Container cell, in particular bottle cell, and container rack having such container cells

A chamber and container technology, applied in the field of container racks, can solve problems such as energy loss, and achieve the effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

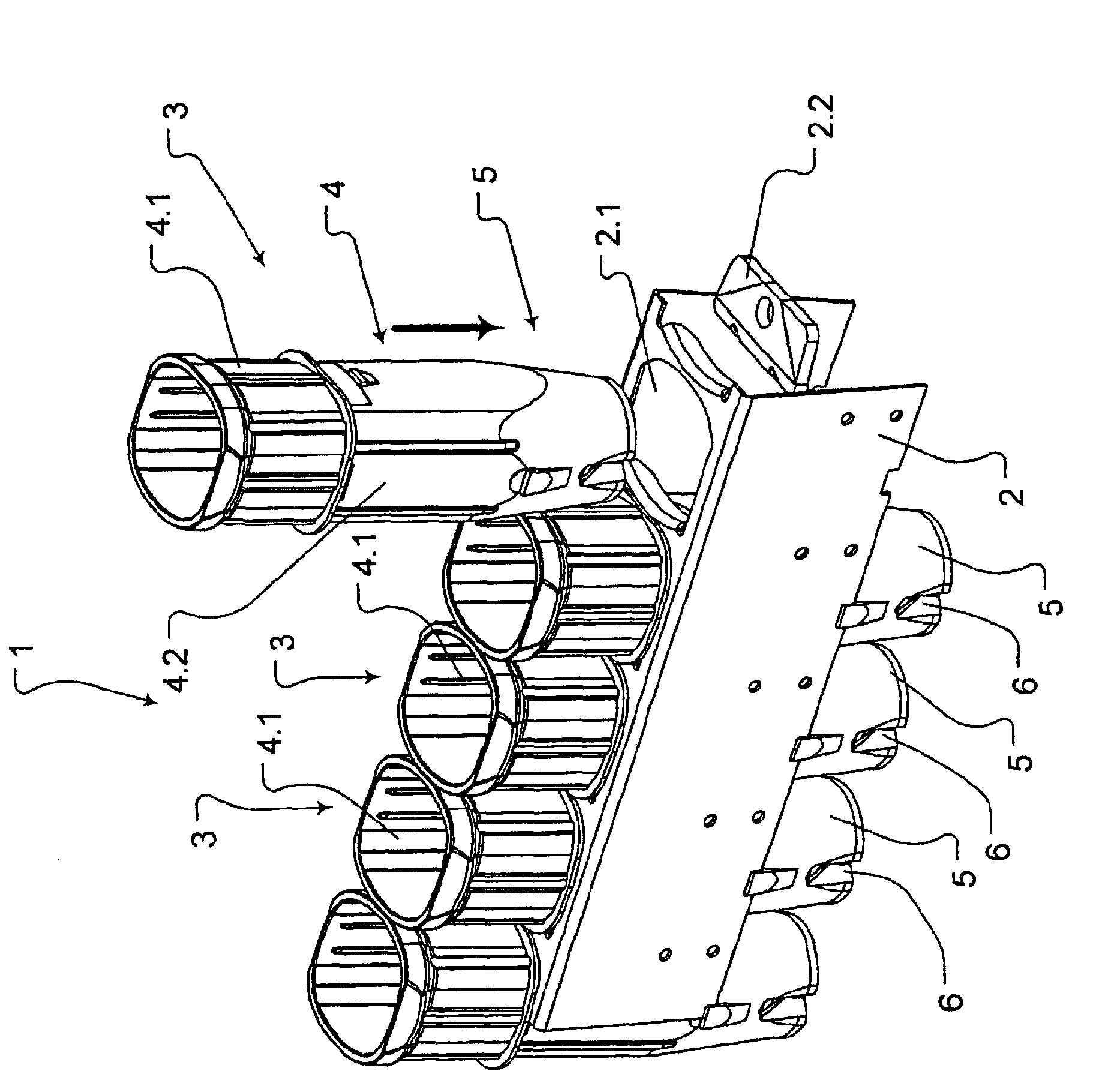

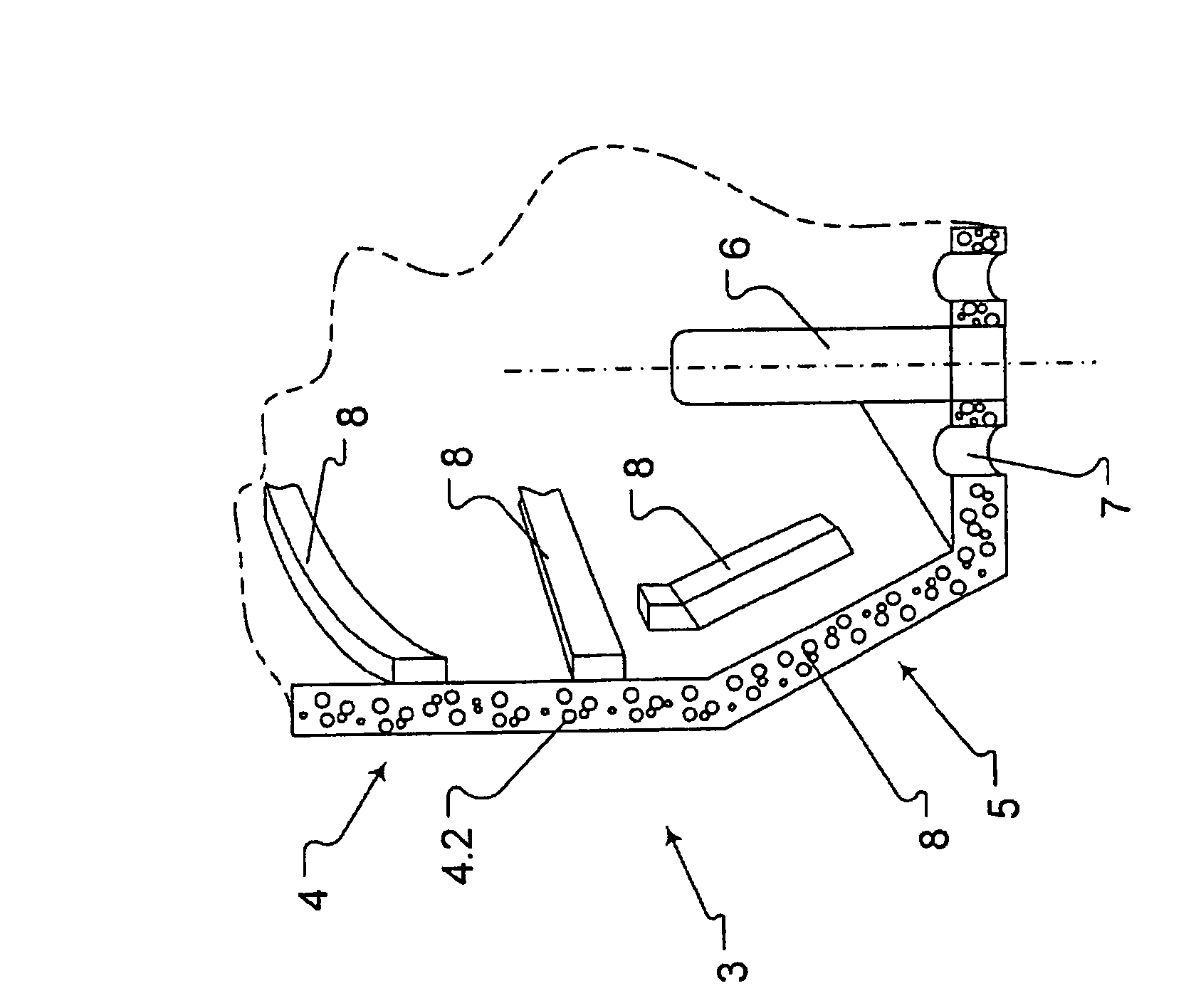

[0011] The container rack generally identified by the reference numeral 1 in the figure basically comprises a box-shaped carrier 2, for example made of steel, preferably corrosion-resistant steel; and a plurality of bottle or container compartments 3, wherein the A plurality of bottle compartments or container compartments 3 are each inserted into sockets 2 . 1 of the compartment carrier 2 with a good fit and are held on said compartment carrier in a torque-proof and precise and stable manner, for example by interlocking.

[0012] The container rack 1 is a component part of a container cleaning machine, not shown, for cleaning bottles or similar bottles of this type of container, and at the same time it is a special part of the conveyor system of the container cleaning machine. The system comprises a plurality of container racks 1 of the same type, which are respectively held with their chamber carriers 2 at both ends by means of fastening strips 2.2 on an endless conveying ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com