Crawler-type carrier vehicle

A transport vehicle and crawler-type technology, which is applied in the field of crawler-type transport vehicles, can solve problems such as bumpy, labor-intensive, rollover, etc., and achieve the effect of improving safety performance and improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] best practice

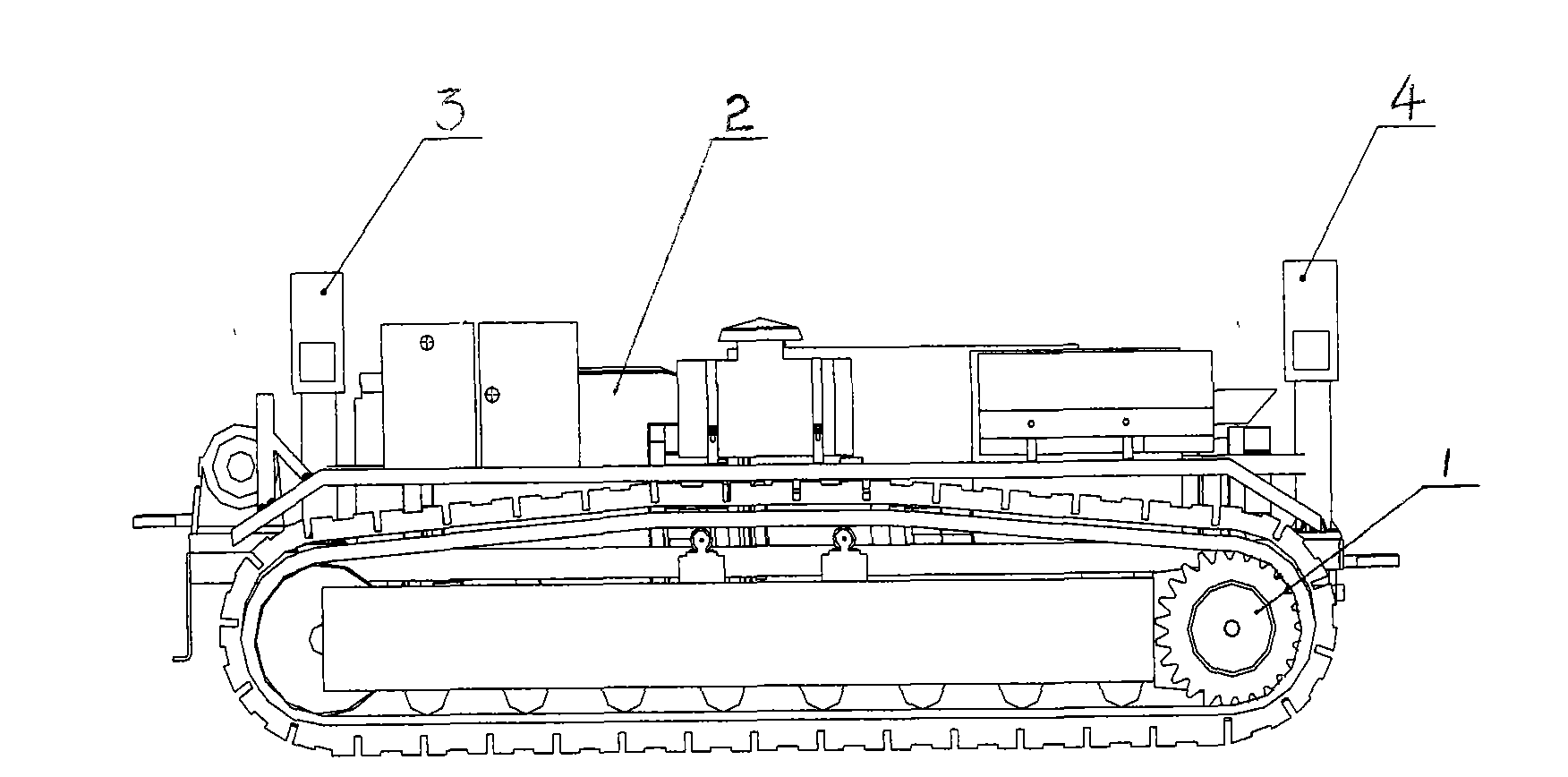

[0029] Refer to attached figure 2 combined with the attached figure 1 , a crawler transport vehicle, including a transmission assembly 1, a power assembly 2 and a storage member, the transmission assembly 1 is a crawler transmission assembly; the power assembly 2 includes an engine and a hydraulic oil tank and a battery device connected thereto, and the storage member includes There are a front gantry component 3 and a rear gantry component 4, respectively corresponding to the front and rear of the transport vehicle.

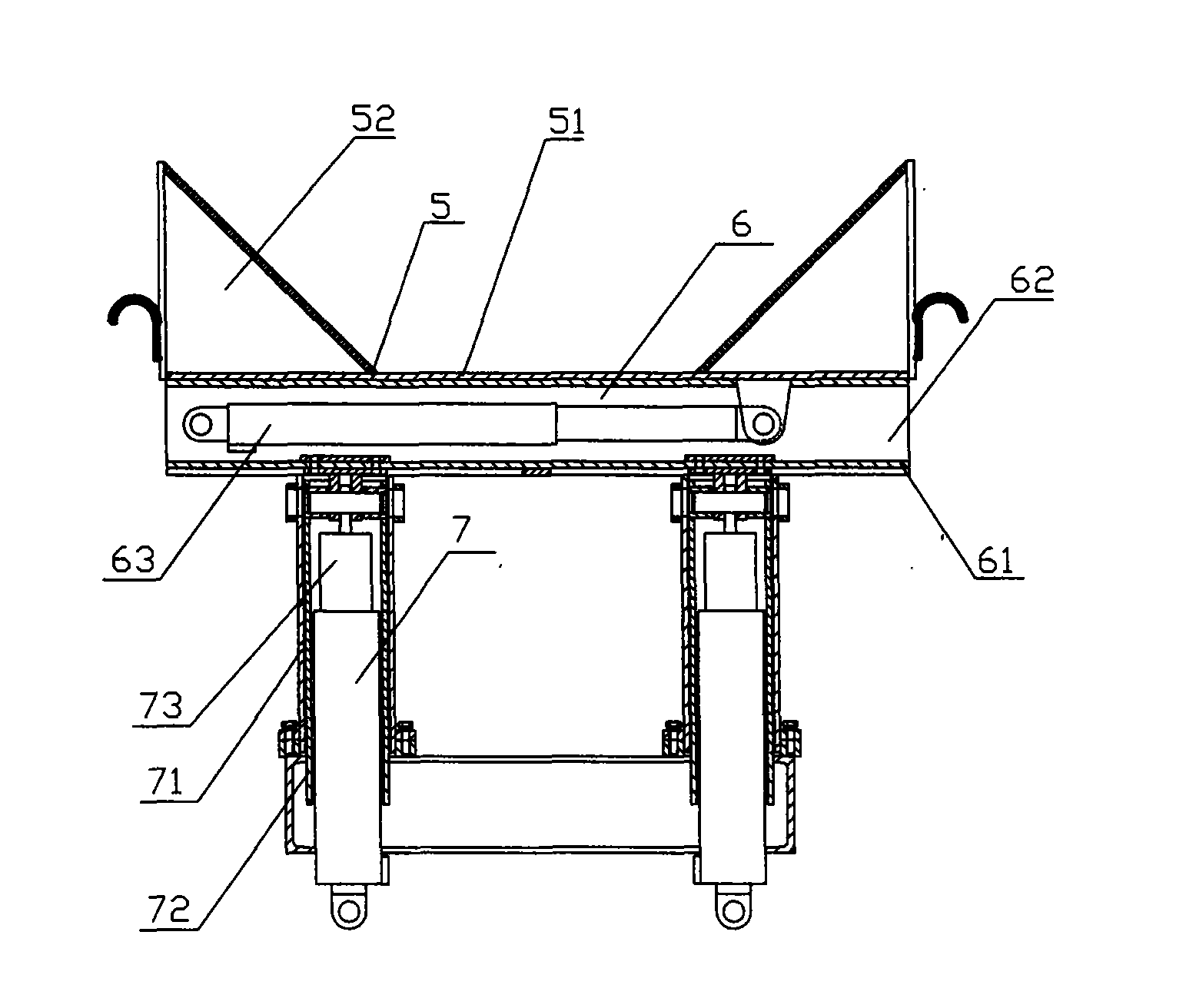

[0030] The gantry main part 5 in the front gantry member 3 and the rear gantry member 4 all includes a load-bearing part 51 and a support stopper 52, and the support stopper 52 has two pieces, which are installed on the top of the load-bearing part 51 and are positioned at the load-bearing part 51. both ends of the.

[0031] The translation drive member 6 includes a translation outer tube 61 , a translation inner tube 62 and a translat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com