Multifunctional modification processing method for wool

A processing method and a multifunctional technology, applied in the field of multifunctional modification of wool, can solve problems such as limited use, and achieve the effects of improving dyeing performance, saving energy, and improving antibacterial properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

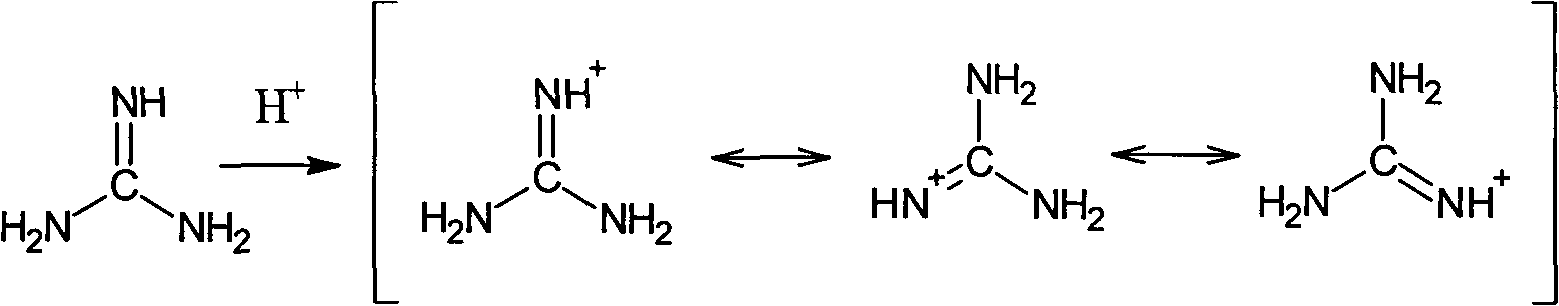

Method used

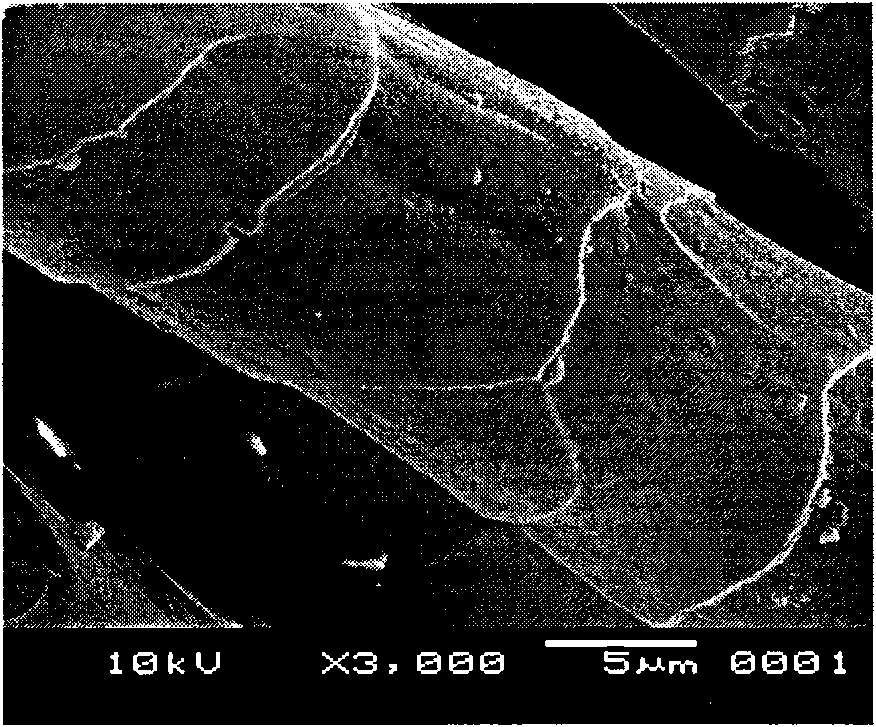

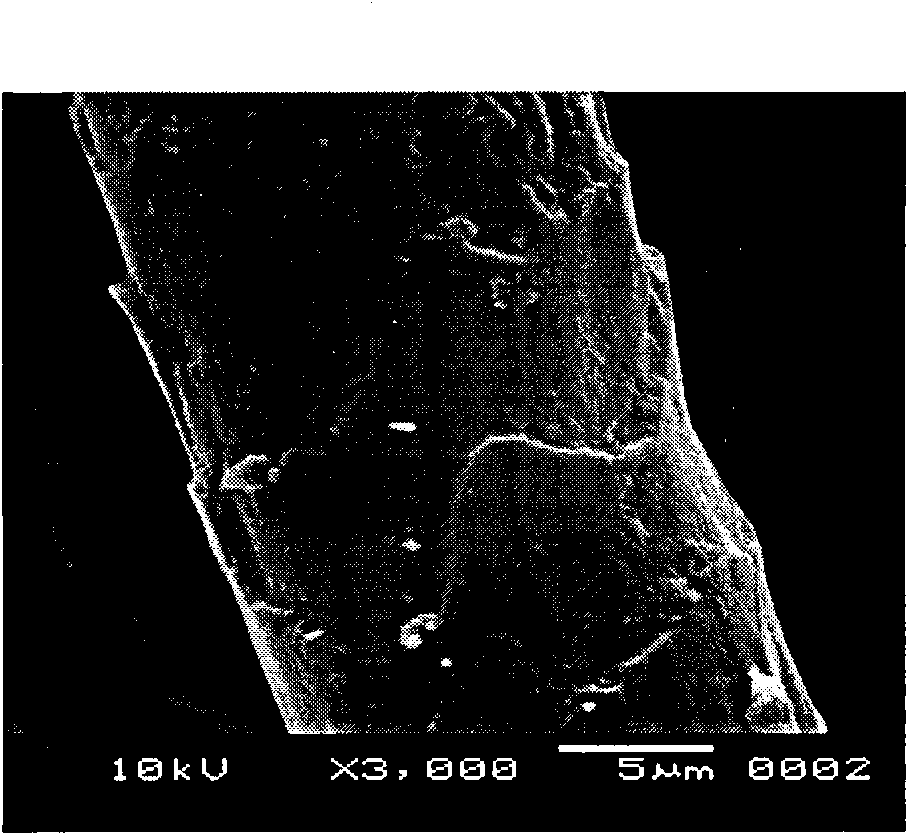

Image

Examples

Example Embodiment

[0025] Example 1

[0026] A kind of multifunctional modification treatment method of wool, comprising steps: wool fabric is contained 0.5% (0.5g) chitosan monoguanidine hydrochloride, 0.5% (0.5g) butanetetracarboxylic acid, 0.5% (0.5g) ) sodium hypophosphite in the finishing solution for 5 minutes, dipping and rolling twice, the excess rate is 80%, then drying at 80°C for 5 minutes, baking at 120°C for 6 minutes, fully washing with hot water at 50°C, washing with cold water, and finally drying .

Example Embodiment

[0027] Example 2

[0028] A kind of multifunctional modification treatment method of wool, comprises steps: the wool fabric contains 1.0% (1.0g) chitosan monoguanidine hydrochloride, 1.0% (1.0g) butanetetracarboxylic acid, 1.0% (1.0g) ) in the finishing liquid of sodium hypophosphite for 10 minutes, dipping and rolling twice, the excess rate is 80%, then drying at 80°C for 5 minutes, baking at 130°C for 5 minutes, fully washing with hot water at 50°C, washing with cold water, and finally drying .

Example Embodiment

[0029] Example 3

[0030] A kind of multifunctional modification treatment method of wool, comprising steps: wool fabric is contained in 1.5% (1.5g) chitosan biguanide hydrochloride, 1.0% (1.0g) tricarboxylic acid, 1.5% (1.5g) Immerse in sodium hypophosphite finishing solution for 20 minutes, double dipping and rolling, the excess rate is 100%, then dry at 80°C for 5 minutes, bake at 140°C for 4 minutes, fully wash with hot water at 50°C, wash with cold water, and finally dry.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap