Fluid level sensor

A technology of liquid level sensor and fluid sensor, which is applied in the direction of liquid level indicator, liquid/fluid solid measurement, instrument, etc., and can solve the problem that the sensor cannot distinguish liquid droplets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

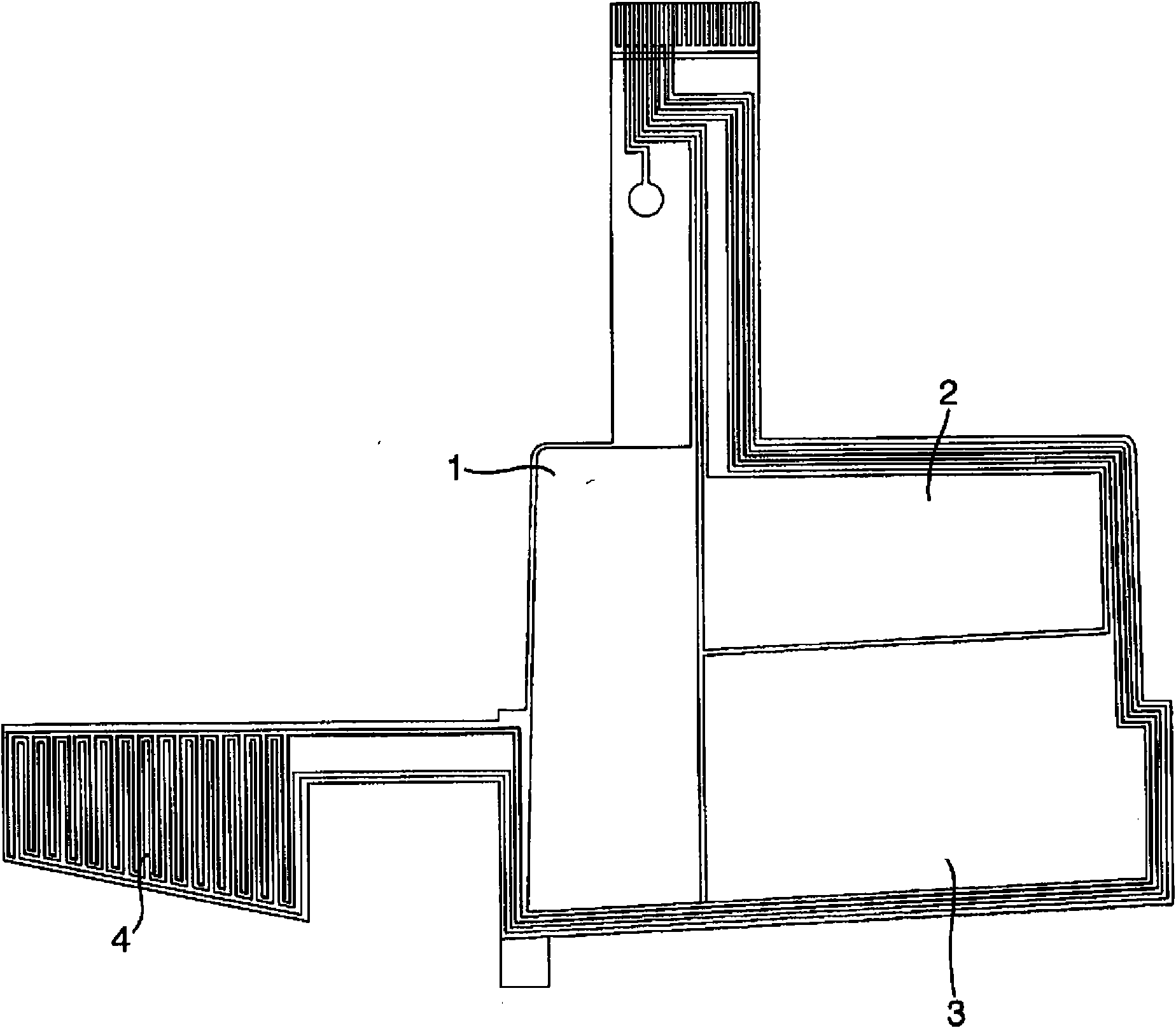

[0020] refer to figure 1 , a fluid sensor in a preferred embodiment comprises an array of conductive plates in the basic layout shown in the figure. Located on the front side of the array are conductive plates 1 to 4 configured as thin strips. These strips have a height designed to cover the height of the container in both the vertical and horizontal orientations of the container. The conductive strips 1 to 4 are preferably made of thin flexible metallic material and are separated from each other by insulating material. The strips are mounted on a conventional flexible circuit board, which is not described in detail here.

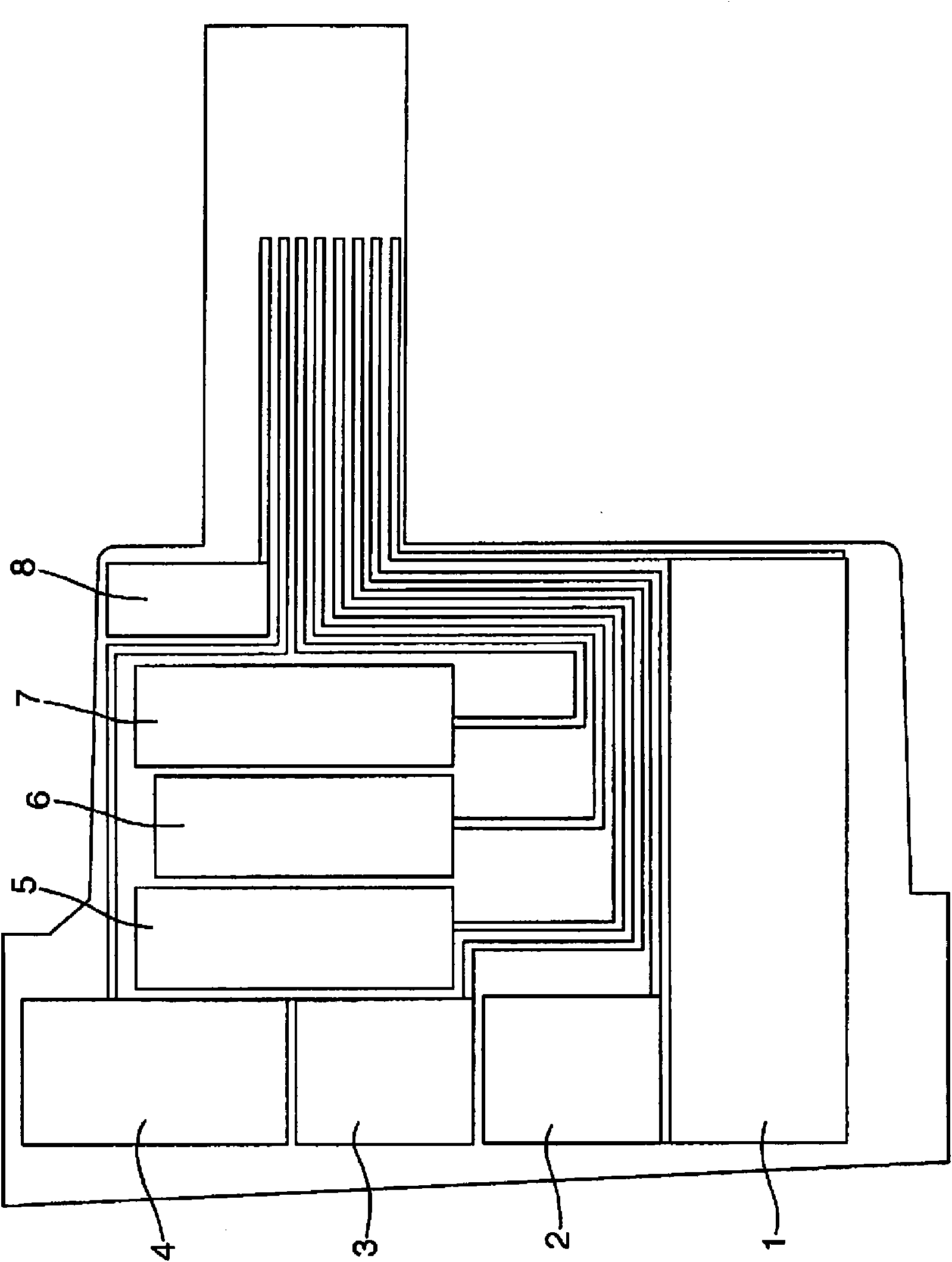

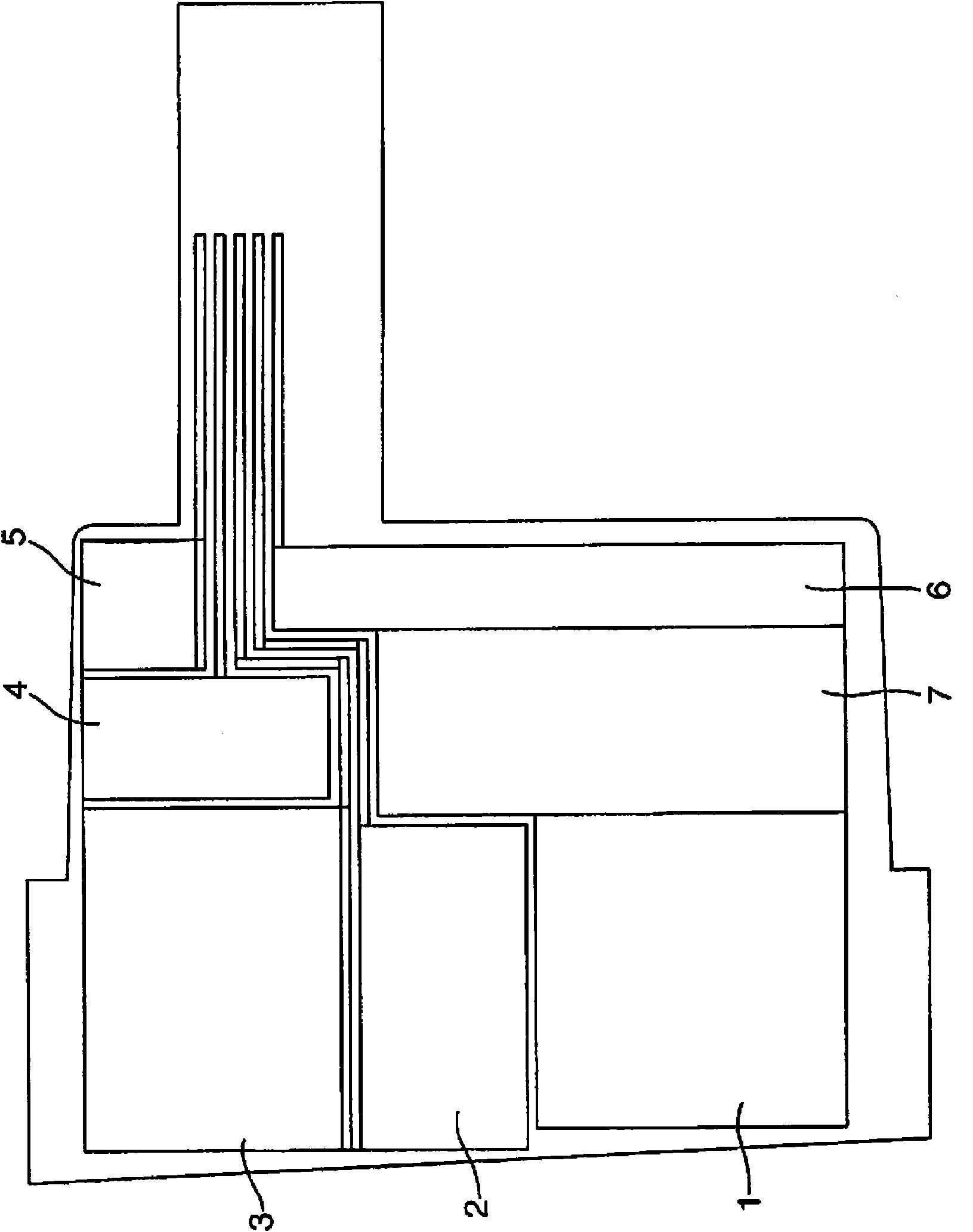

[0021] There is no limit to the number of conductive plates that can be used, as in the Figures 2 to 5 The different arrangements of fluid sensors shown in are illustrated in . Furthermore, depending on the container size and shape, the conductive plates may even be in the shape of thin strips, thin lines or even points. Figures 9a to 9d Shows the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com