Method and special device for automatically identifying suction/discharge mechanism range of electronic pipette

An automatic identification and pipette technology, applied in the direction of measuring tube/pipette, etc., can solve the problems of troublesome operation, wrong operation, and complicated switching steps of operation mode, so as to save time and avoid wrong operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

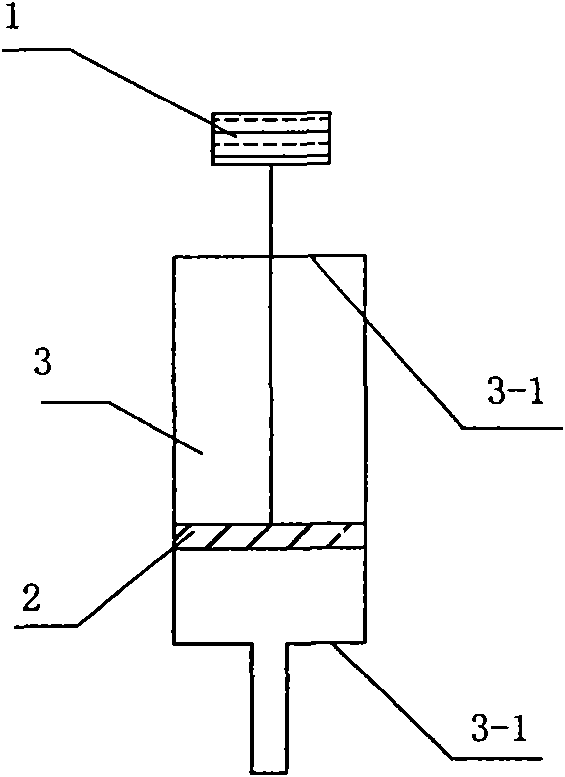

[0028] figure 1 Structure Cost Example 1.

[0029] The inner cavity of the electronic pipette is provided with a control unit, a stepping drive unit, a reciprocating movement unit and a reciprocating movement termination point; the reciprocation movement unit moves within the range limited by the reciprocation movement termination point; the signal output terminal of the detection and control unit is connected The control signal input end of the stepping drive unit, the signal output end of the stepping drive unit are connected to the signal input end of the reciprocating motion unit, the feedback signal output end of the stepping drive unit is connected to the feedback signal input end of the detection and control unit.

[0030] In this embodiment, the detection and control unit of the electronic pipette includes a detection controller; a stepping driver and a stepping motor form a stepping drive unit; a piston and a piston cylinder form a reciprocating movement unit; Moveme...

specific Embodiment 2

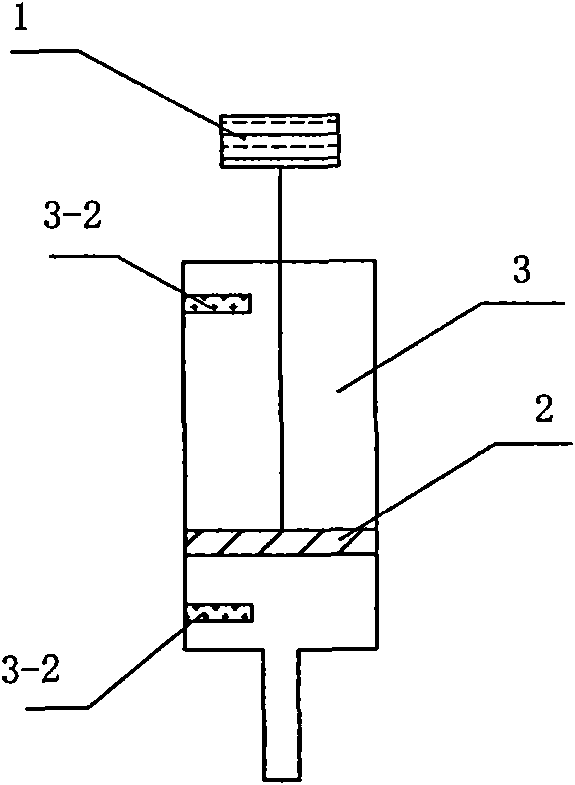

[0033] Such as figure 2 As shown, the characteristics of this embodiment are: two blocking parts 3-2 are installed on the inner walls at both ends of the piston cylinder 3 as the positive termination point and the reverse termination point of the reciprocating motion of the piston 2; the blocking parts at both ends of the piston cylinder The space between 3-2 is the range of the piston cylinder. All the other are identical with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com