Generator of diffusion absorption type refrigeration machine core

An absorption refrigeration and generator technology, applied in refrigerators, generators/analyzers, refrigeration components, etc., can solve the problems of increasing heating volume, unsatisfactory effect, and affecting evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

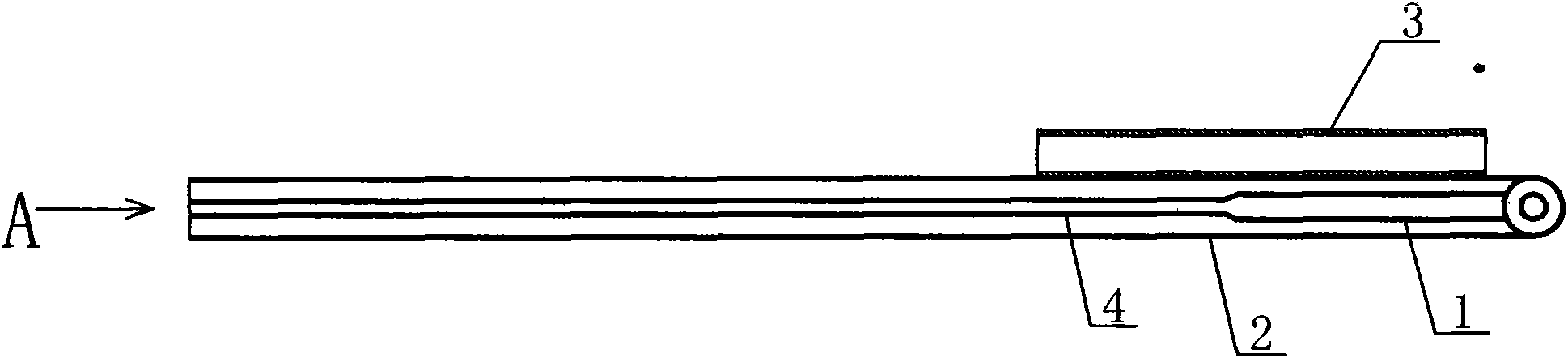

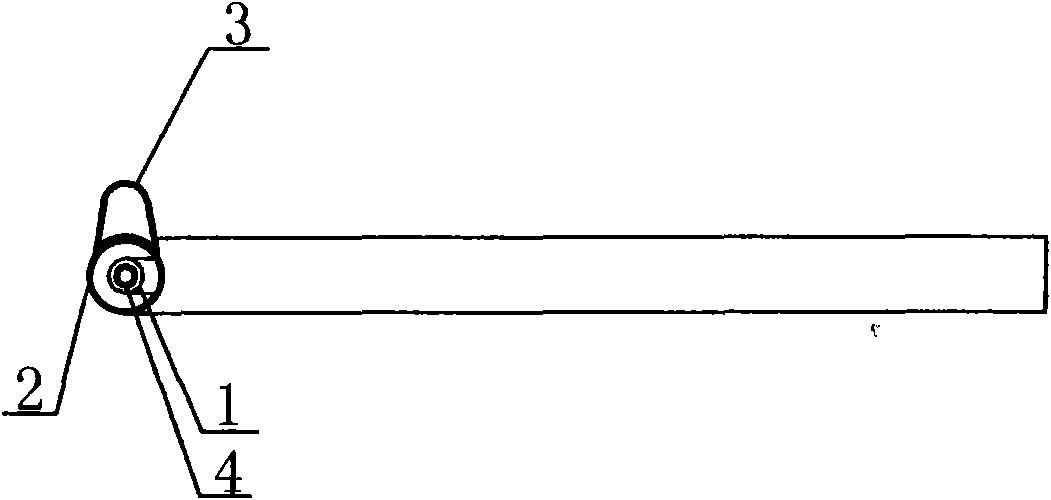

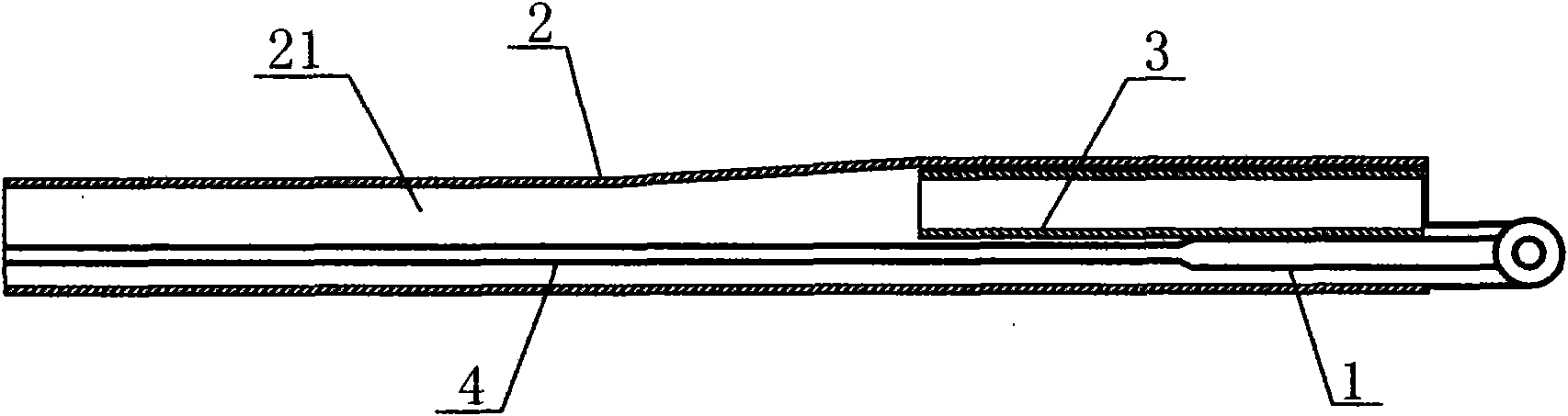

[0022] Example: such as Figure 4 , Figure 5 As shown, a generator of a diffusion-absorption refrigeration core of the present invention includes an inner tube 1, an outer tube 2, a heating jacket 3, and the heating jacket 3 is made of iron or stainless steel, and the outer tube 2 is made of thick The tube 11 and the thin tube 12 are connected in two sections. An opening 8 is provided on the thick tube 11. The heating jacket 3 is inserted into the opening. In order to prevent the liquid in the outer tube from flowing out, the opening 8 of the thick tube 11 is connected with the heating Set of 3 welded hermetic connections. In order to make the refrigeration system start quickly and reduce heat loss as much as possible, the outer peripheral wall of the heating jacket 3 is attached to the outer wall of the inner tube 1, and the thick tube 11 tightly wraps the heating jacket 3 between the inner tube 1 and the thick tube 11 In between, that is, a part of the outer tube wall of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com