Multifunctional tipping-bucket hydraulic excavator bucket

A hydraulic excavator, multi-functional technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of small single bucket capacity, waste of energy, low work efficiency, etc., to achieve flexible and convenient operation, expand application scope, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

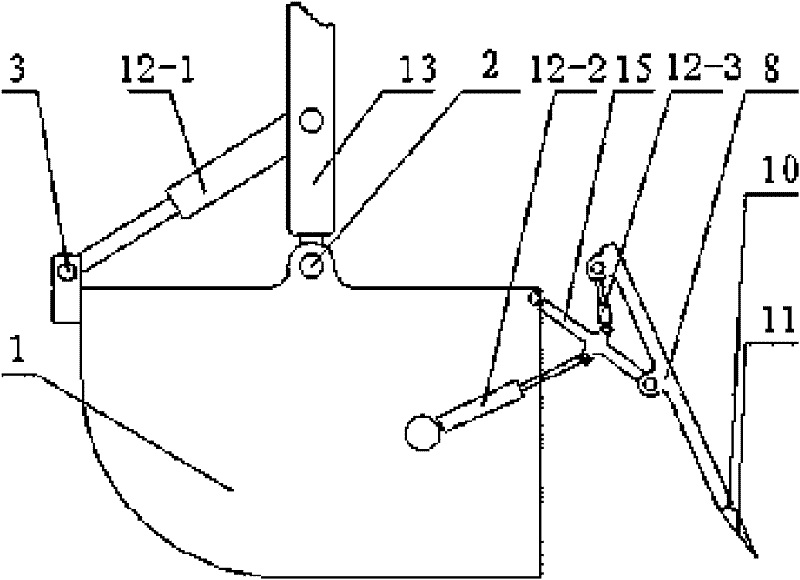

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0014] Referring to the attached picture:

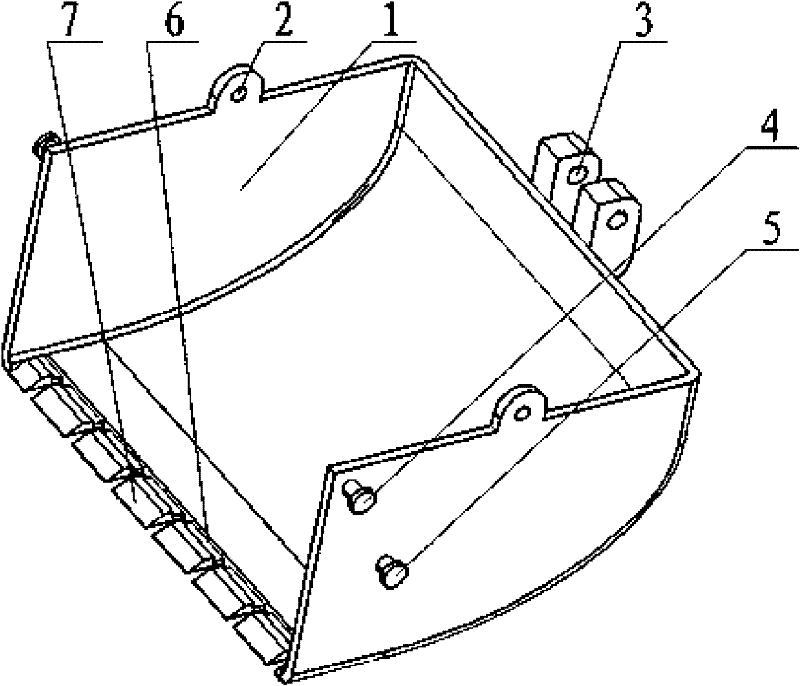

[0015] The tipping bucket 1 of this embodiment is a semi-open structure, and there are tipping bucket fixing earholes 2 connected with the excavator extension arm 13 in the middle of both sides of the upper end. There is a supporting and fixing ear hole 3 at the rear end of the dumping bucket, and a pull-back two-way hydraulic cylinder 12-1 is installed between the supporting and fixing ear hole 3 and the extension arm 13 of the excavator. The connecting fixing bolts 4 and 5, the bucket tooth seat 6 at the front end of the bottom of the dumping bucket are straightly distributed, the bucket tooth seat 6 is equipped with bucket teeth 7, and the end of the bottom of the dumping bucket is 1 / 4 oval.

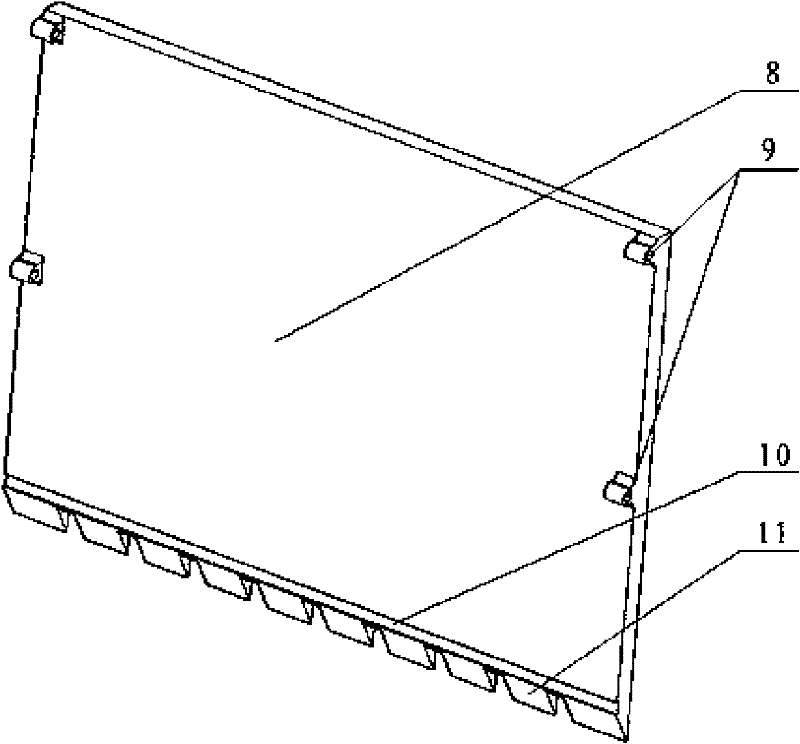

[0016] Both sides of the multifunctional shovel 8 are processed with shovel fixing holes 9 , and a shovel tooth seat 10 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com