Vibration control equipment

An anti-vibration device and anti-vibration technology, applied in non-rotational vibration suppression, mechanical equipment, low internal friction springs, etc., can solve problems such as increased production costs and cumbersome assembly operations, and achieve the effects of easy assembly and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

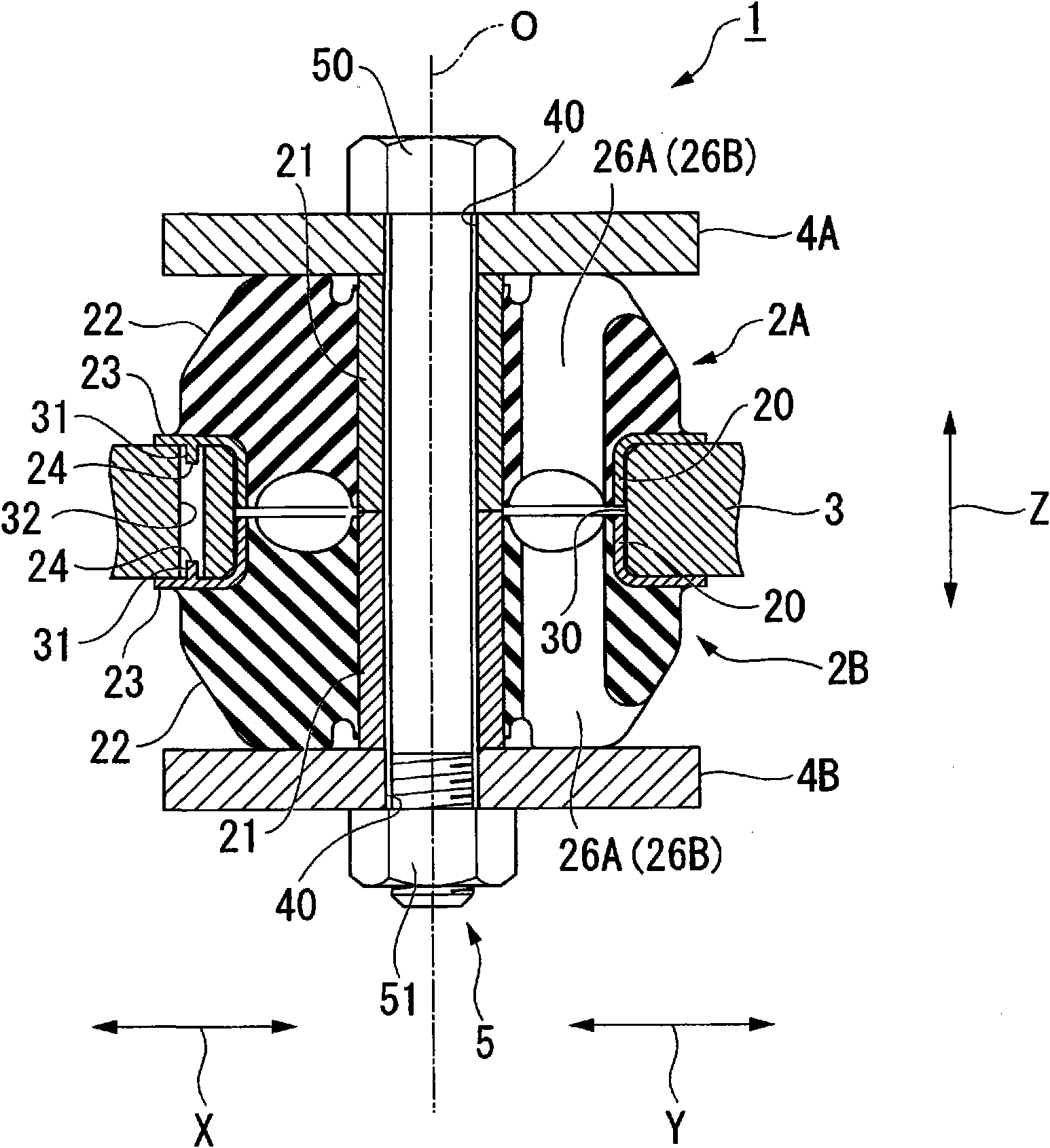

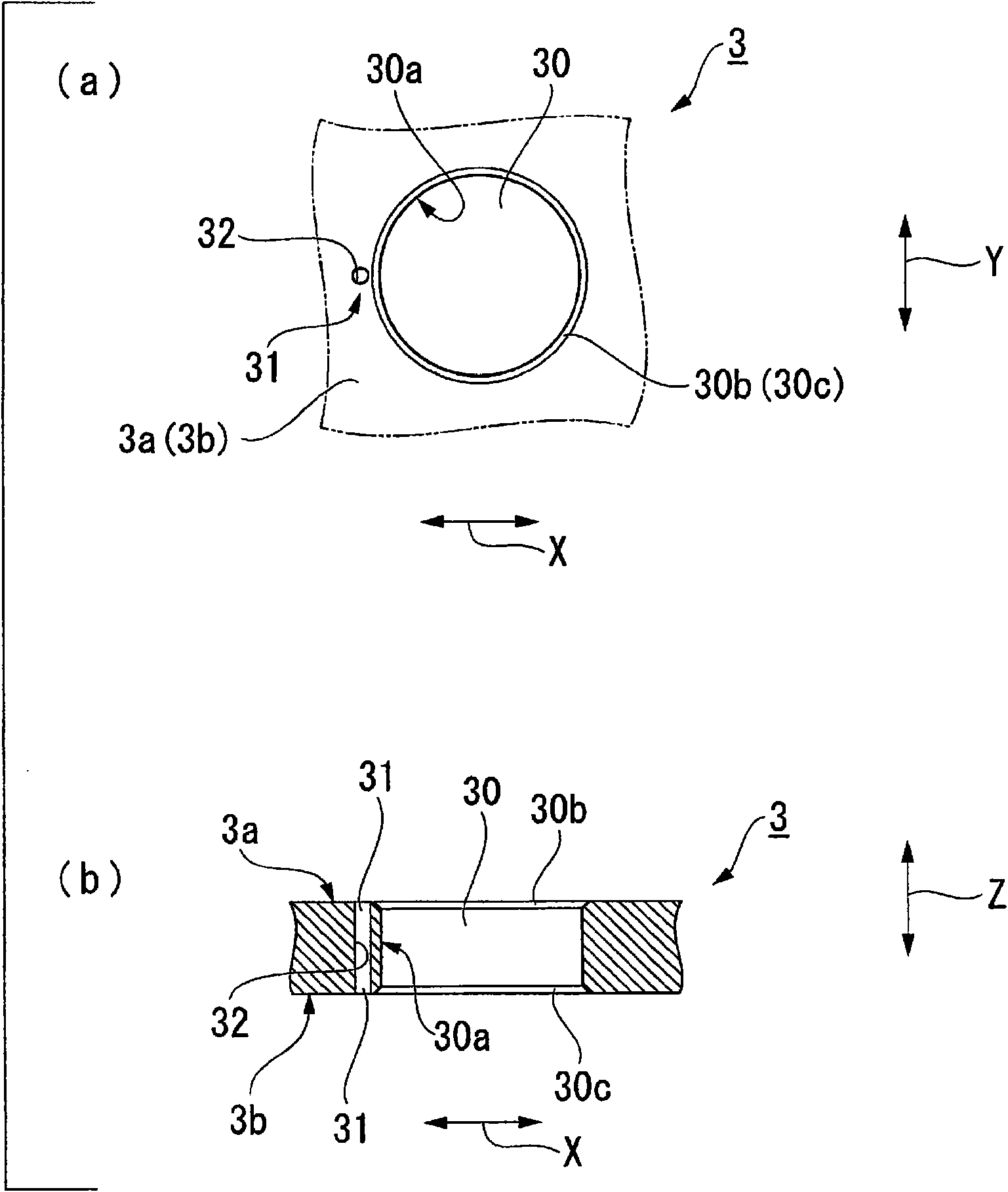

[0045] First, use Figure 1 ~ Figure 3 The anti-vibration device 1 of the first embodiment will be described.

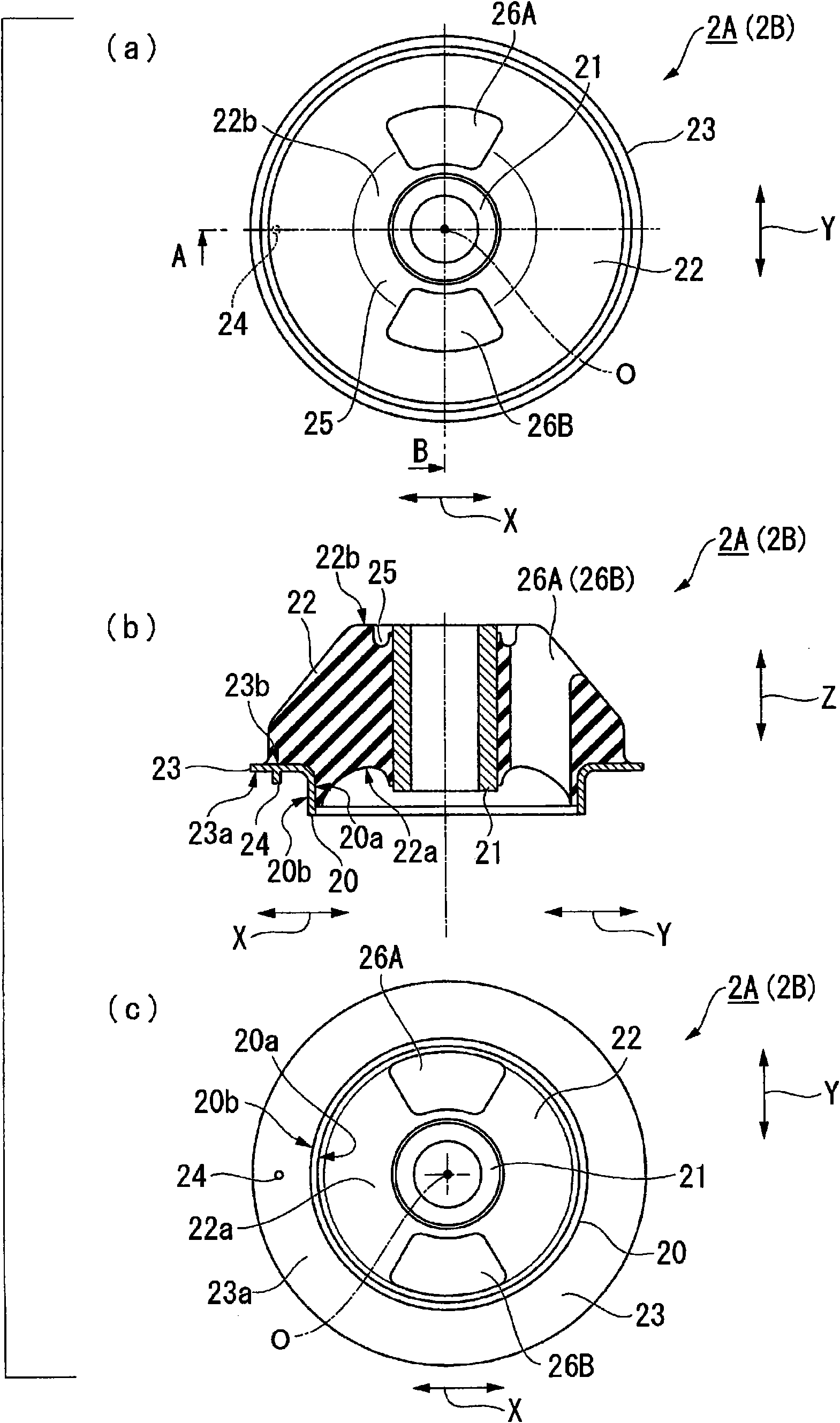

[0046] In the following description, the direction of reference sign X (horizontal direction) in the drawings is referred to as the front-rear direction, the direction of reference sign Y (vertical direction) is referred to as the left-right direction, and the direction of reference sign Z (vertical direction) is referred to as the up-down direction. In addition, the side opposite to the other anti-vibration rubber 2B (2A) viewed from one anti-vibration rubber 2A (2B) ( figure 2 The lower side in (b)) is regarded as the inner side of the axis direction, and the opposite side ( figure 2 The upper side in (b)) is defined as the outer side in the axial direction.

[0047] figure 1 It is a sectional view of the anti-vibration device 1 of the first embodiment.

[0048] figure 2 It is a figure which shows the anti-vibration rubber 2A (2B) of the state which does no...

no. 2 Embodiment approach

[0083] Next, the anti-vibration device 101 of the second embodiment will be described. In addition, the same code|symbol is attached|subjected to the same structure as said 1st Embodiment, and the description is abbreviate|omitted.

[0084] Figure 4 It is a sectional view of the anti-vibration device 101 of the second embodiment.

[0085] Figure 5 is a diagram showing the inner cylinder side split body 110, Figure 5 (a) is a side view, Figure 5 (b) is a sectional view, Figure 5 (c) is a plan view seen from the inner side in the axial direction.

[0086] Figure 6 is a diagram showing the outer cylinder side split body 111, Figure 6 (a) is a plan view seen from the outside of the axial direction, Figure 6 (b) is a sectional view.

[0087] in addition, Figure 4 , Figure 5 of (b), Figure 6 The left half (left side of the central axis O) of (b) is a cross-sectional view in the front-rear direction, and the right half (right side of the central axis O) is a cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com