Composition for reacting with isocyanate, rigid polyurethane sheet and preparation method thereof

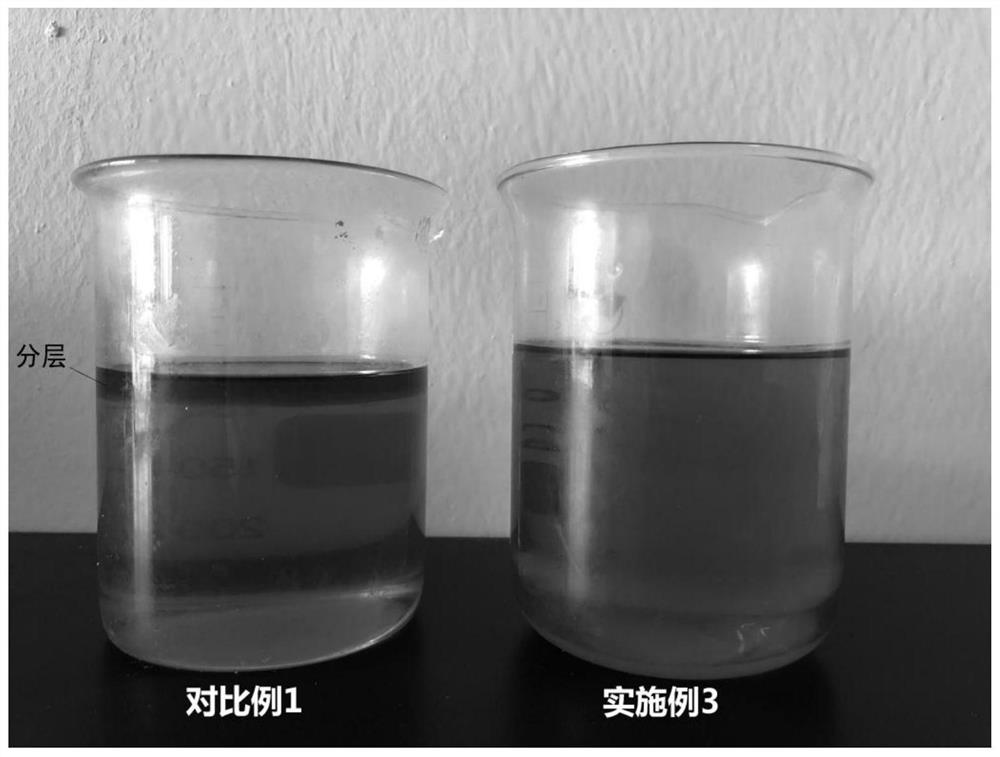

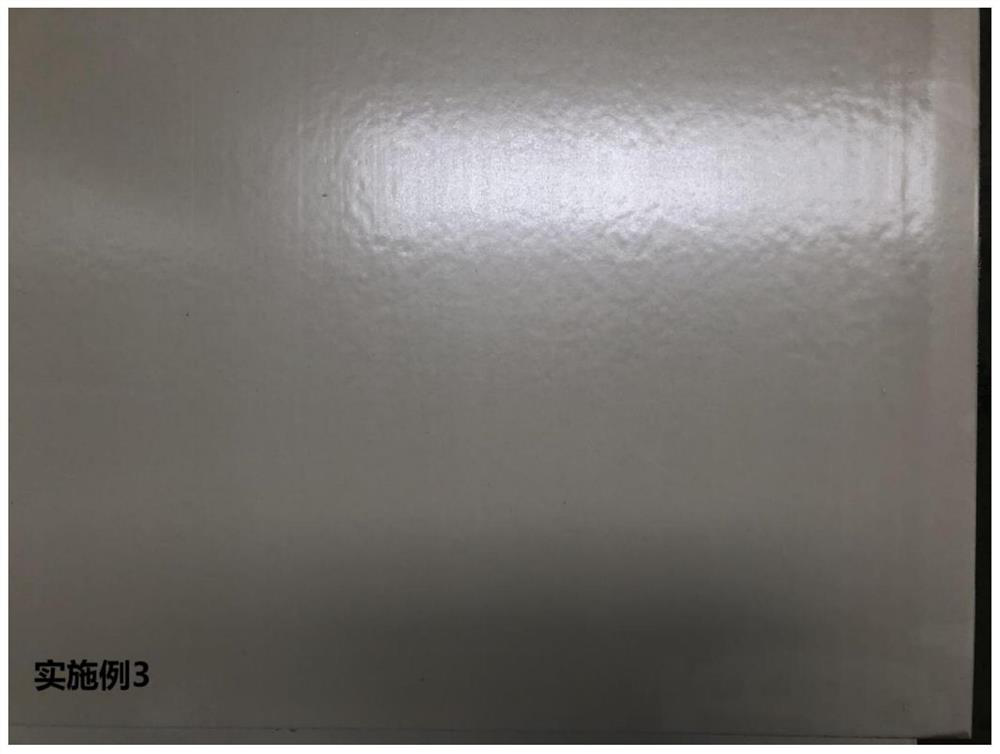

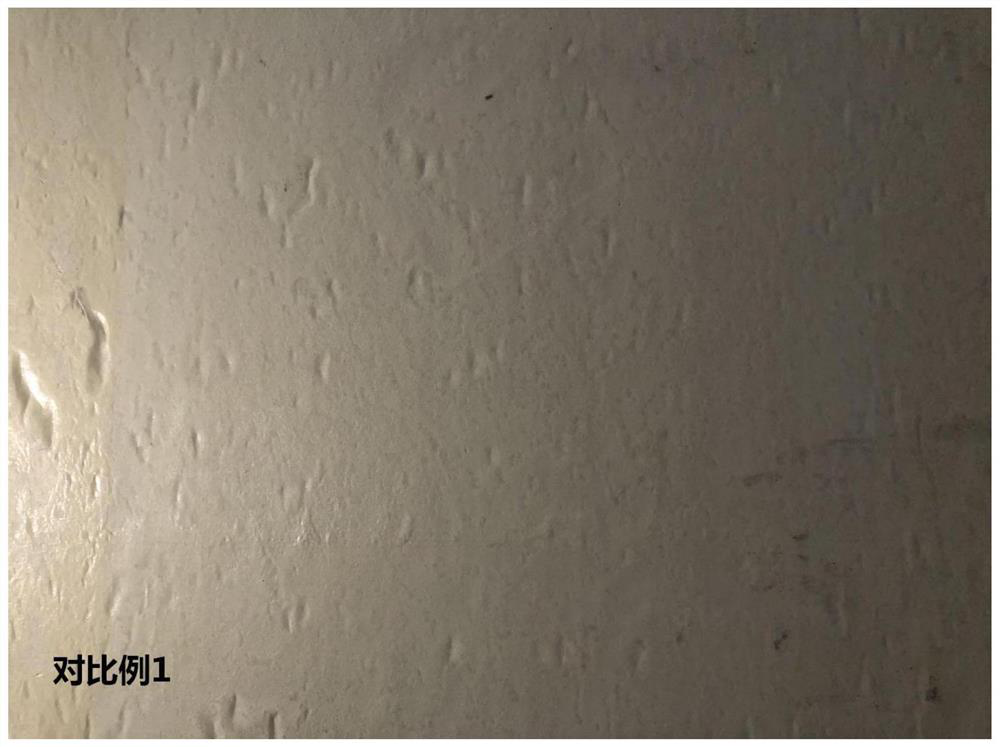

A technology of isocyanate and composition, applied in the field of thermal insulation materials, can solve problems such as unsatisfactory long-term storage and limited use range, and achieve the effects of good dimensional stability, good surface quality and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In the following embodiments, the steps of the preparation method of the rigid polyurethane sheet are as follows:

[0047] (1) Mix the first component of polyol, catalyst, syntactic foam stabilizer, water, and flame retardant uniformly in the container to obtain the first mixture; then add the second component of physical foaming agent and syntactic foam stabilizer in turn , fully mixed to obtain a composition, which is called component A; in the process of preparing component A, the temperature is controlled at 20-30 °C;

[0048] (2) Component A and Component B are respectively poured into the foaming machine material tank, fully mixed and poured on the surface layer material, and a rigid polyurethane sheet is obtained after lamination curing and curing;

[0049] Component B is polymethylene polyphenyl polyisocyanate.

[0050] Table 2 lists Component A, Component B, and mixing temperature for each example.

[0051] In the present embodiments, the surface layer materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com