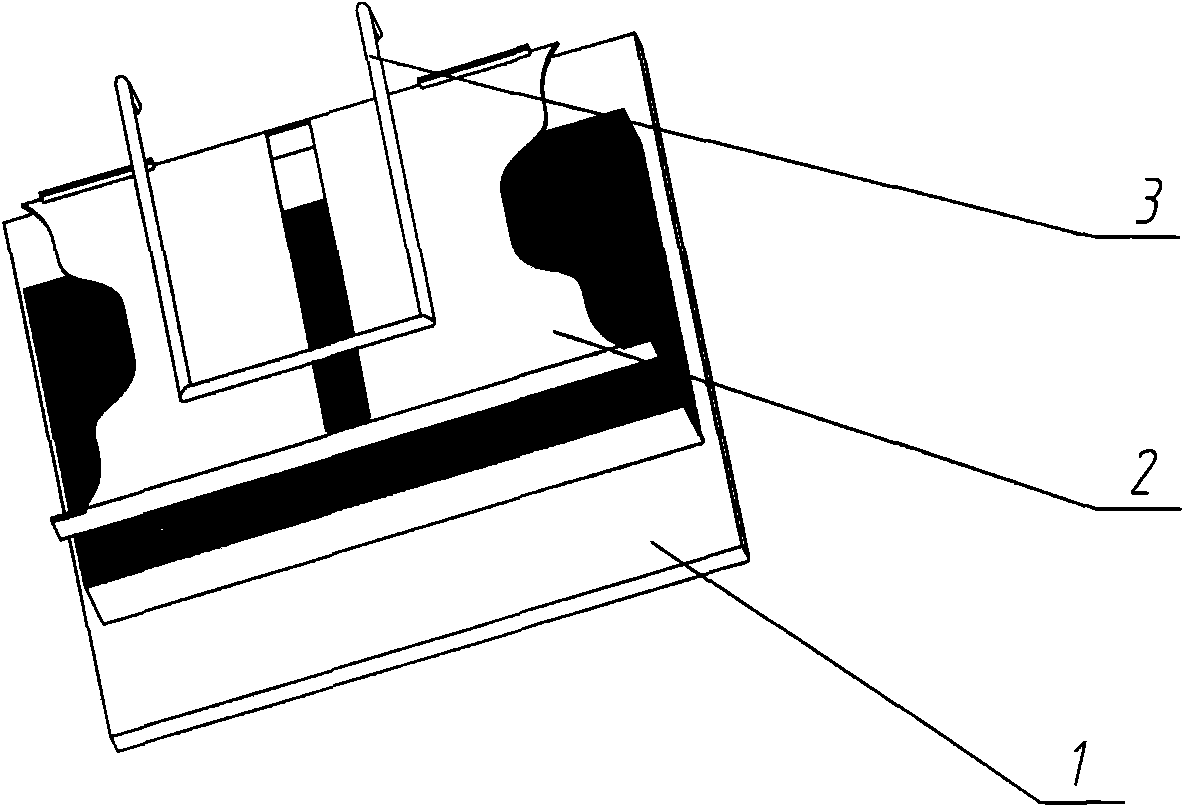

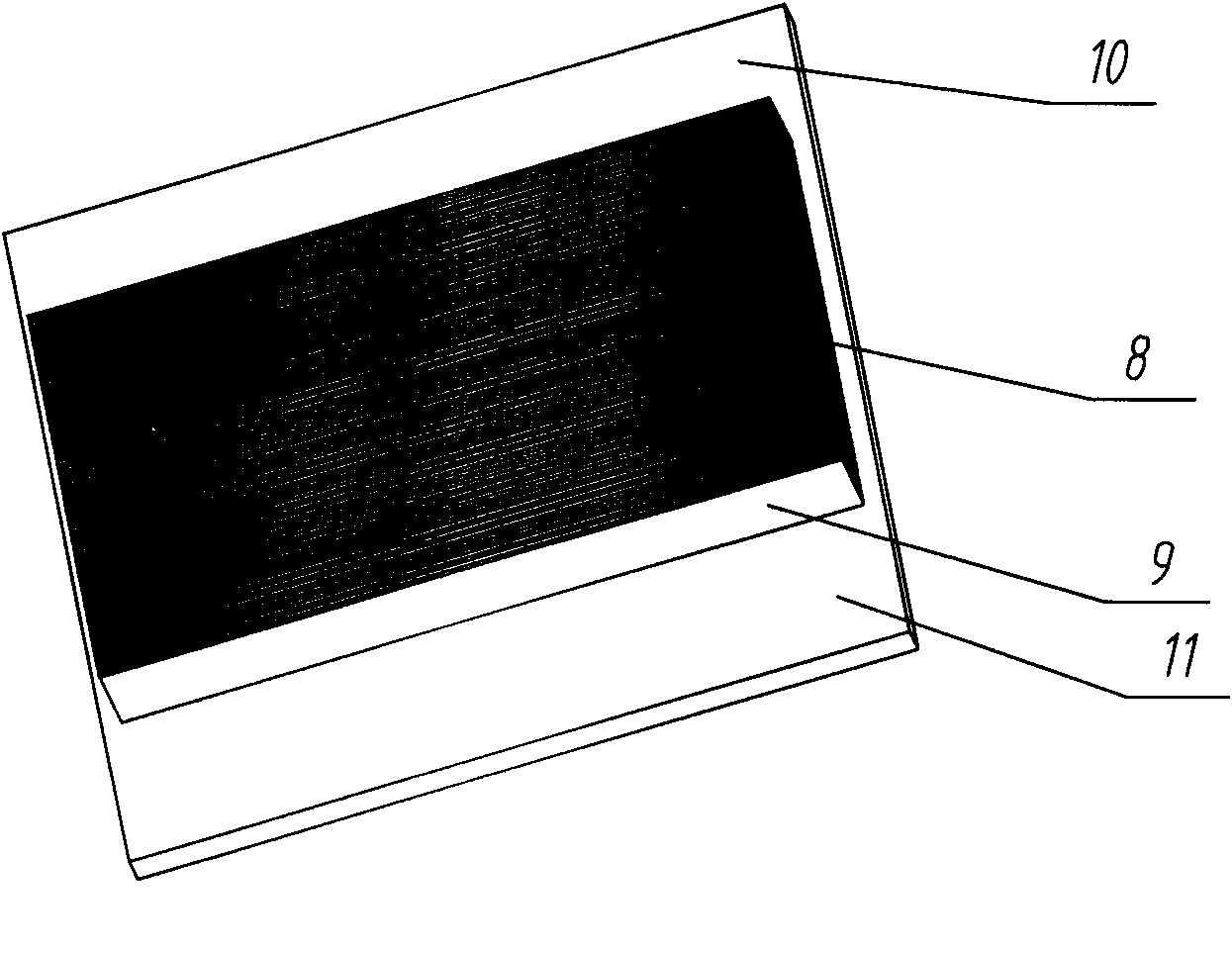

[0011] See figure 1 , figure 2 , image 3 , Figure 4 , which includes a base plate 1, a cover plate 4, a water inlet 7, and a water outlet 6. The cover plate 4 covers the upper part of the base plate 1. The cover plate 4 is equipped with a water inlet 7 and a water outlet 6. The central part of the upper surface of the base plate 1 is a heat sink area 8. , which is a combination of multiple sheet heat sinks 9, the upper and lower sides of the heat sink area 8 are flat plates 10, 11, the shunt assembly covers the heat sink area 8, and the shunt assembly connects the cavity formed by the base plate 1 and the cover plate 4 It is divided into a liquid inlet area, a cooling area, and a liquid discharge area. The space area formed by the shunt assembly and its lower multi-piece thin heat sink 9 is a cooling area. The liquid inlet area is connected to the cooling area, and the cooling area is connected to the liquid discharge area. The liquid inlet area, The drain area is separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com