Adhesive tape stamping device and method for stamping an adhesive tape section onto an object

A tape and object technology, applied in adhesives, sending objects, transportation and packaging, etc., can solve problems such as transfer of clumsy mechanical structures, and achieve high working speed, easy use, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

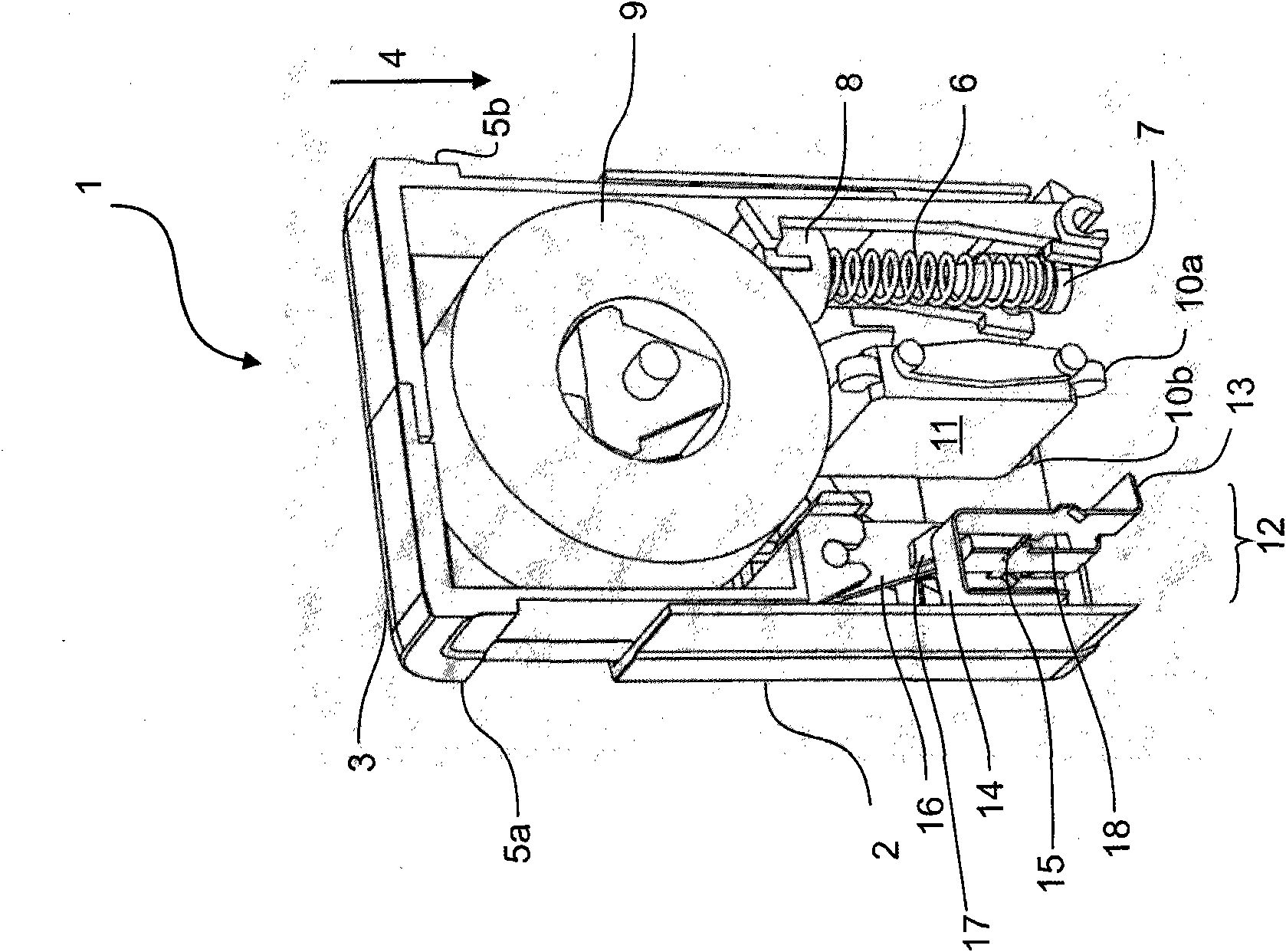

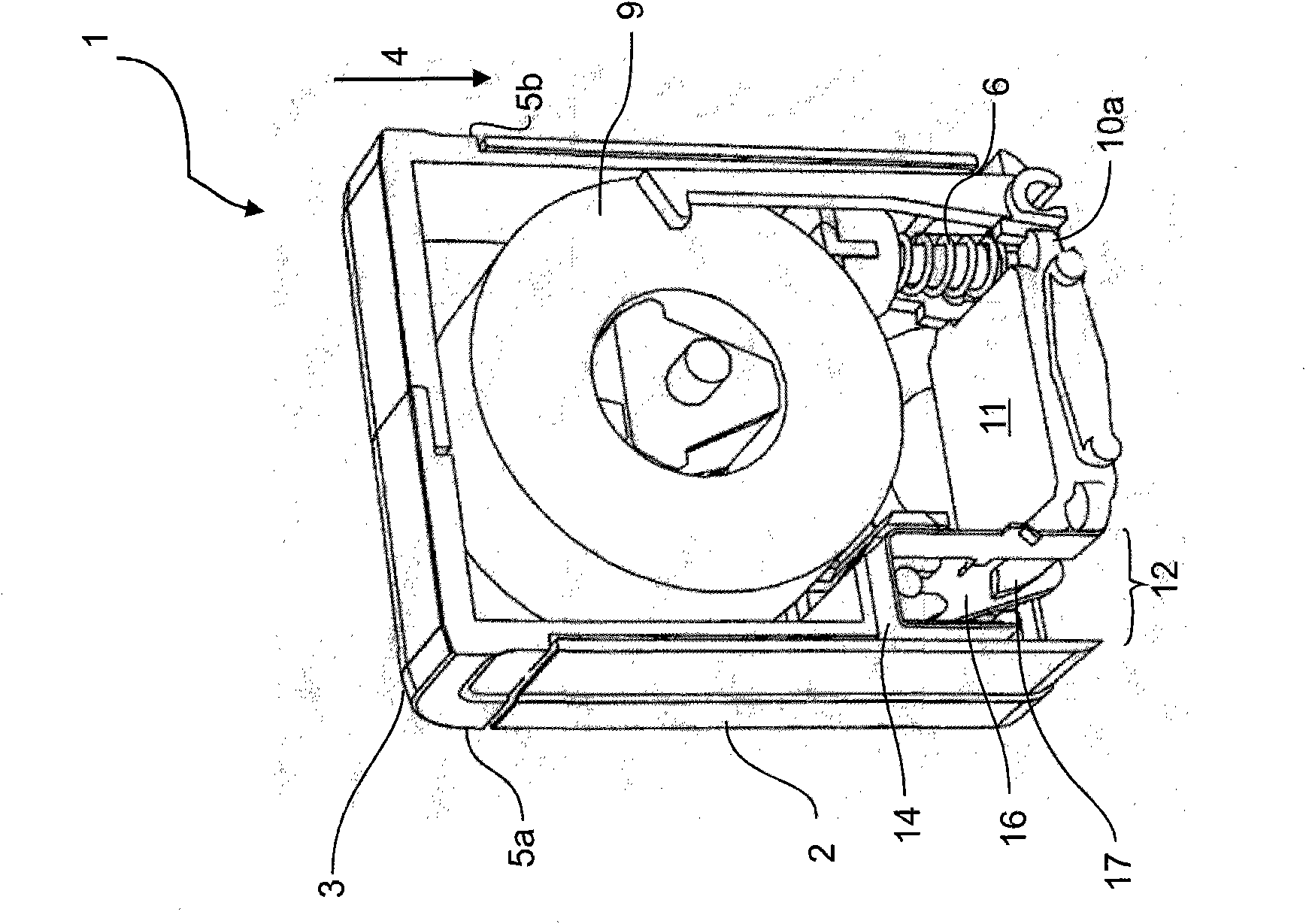

[0089] figure 1 It is a three-dimensional view of the tape imprinting device 1 according to a first embodiment of the present invention, but some components thereof are omitted to show other details. like figure 1 As shown, the adhesive tape imprinting device 1 includes a supporting member 2 as a housing and a driving member 3 as a housing. 3 is arranged such that at least a part thereof can be pressed into the abutment 2 and can be guided to move linearly in the abutment 2 . The linear guide is arranged so that the driving part 3 can be driven by a human force, and a pressure is applied above the driving part 3, so that the driving part 3 moves along an arrow direction 4 . like figure 1 and figure 2 As shown, the linear movement of the driving member 3 along the embossing direction 4 can be selectively restricted by the protrusions 5a, 5b integrally formed with the driving member 3, that is, the driving member 3 is relatively When the movement of the leaning member 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com