Inner stopper combined machine

A combined machine and frame technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as affecting the life of the equipment and the lack of lubrication of components, so as to prolong the service life, improve lubrication, and avoid chip removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

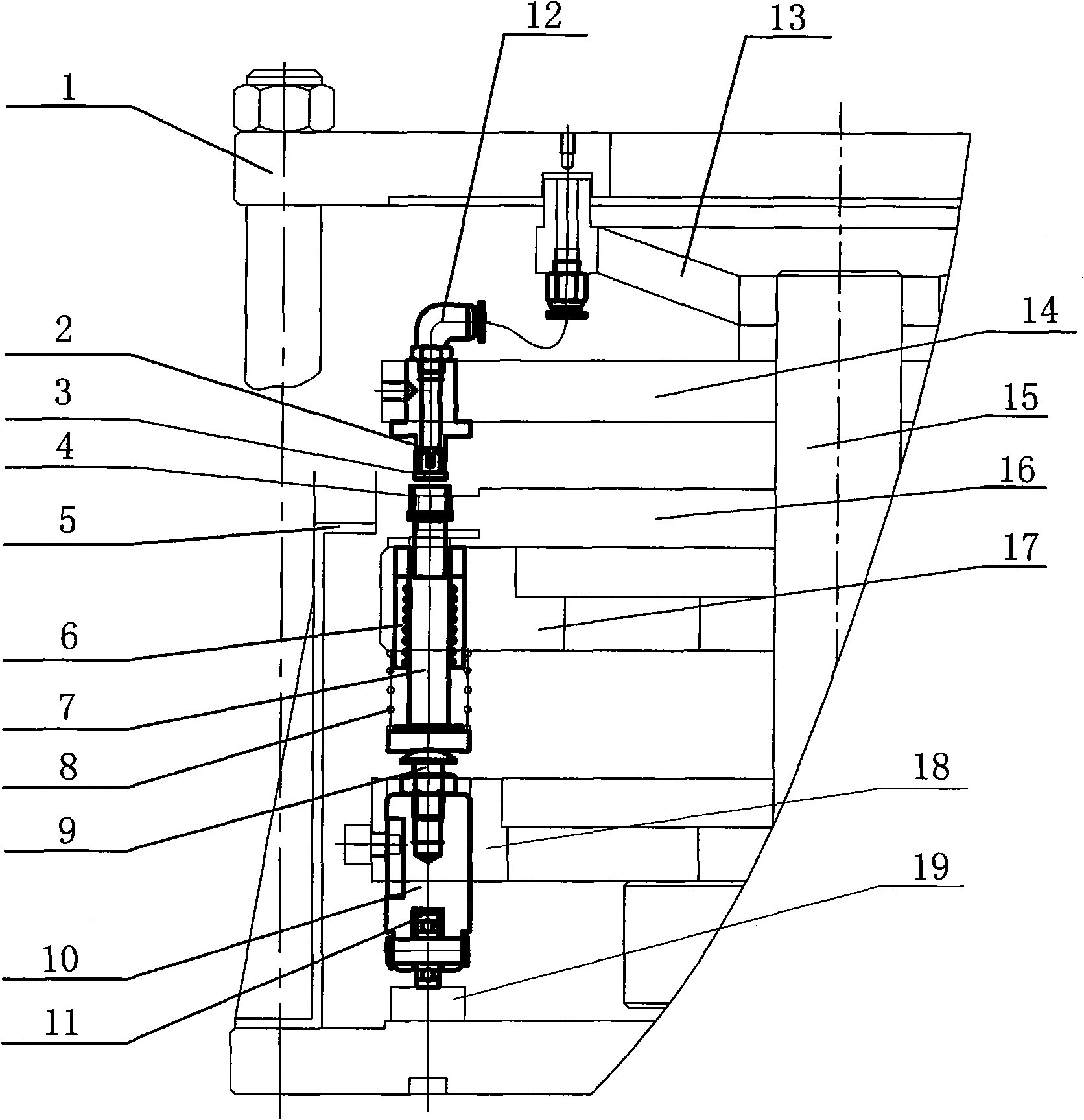

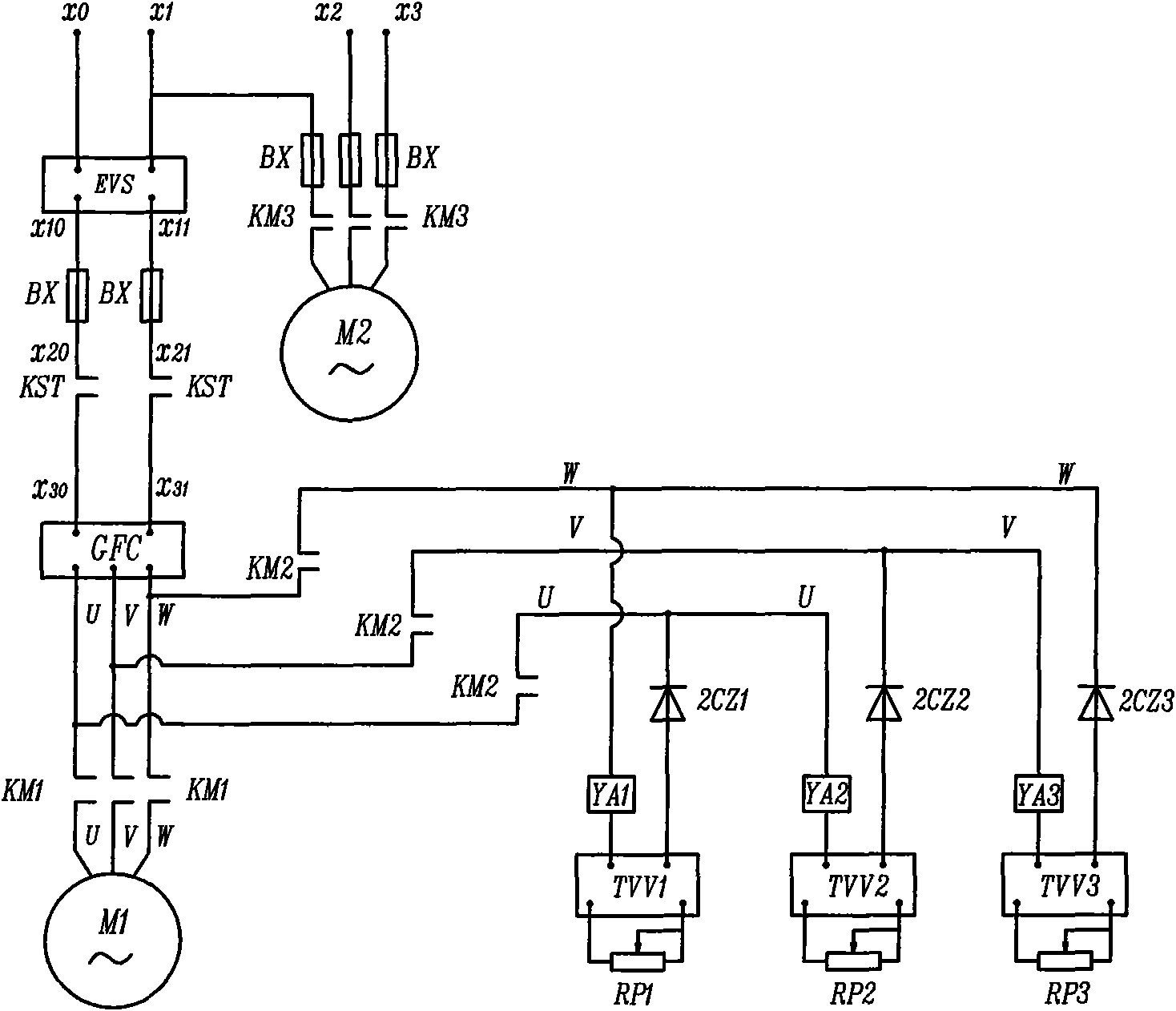

[0021] Such as figure 1 or figure 2 As shown, an inner plug combination machine includes a frame 1, a main shaft 15 is connected to a frequency conversion power system, a gas distribution panel 13 is connected to an oil-free vacuum pump, and a gas distribution panel 13 and a fixed insert plate are installed on the main shaft 15 from top to bottom. 14. The dial 16, the hot plate 17 and the guide plate 18. The fixed plug 2 is provided on the fixed plug plate 14. The fixed plug 2 is connected with the gas distribution plate 13 through the vacuum tube 12. The hot plate 17 is provided with the corresponding fixed plug 2. Movable plug 7, movable plug 7 contacts and cooperates with the guide rod 10 that guide plate 18 installs, and frame 1 is provided with track cam 19, and guide rod 10 cooperates with track cam 19.

[0022] There are multiple fixed plugs 2, movable plugs 7 and guide rods 10, arranged in a circle with the axis of the main shaft 15 as the center of the circle.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com