Electrode heating heating device with ceramic box

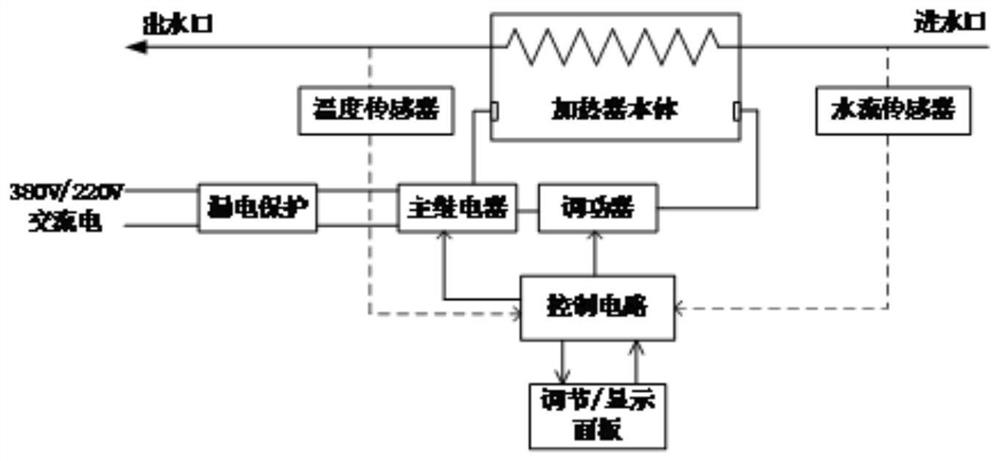

An electrode heating and heating device technology, which is applied to fluid heaters, heat storage heaters, lighting and heating equipment, etc., can solve the problems of not being able to use electric energy for easy transmission, and it is difficult to use medium and high voltage conditions, and achieves significant energy-saving effects. The effect of long service life and improved heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

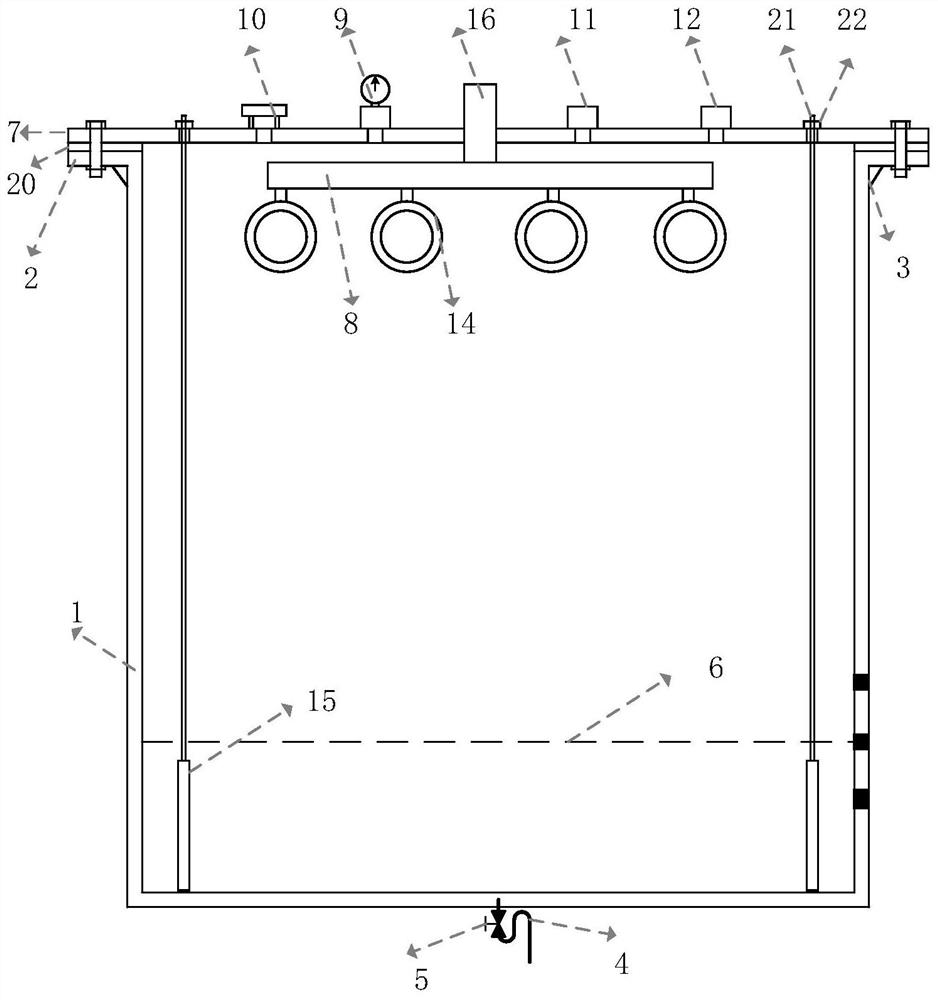

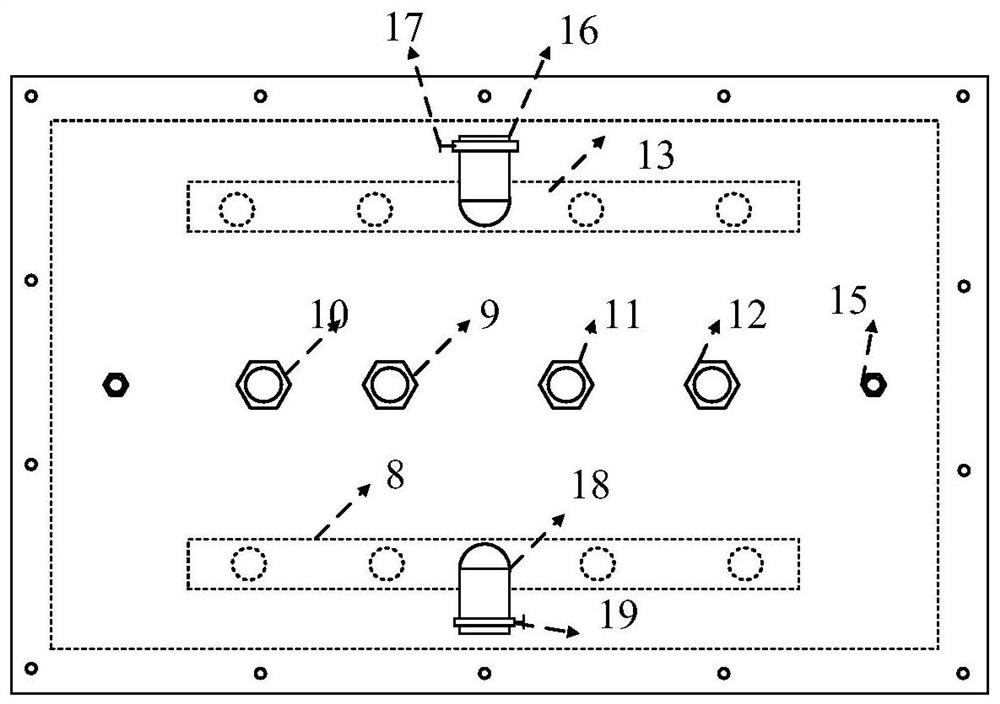

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] like Figure 1 to Figure 3 As shown, the electrode heating heating device using a ceramic box of the present invention includes two parts, one is a ceramic box, and the other is an integrated cover plate. The ceramic box body includes a ceramic square barrel 1, a skirt 2 and a reinforcing rib 3. The reinforcing rib is arranged at the joint between the ceramic square barrel and the skirt, and a certain number of through holes are arranged on each skirt to facilitate integration with the integrated cover. The plates are sealed and connected, and a drain is provided at the center of the bottom of the ceramic square barrel. The drain is connected to a drain pipe 4, and a drain valve 5 is arranged on the drain pipe. A certain volume and a certain concentration of an electrolyte solution 6 is installed inside the ceramic box. A water collector 8, a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com