Patents

Literature

49results about How to "Meet safety production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for achieving natural striding, falling and filling of coal beds, flexible roadway protection and complete gob-side entry retaining

InactiveCN103397905AEliminate the effects of concentrated stressImprove recovery rateMaterial fill-upArchitectural engineeringSolid base

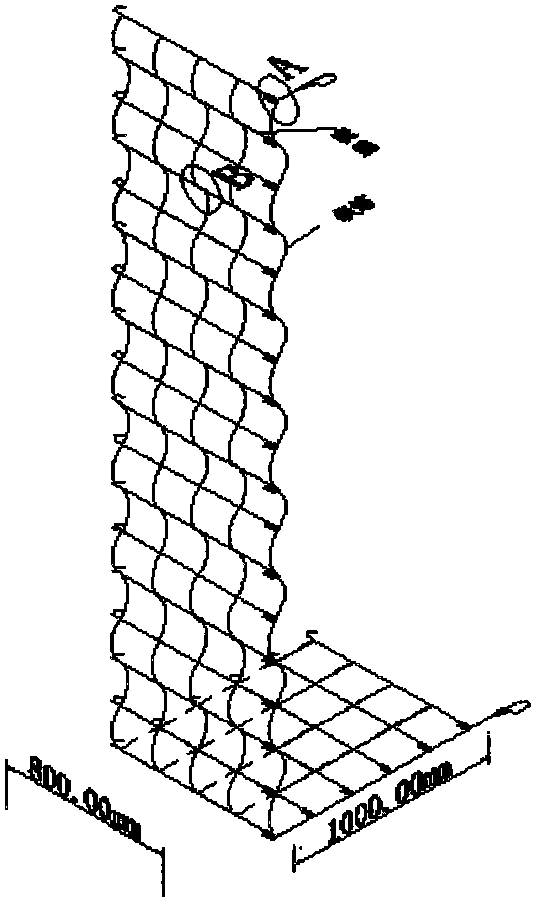

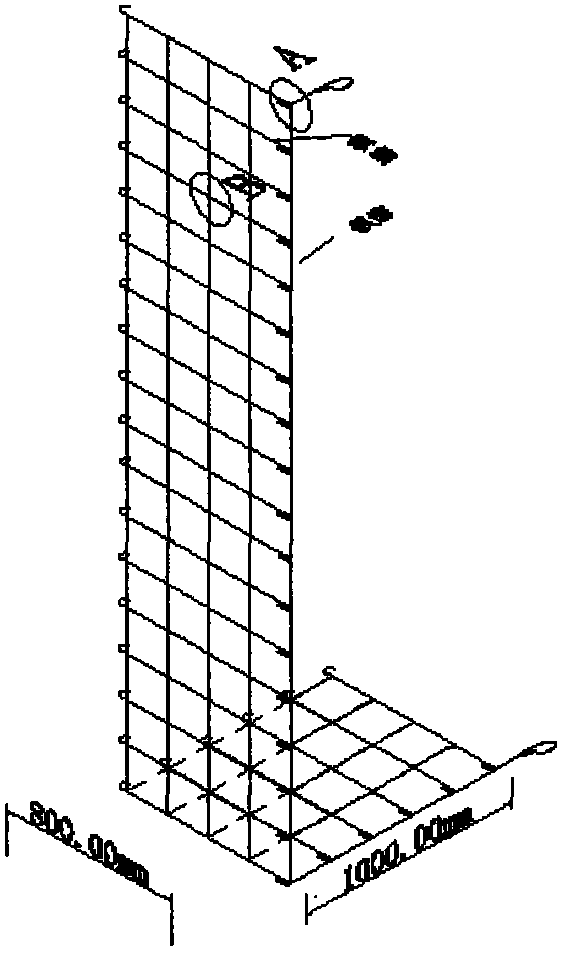

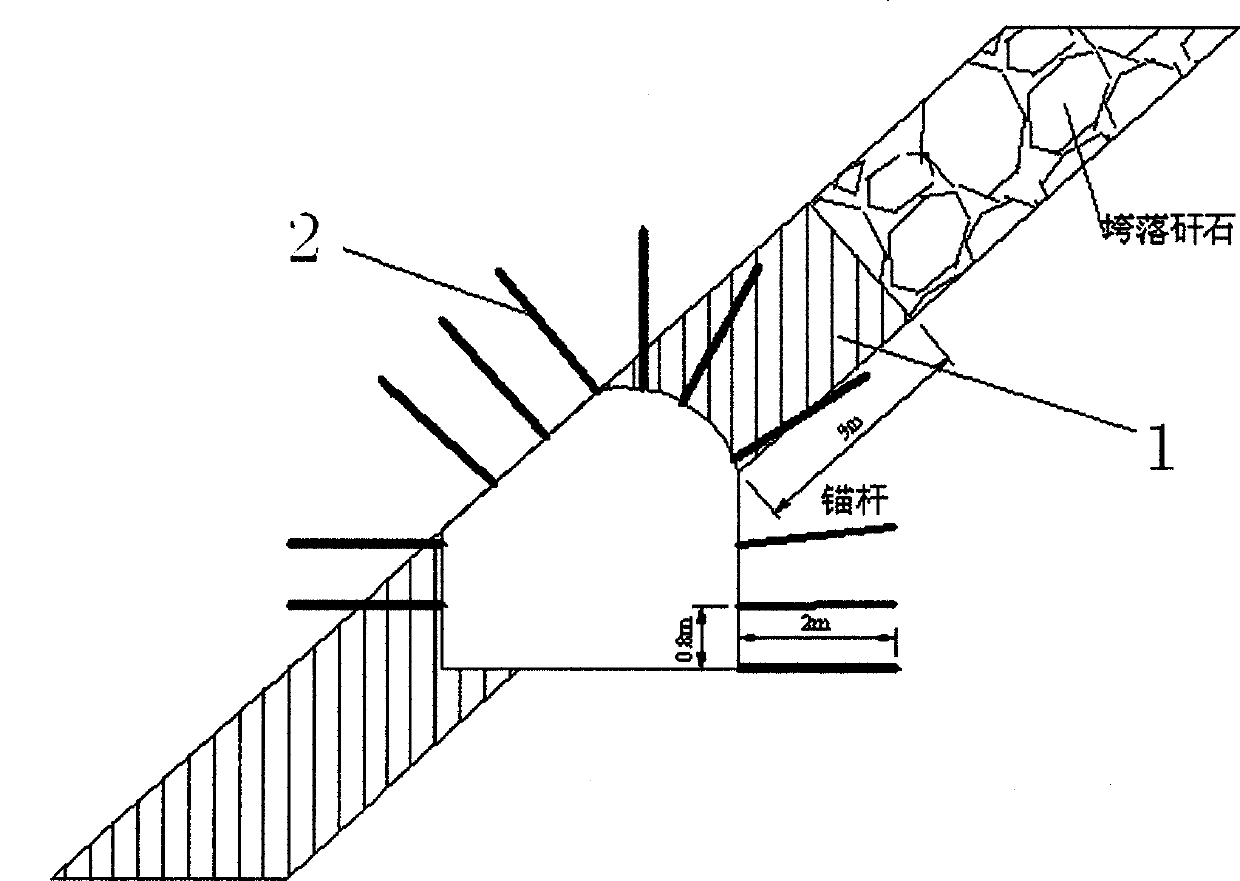

The invention provides a system and method for achieving natural striding, falling and filling of coal beds, flexible roadway protection and complete gob-side entry retaining. Gob-side entry retaining is conducted in a primary mining retaining and protecting area, small coal columns are reserved on one side of a goaf to support and block gangues sliding down from the goaf, anchor bolt support is conducted in a roadway, and three types of roadway-side supporting technologies are adopted in a normal recovery period according to the thickness of the coal beds and the lithology of a top plate and a base plate. According to the system and method, influences of coal column concentrated stress are eliminated, the roadway strata behavior appearing degree is greatly lowered, the gob-side entry retaining is guaranteed to meet requirements for safety in production, disaster accidents such as fire disasters and coal and gas outbursts caused by the reserved coal columns are eliminated, the roadway digging rate is lowered, the ton-coal cost is reduced, the working environment is improved, the high yield and the high-efficiency are achieved, the working face is continuously and rapidly pushed forward, and a solid foundation is established for eliminating the short supply of successive excavating. The medium-inclining and sharp-inclining coal bed goaf top plate naturally strides, falls and slides down to conduct filling under the action of the gravity, and the filling cost of the top plate is zero.

Owner:唐建新

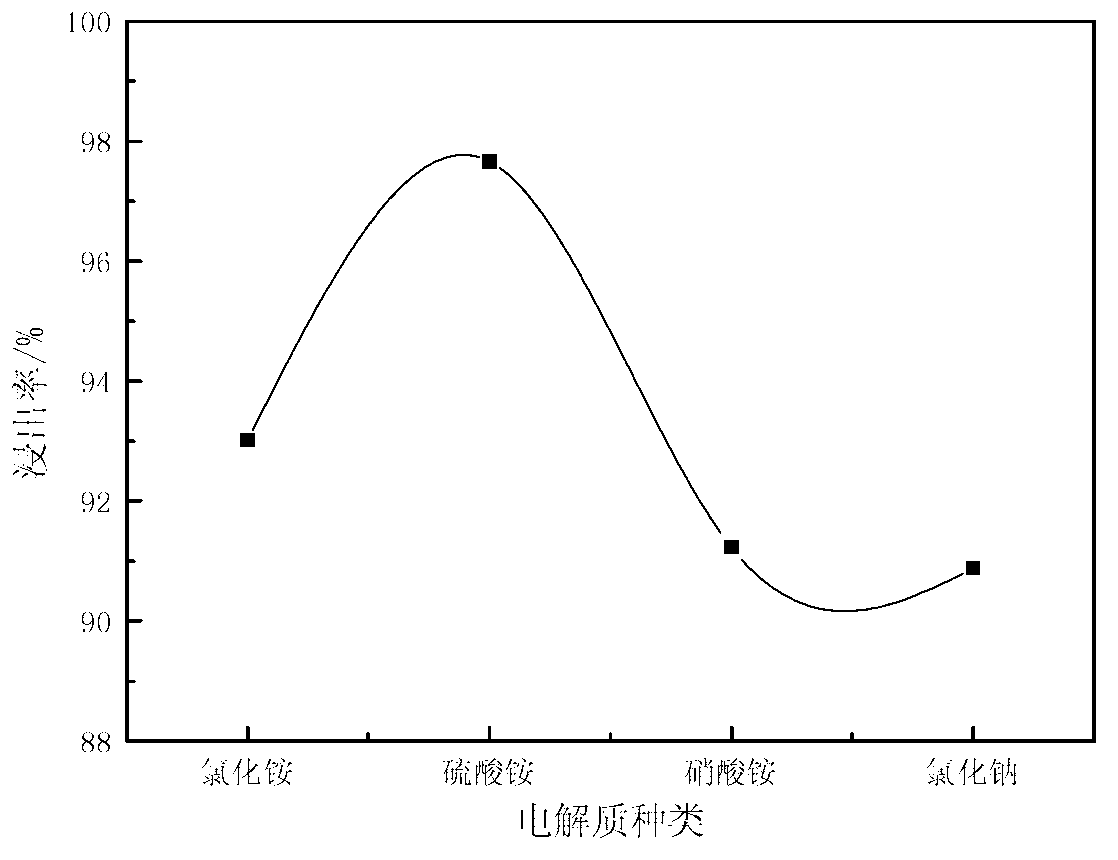

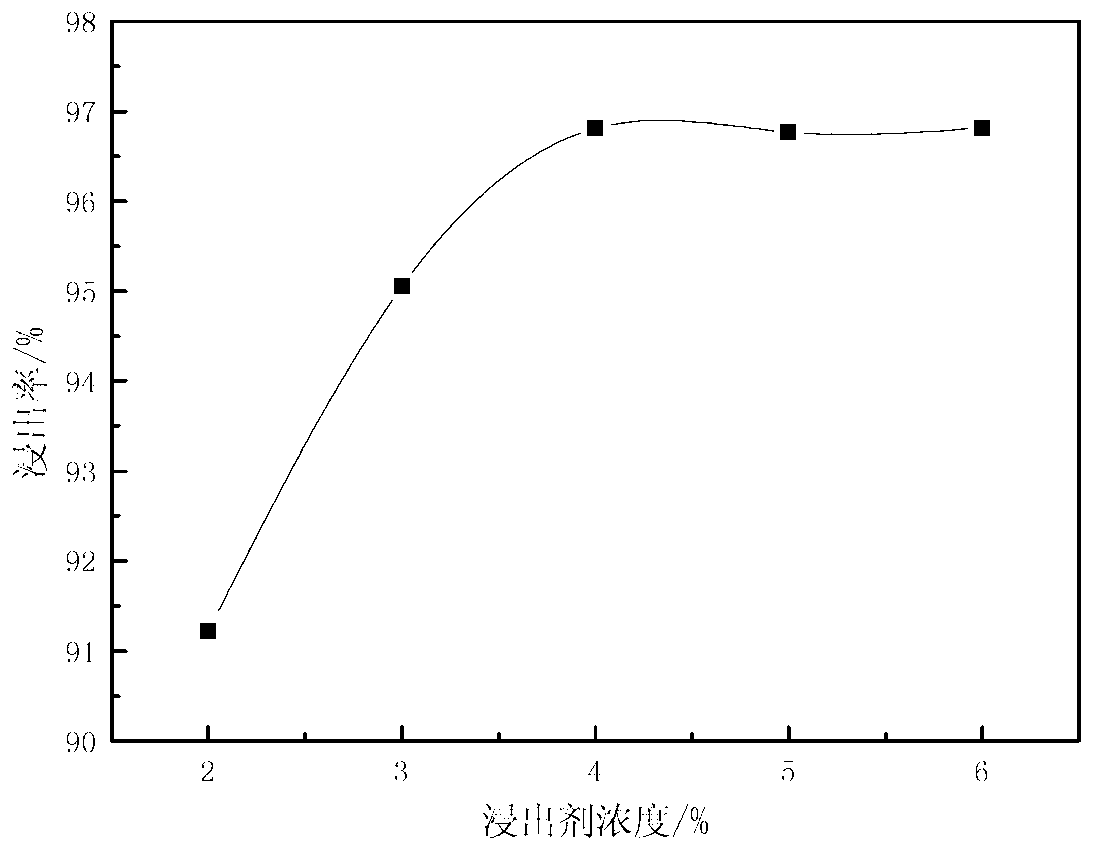

Method for removing impurities from ionic rare-earth ore

InactiveCN102796867AReduce contentMeet environmental protection requirementsProcess efficiency improvementPregnant leach solutionRare earth

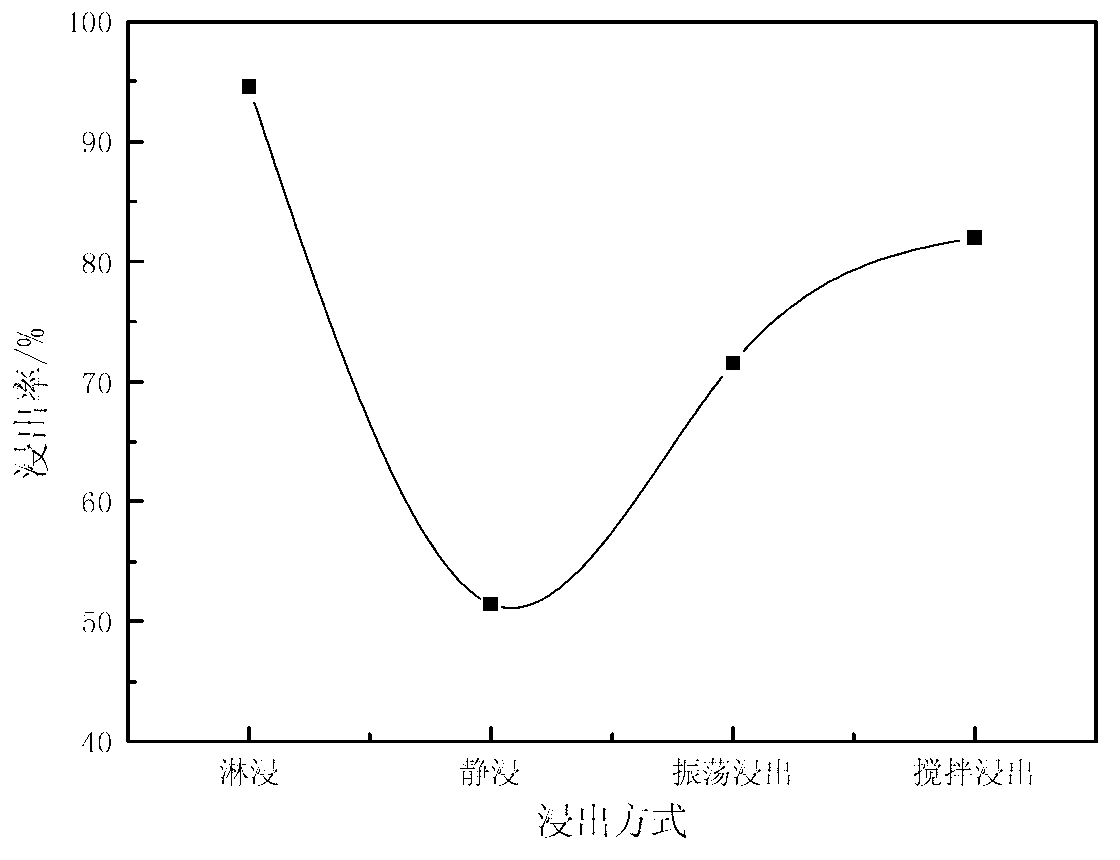

The invention relates to a new method for removing impurities from leachate in a wet metallurgy technology, in particular to a method for removing impurities from ionic rare-earth ore. The method comprises the following steps: A, preparing leachate: dissolving a rare-earth leaching agent and an impurity inhibitor tartaric acid into water, completely mixing, stirring and dissolving to obtain the leachate, wherein in the leachate, the mass percentage concentration of the rare-earth leaching agent is 1 to 6 percent, the mass percentage concentration of the tartaric acid is 0.01 to 1.0 percent and the mass ratio of the rare-earth leaching agent to the tartaric acid is 2 to 100; and B, controlling the leaching process: performing impurity-inhibiting leaching on the ionic rare-earth ore by using the prepared leachate, wherein the flow velocity of the leach is 0.5 to 10 ml / min, the water content of the original ore is 0 to 20 mass percent, and the liquid solid ratio is 0.6:(1-1.4):1. In the leachate subjected to impurity-inhibiting leaching, the impurity ion content is reduced by over 90 percent. The method has the advantages of low energy consumption, low cost, safety and simplicity in operation and the like.

Owner:JIANGXI UNIV OF SCI & TECH

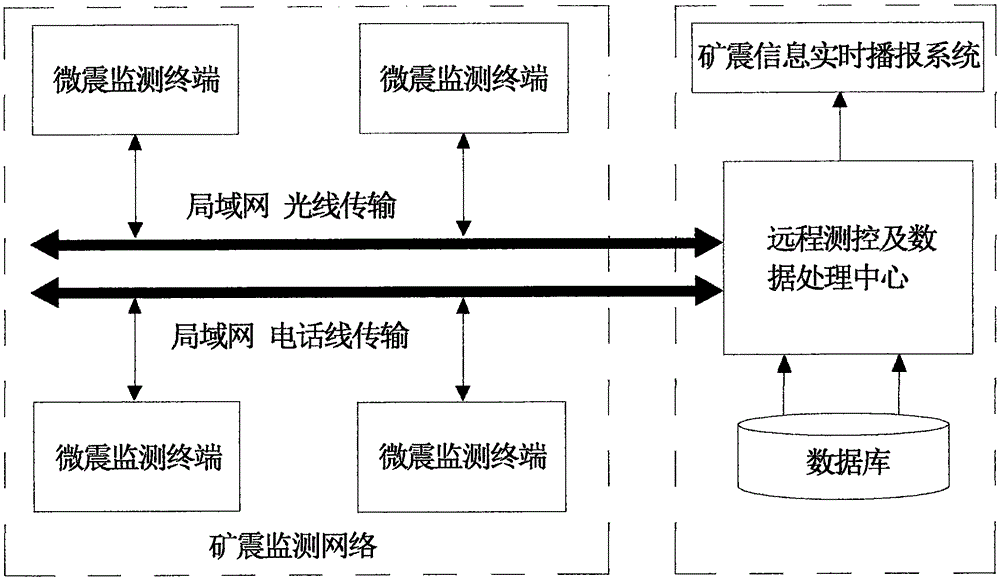

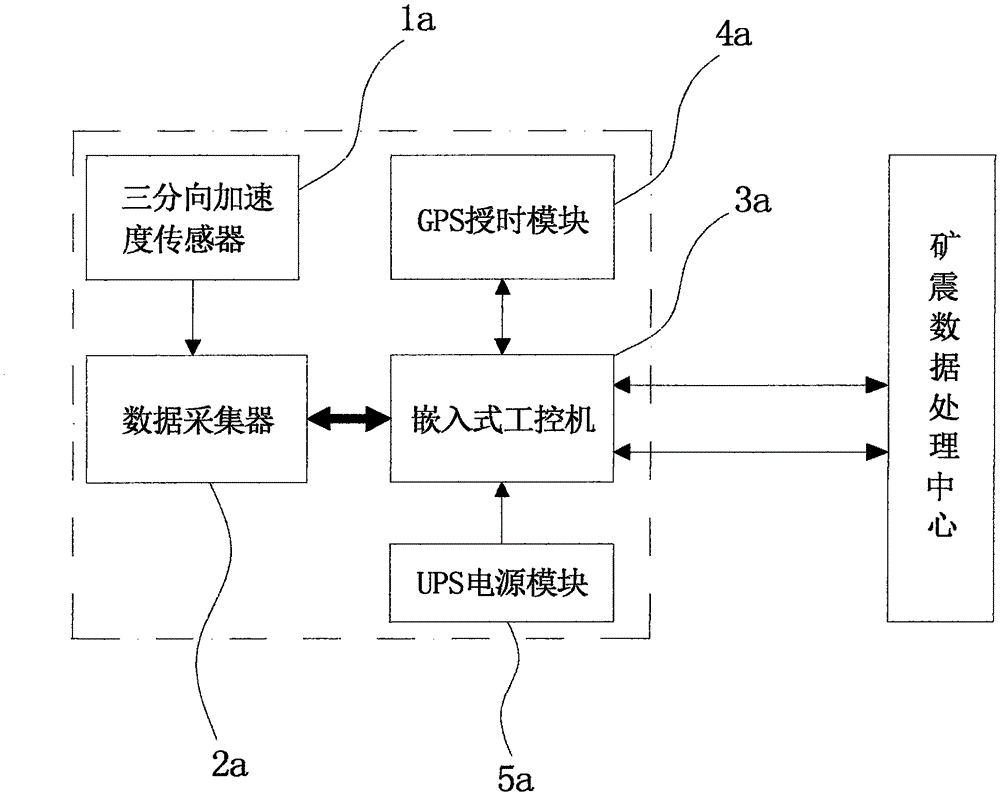

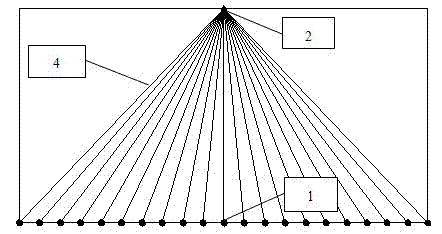

Speed anisotropic microseismic monitoring positioning method, microseismic monitoring positioning terminal and microseismic monitoring positioning system

InactiveCN105388511AReasonable ideaHigh precisionEarthquake measurementSeismic signal receiversSingle pointGeophysics

The invention provides a speed anisotropic microseismic monitoring positioning method, a microseismic monitoring positioning terminal and a microseismic monitoring positioning system, wherein the microseismic monitoring positioning method can overcome the problems of high difficulty, low precision, etc., in monitoring and positioning a mining-induced seismicity by other similar methods. The speed anisotropic microseismic monitoring positioning method has advantages of improving arrival time reading precision and effectively improving microseismic detection precision and positioning calculating precision. The microseismic monitoring positioning method has an advantage of simple and reasonable positioning terminal structure and performs functions of performing real-time monitoring on a seismic signal and automatically identifying the mining seismic signal by means of phase identification technology. Key data of hypocentral location, earthquake magnitude, mining-induced seismicity time, etc., of pre-identified mining-induced seismicity signals can be calculated through a single-point positioning algorithm, an earthquake estimation algorithm and a P-wave accurate arrival time estimation algorithm. The microseismic monitoring positioning system has a reasonable structure and can perform origin time, hypocentral location and seismic magnitude calculation in real time. The calculation result and the stored mining-induced seismicity data are converted through photoelectric conversion and transmitted through a network. The speed anisotropic microseismic monitoring positioning method, the microseismic monitoring positioning terminal and the microseismic monitoring positioning system are suitable for popularization and application.

Owner:LIAONING TECHNICAL UNIVERSITY

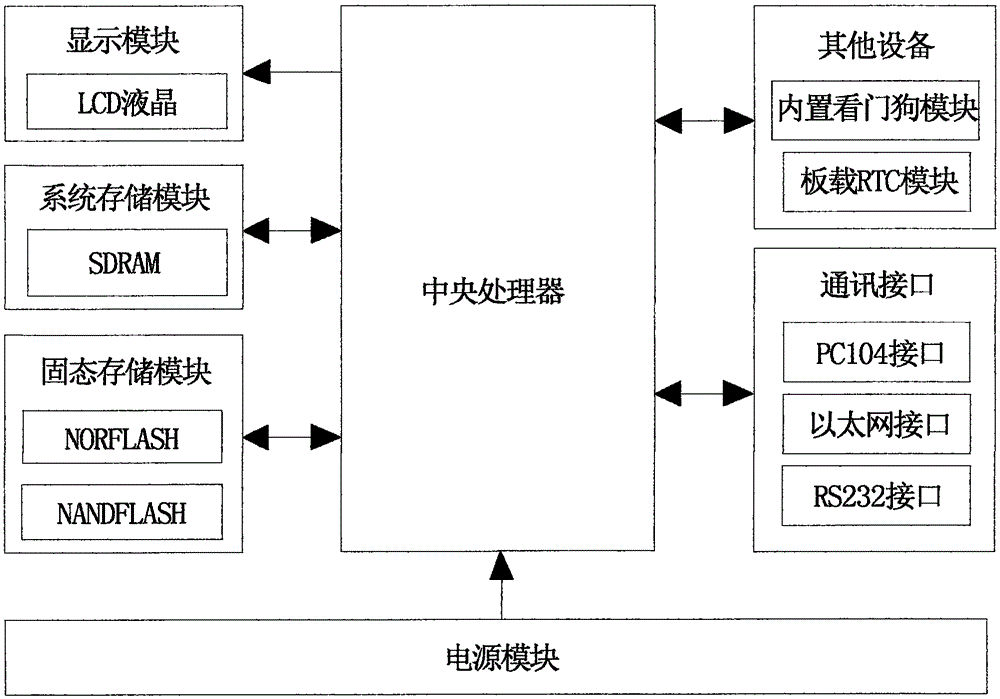

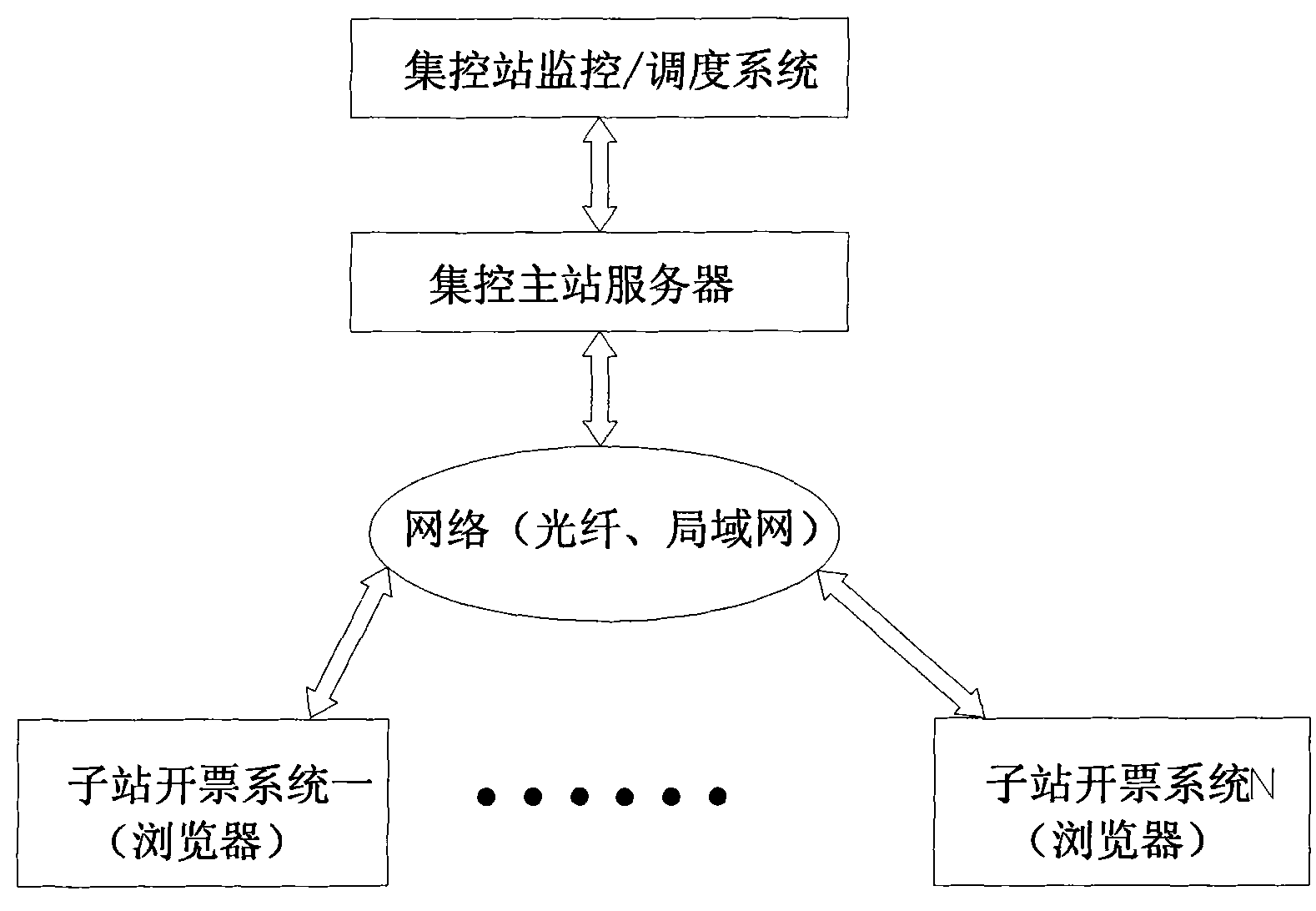

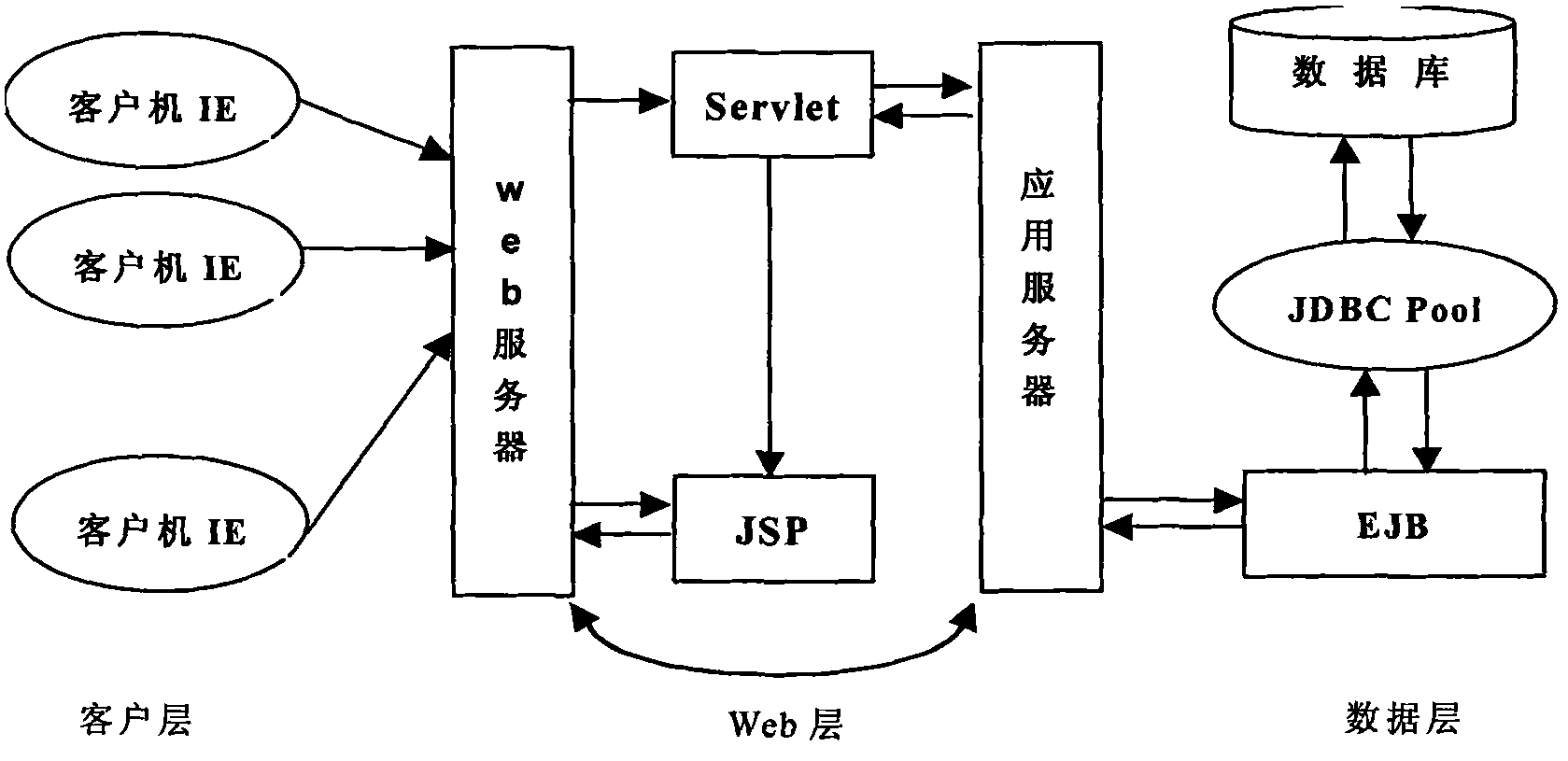

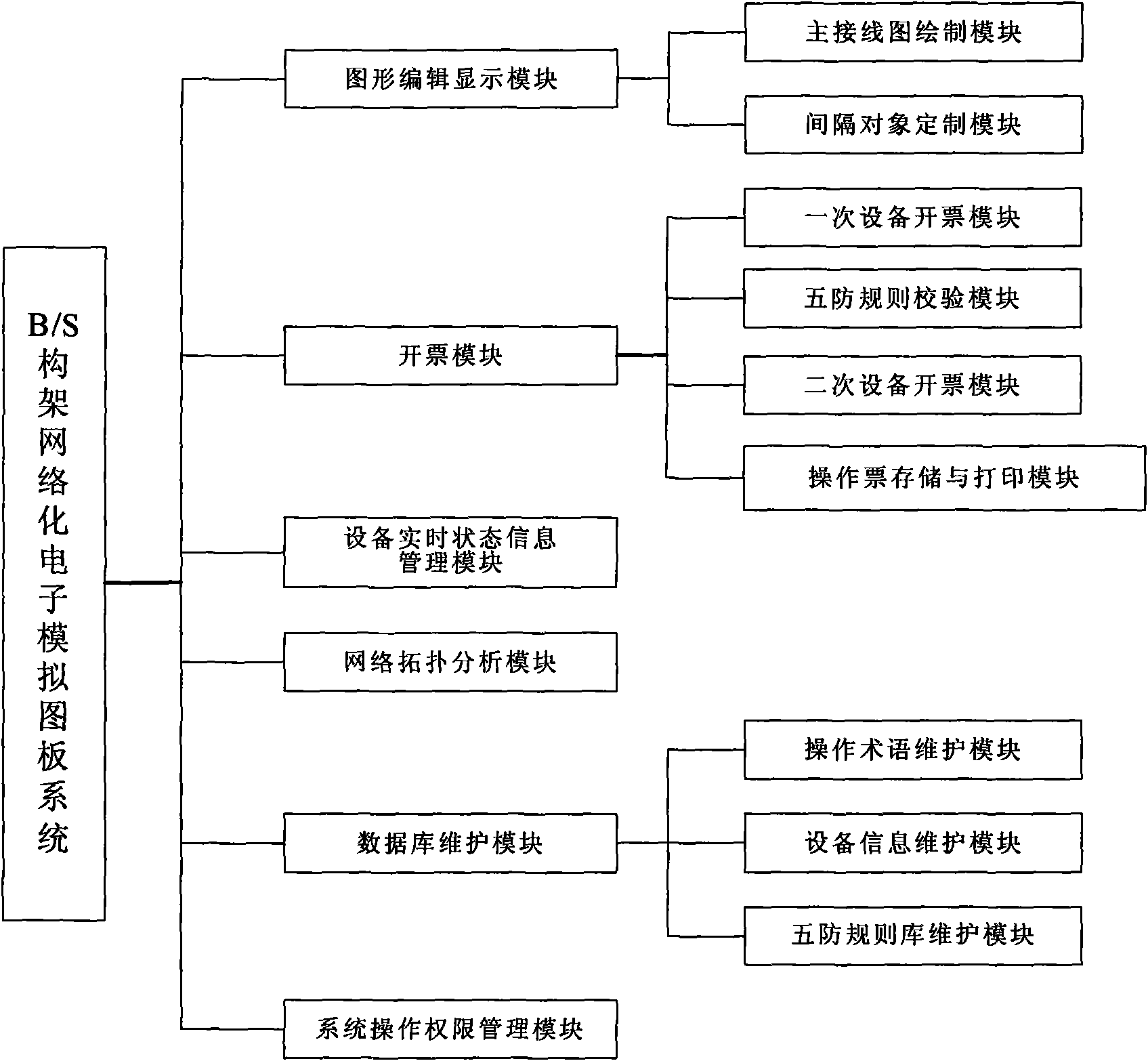

Operating method of B/S framework networked electronic simulation drawing board system

InactiveCN102064602AGuaranteed workloadReduce workloadCircuit arrangementsInformation technology support systemSafety controlNetwork topology

The invention discloses an operating method of a browser / server (B / S) framework networked electronic simulation drawing board system, which relates to a safety control method used when a power supply system operates electrified equipment. On the premise of ensuring correct and reliable billing, remote interaction of a field and a centralized control center is realized. The system is communicated with each field and the centralized control center; the centralized control center is provided with a monitoring system, a dispatching system and a main station server; the system is provided with a browser device which can be moved to each field; a communication device is communicated with a plurality of browser devices; and an application server is provided with a graphic edition and display module, a billing module, an equipment real-time status information management module, a network topology analysis module, a database maintenance module and a system operation authority management module. The operating method mainly comprises the following operating steps of: 1) transmitting an operation order billing request; 2) generating an operation order; 3) transmitting the generated operation order to a browser through the communication device; and (4) performing field operation through field operating personnel according to the operation order received by the browser.

Owner:JIANGSU ELECTRIC POWER COMPANY YANGZHOU POWER

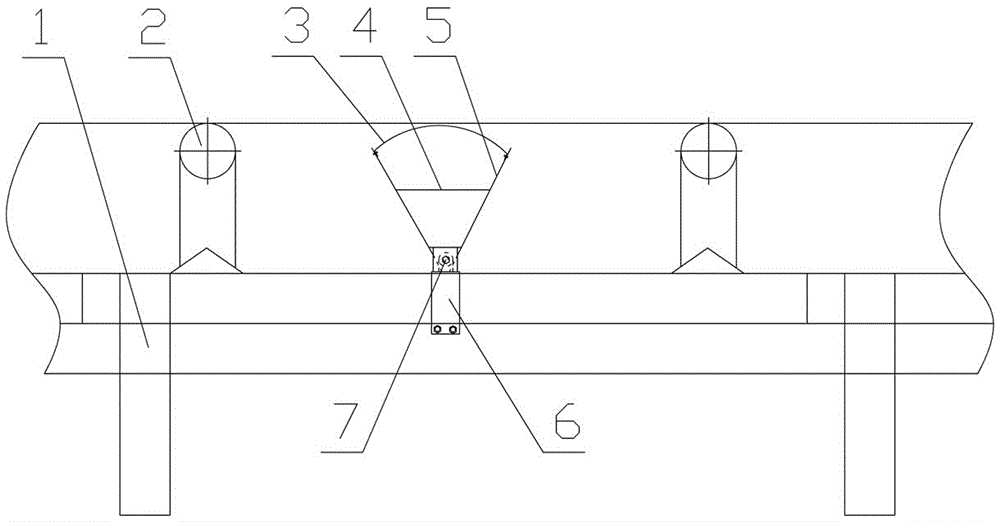

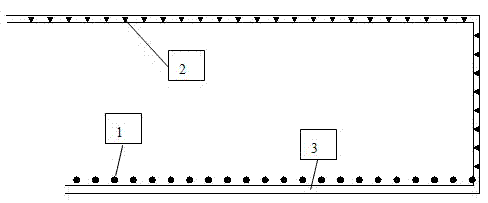

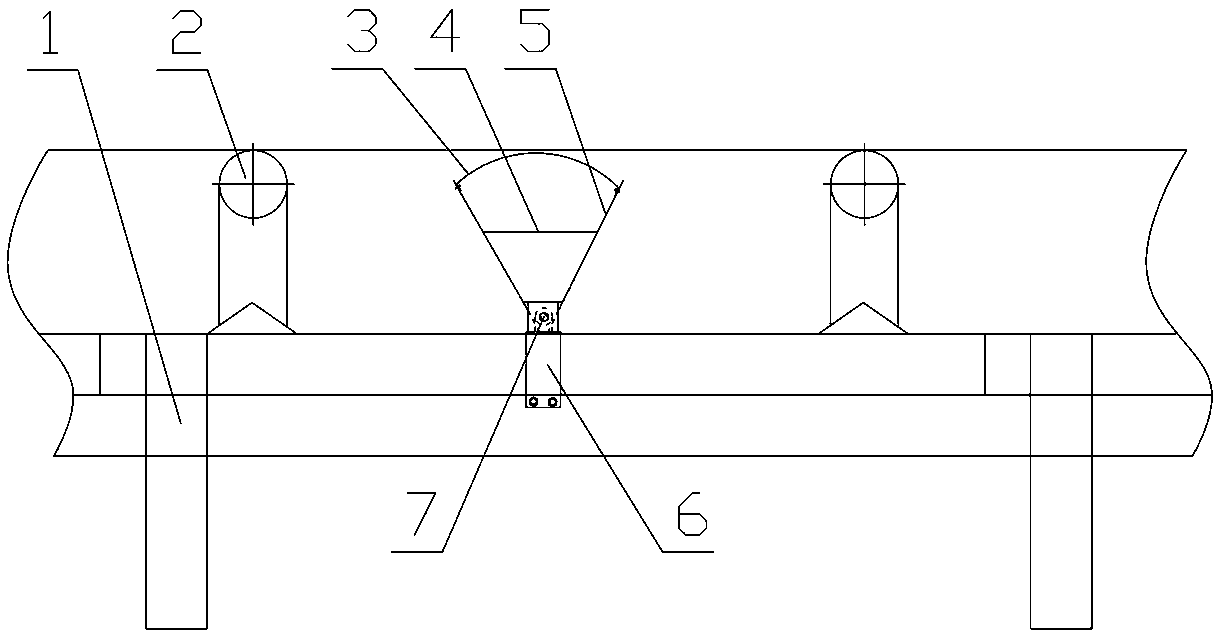

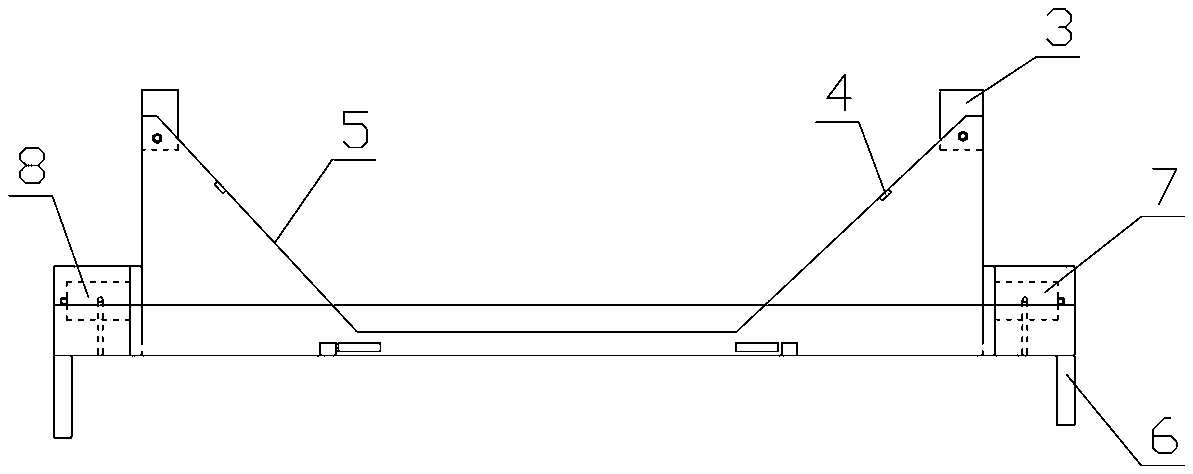

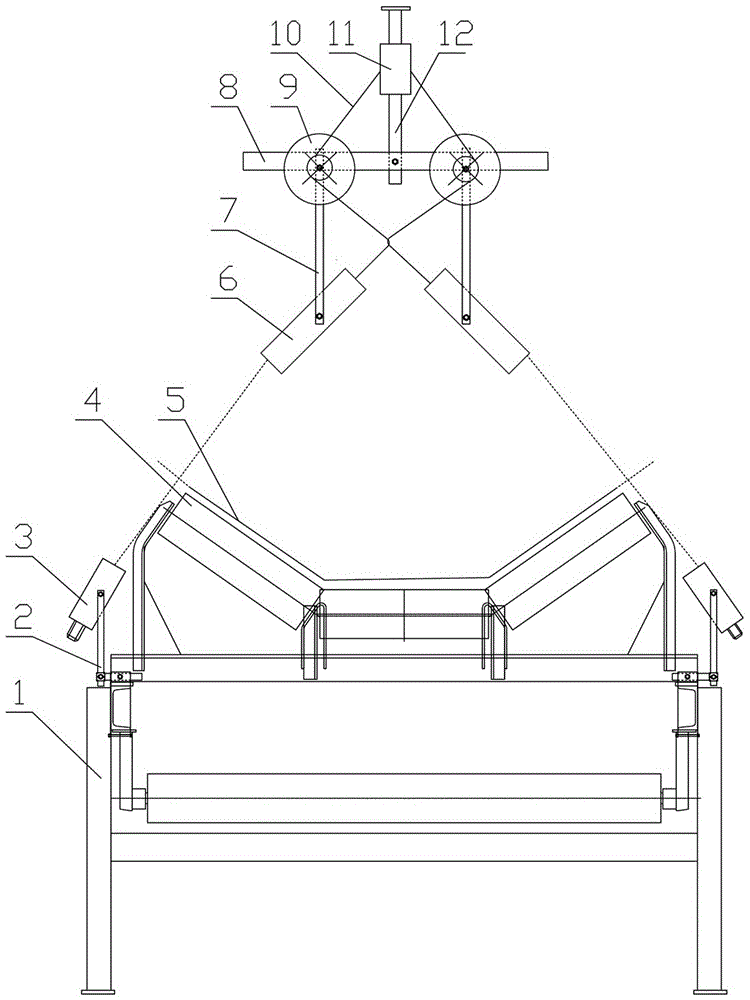

Infrared opposite-type coal mine conveyor adhesive tape anti-tearing protection method and device

ActiveCN106185240AEnsure safe productionReduce investmentConveyorsControl devices for conveyorsEngineeringCoal

The invention discloses an infrared opposite-type coal mine conveyor adhesive tape anti-tearing protection method and device. An infrared emitter and an infrared receiver are installed on longitudinal beams on the two sides of a conveyor through lower fixing frames correspondingly; a coal receiving mechanism is arranged between upper adhesive tape and lower adhesive tape of the conveyor and comprises two coal receiving boards and one coal receiving tank; the two coal receiving boards are arranged obliquely, and the interval between the upper ends of the two coal receiving boards is greater than the interval between the lower ends of the two coal receiving boards; meanwhile, the lower ends of the two coal receiving boards are connected with the upper ends of the two sides of the coal receiving tank correspondingly; the coal receiving tank is rectangular, and the upper end of the coal receiving tank is open; a connection rod is arranged at the interval between the two ends of the two coal receiving boards; and the infrared emitter and the infrared receiver are located in the middles of the two ends of the two coal receiving boards correspondingly. The infrared sensors are used as collection elements to achieve all the functions of an original anti-tearing protection device, the defects of the original anti-tearing protection device are overcome, safe production of a mine is ensured, and investment of the production cost is reduced.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

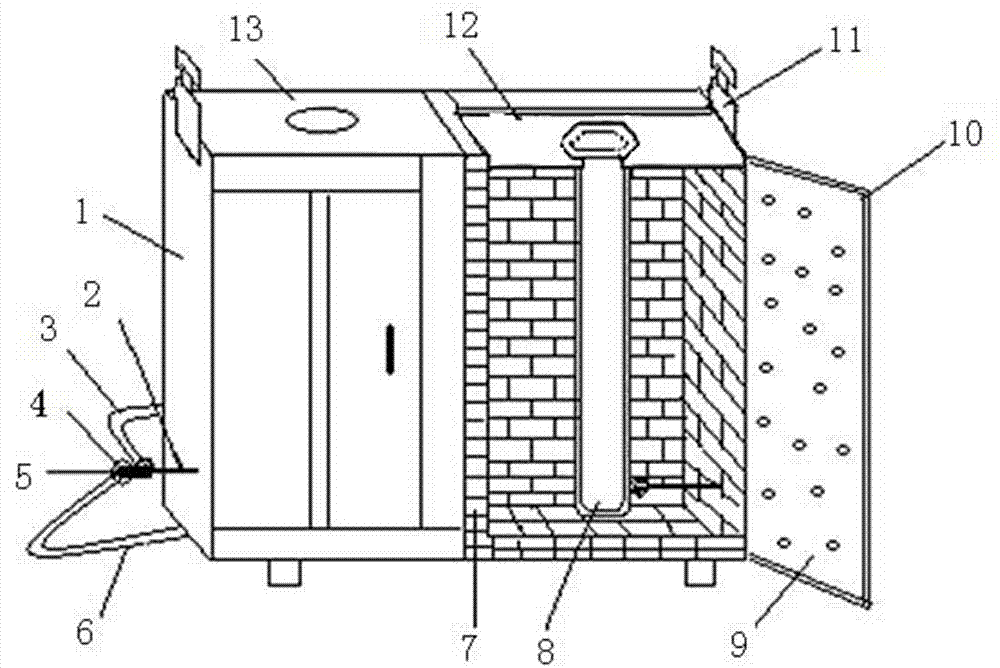

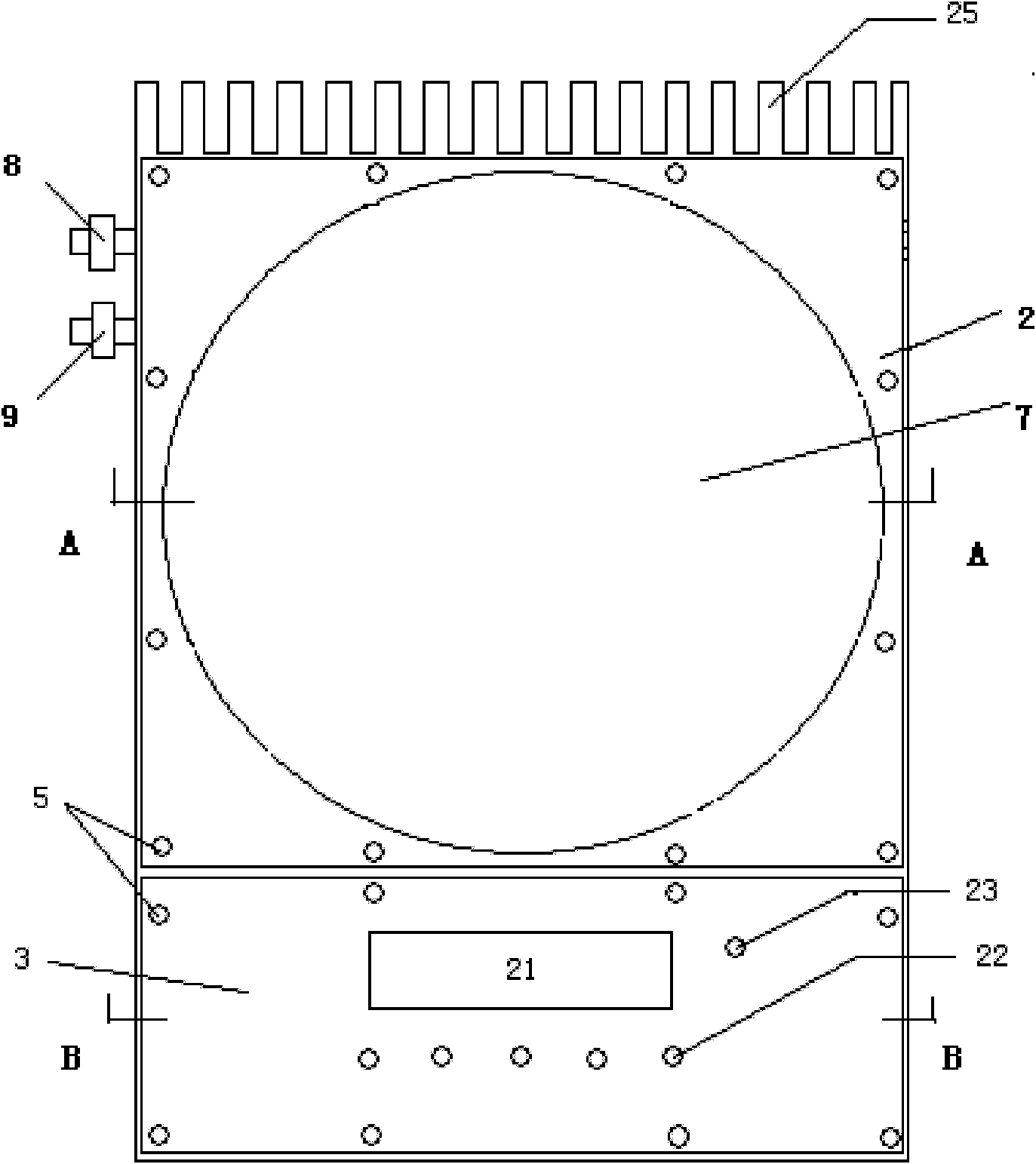

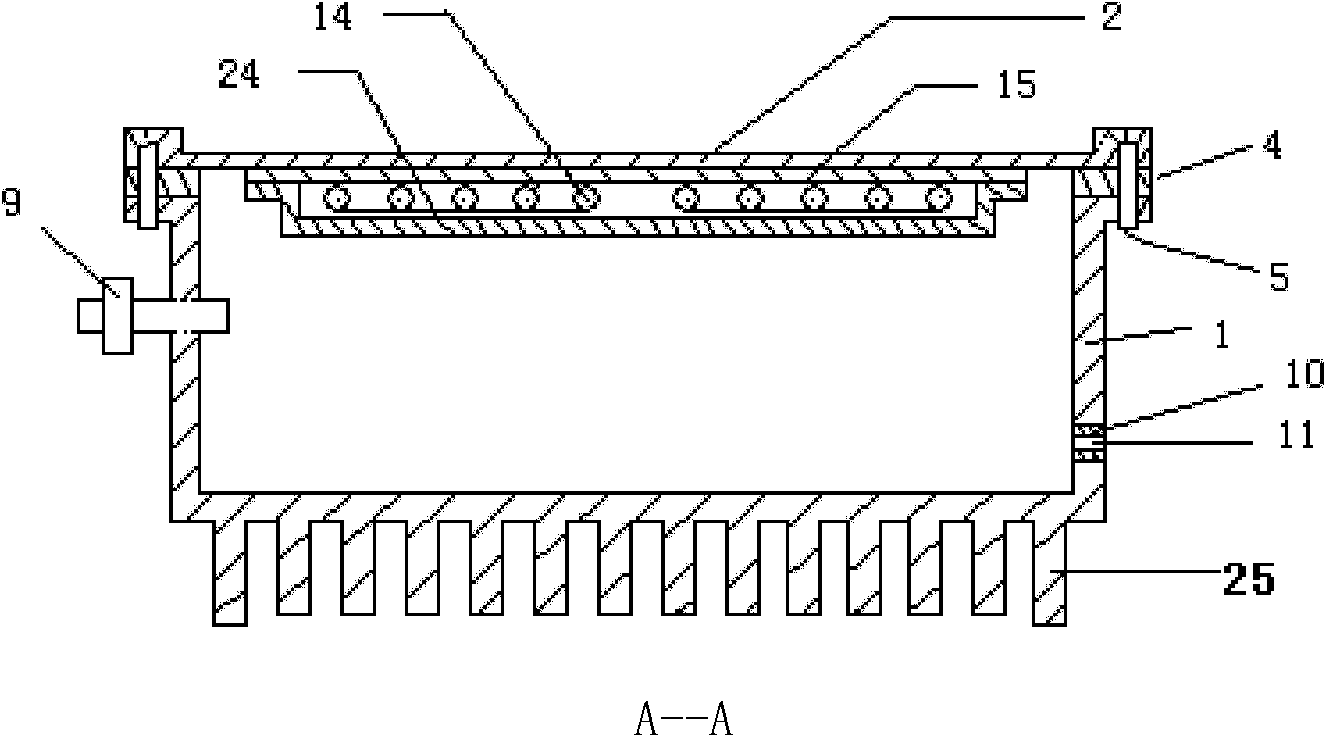

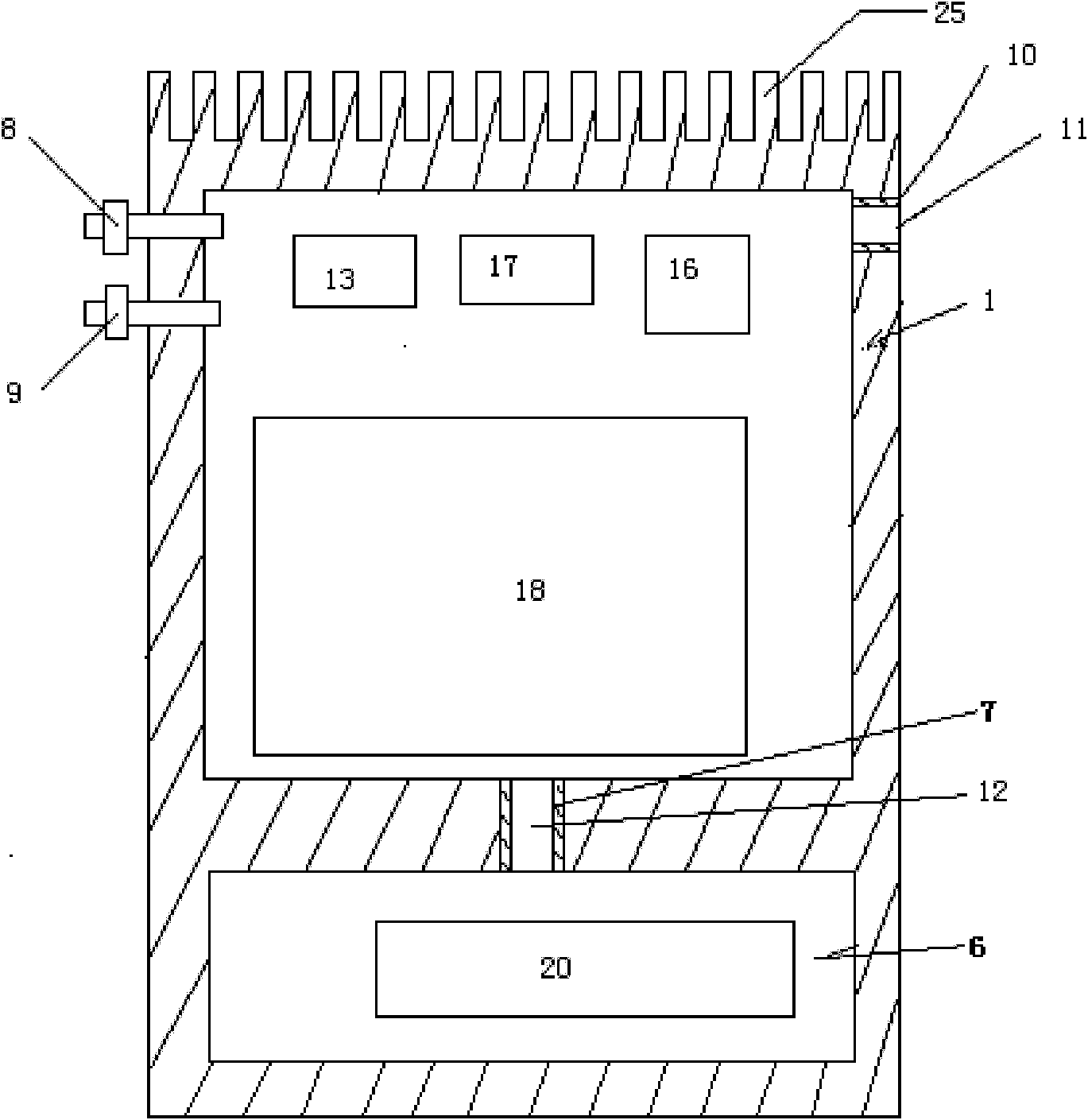

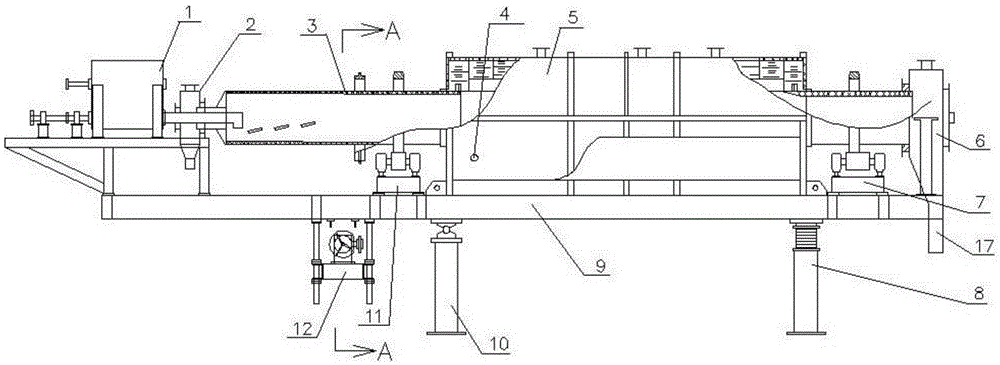

Continuous casting machine tundish submersed nozzle baking furnace

InactiveCN103878357AGuaranteed baking qualitySave on insulationMelt-holding vesselsMetallurgySpray nozzle

The invention relates to the field of metallurgical equipment, in particular to a continuous casting machine tundish submersed nozzle baking furnace. The continuous casting machine tundish submersed nozzle baking furnace comprises a furnace body, wherein two baking chambers are arranged in the furnace body, each baking chamber is provided with a spraying nozzle, each spraying nozzle is connected with a mixing valve, each mixing valve is connected with an air inlet pipe and a fuel gas inlet pipe, each air inlet pipe and each fuel gas inlet pipe are respectively provided with a control hand valve, an installation plate is arranged at the top of each baking chamber, a clamping groove is formed in each installation plate to fix a submersed nozzle, the furnace body is provided with a furnace door, a heat-preservation layer is arranged at the inner side of the furnace door, a flame retardant layer is arranged on the inner wall of each baking chamber, a heat preservation plate is formed at the top of the furnace body and provided with openings matched with the submersed nozzles, pulleys are arranged at the bottom of the furnace body, and pothooks are arranged at the top of the furnace body. The continuous casting machine tundish submersed nozzle baking furnace has the advantages of being safe to operate, capable of meeting production requirements, capable of guaranteeing baking quality and convenient to move and transport, saving energy and the like.

Owner:JIGANG GRP

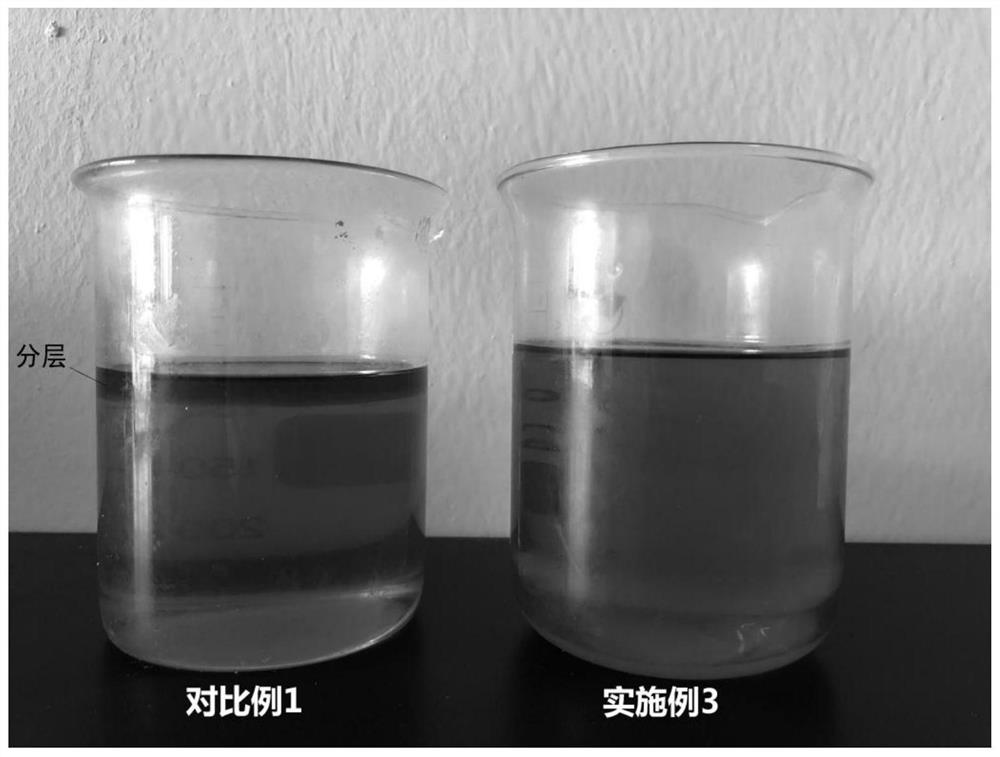

Ferrite material, laminated sheet type inductor and preparation method of laminated sheet type inductor

ActiveCN104250096AImprove rheologyImprove shrinkageInductances/transformers/magnets manufactureFixed signal inductancesWater basedThinning

The invention provides a ferrite material, a laminated sheet type inductor and a preparation method of the laminated sheet type inductor, wherein the ferrite material comprises the following components by the weight percentage: 32-52 parts of a ferrite powder, 4-9 parts of an adhesion agent, 40-60 parts of a solvent, 1.5-5 parts of a plasticizer, 0.5-2.5 parts of a dispersion agent, 0.5-3 parts of an emulsifier, and 0.05-0.25 part of a defoaming agent, wherein the adhesion agent is polyvinyl alcohol or a compound adhesion agent of polyvinyl alcohol and water-borne acrylic acid. The ferrite material provided by the invention adopts a water-based solvent system; and with the synergistic effect among the components, the ferrite material has excellent rheological property and shrinkage property and can eliminate bubbles and needle eyes on a thin strip, and thus an excellent-performance ferrite membrane sheet and the excellent-performance thinning laminated sheet type inductor are obtained, and the defects of VOC emissions, high production cost and large energy consumption caused due to the use of organic solvents in an traditional inductor production are reduced.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

Explosion-proof electromagnetic heating cooker

InactiveCN102135280AEnsure personal safetyImprove securityDomestic stoves or rangesLighting and heating apparatusEngineeringElectromagnetic heating

The invention discloses an explosion-proof electromagnetic heating cooker, which comprises an explosion-proof electromagnetic oven and a pan. A heating circuit is arranged in the inner cavity of a box body of the explosion-proof electromagnetic oven, and a box cover is the oven face of the electromagnetic oven; the pan is arranged on the oven face of the electromagnetic oven; the bottom surface of the pan is matched with the oven face of the electromagnetic oven; an inflation pipe connected with a safety air source and an exhaust pipe are arranged on the sidewall of the box body; the sidewall of the box body is provided with an inlet hole of a power cord; the bottom and the sidewall of the box body are provided with radiating fins; a heat-insulation sealing gasket is arranged between the box body and the box cover; and a heat-resistant silicon rubber sealing ring is arranged on the inner wall of the inlet hole. An electric box is connected to the external of the front sidewall of the box body, the upper cover surface of the electric box is provided with a light emitting diode (LED) display, a control button and an LED signal lamp, and a computer-controlled auxiliary board is arranged in the inner cavity. The explosion-proof electromagnetic heating cooker has the advantages that: as the explosion-proof sealing box body is filled with safety gas, an external environment is isolated from the electrical parts, so safety production requirement of a coal mine or other places are met. Due to the arrangement of a heat-insulation board, the electricity is completely isolated from the heat, so the safety performance is greatly improved.

Owner:许广胜

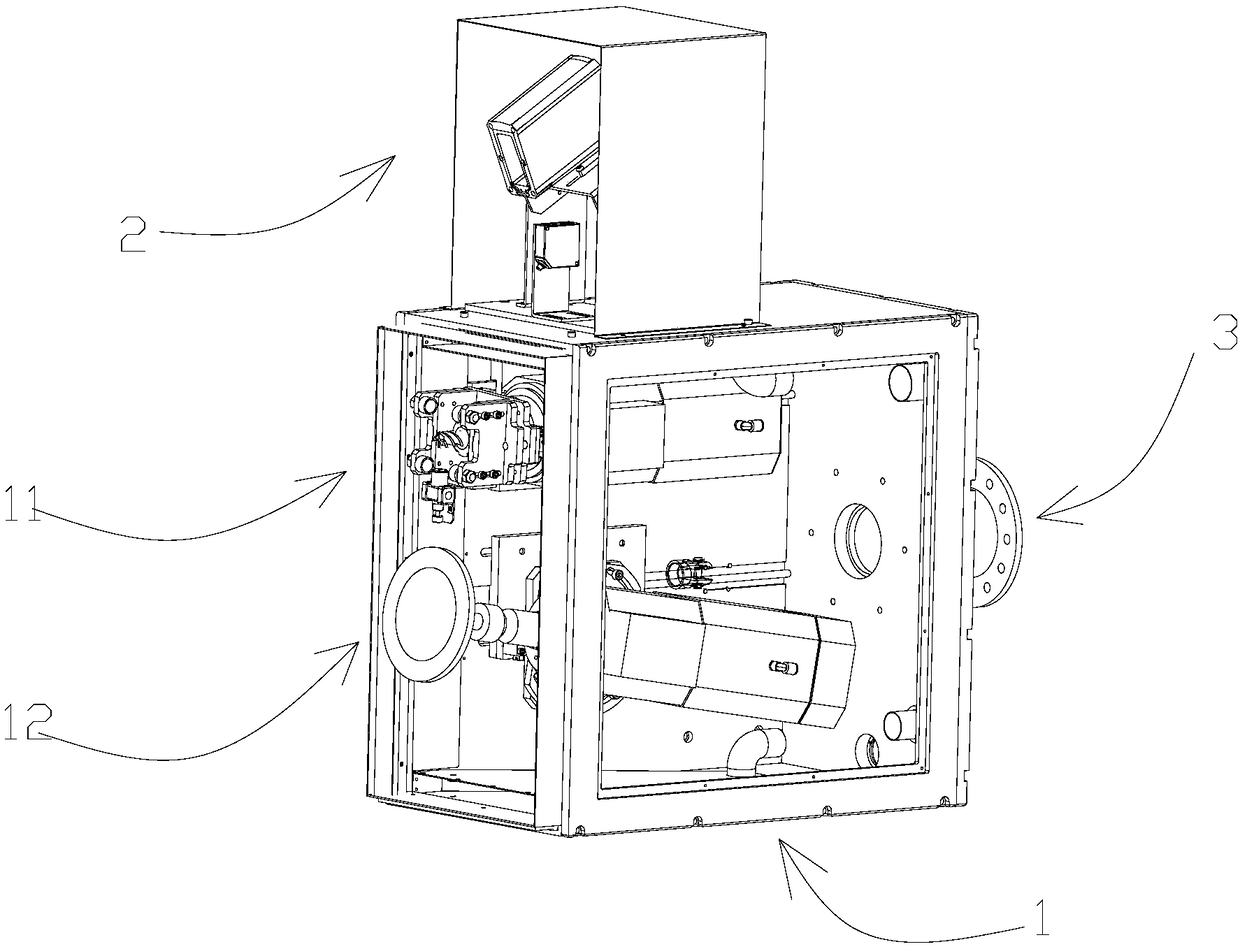

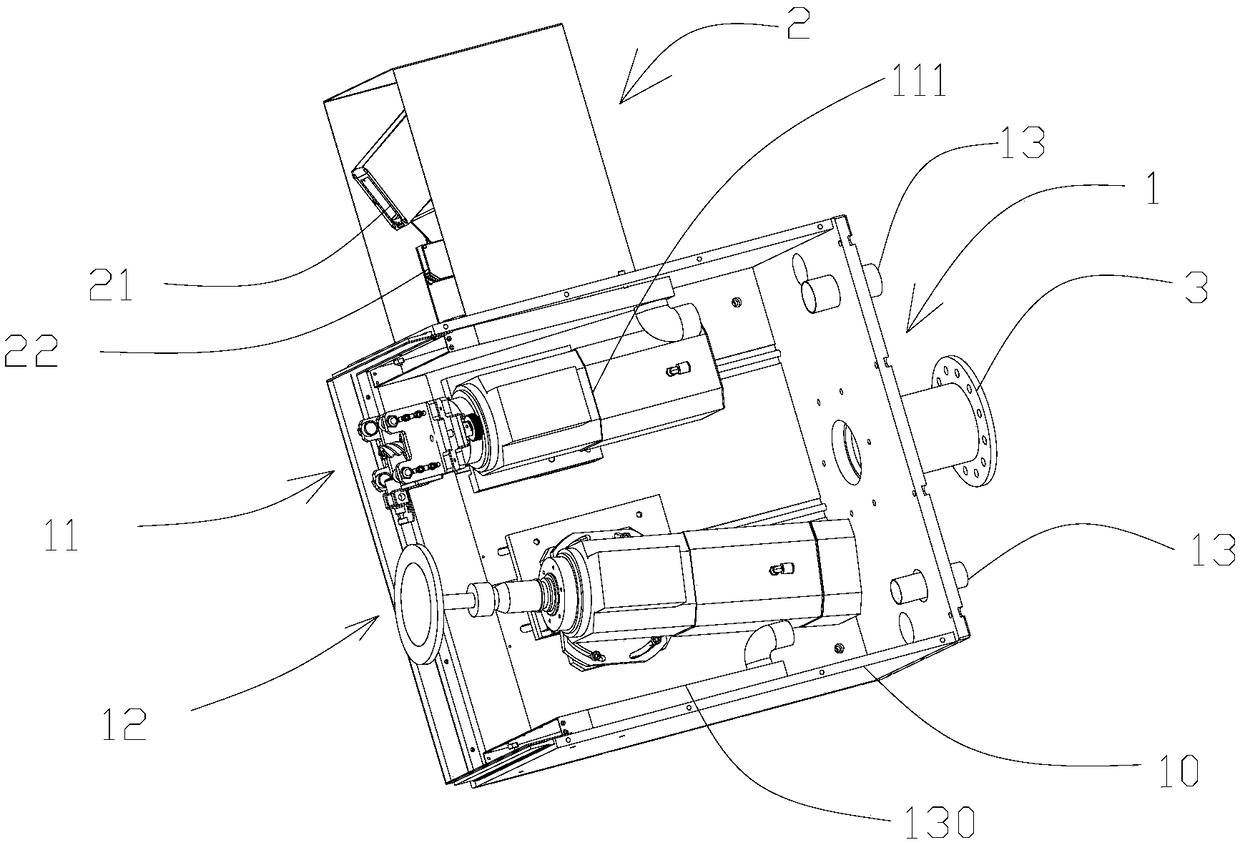

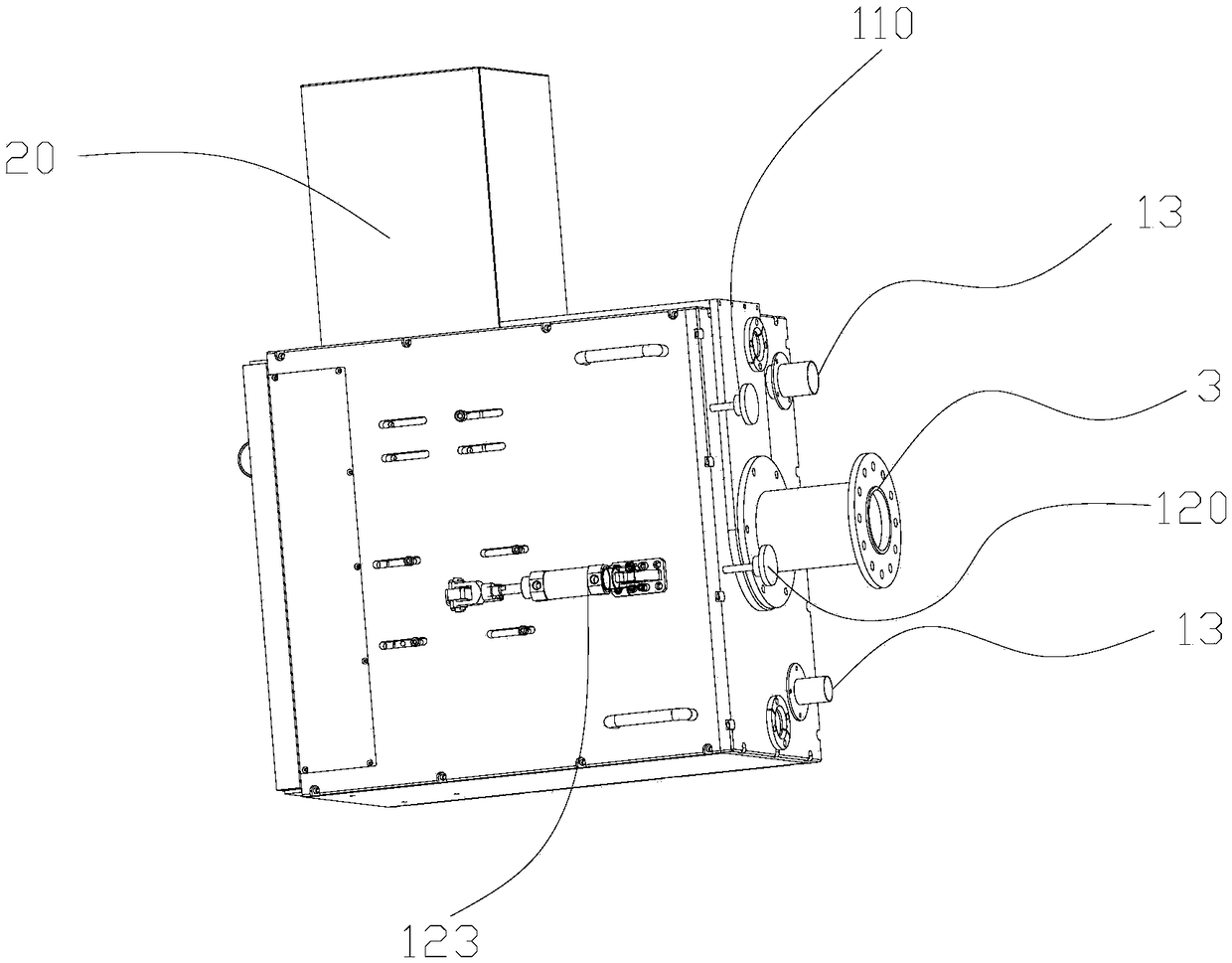

Improved combined device for milling and grinding weld joint of side wall of high-speed train

PendingCN108406545AReduce harmImprove milling efficiencyGrinding machinesGrinding/polishing safety devicesMilling cutterEngineering

The invention provides an improved combined device for milling and grinding a weld joint of the side wall of a high-speed train. The combined device comprises a main box component and a visual systemcomponent, and the visual system component is arranged on the main box component; the main box component comprises a main box body, a milling component and a grinding component; the milling componentand the grinding component are both arranged in the main box body, and the positions of the milling component and the grinding component can be adjusted; the milling component comprises a milling motor, a milling cutter directly driven by a rotating shaft of the milling motor, and a cooling spray head arranged at the position of the milling cutter; and the milling cutter is an end milling cutter,and the grinding component comprises a grinding motor, and a grinding disk driven by the grinding motor. According to the combined device, the milling efficiency is improved greatly, and dust harm tooperators is reduced; the labor intensity is reduced, and the consistency and stability of the surface quality of the ground weld joint can be improved effectively; the safe production requirements are met; according to the combined device, the end milling cutter is driven by an electric main shaft, and the speed of the end milling cutter can reach 20000 rpm, and the efficiency of the end millingcutter is 5-6 times the efficiency of a conventional cylindrical milling cutter.

Owner:天津智通信息系统集成有限公司

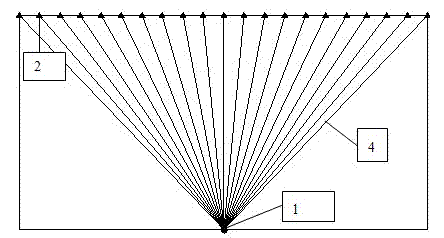

Method for detecting anisotropism P-wave of fractures of working face of mine

InactiveCN102928869AGuide safe productionThe detection results are intuitiveSeismic signal receiversMining engineeringStructural engineering

A method for detecting anisotropism P-wave of fractures of a working face of a mine belongs to a detecting method of a fracture development abnormal area in the working face of the mine. The technical scheme of the method for detecting the P-wave is that (1) trigger points are arranged on one roadway in the working face of the mine; (2) detector groups for receiving elastic P-wave signals are arranged; (3) an original single-cannon earth shake record is obtained; (4) P-wave first break time is picked up; (5) anisotropism parameters of the roadway on one side of a cannon point are calculated; (6) the anisotropism parameters of the roadway on one side of a detection point are calculated; (7) the anisotropism parameters of a concentric transmission point connecting line are calculated; and (8) anisotropism distribution of the fractures of the working face of the mine is obtained. By means of the method, detecting precision of fracture development abnormal bodies in the working face of the mine is improved, quantification detection of development density and development directions of the fractures in the working face of the mine is possible, detection is real and reliable, a detecting method is scientific and simple, a detecting result is quantitative, visual and high in precision, and safety production requirements of the working face of the mine are fully met.

Owner:CHINA UNIV OF MINING & TECH

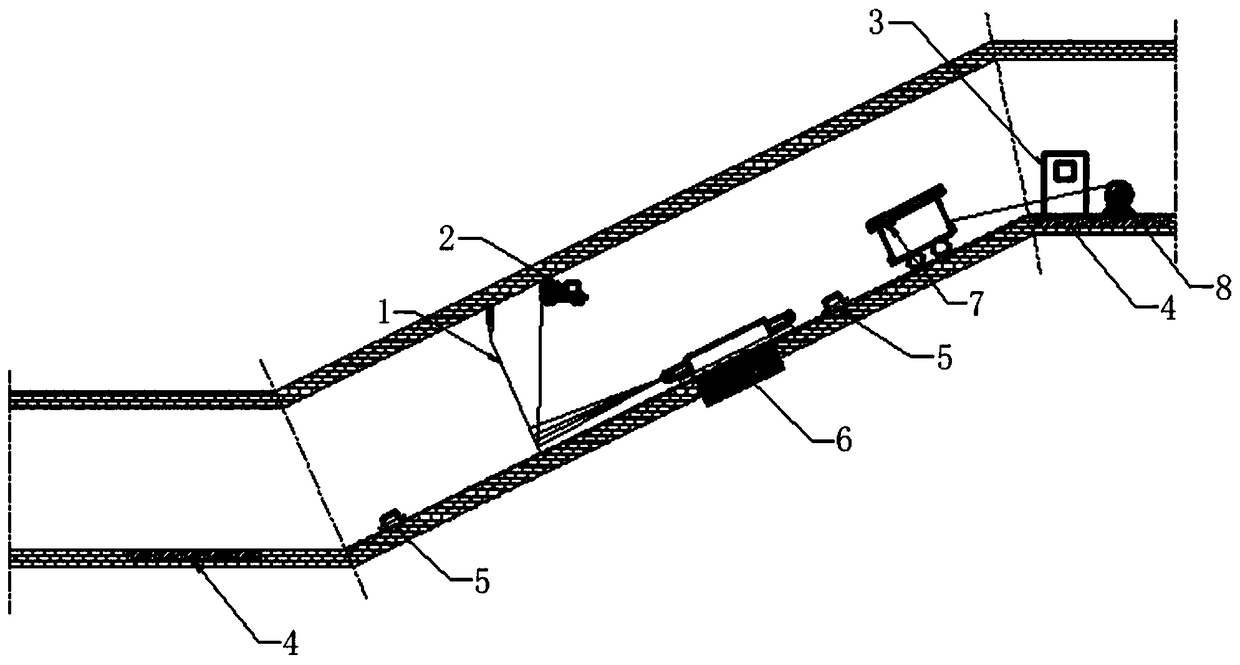

Car-sliding-prevention self-adjusting buffer system for transportation on oblique alley and application of system

PendingCN108725510APrevent sports car accidentsSolve the weight problemPositive railway stopsYardWinch

The invention relates to a car-sliding-prevention self-adjusting buffer system for transportation on an oblique alley and application of the system. The system comprises a mine car lifting winch, a car barrier lifting system and a car barrier buffer system; through sensors arranged on an upper car yard, the oblique alley, a lower car yard and a mine car, conditions of the mining car during transportation on the oblique alley of a coal mine are monitored in real time and transmitted to a controller through a signal repeater arranged along the oblique alley, and the controller collects data of each sensor to judge whether or not there is an accident during transportation and controls each subsystem to make corresponding actions and adjustments to prevent occurrence of the accident. The car barrier buffer system is additionally arranged in a car sliding prevention device, so that the buffering process is more stable and controllable. At the same time, a buffer device in the car barrier buffer system adopts a magnetorheological buffer for cooperating with a pressure sensor and a speed sensor, so that the problem is solved that buffering forces of conventional car barrier system cannotbe automatically adjusted according to the weight of mine cars and the speed of the mine cars.

Owner:SHANDONG UNIV OF SCI & TECH

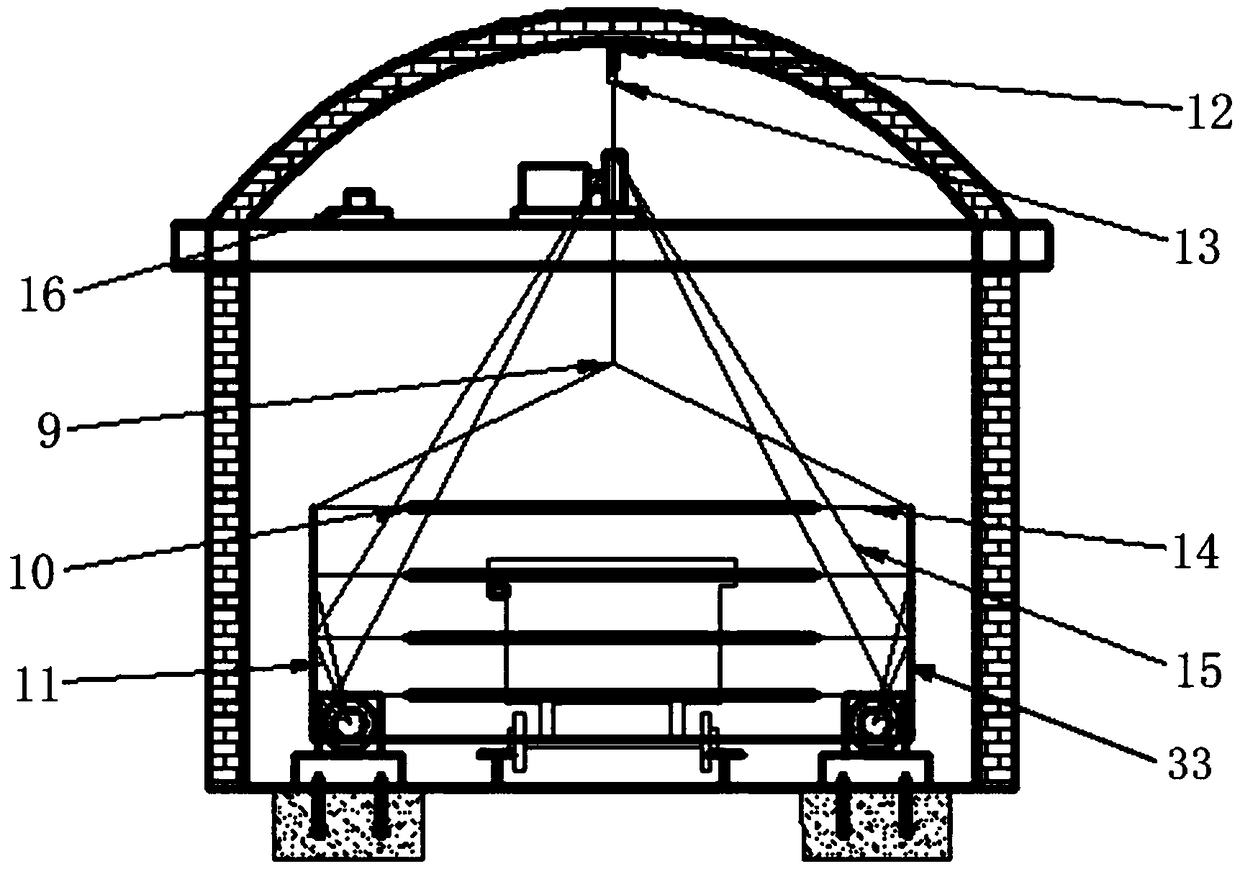

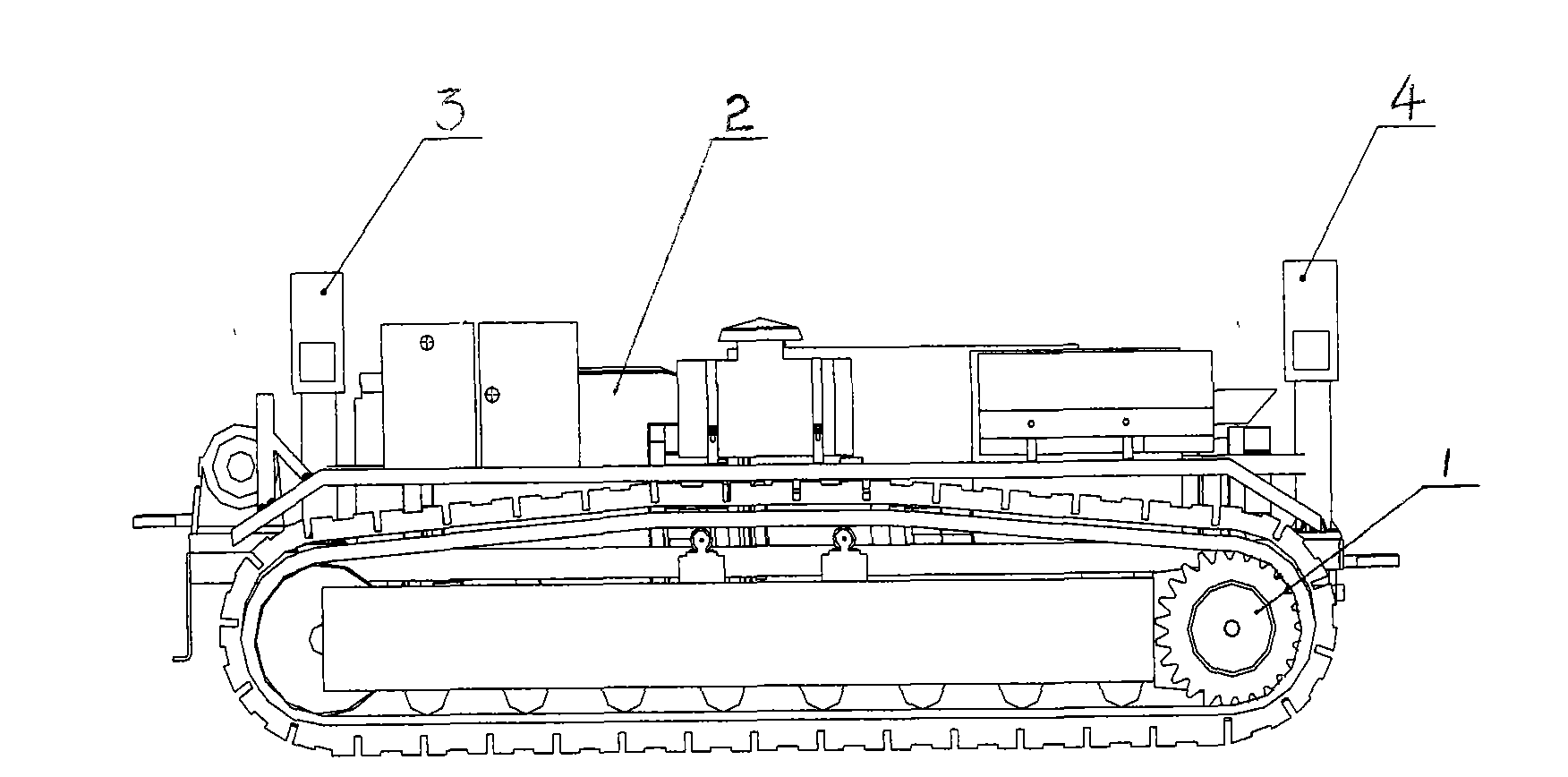

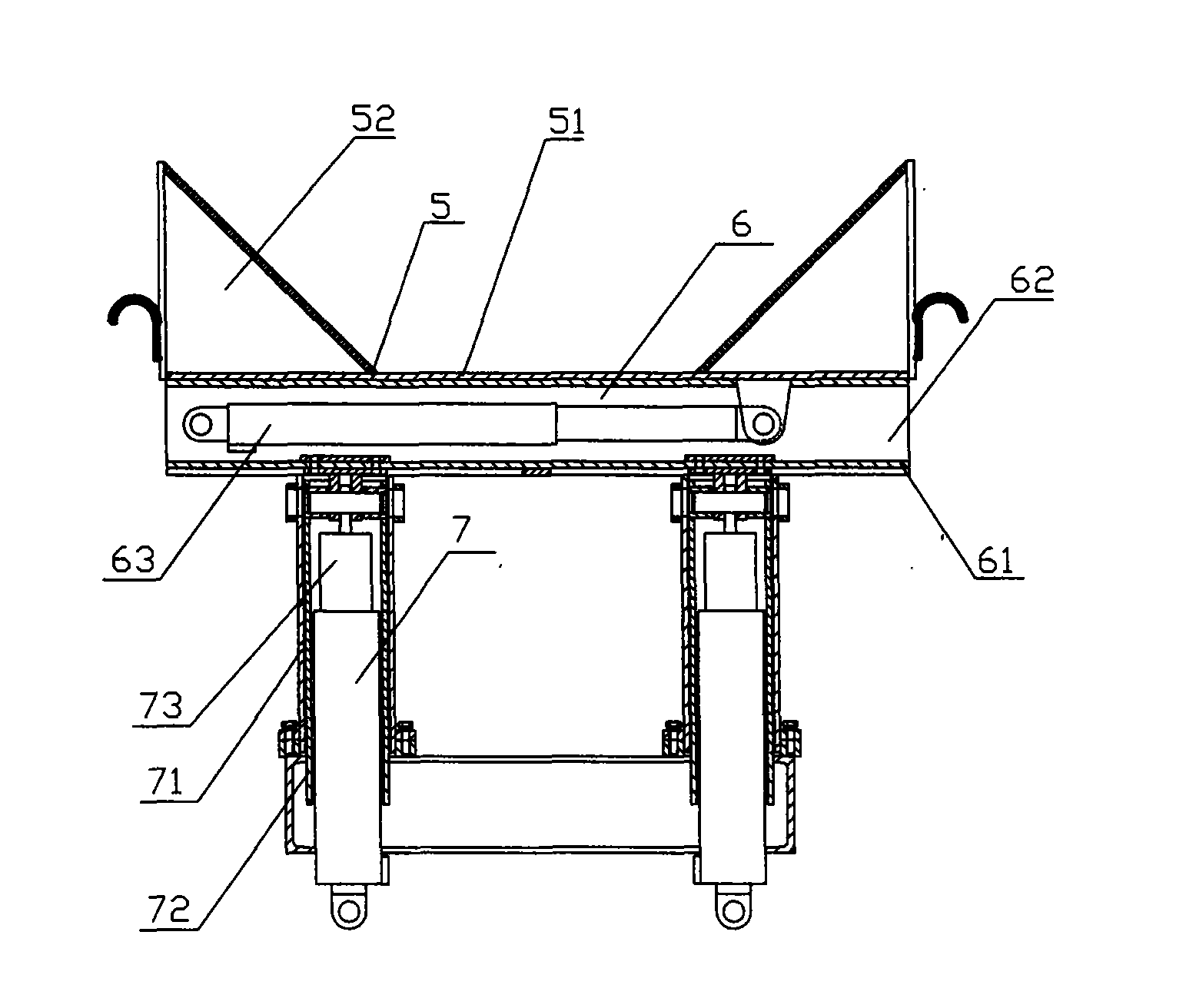

Crawler-type carrier vehicle

ActiveCN101659286AChange center of gravityImprove securityEndless track vehiclesGravity centerPortal frame

The invention relates to a traffic and transport means, in particular to a crawler-type carrier vehicle. The invention provides the crawler-type carrier vehicle which is provided with a front portal frame component and a back portal frame component, the positions of which can be adjusted, wherein transported building materials and the like are arranged on the front and the back portal frame components; the upward movement, the downward movement, the left movement and the right movement of the front and the back portal frame components can be realized under the actions of a translation drivingcomponent and a lifting driving component, therefore, the building materials can be moved upwards, downwards, to the left and to the right according to the specific transportation conditions of the carrier vehicle, so that the center of gravity of the carrier vehicle is changed and the running dynamics of the whole vehicle during transportation is balanced to conform with the road condition and the condition of the carrier vehicle, thus easily realizing one-time variable speed turning, playing important role in adjusting the center of gravity of the carrier vehicle when ascending or descending, greatly improving the transportation efficiency, improving the safety performance of the carrier vehicle, and being consistent with the requirements of safe production and construction; and the crawler-type carrier vehicle is an innovative invention in the filed of the crawler-type carrier vehicle, thus having significant meaning.

Owner:STATE GRID CORP OF CHINA +2

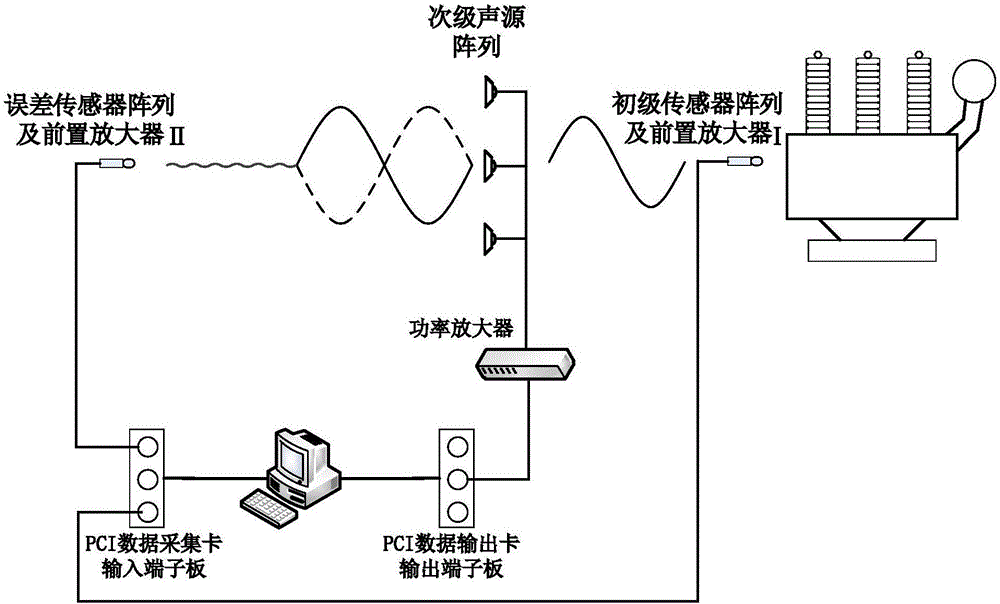

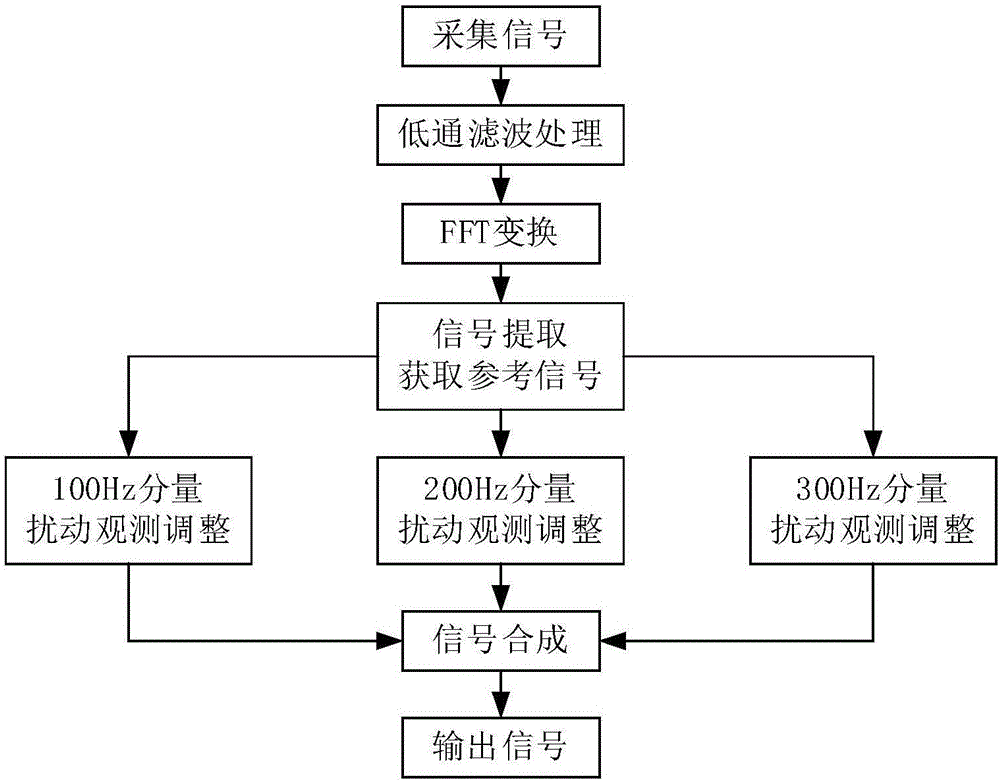

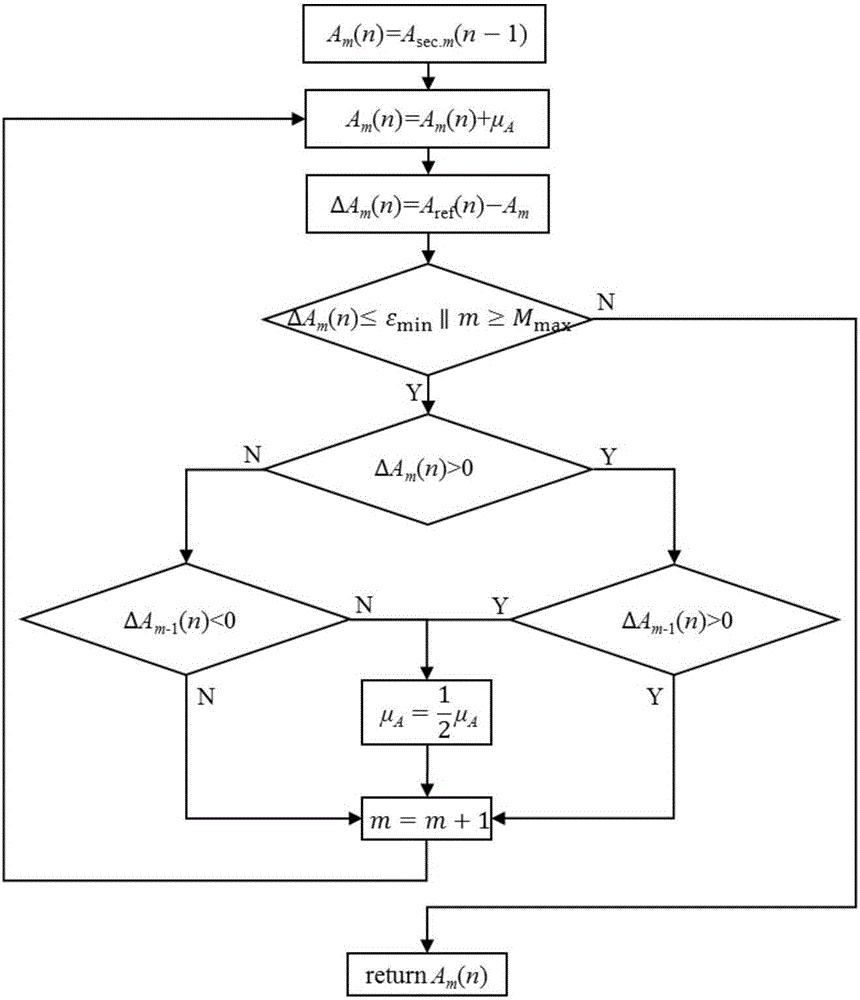

Disturbance observation method based power transformer active noise control system

ActiveCN106094654AReal-timeAchieving processing powerProgramme controlComputer controlNoise controlSensor array

The invention relates to the technical field of active noise control, and particularly relates to a disturbance observation method based power transformer active noise control system. The power transformer active noise control system comprises a primary sensor array, a preamplifier I, an error sensor array, a preamplifier II, a power amplifier, an industrial control computer, a PCI data acquisition card, a PCI data output card, a visual disturbance observation control module and a secondary sound source array, wherein the primary sensor array and the error array are connected to the PCI data acquisition card respectively through the preamplifier I and the preamplifier II, the PCI data acquisition card is connected to the PCI data output card through the industrial control computer, and the PCI data output card is connected to the secondary sound source array through the power amplifier; and the industrial control computer serves as a carrier of the PCI data acquisition card, the PCI data output card and the visual disturbance observation control module. The power transformer active noise control system track noise signals in real time through a disturbance observation control algorithm, and realizes effective noise reduction after being put into an actual transformer station.

Owner:WUHAN UNIV

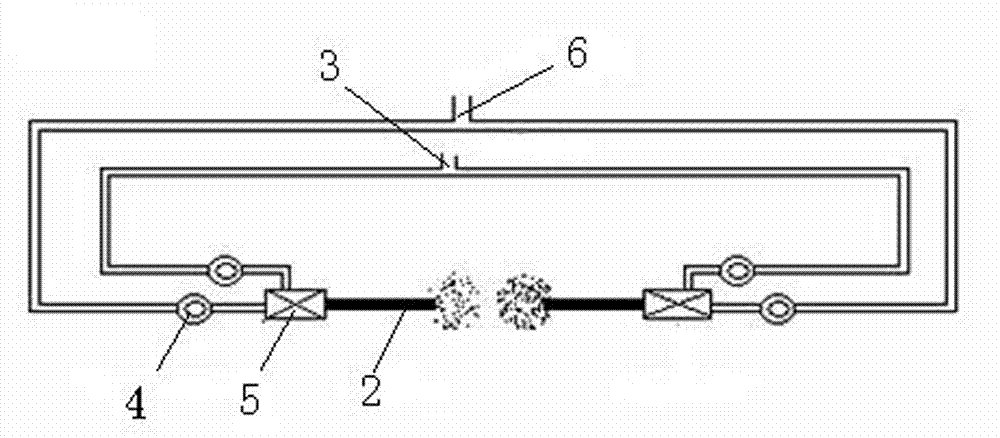

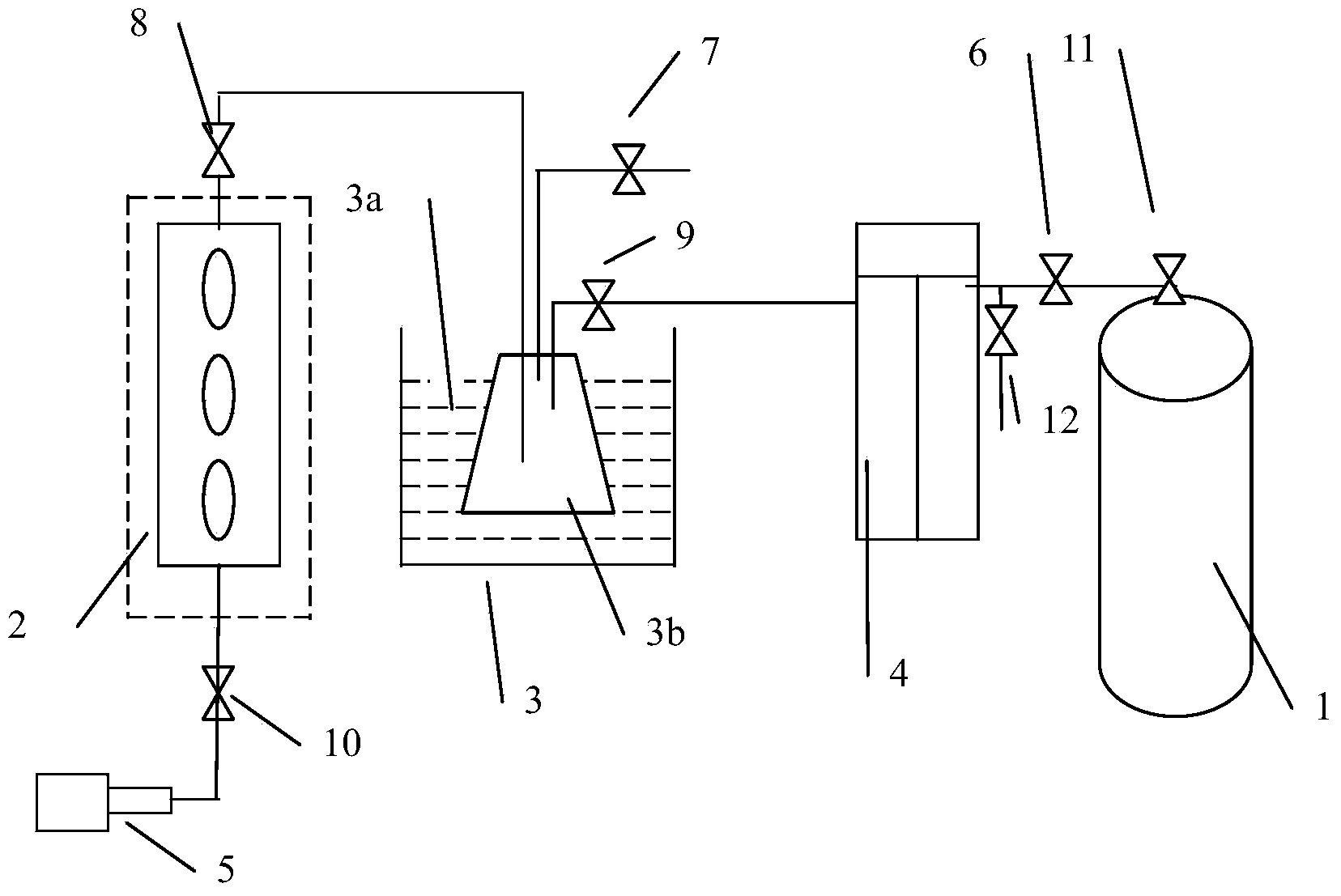

Air simulating and sampling device for air displacement oil output and simulating and sampling method

InactiveCN104373115AReal-time monitoring of production statusEasy to operateSurveyConstructionsGas meterEngineering

The invention relates to an air simulating and sampling device for the air displacement oil output and a simulating and sampling method, and belongs to the technical field of oil field development experiments. The air simulating and sampling device for the air displacement oil output comprises an oxidation reaction kettle, a separator, a gas meter and an air metering pump. The air metering pump, the oxidation reaction kettle, the separator and the gas meter are sequentially connected in series through pipelines and valves. A sampling valve is installed on an outlet of the gas meter. By means of the air simulating and sampling device for the air displacement oil output, the formation temperature and pressure of a site displacement well can be simulated in a laboratory, an air displacement oxidation reaction model similar to the site displacement well is set up, and sampling in the laboratory is achieved. Operation is simple and easy to implement, the production condition of the site displacement well can be monitored in real time without site sampling, and the safe production requirement is met.

Owner:CHINA PETROLEUM & CHEM CORP +1

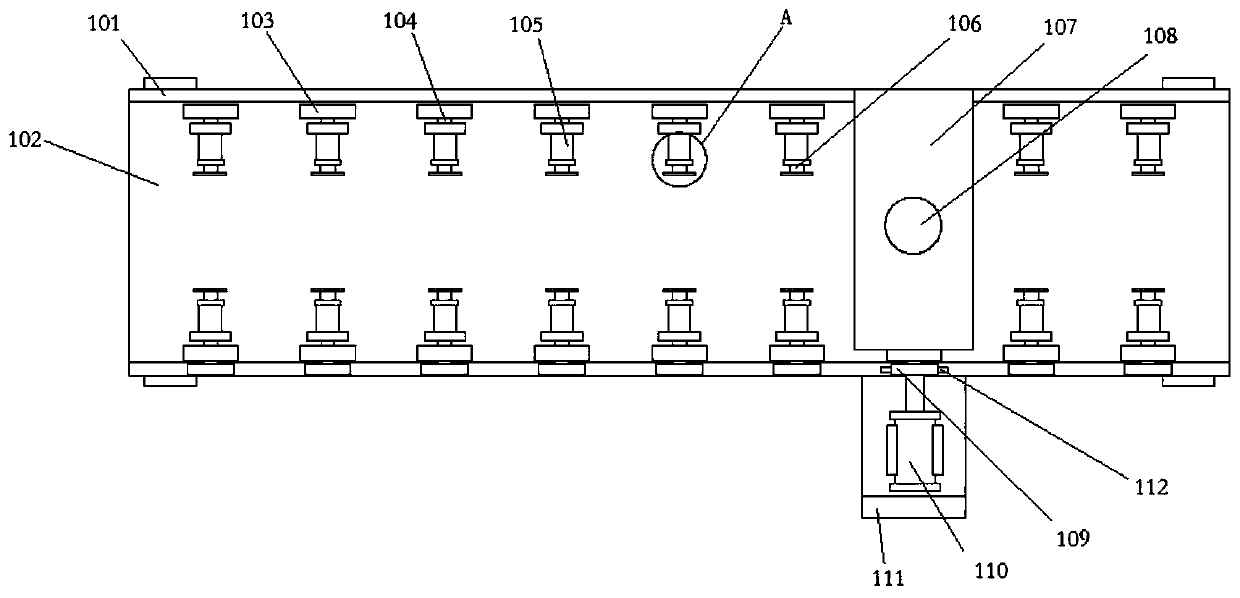

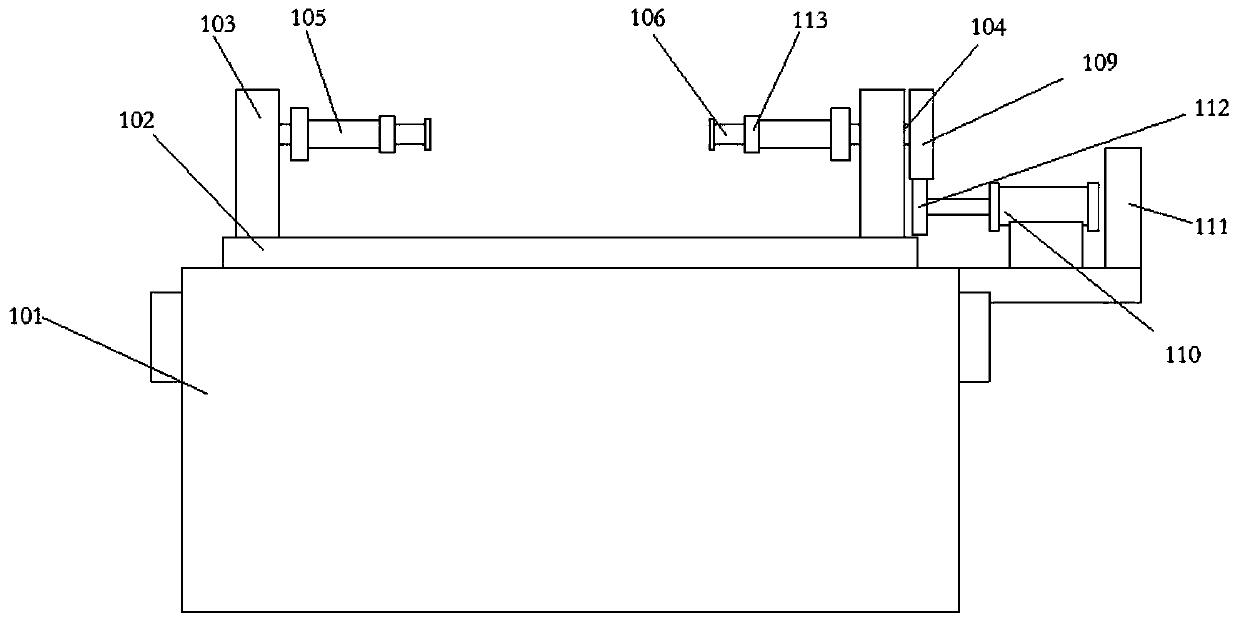

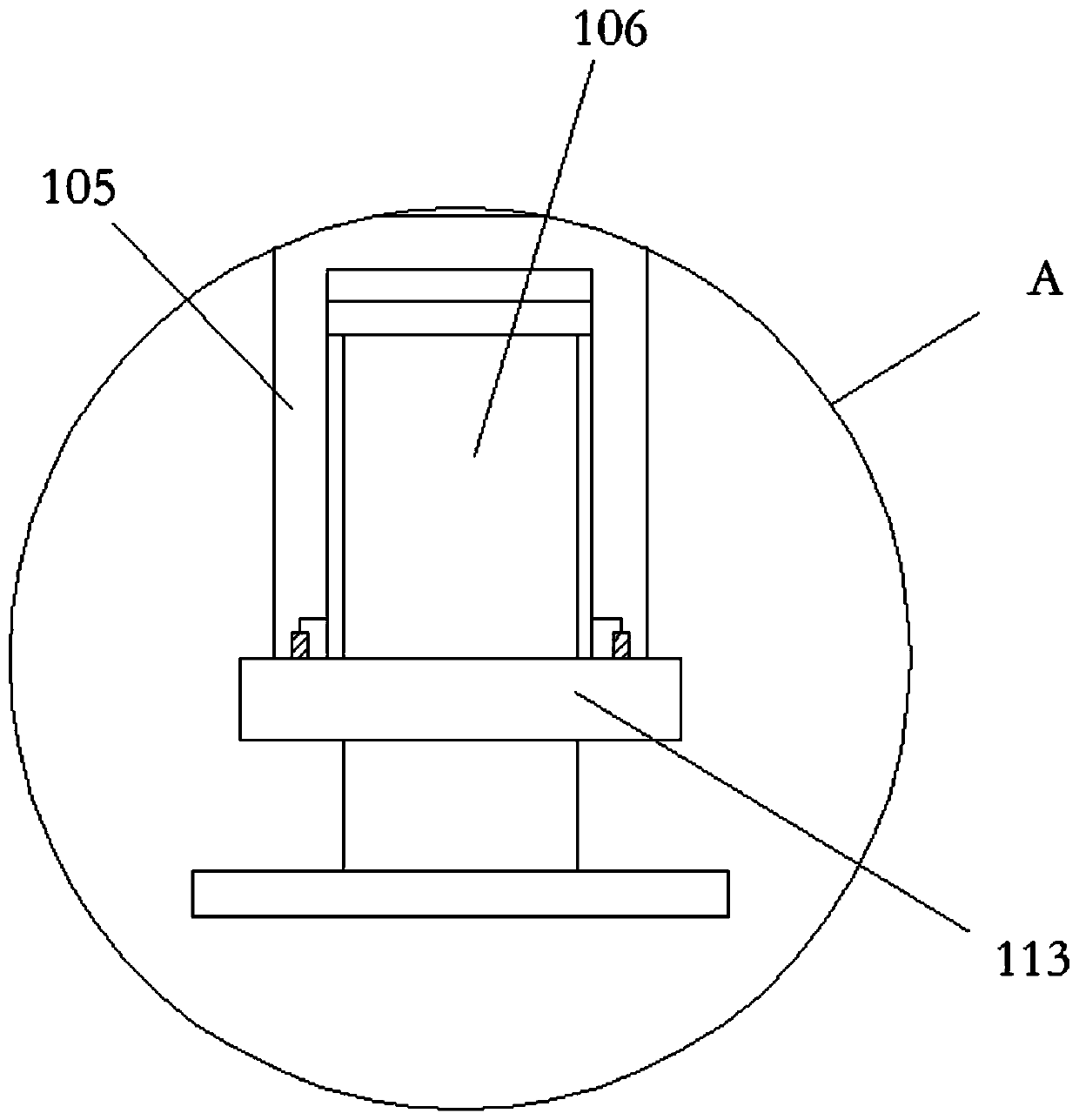

Laser cleaning system for stainless steel cable ties

InactiveCN111167868ARealize all-round cleaningPrecise positioningWork cleaning devicesCleaning processes and apparatusProcess engineeringMechanical engineering

The invention relates to a laser cleaning system for stainless steel cable ties. The laser cleaning system comprises a laser cleaning machine, a material conveying device for conveying to-be-cleaned materials, a positioning device for clamping and positioning the laser cleaning machine, and a dust collection mechanism for collecting dust generated in the laser cleaning process. According to the laser cleaning system, through structure innovation, non-pollution cleaning of the surfaces of the stainless steel cable ties can be achieved through laser, all-around cleaning can be achieved based onthe conveying device, precise positioning can be conducted, and accordingly, the cleaning effect is ensured; and in addition, by arranging the dust collection mechanism and a protective mechanism, theenvironment-friendly production performance and the safe production performance are further improved, and the system can meet the environment-friendly safe production requirements.

Owner:SHANDONG ENERGY HEAVY EQUIP MFG GRP CO LTD +1

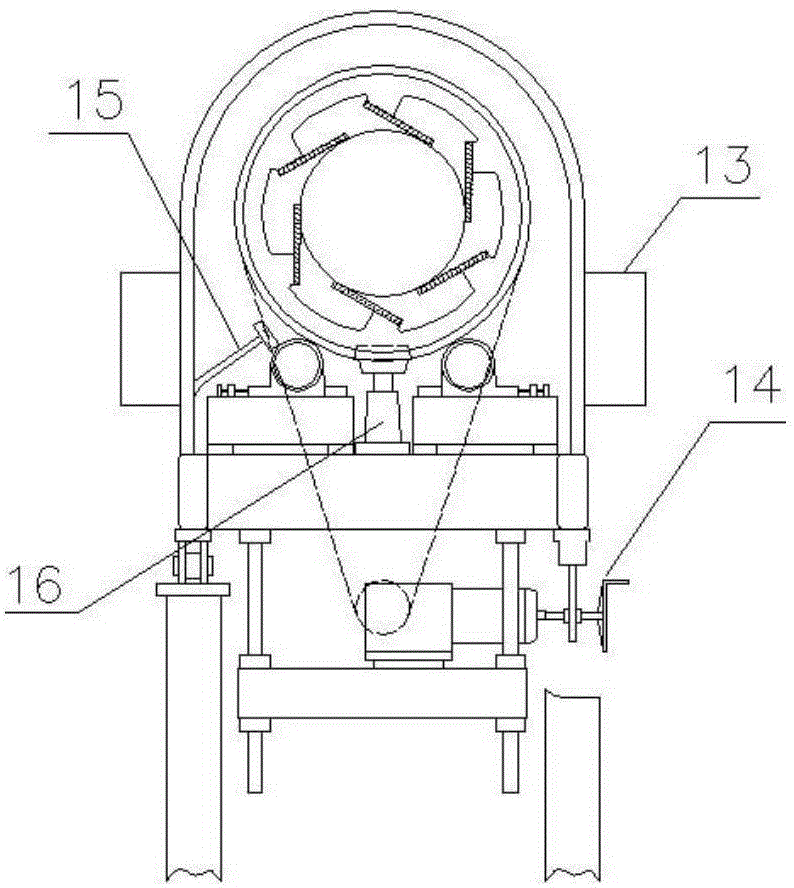

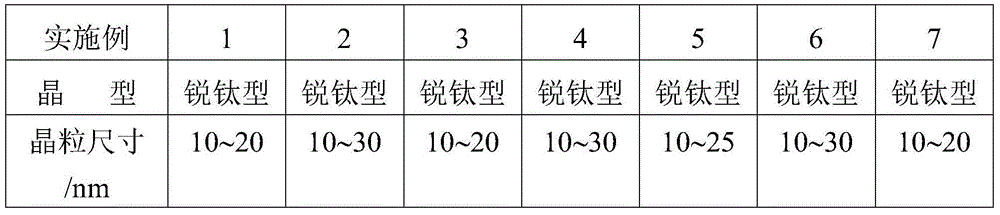

Calcination crystallization method of nanometer TiO2/porous mineral composite material

InactiveCN104874345AMeet the process requirementsMeet safety production requirementsPhysical/chemical process catalystsOther chemical processesHydrolysisCalcination

The invention discloses a calcination crystallization method of a nanometer TiO2 / porous mineral composite material. The method is characterized in that a cylinder type rotary calcining furnace is used for calcining and crystallizing the nanometer TiO2 / porous mineral composite material. The temperature in the cylinder type rotary calcining furnace is divided into three sections: a warming region, a high-temperature calcining region and a cooling region, wherein the temperature at the warming region is normal temperature to 650 DEG C, the temperature at the high-temperature calcining region is 550-650 DEG C, and the temperature at the cooling region is 650-80 DEG C. The nanometer TiO2 / porous mineral composite material is uniformly and continuously fed into the cylinder type rotary calcining furnace after being prepared through a hydrolysis precipitation method and dried, the composite material orderly passes through the warming region, the high-temperature calcining region and the cooling region, wherein the composite material is remained at the warming region for 0.5-1.5h, remained at the high-temperature calcining region for 1.5-3.0h, and remained at the cooling region for 0.5-1.5h, and then discharged. Compared with a static calcination method, the continuous production is realized through the adoption of the method disclosed by the invention, the nanometer TiO2 is uniformly crystallized, the obtained product is stable in quality, the calcining time is shortened, the energy source is saved, and the operation and the maintenance are convenient.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Anti-tear protection method and device for infrared ray beaming coal mine conveyor belt

ActiveCN106185240BEnsure safe productionReduce investmentConveyorsControl devices for conveyorsFixed frameEngineering

The invention discloses an infrared opposite-type coal mine conveyor adhesive tape anti-tearing protection method and device. An infrared emitter and an infrared receiver are installed on longitudinal beams on the two sides of a conveyor through lower fixing frames correspondingly; a coal receiving mechanism is arranged between upper adhesive tape and lower adhesive tape of the conveyor and comprises two coal receiving boards and one coal receiving tank; the two coal receiving boards are arranged obliquely, and the interval between the upper ends of the two coal receiving boards is greater than the interval between the lower ends of the two coal receiving boards; meanwhile, the lower ends of the two coal receiving boards are connected with the upper ends of the two sides of the coal receiving tank correspondingly; the coal receiving tank is rectangular, and the upper end of the coal receiving tank is open; a connection rod is arranged at the interval between the two ends of the two coal receiving boards; and the infrared emitter and the infrared receiver are located in the middles of the two ends of the two coal receiving boards correspondingly. The infrared sensors are used as collection elements to achieve all the functions of an original anti-tearing protection device, the defects of the original anti-tearing protection device are overcome, safe production of a mine is ensured, and investment of the production cost is reduced.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

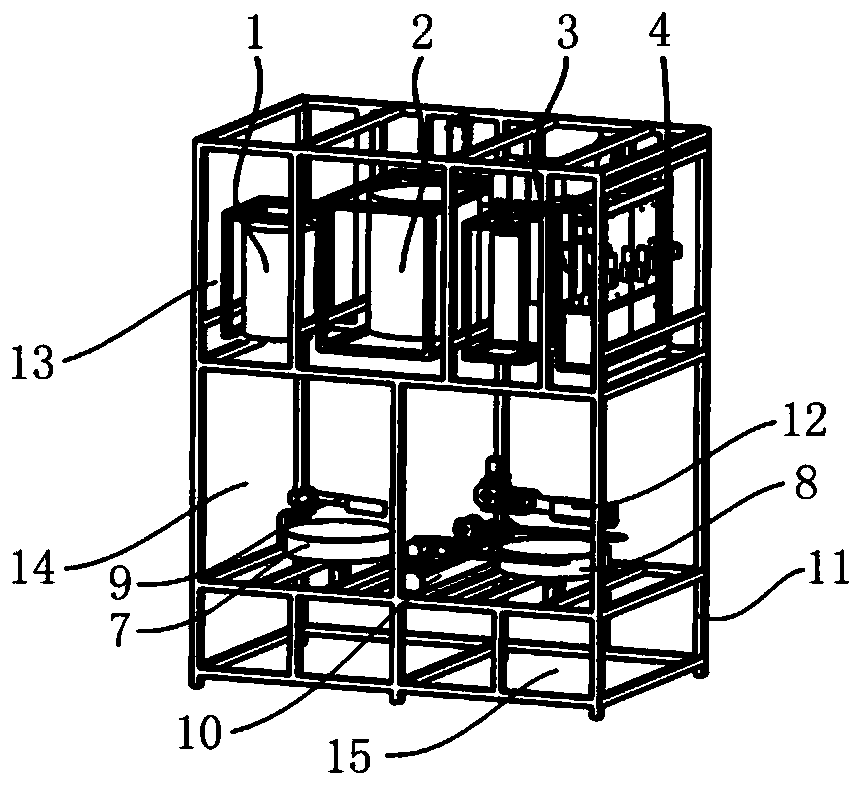

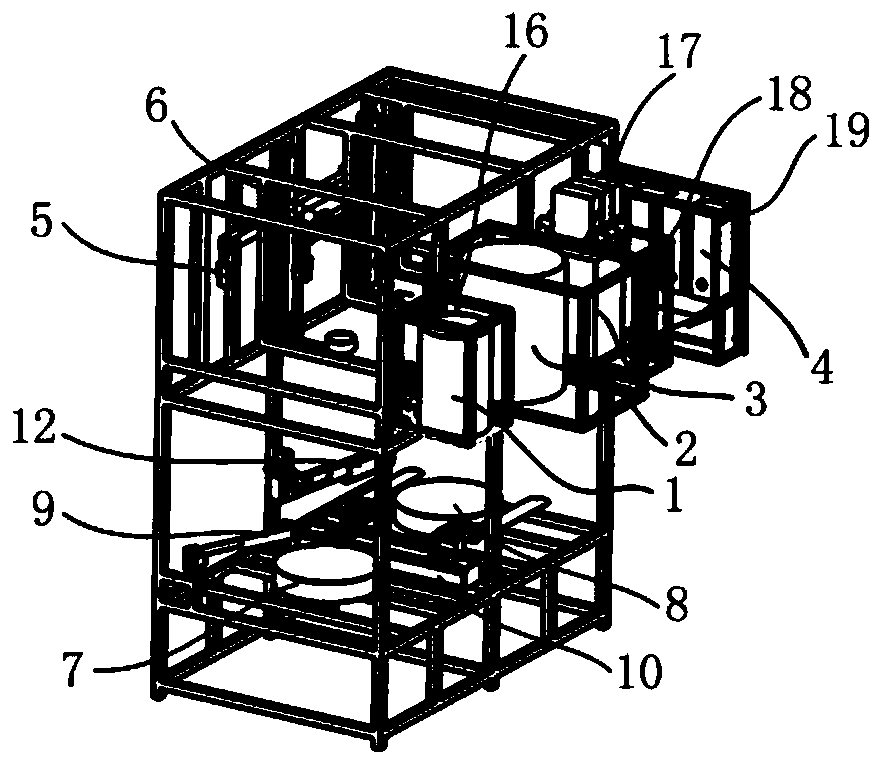

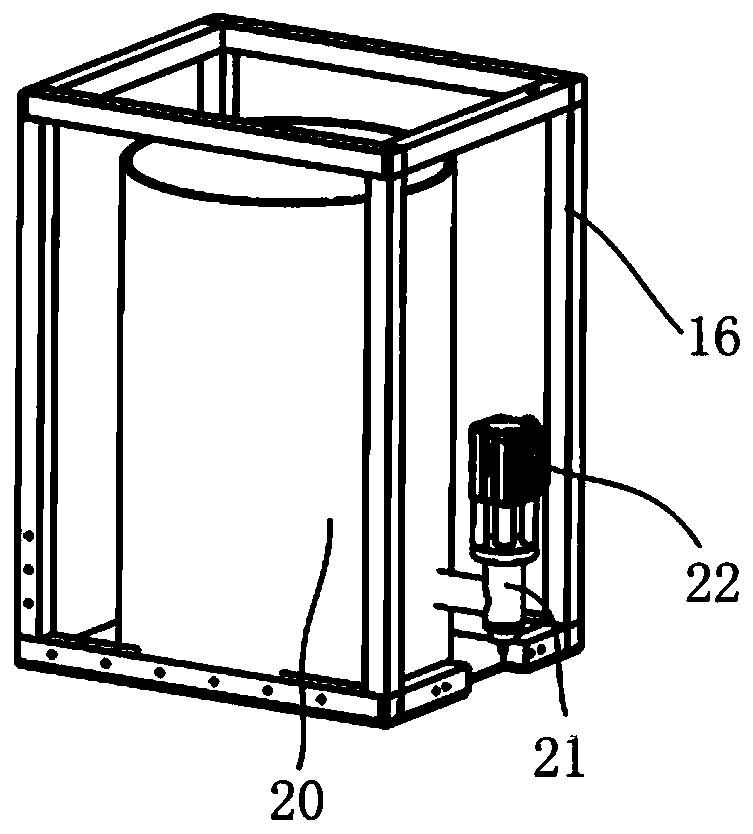

Fully automatic cake food processing and making device and making method and vending machine

ActiveCN111513092AFully automatedMeet safety production requirementsOil/fat bakingApparatus for meter-controlled dispensingProcess engineeringRefrigeration

The embodiment of the invention discloses a fully automatic cake food processing and making device and making method and a vending machine. A machine body framework is subjected to hierarchical design, an upper layer is a raw material refrigeration layer, a thermal insulating layer is arranged below the raw material refrigeration layer, the fully automatic cake food processing and making device adopts a compact cabinet-shaped shape, and has perfect environment and a temperature control functions, raw materials are subjected to refrigeration closing storage, and safety production requirements for foods can be met. Two heating structural members are used for respectively setting heating time to heat two surfaces of a thin pancake, and a paste dilution structural member is used for being close to the heating surface of a first heating structural member, and under rotation of the first heating structural member, paste is made into the thin pancakes. Through a turnover structural member, the thin pancake is transferred between the heating surfaces of the first heating structural member and the second heating structural member, and full automatization of spreading the thin pancake can berealized. Manual operations are replaced, human resource cost can be effectively reduced, and twenty-four hour operation can be realized. The fully automatic cake food processing and making device can provide safe, hygienic, convenient and swift delicious foods for customers all the daytime.

Owner:北京鸣犀科技有限公司

A rotating assembly capable of generating electricity by utilizing self-radial rotating power

PendingCN109245490AExtended service lifeGuarantee job stabilityDynamo-electric machinesElectricityEngineering

The invention discloses a rotating assembly capable of generating electricity by utilizing self-radial rotating power, which includes a rotating shaft, bearings, bearing end caps and magnet mounting plates; n groups of N-pole magnets and n groups of S-pole magnets are uniformly distributed on the magnet fixing disk with center symmetry, and the N-pole magnets and the S-pole magnets are arranged atintervals, and n groups of coil windings are uniformly distributed with center symmetry on the inner surface of the bearing end cover opposite to the magnet surface of the magnet fixing disk, and then is a natural number; The magnet fixing disk is interference-connected with the rotating shaft between the bearing and the bearing end cover, wherein the magnet surface of the magnet fixing disk andthe inner side of the bearing end cover are slidably connected, and the back surface of the magnet fixing disk and the bearing end face are clearance-connected. The invention not only realizes the simultaneous generation of electricity by utilizing the radial rotating power of the invention, but also avoids the generation of fat accumulation, and obviously meets the requirements of energy saving,environmental protection and safe production.

Owner:浙江中控慧机科技有限公司

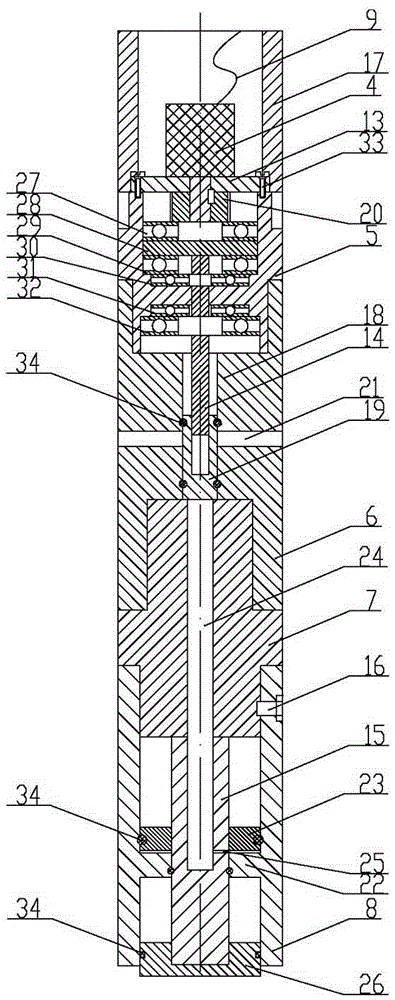

Electronic control hydraulic automatic setting bridge plug device

ActiveCN106499361ARealize the goal of sitting and throwing awayCompact and reasonable structureSealing/packingElectricityEngineering

The invention provides an electronic control hydraulic automatic setting bridge plug device. The electronic control hydraulic automatic setting bridge plug device comprises a control device, a collar locator, a bridge plug hydraulic setting device and a bridge plug, wherein the collar locator, the bridge plug hydraulic setting device and the bridge plug are sequentially fixed and mounted together from top to bottom; the bridge plug hydraulic setting device comprises a driving device, an intermediate joint, a piston sleeve, a connector and a setting drum; and a signal input terminal of the control device and a signal output terminal of the collar locator are electrically connected together by virtue of an electric cable, and the signal input terminal of the control device and a signal input terminal of the driving device of the bridge plug hydraulic setting device are electrically connected together by virtue of an electric cable. The electronic control hydraulic automatic setting bridge plug device is reasonable and compact in structure and easy to use; by virtue of coordinated application of the control device, the collar locator, the bridge plug hydraulic setting device and the bridge plug, the aims of setting and releasing at a preset position by the bridge plug are realized; the electronic control hydraulic automatic setting bridge plug device has the characteristics of safety, reliability, short setting time and convenience in taking out and recycling of the bridge plug; and the operation is facilitated, the working efficiency is improved, and on-site safety production and quality requirements are met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

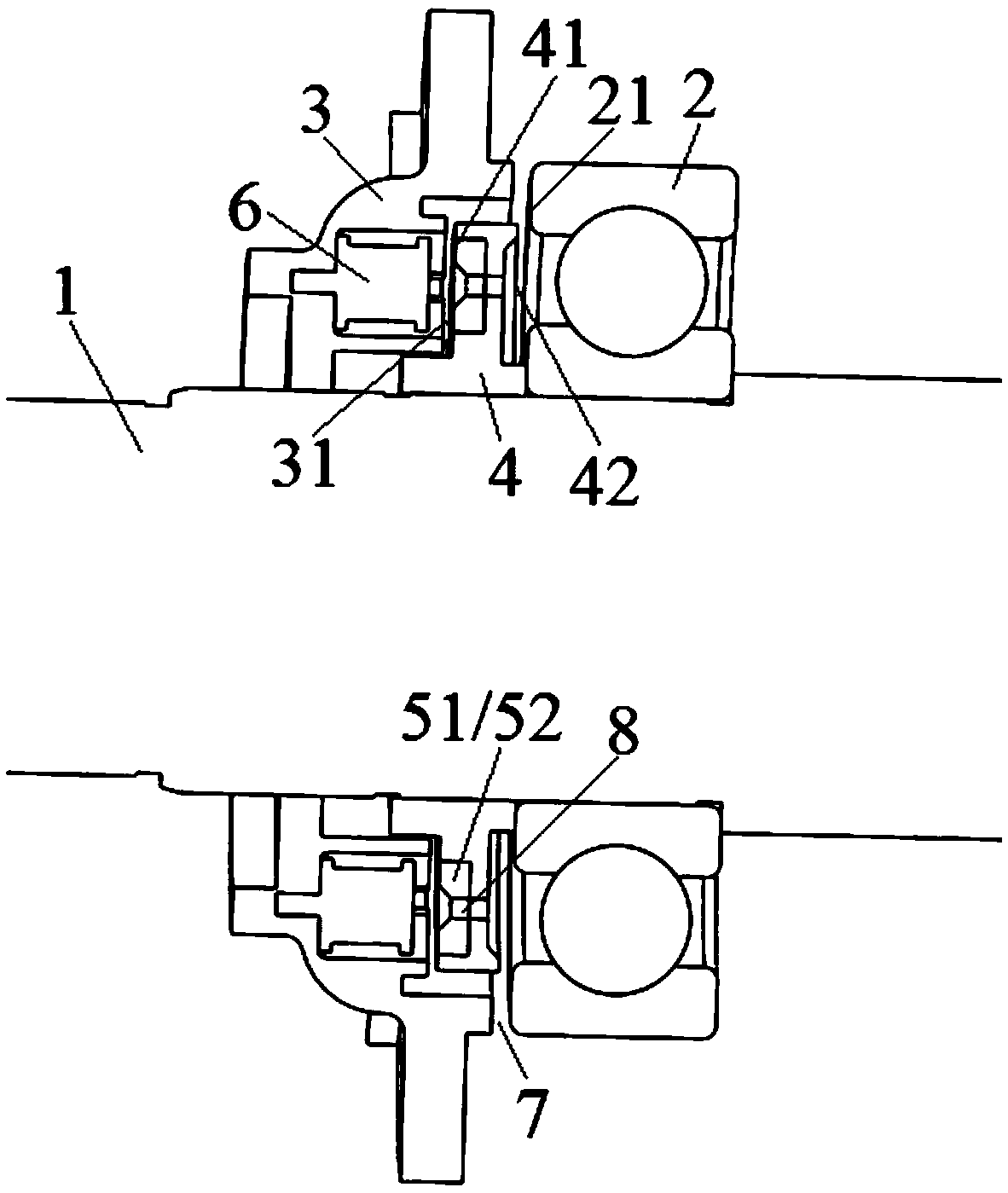

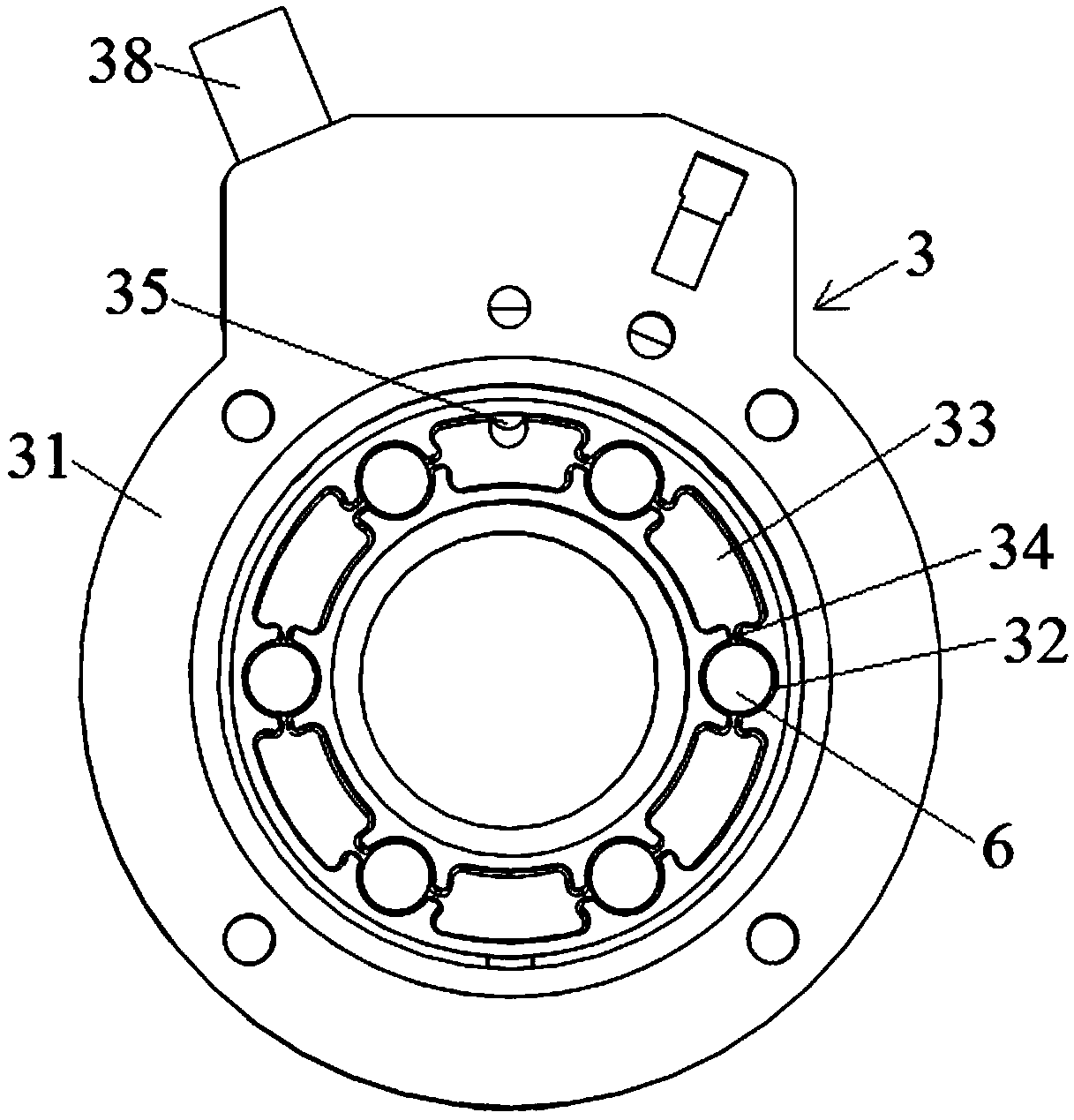

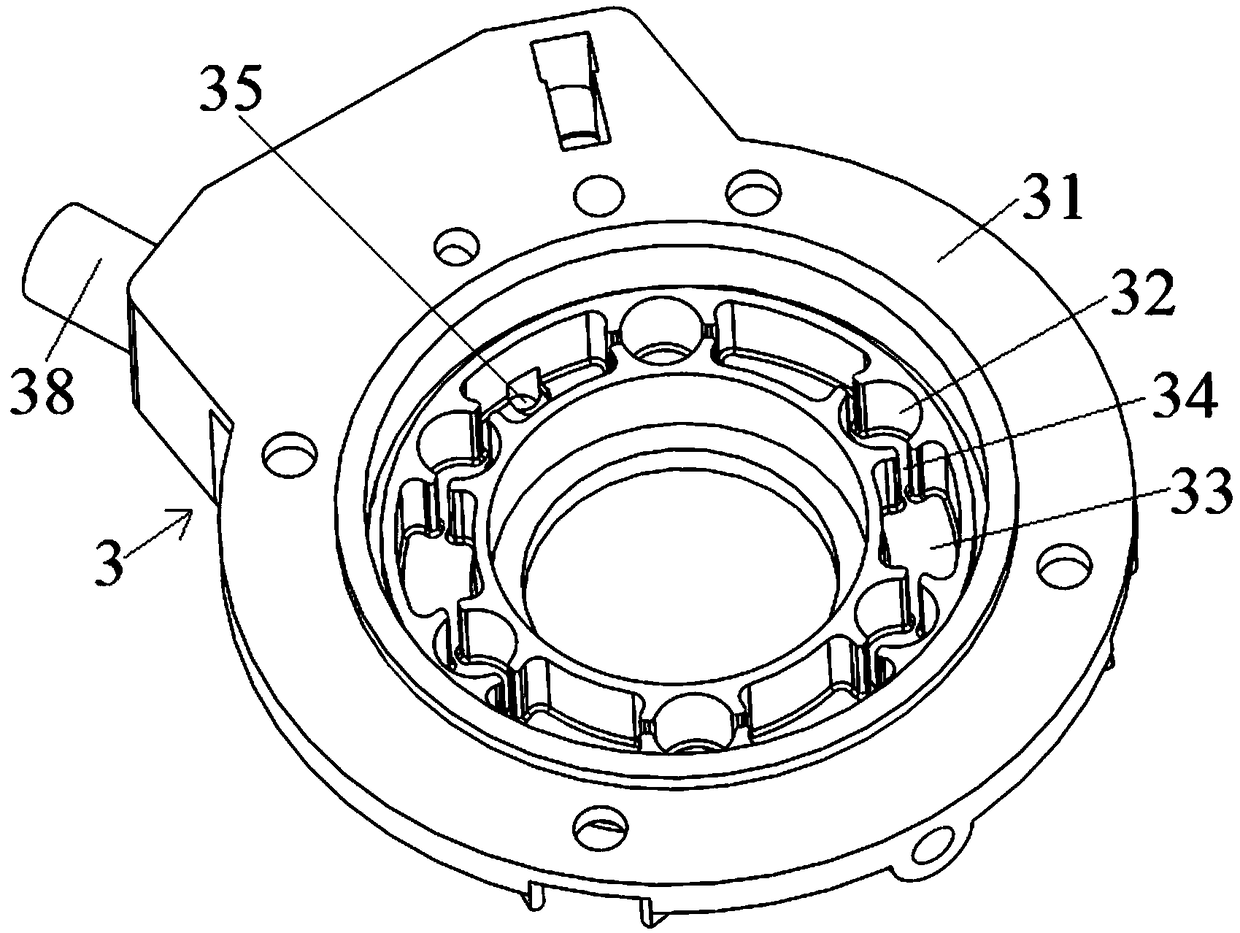

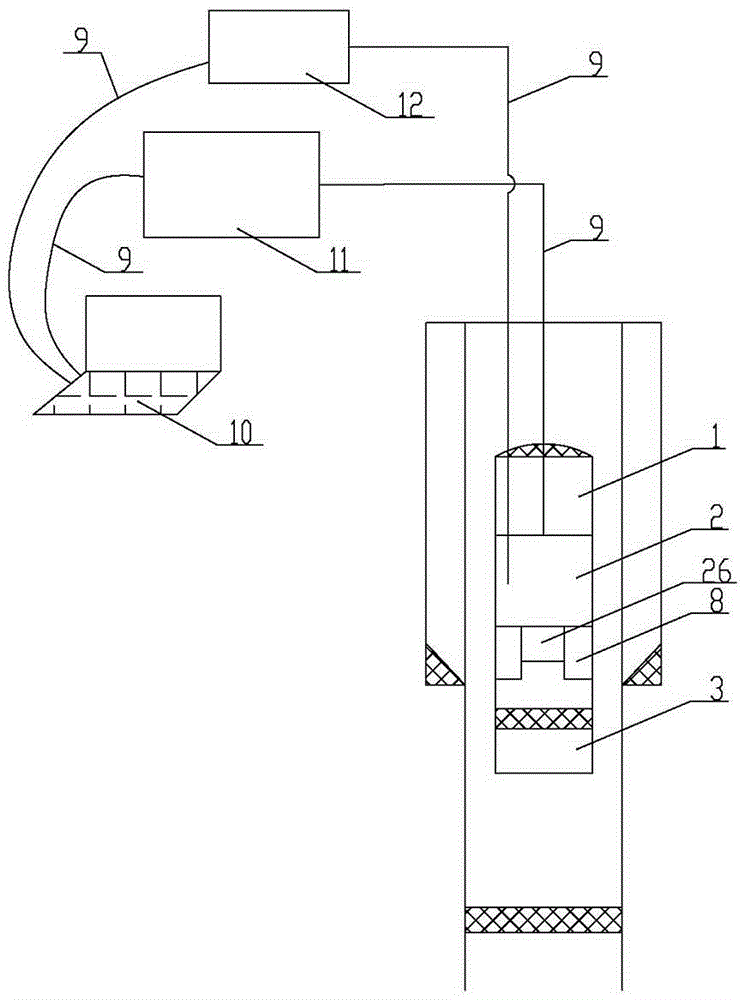

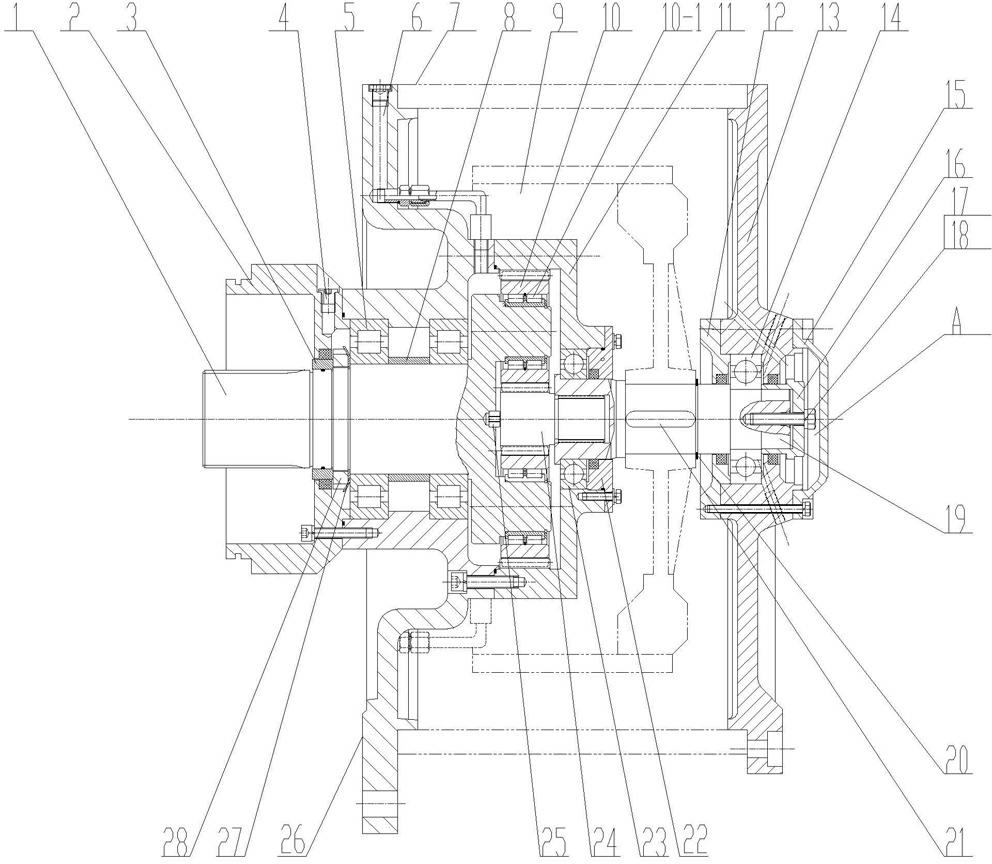

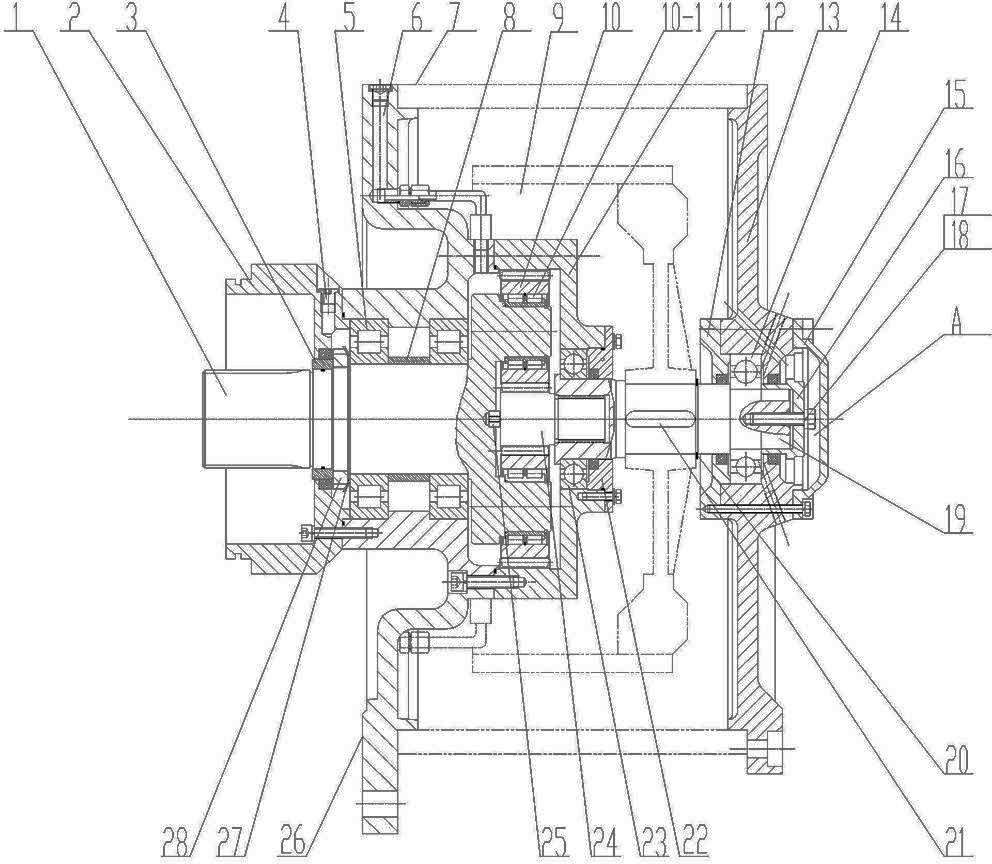

Mining motor built-in traction machine

InactiveCN102332777AReduce volumeEasy to installMechanical energy handlingAgricultural engineeringFront cover

The invention, which belongs to the traction machine field, discloses a mining motor built-in traction machine. The traction machine comprises a motor and a speed reducer, wherein the motor and the speed reducer are integrated in a same housing. The traction machine has a cylindrical housing case; a front end cap and a rear end cap are respectively fixed at two sides of the housing case; a speed reducer housing is fixed on the front end cap and comprises a speed reducer front cover and a tooth ring; and a speed reducer rear cover is fixed at a rear end of the tooth ring. A planet speed changemechanism is installed in the speed reducer housing; a transmission shaft is installed between the speed reducer housing and the rear end cap as well as is connected with a motor rotor; the other endof the transmission shaft is installed at the rear end cap by a bearing II; an inner cover and an outer cover are respectively at an inner side and an outboard of the rear end cap; a shaft end cover is fixed at an end of the transmission shaft; and a motor encoder is installed in a space between the shaft end cover, the rear end cap and the outer cover. According to the invention, a speed reducerand a motor are integrated into one and advantages of the two are combined; a volume of the traction machine is substantially reduced; it is convenient for installation; materials and costs are saved; and the traction machine can be used safely and conveniently.

Owner:XUZHOU KEYUAN HYDRAULIC

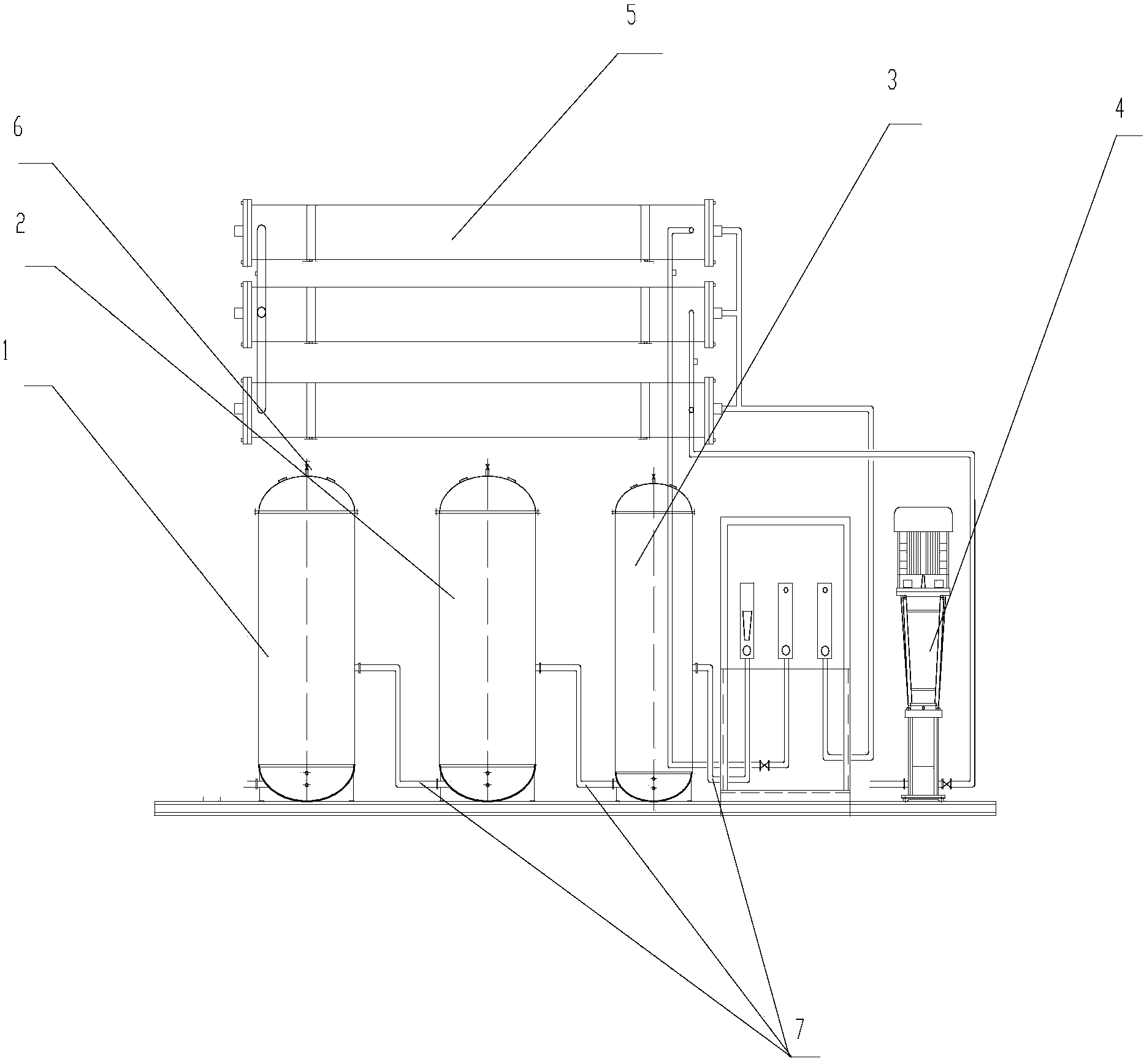

Mine-use water-purifying device

InactiveCN104291457AReasonable structureEasy to installTreatment involving filtrationMultistage water/sewage treatmentFiberReverse osmosis

A mine-use water-purifying device comprising: a precision filter, a carbon fiber filter, a security filter, a high-pressure delivery pump, a reverse osmosis apparatus and a connecting and transporting pipeline. Raw water is purified successively through the precision filter, the carbon fiber filter and the security filter step by step, and is transported to the reverse osmosis apparatus through the high-pressure delivery pump for achieving deep purification. The device is reasonable in structure, is convenient and quick to install, is high in purification rate, can be moved integratedly, can satisfy underground coal mine production and underground coal mine safety production requirements, is suitable for an adverse production environment in underground coal mine and is convenient to inspect, maintain and repair.

Owner:JIANGSU YUANTAIHENG ENVIRONMENTAL ENG

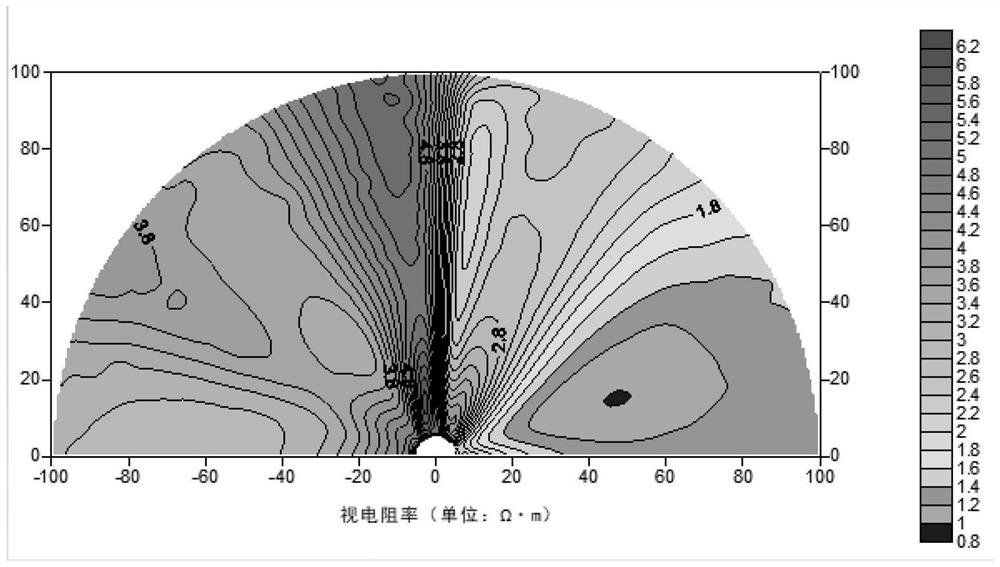

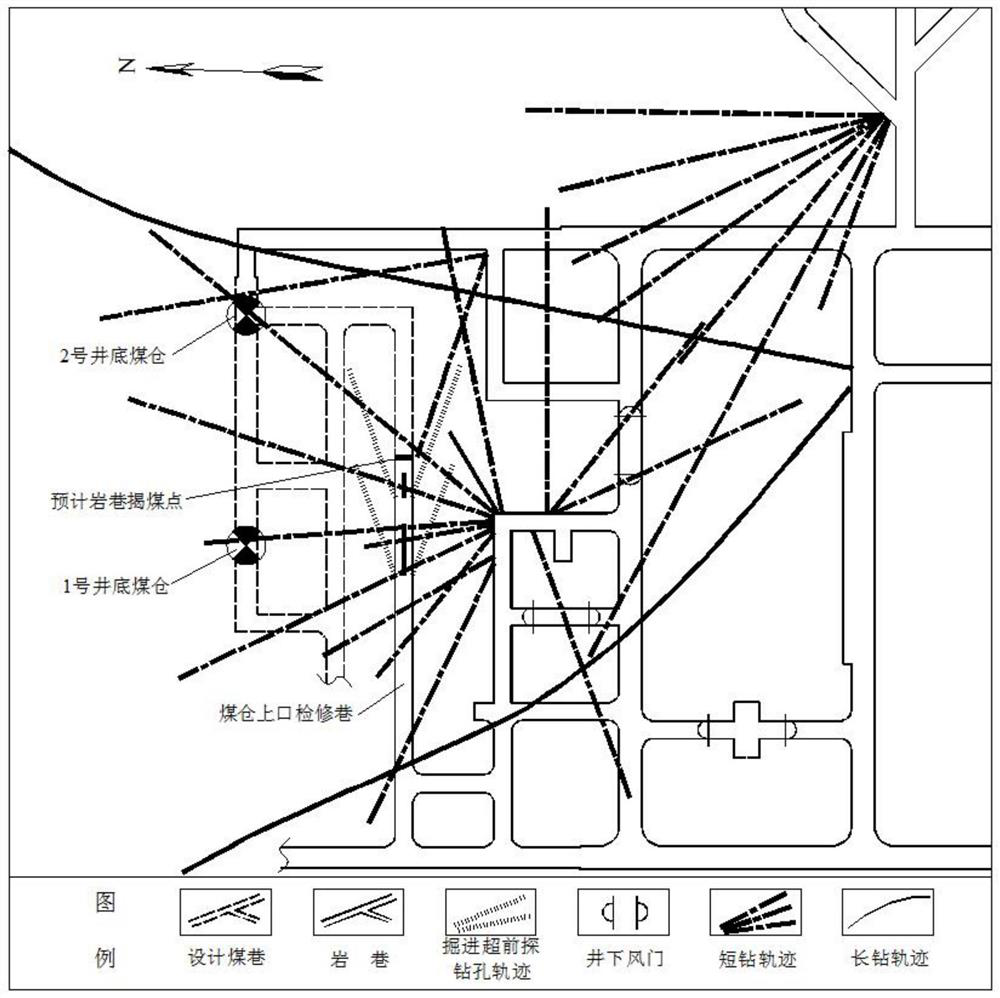

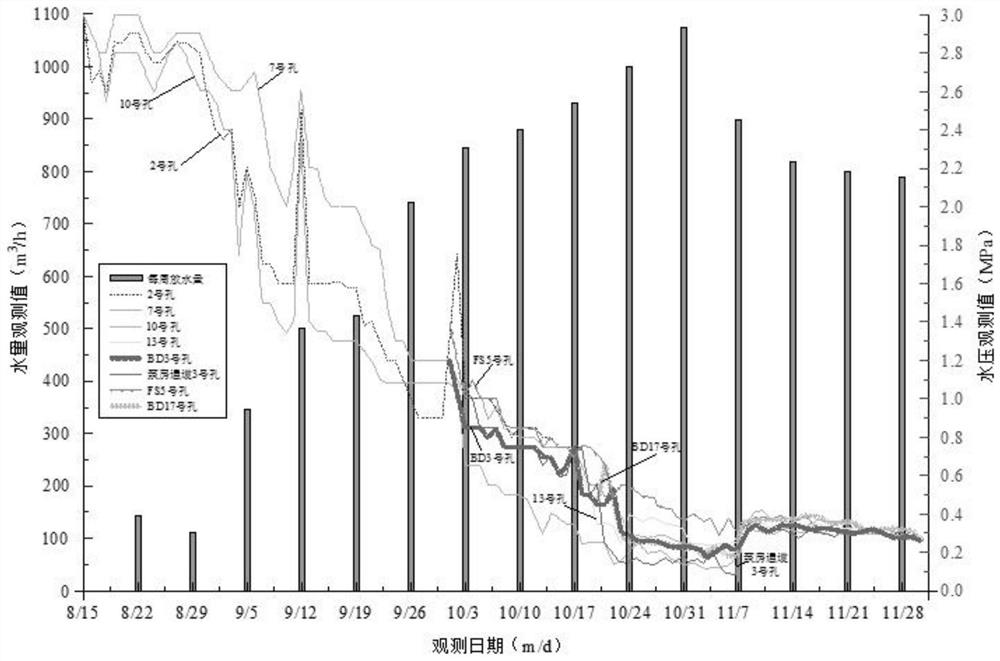

Coal uncovering water prevention and control protection method for safe tunneling in water-rich coal seam rock roadway

InactiveCN113294203AIncrease the difficultyExpedited time requirementsUnderground miningSurface miningWater volumeMining engineering

The invention discloses a coal uncovering water prevention and control protection method for safe tunneling in a water-rich coal seam rock roadway. The coal uncovering water prevention and control protection method comprises the following steps that: in combination with ground transient electromagnetic method exploration and underground direct current method exploration, a water-rich abnormal area distribution condition of an underground rock roadway tunneling coal uncovering preparing area is mastered, and advanced exploration is carried out on a head-on low-resistance abnormal area of a tunneling roadway from a three-dimensional angle; in the underground rock roadway tunneling coal uncovering preparing area, advanced water drainage is carried out by adopting a long drilling and short drilling method, and then a group of advanced exploration holes are respectively constructed in areas which are vertically close to a coal seam bottom plate by 5m and 2m; coal seam water is explored in a target area, and final hole water quantity and water pressure of a drainage drill hole are observed; an effluent water sample of a water-rich coal seam of the drainage drill hole is collected, and the hydrochemical characteristics of the effluent water sample are analyzed; and the coal seam in the hole and the water outlet condition are observed and researched by adopting a drilling observation instrument. According to the method, the economic investment is relatively small, the construction period is short, and the time requirement for quickening infrastructure construction of a mine is met.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

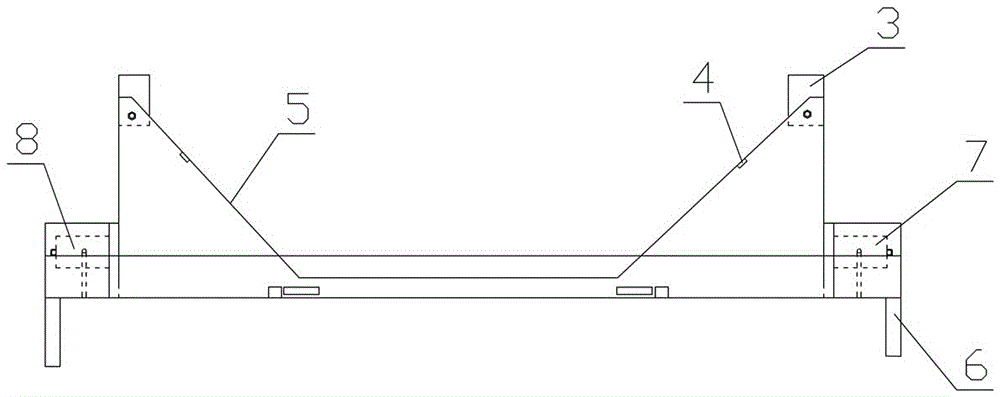

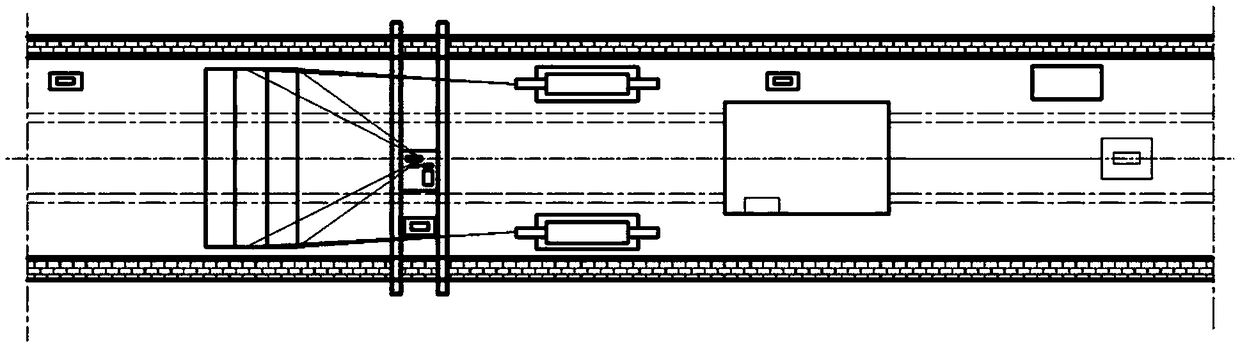

Deviation protection method and device for rubber belt of non-contact coal mine conveyor

ActiveCN106144492ASolve the problem of wear and tearImprove work efficiencyConveyorsControl devices for conveyorsFixed frameEngineering

The invention discloses a deviation protection method and device for a rubber belt of a non-contact coal mine conveyor. Two infrared receivers are mounted on longitudinal beams on the two sides of the conveyor through lower fixed frames correspondingly. The middle portions of two infrared transmitters are rotationally connected with the lower ends of two vertical rods correspondingly. The upper ends of the two vertical rods are connected with a cross rod. The upper end of the middle of the cross rod is connected with the lower end of a suspender. A controller is arranged on the suspender. A connecting plate is arranged at the upper end of the suspender and fixed to a tunnel top wall over the rubber belt of the conveyor through a connecting piece. The upper portions of the two vertical rods are each provided with a wire coil. A wire of each infrared transmitter passes through the wire coil on the same vertical rod and then is connected with the controller. A splayed structure is formed by the two infrared transmitters and the two infrared receivers. According to the deviation protection method and device, the protection action is sensitive and reliable, the service life is prolonged, the production cost is reduced, and work efficiency is improved.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

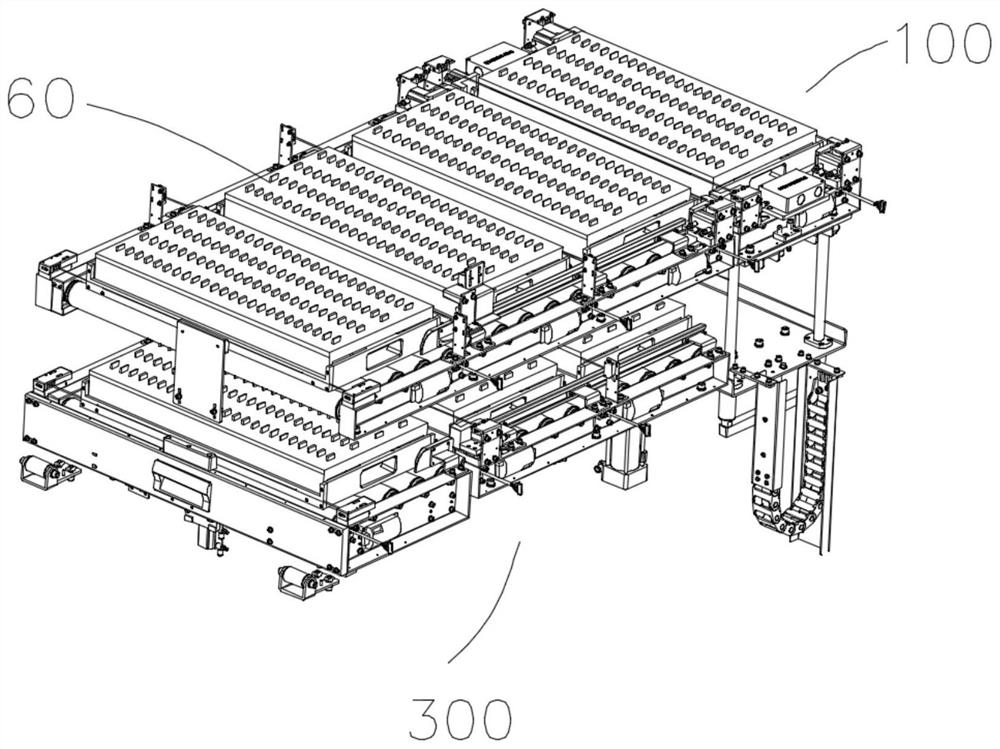

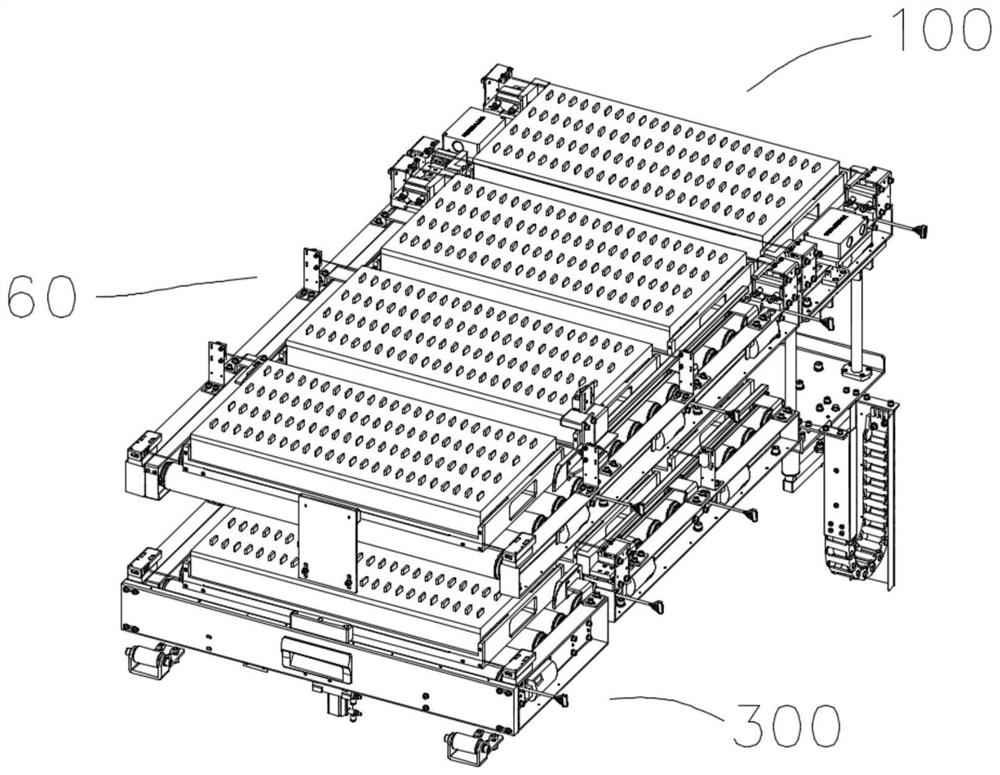

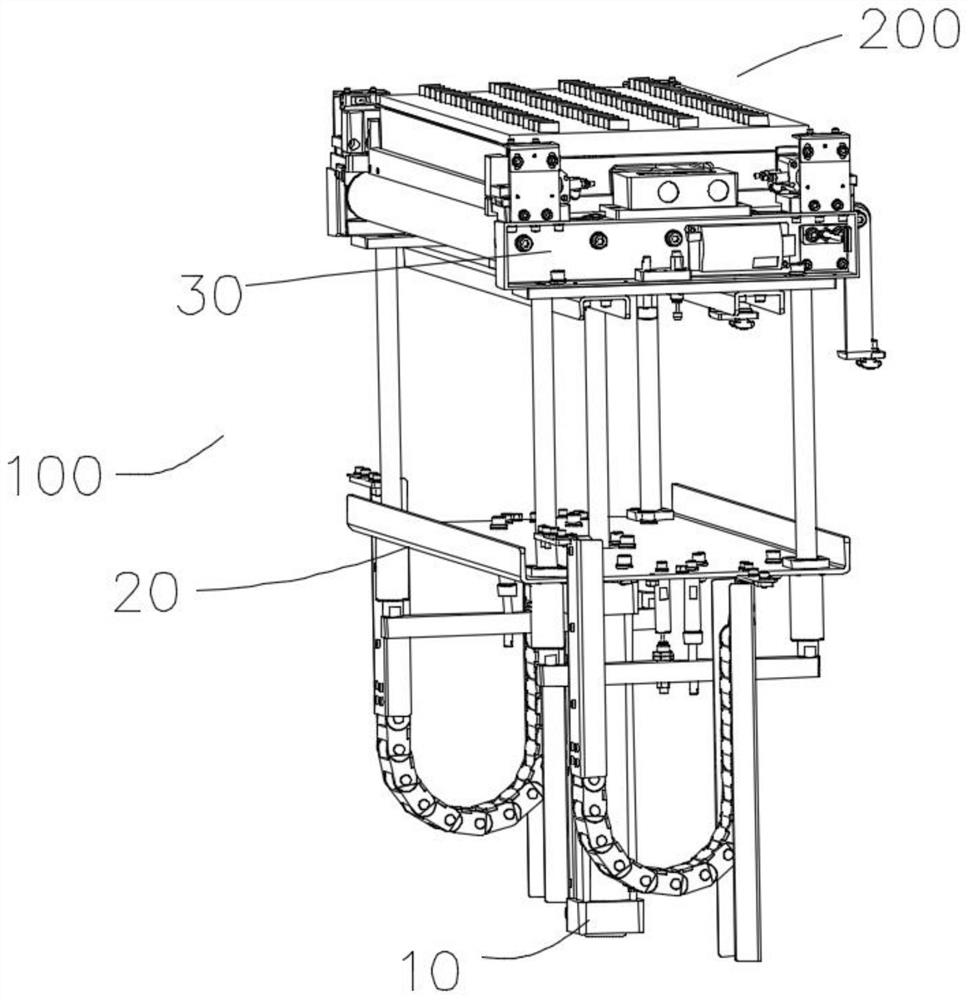

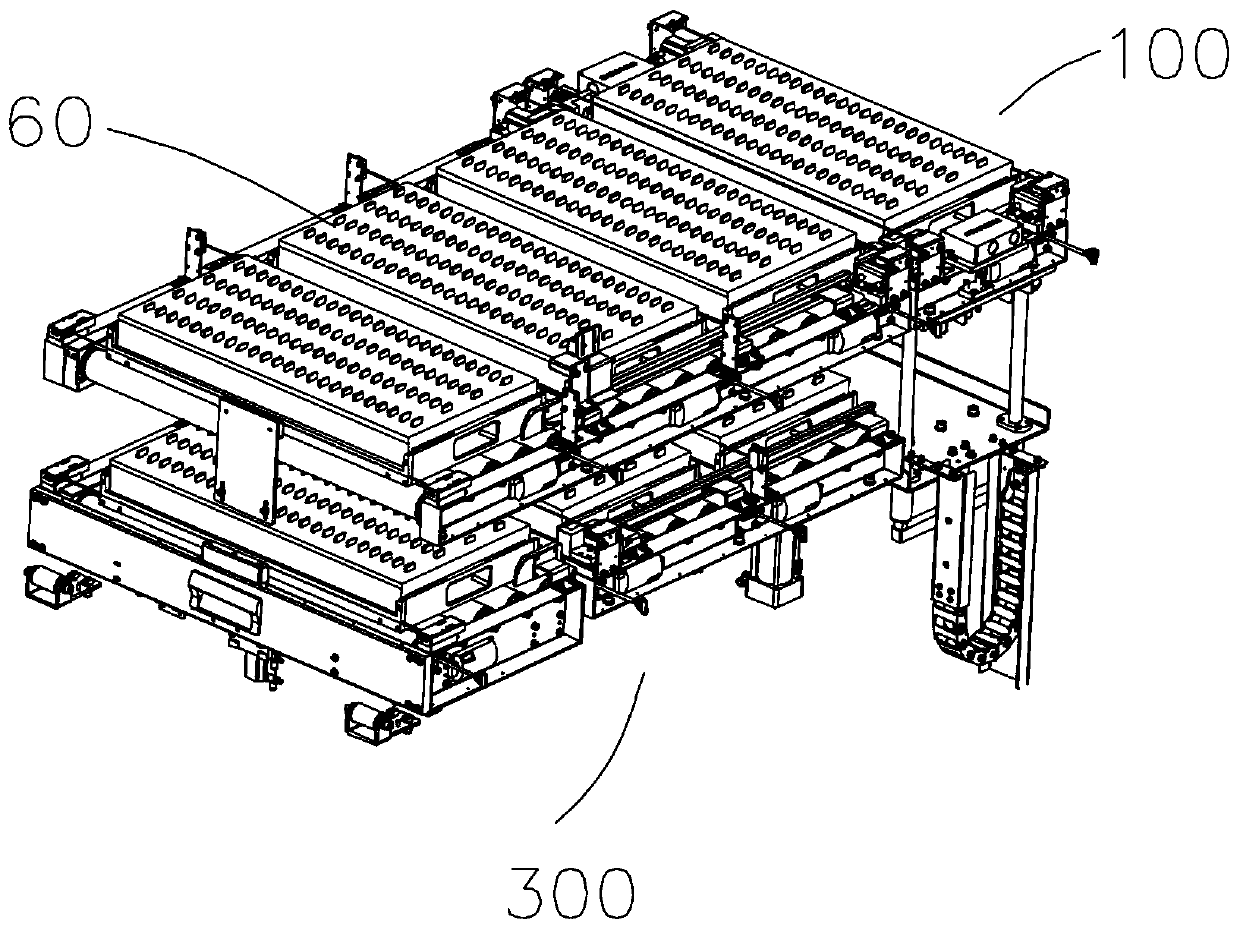

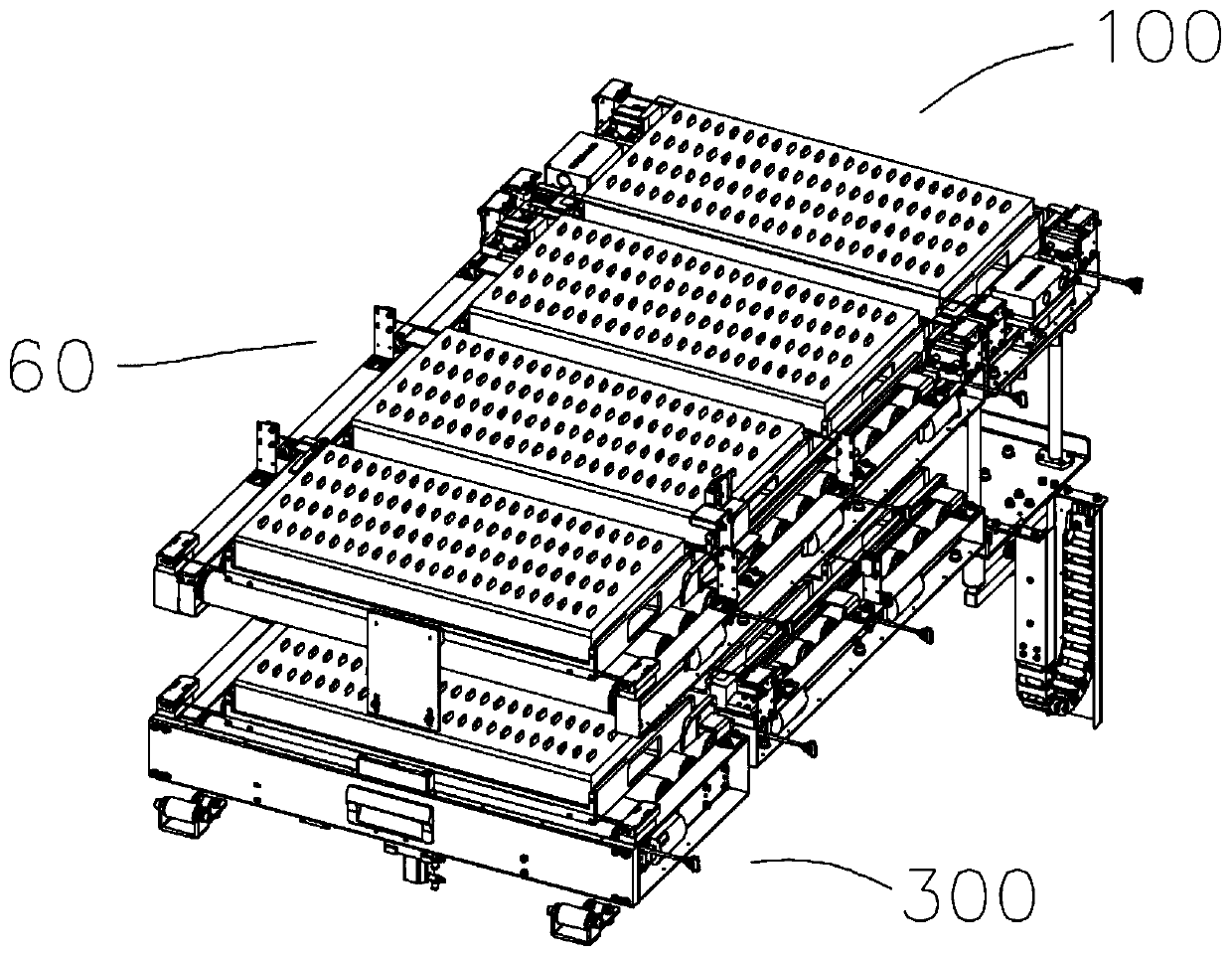

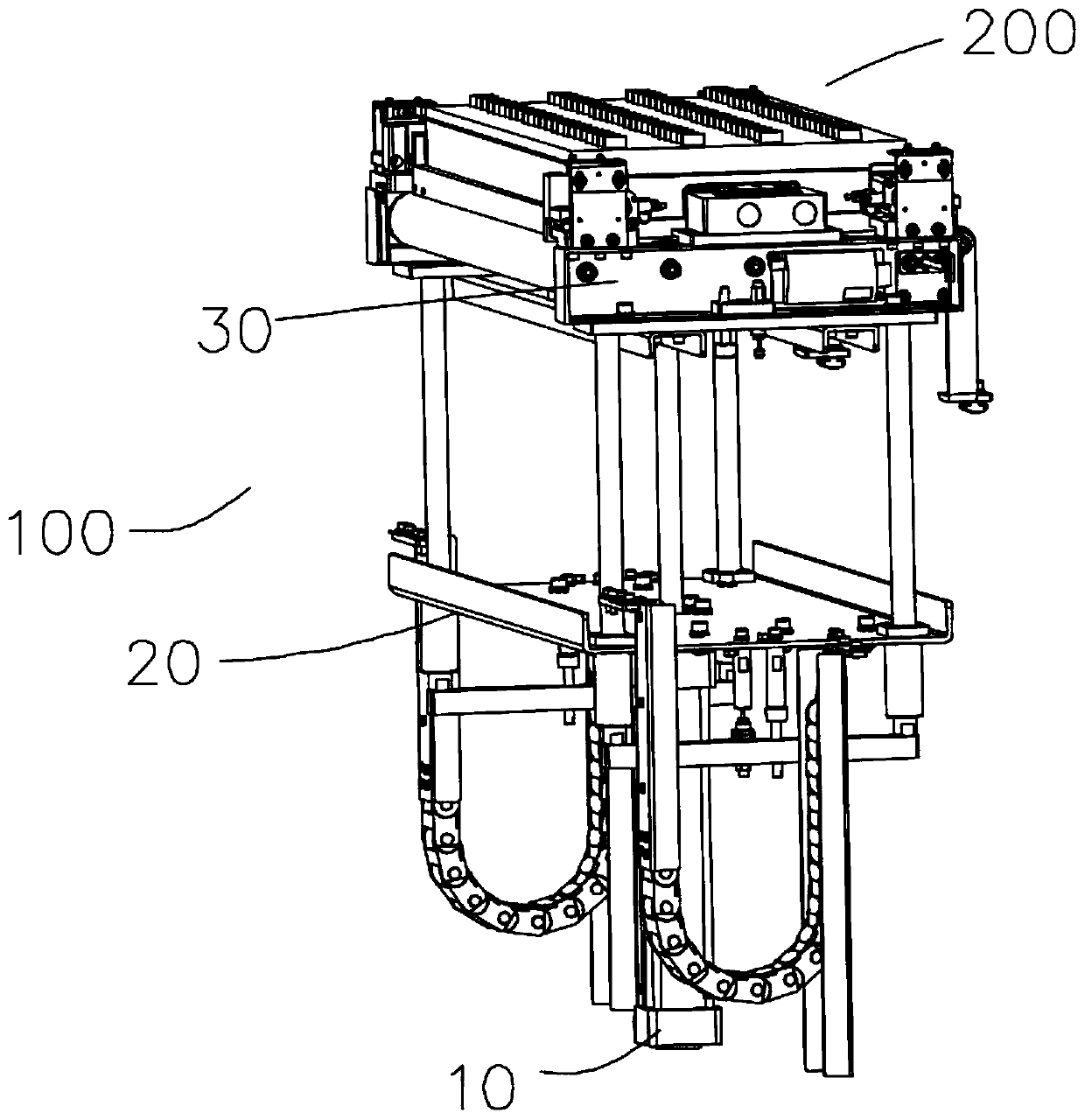

Lithium battery tray automatic loading and unloading roller line

ActiveCN110282379BRealize automatic loading and unloadingMeet safety production requirementsConveyor partsMechanical conveyorsEngineeringMechanical engineering

The invention discloses an automatic loading and unloading drum line for lithium battery trays, which includes a loading and unloading device, an upper conveying line and a lower conveying device. The loading and unloading device includes a driving mechanism, a receiving seat and a moving conveying mechanism. The driving mechanism includes a bottom cylinder and a middle part. The connecting rod, the upper conveying line includes several upper segmental conveying mechanisms and the upper main frame body, the upper segmental conveying mechanism is installed on the upper main frame body; the lower conveying device includes a drawer-type conveying mechanism and a matching conveying mechanism, the drawer-type conveying The mechanism includes a bottom fixing frame, a connecting frame and an edge conveying mechanism. In actual use, the conveying parts are conveyed to the loading and unloading device along the upper conveying line, and the feeding and unloading device transfers the conveying parts to the lower conveying device, and the whole machine replaces the manual to realize automatic loading and unloading of lithium batteries. Integrated, while meeting the safety production requirements of the lithium battery industry, the structure is compact, lightweight, simple, and easy to maintain and operate.

Owner:深圳市运泰利自动化设备有限公司

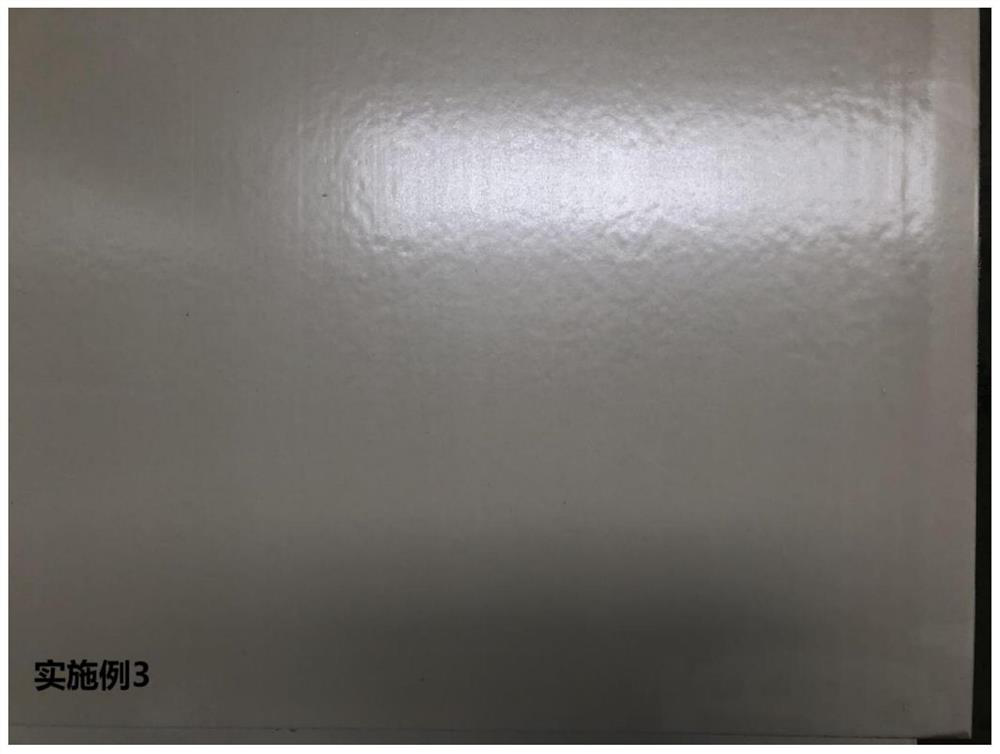

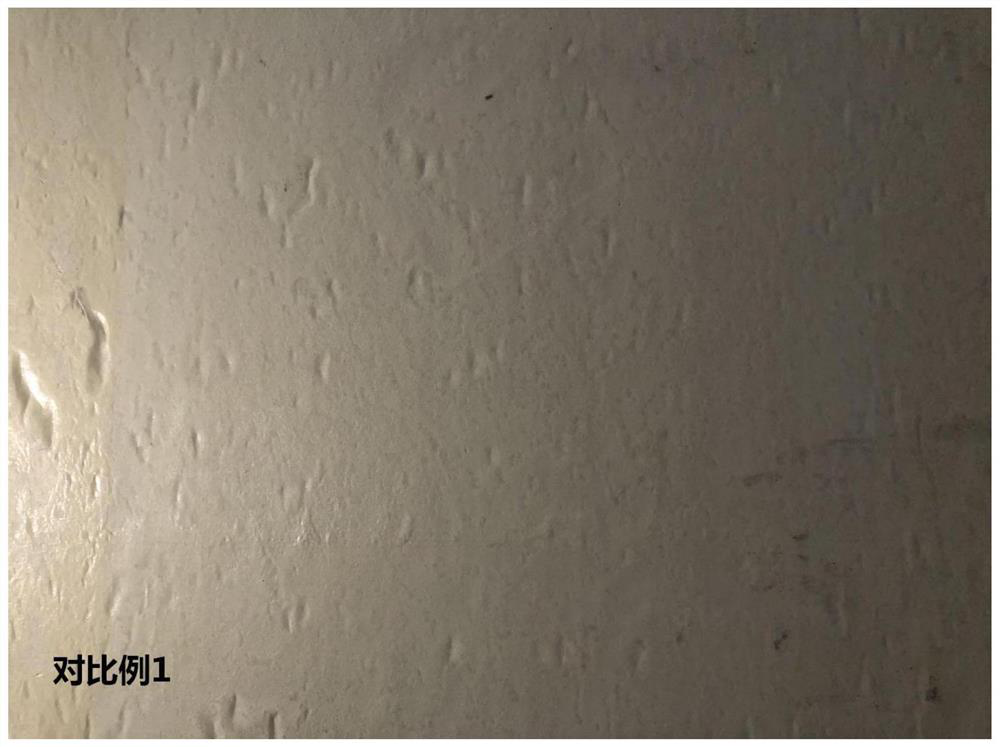

Composition for reacting with isocyanate, rigid polyurethane sheet and preparation method thereof

ActiveCN112375195BImprove surface qualityCompliant with flat surface requirementsPolymer sciencePtru catalyst

The present application provides a composition for reacting with isocyanate, comprising a polyol, a catalyst, a physical blowing agent, a syntactic foam stabilizer, water and a flame retardant; the syntactic foam stabilizer has a first component, the first One component is a silicon-carbon bond type polyether siloxane terminated with at least one of an alkyl group or an acyl group; the physical blowing agent comprises cyclopentane. The present application also discloses a method for producing a rigid polyurethane sheet by using the above composition and polymethylene polyphenyl polyisocyanate and a rigid polyurethane sheet produced by the method. After the syntactic foam stabilizer is used, it has better stability due to effectively improving the surface tension of the composition. The produced rigid polyurethane sheet can effectively reduce the voids on the foam surface, and has the advantages of low thermal conductivity and good dimensional stability.

Owner:南京红宝丽新材料有限公司

Automatic feeding and discharging roller line for lithium battery tray

ActiveCN110282379ARealize automatic loading and unloadingMeet safety production requirementsConveyor partsMechanical conveyorsElectricityFixed frame

The invention discloses an automatic feeding and discharging roller line of a lithium battery tray. The automatic feeding and discharging roller line comprises a feeding and discharging device, an upper part conveying line and a lower part conveying device, wherein the feeding and discharging device comprises a driving mechanism, a bearing seat and a movable conveying mechanism; the driving mechanism comprises a bottom air cylinder and a middle connecting rod; the upper part conveying line comprises a plurality of upper part section type conveying mechanisms and an upper main frame body, wherein the upper part section type conveying mechanism is arranged on the upper main frame body; the lower part conveying device comprises a drawer type conveying mechanism and a matched conveying mechanism, wherein the drawer type conveying mechanism comprises a bottom fixing frame, a connecting frame and an edge conveying mechanism. During actual use, conveyed pieces are conveyed to the feeding and discharging device along the upper part conveying line, the feeding and discharging device is used for transferring the conveyed pieces to the lower part conveying device, and lithium batteries can be automatically loaded and unloaded by a whole machine instead of manual operation, thus being efficient and fast in equipment, achieving the integration of collecting and feeding, meanwhile, and meeting requirements of safety production of the lithium-electricity industry. The automatic feeding and discharging roller line of the lithium battery tray has the advantages of being compact, light and simple in structure and convenient in maintenance and operation.

Owner:深圳市运泰利自动化设备有限公司

Citronella oil extraction method

InactiveCN110106025AShort extraction timeImprove extraction rateEssential-oils/perfumesCitronella oilEngineering

Belonging to the field of fine chemicals, the invention discloses a citronella oil extraction method. The method includes: cutting a dried citronella stem leaf product into short pieces; then performing tabletting on the cut citronella stem leaf, then putting the product into a filter bag, and conducting feeding into subcritical equipment extraction kettle; pouring a subcritical fluid into the extraction kettle; and controlling the pressure and temperature for static extraction and decompression separation to obtain a citronella extract. The method provided by the invention has the advantagesof short extraction time, high extraction rate, simple and feasible process, low extraction cost, excellent product quality, environmental friendliness, industrializability, etc.

Owner:南宁辰康生物科技有限公司

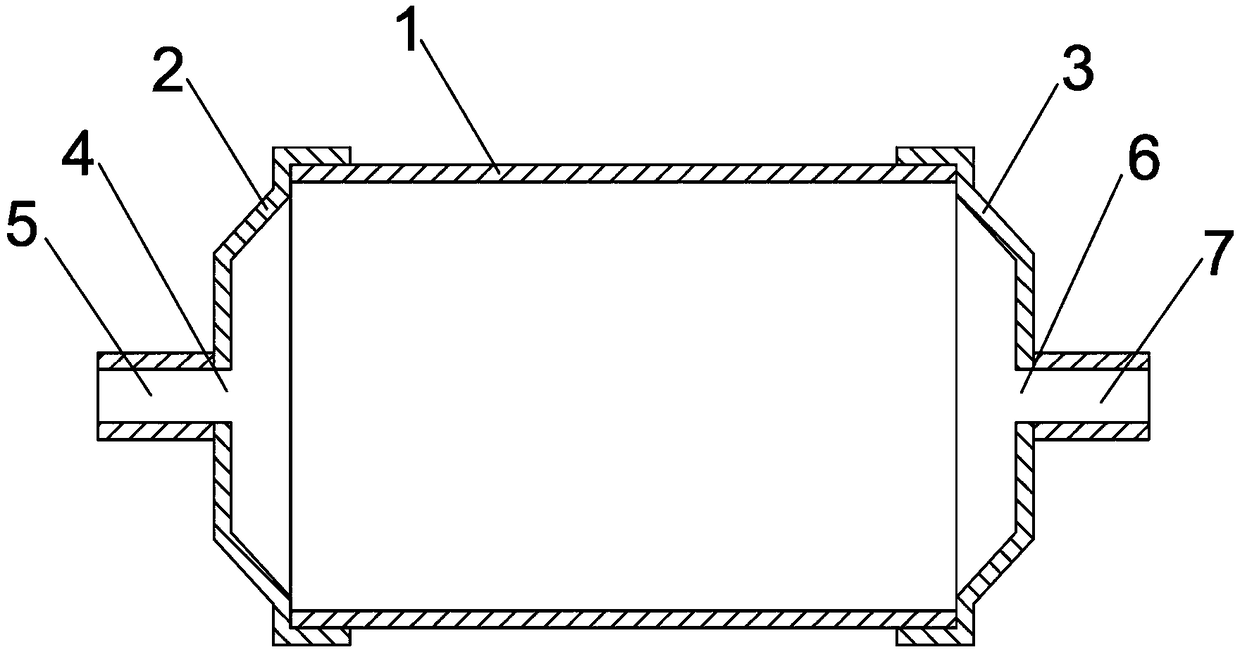

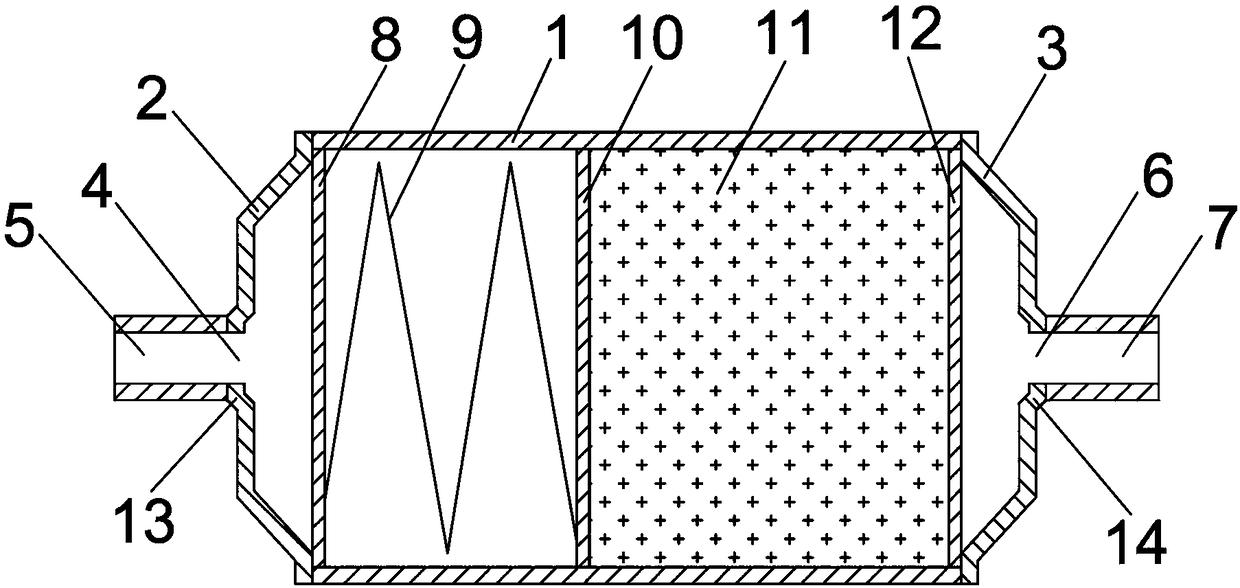

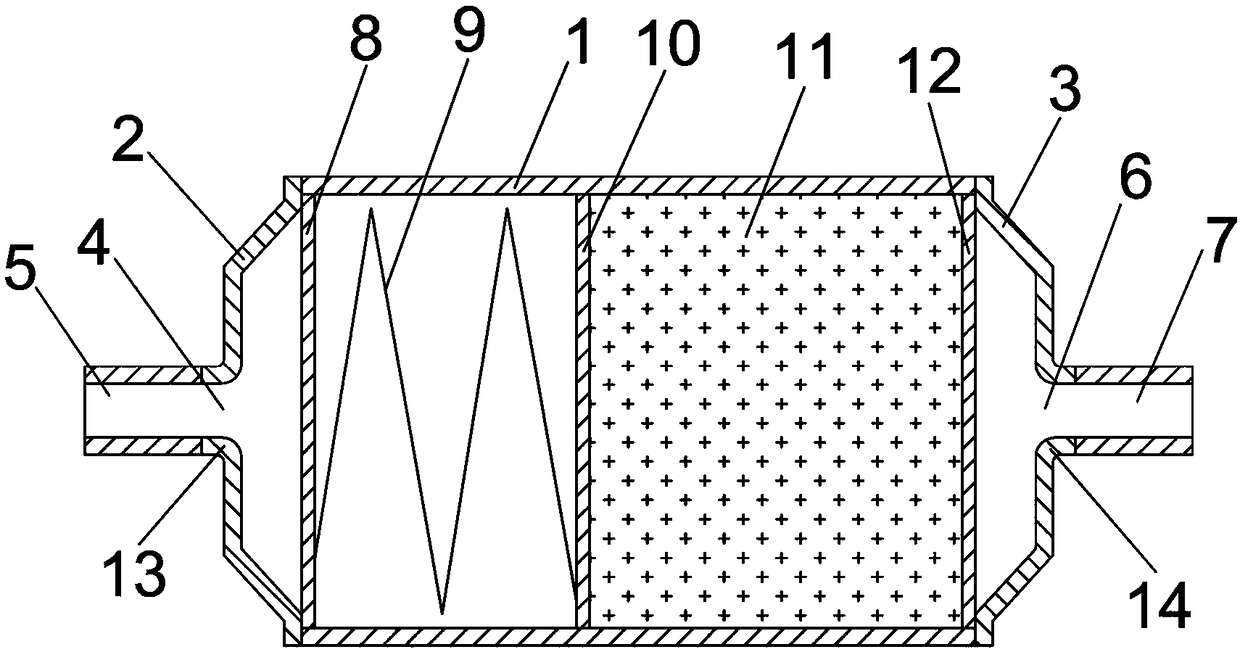

Novel drying filter and preparation method thereof

PendingCN109442823AReduce leak rateLow costDispersed particle filtrationTransportation and packagingFriction weldingMegasonic cleaning

The invention discloses a novel drying filter and a preparation method thereof and belongs to the technical field of refrigerating accessories. The filter comprises a barrel body, a left end cover anda right end cover; the left end cover is provided with a gas inflow hole, and a gas inflow pipe is welded to the edge of the gas inflow hole through a first connection portion; and the right end cover is provided with a gas outflow hole, and a gas outflow pipe is welded to the edge of the gas outflow hole through a second connection portion. According to the novel drying filter and the preparation method thereof, due to the fact that to-be-welded faces of various parts are machined, oil dirt and impurities are removed due to cleaning of an ultrasonic cleaning machine; then the left end coverand the gas inflow pipe are subjected to friction welding to be made into a left end cover assembly; the right end cover and the gas outflow pipe are subjected to friction welding to be made into a right end cover assembly; finally, the two ends of the barrel body are subjected to friction welding with the left end cover assembly and the right end cover assembly correspondingly, and a finished filter is made; and flame brazing and carbon dioxide protecting welding are changed into friction welding, the energy consumption can be greatly lowered, the leaking rate of the welded portion is lowered, and the phenomenon that due to flame brazing, the welded portion is dirty in surface and has residues is improved.

Owner:ZHEJIANG MAIDI REFRIGERATION TECH CO LTD

Ferrite material, multilayer chip inductor and preparation method thereof

ActiveCN104250096BImprove uniformityImprove solubilityInductances/transformers/magnets manufactureFixed signal inductancesWater basedPolyvinyl alcohol

The invention provides a ferrite material, a laminated sheet type inductor and a preparation method of the laminated sheet type inductor, wherein the ferrite material comprises the following components by the weight percentage: 32-52 parts of a ferrite powder, 4-9 parts of an adhesion agent, 40-60 parts of a solvent, 1.5-5 parts of a plasticizer, 0.5-2.5 parts of a dispersion agent, 0.5-3 parts of an emulsifier, and 0.05-0.25 part of a defoaming agent, wherein the adhesion agent is polyvinyl alcohol or a compound adhesion agent of polyvinyl alcohol and water-borne acrylic acid. The ferrite material provided by the invention adopts a water-based solvent system; and with the synergistic effect among the components, the ferrite material has excellent rheological property and shrinkage property and can eliminate bubbles and needle eyes on a thin strip, and thus an excellent-performance ferrite membrane sheet and the excellent-performance thinning laminated sheet type inductor are obtained, and the defects of VOC emissions, high production cost and large energy consumption caused due to the use of organic solvents in an traditional inductor production are reduced.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com