Boot shape maintaining body

A technology for maintaining body and boots, which is applied in the directions of boot legs, shoe uppers, clothing, etc., and can solve the problem that moisture cannot be released.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

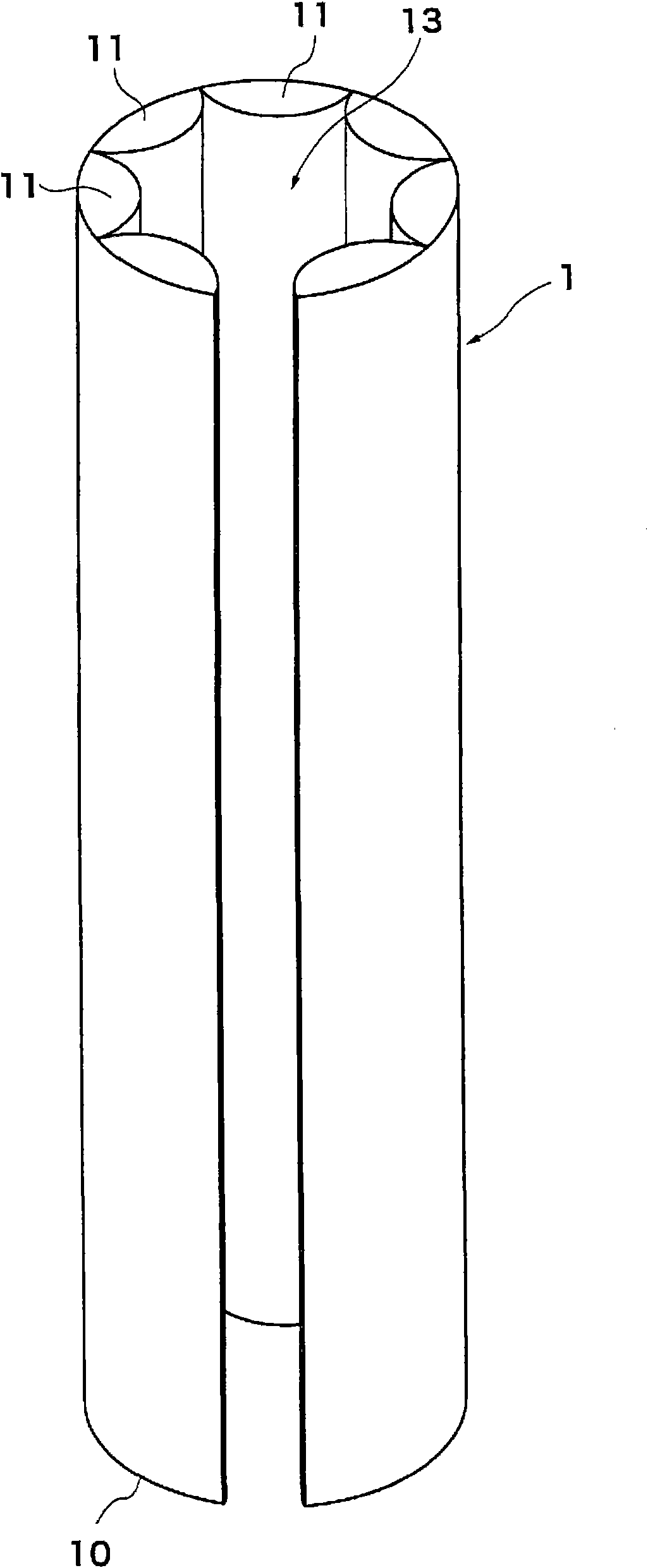

[0027] figure 1 A perspective view showing a boot shape retainer 1 as a first embodiment to which the present invention is applied. This boot shape retainer 1 is mainly constituted by rolling and connecting a plastic film 10 in a cylindrical shape.

[0028] The plastic film 10 is a thermoplastic resin film such as polyethylene that does not have air permeability. That is, the thermoplastic resin can be appropriately selected from polypropylene, polyethylene terephthalate, nylon, polyvinyl chloride, polycarbonate, and the like in addition to polyethylene.

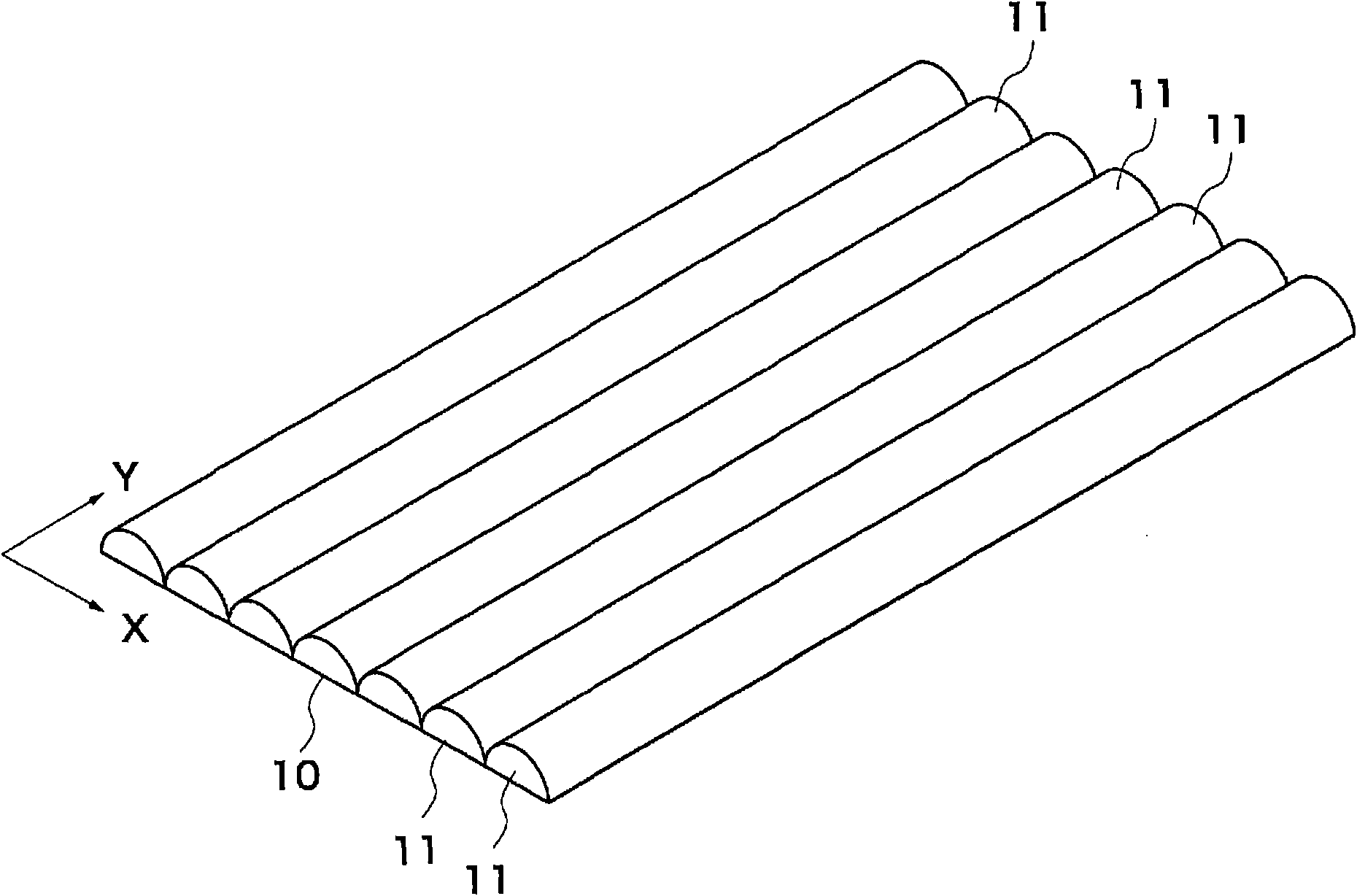

[0029] Such as figure 2 As shown, in the plastic film 10 , the air cells 11 are arranged in a row along the width direction x. The air cells 11 are preliminarily sealed with gas and are formed in a long and thin shape in the vertical direction y. The air chamber 11 is constituted by forming the plastic film 10 by two rectangular film sheets, and after overlapping the two film sheets, performing thermocompression bonding ...

no. 2 approach

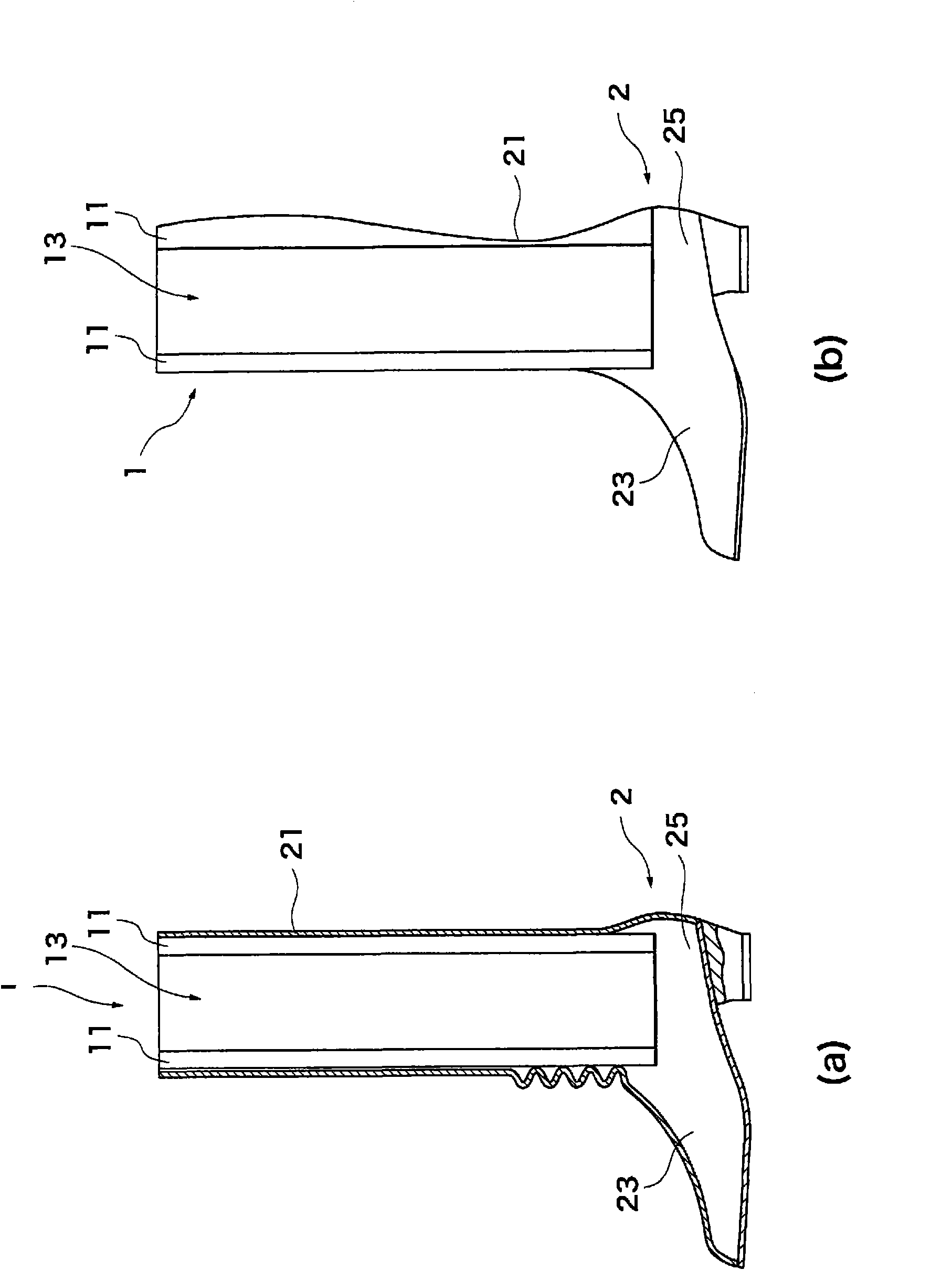

[0040] Figure 5 (a) is a perspective view showing a boot shape retainer 3 as a second embodiment to which the present invention is applied. The boot shape retainer 3 has a cylindrical main body 30 formed of a plastic film preliminarily sealed with gas, and at least one protrusion 32 protruding further downward from the lower end of the main body 30 . A through hole 31 is provided in the cylindrical body portion 30 . In addition, in the following description, the case where two protrusion parts 32 are formed is demonstrated as an example, However, It is not limited to this, You may comprise in any number, volume, and shape.

[0041] The plastic film is a thermoplastic resin film such as polyethylene that does not have air permeability. That is, the thermoplastic resin can be appropriately selected from polypropylene, polyethylene terephthalate, nylon, polyvinyl chloride, polycarbonate, and the like in addition to polyethylene.

[0042] The main body portion 30 can maintain ...

no. 3 approach

[0054] Figure 8 (a) and (b) are perspective views showing a boot shape retainer 4 as a third embodiment to which the present invention is applied. The boot shape retainer 4 has a cylindrical main body 40 formed of a plastic film pre-enclosed with gas, and a through-hole 42b provided in the lower part of the side wall surface of the main body 40 or a hole formed in the lower end of the side wall of the main body 40. Groove portion 42a. In addition, the groove portion 42a or the through-hole 42b may be formed in any shape, and may be formed in any number. The through hole 42b is connected to the through hole 41 formed in the cylindrical body part 40 . The position where the through hole 42b is provided is pre-adjusted at least in relation to the position of the inner bottom 23 of the boot 2, but it is preferably formed at least at an arbitrary position of the lower half. The main body portion 40 can maintain its shape by enclosing air.

[0055] When actually using the boot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com