On-line detection device with function of calibrating systematic error for wave aberration of projection objective of photoetching machine

A technology of projection objective lens and calibration system, which is applied in the field of optical detection, can solve problems such as errors and measurement results, and achieve the effect of improving measurement accuracy

Active Publication Date: 2011-01-05

BEIJING INSTITUTE OF TECHNOLOGYGY

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to propose an on-line detection device for the wave aberration of the projection objective lens of a lithography machine that can calibrate the system error in view of the existing PSPDI structure that causes systematic errors in the measurement results.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

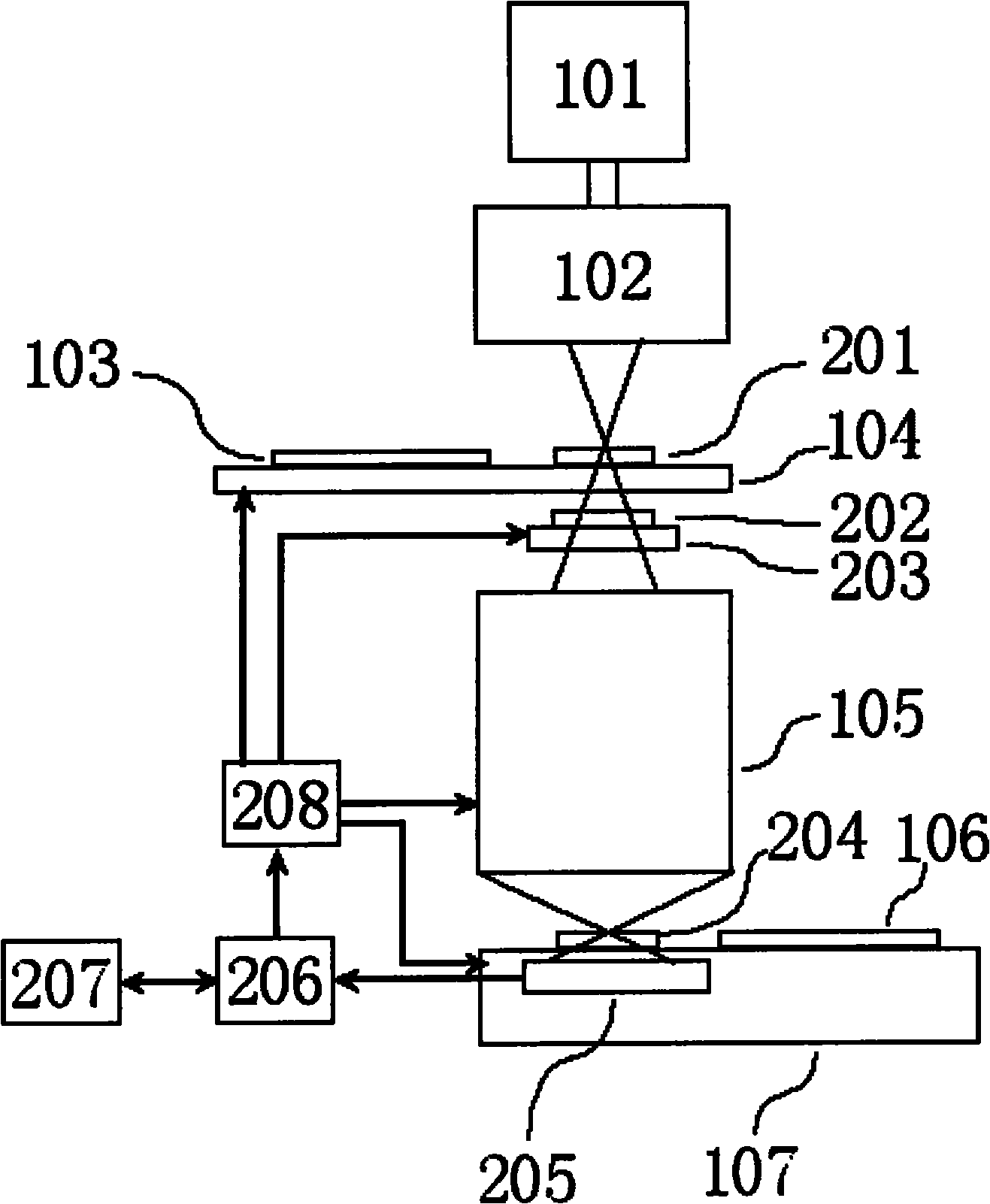

The invention discloses an on-line detection device with the function of calibrating a systematic error for wave aberration of a projection objective of a photoetching machine, belonging to the field of optical detection. The device comprises an object space mask plate with circular holes, a phase-shifting device, a photoelectric sensor, a memorizer, a controller, an arithmetic unit, a beam splitting device and an image space mask plate, wherein the beam splitting device comprises two binary diffraction gratings: a first grating and a second grating; and the image space mask plate comprises awindow and a first circular hole and a second circular hole with equal diameters. The second grating of the beam splitting device and the second circular hole of the image space mask plate are used as elements for calibrating the systematic error, and the systematic error of the device is calibrated according to the orthogonal property and the odd-even symmetrical property of the Zernike multinomial in a unit circle. The device of the invention is integrated on a masking workpiece platform and a silicon slice workpiece platform of the photoetching machine, and compared with the prior art, thedevice can calibrate the systematic measurement error introduced by a measuring device, thereby increasing the accuracy of measurement.

Description

On-line detection device for wave aberration of projection objective lens of lithography machine that can calibrate system error technical field The invention belongs to the field of optical detection, and relates to an online detection device for wave aberration of a projected objective lens of a lithography machine with a system error calibration function, in particular to an online detection device for wave aberration of a projected objective lens of an extreme ultraviolet lithography machine. Background technique In the preparation process of large-scale integrated circuits, a projection exposure device is often used to reduce and project the pattern on the mask plate on the silicon wafer coated with photoresist through the projection objective lens. The 2007 International Semiconductor Technology Roadmap (ITRS2007) pointed out that extreme ultraviolet lithography (EUVL) is the most potential candidate technology to achieve 32nm and below technology nodes. EUVL uses an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G03F7/20G01M11/02

Inventor 刘克李艳秋刘丽辉

Owner BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com