Multi-mainshaft numerical-control processing center

A machining center, multi-spindle technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of low processing efficiency, difficult to adapt to large-scale production of enterprises, single processing mode, etc., to meet production requirements, The effect of many processing modes and speeding up the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

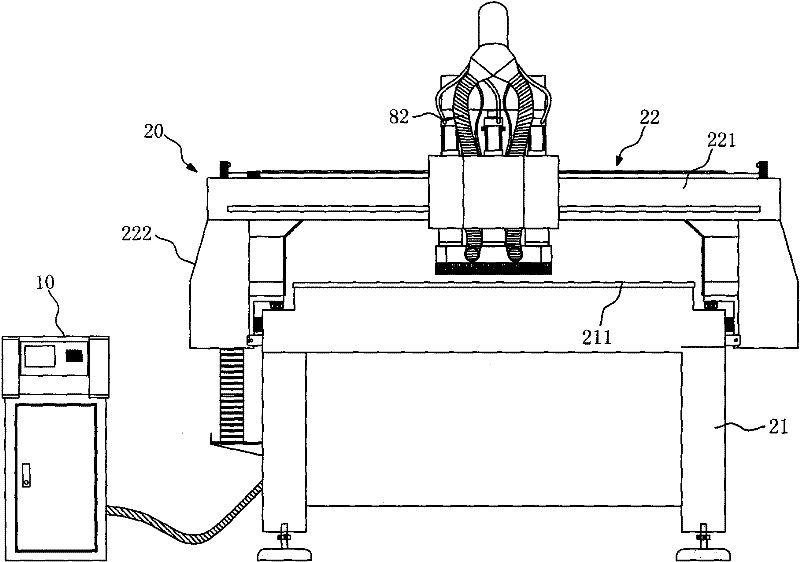

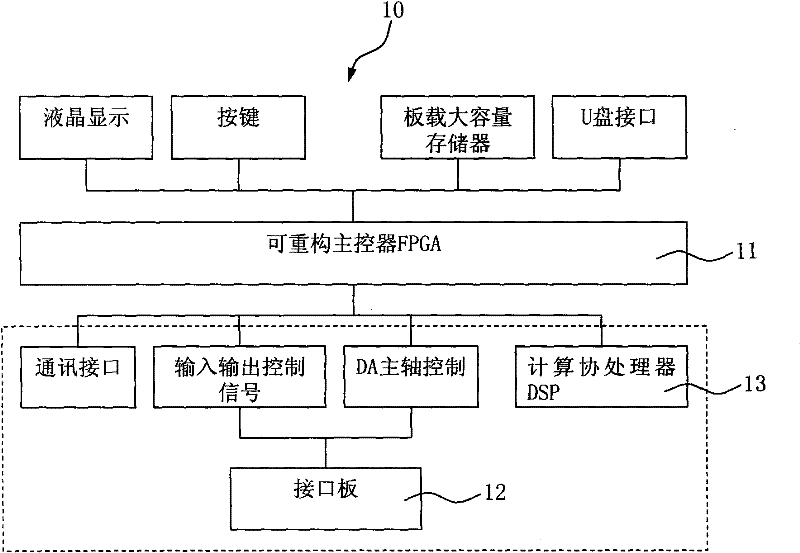

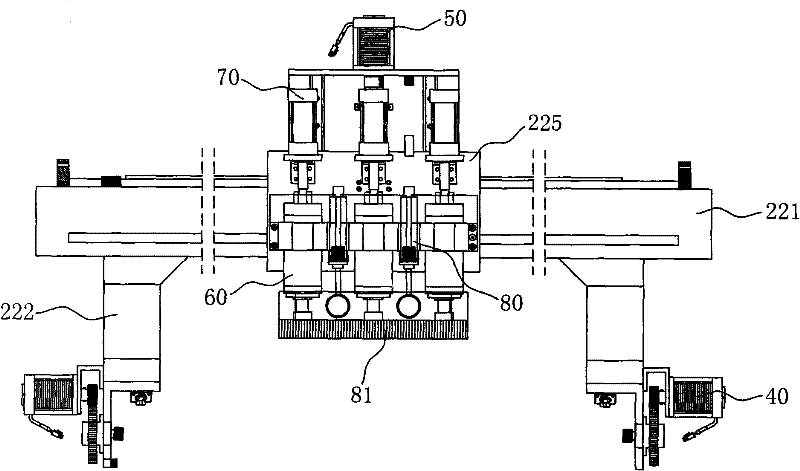

[0012] Such as Figure 1~6 As shown, a multi-spindle CNC machining center includes a control cabinet 10 and an engraving and milling machine. The control cabinet 10 is electrically connected to the engraving and milling machine through a control system disposed therein. The engraving and milling machine includes a machine tool frame 20 and The processing mechanism arranged on the machine tool frame 20. The machine tool frame 20 includes a bed body 21 and a gantry 22 erected on the bed body 21. The gantry 22 includes a beam 221 placed horizontally above the bed body 21 and a beam 221 arranged on the bed body 21. The columns 222 on both sides, the beam 221 is fixed on the top of the column 222, the processing mechanism includes a drive device and a spindle device for engraving and milling, and the drive device includes an X-axis drive device, a Y-axis drive device and a Z axis drive device. Shaft driving device, the main shaft device is arranged on the gantry 22, and there are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com