Balance shaft of two-cylinder diesel

A technology for balance shafts and diesel engines, applied in the field of balance shafts, can solve problems such as two-cylinder diesel engines and single balance shafts that have not yet been seen, and achieve the effects of simple structure, simplified structure, and strong practicability

Active Publication Date: 2010-02-24

KUNMING YUNNEI POWER +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The function of the balance shaft of the traditional two-cylinder diesel engine is only the function of a single balance shaft

Up to now, there has not been a structure that integrates the high-pressure oil pump driving the cam and the balance weight on the two-cylinder diesel engine

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0008] Further detailed description will be made below in conjunction with the embodiments.

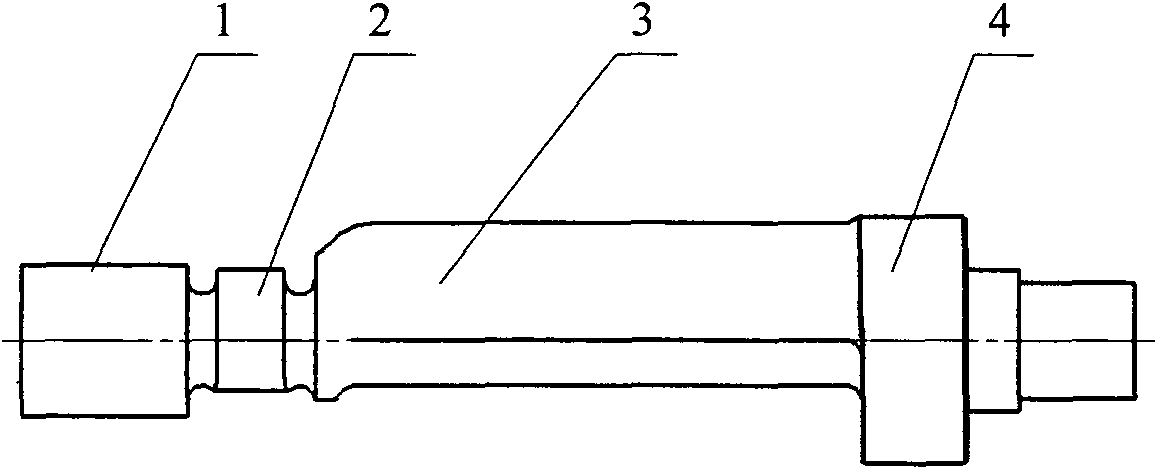

[0009] Such as figure 1 As shown, the balance shaft of the two-cylinder diesel engine proposed by the present invention has the driving cam 2 of the high-pressure oil pump on the balance shaft close to the left journal 1, and has a balance between the driving cam of the high-pressure oil pump and the right journal 4. Heavy 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a balance shaft of a two-cylinder diesel, a driving cam 2 of a high-pressure oil pump is arranged near the left shaft neck 1 of the balance shaft, and a balance weight 3 is arranged between the driving cam and the right shaft neck 4 of the high-pressure oil pump; the balance shaft of a two-cylinder diesel can meet the requirements of high rotation and high load for the diesel, and can reduce the vibration and noise of the two-cylinder diesel; simultaneously, the balance shaft integrated with the driving cam and the balance weight of the high-pressure oil pump of the diesel not only meets the balance requirement of the two-cylinder diesel, but also realizes the function of the driving high-pressure oil pump; and the invention improves the comfort of the diesel and decreases the cost of the diesel, and has simple structure, easy production and processing and high practicality.

Description

technical field [0001] The invention relates to a balance shaft of an engine, in particular to a balance shaft of a two-cylinder diesel engine. Background technique [0002] In order to meet the vibration and smoothness requirements of the diesel engine, a balance shaft needs to be added to the two-cylinder diesel engine to reduce the vibration and noise of the whole machine. The function of the balance shaft of the traditional two-cylinder diesel engine is only the function of a single balance shaft. So far, there has not been a structure integrating a high-pressure oil pump driving a cam and a balance weight on a two-cylinder diesel engine. Contents of the invention [0003] The object of the present invention is to provide a balance shaft of a two-cylinder diesel engine, which not only meets the requirements of the two-cylinder diesel engine to reduce the vibration and noise of the whole machine, but also drives the high-pressure oil pump of the diesel engine, so as to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16F15/26

Inventor 张学文杨永忠

Owner KUNMING YUNNEI POWER

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com