Infrared opposite-type coal mine conveyor adhesive tape anti-tearing protection method and device

An infrared transmitter and conveyor technology, which is applied to conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of prolonged protection action time, large tape tearing degree, and high cost input, and achieves simple structure and low cost. Low cost and the effect of ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

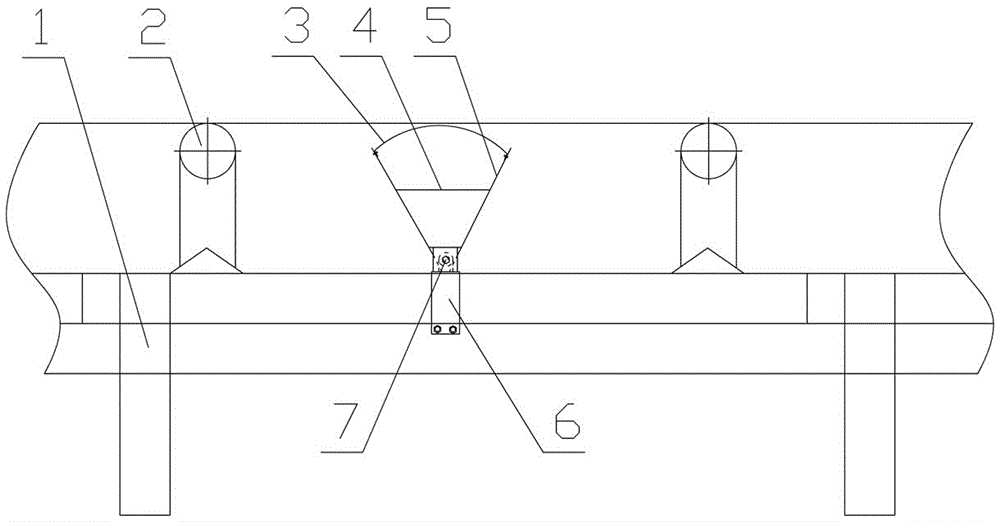

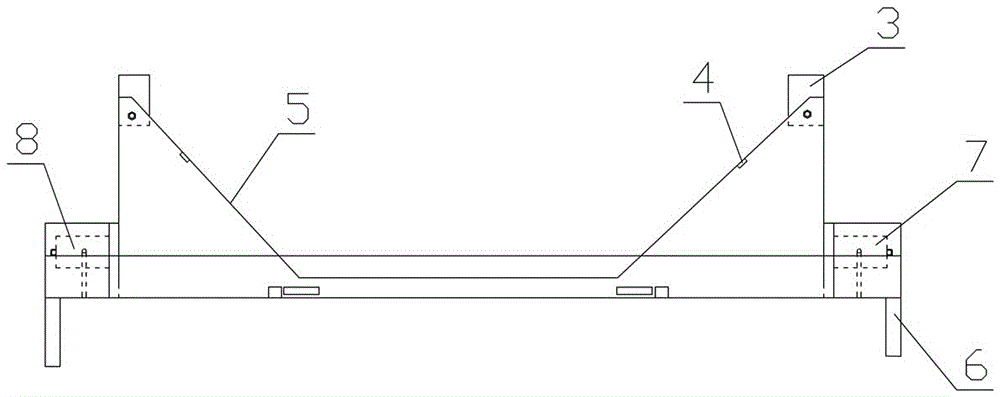

[0024] Example: see figure 1 with figure 2 , In the figure, 1-conveyor, 2-roller, 3-wear plate, 4-connecting rod, 5-coal receiving plate, 6-lower fixing frame, 7-infrared transmitter, 8-infrared receiver.

[0025] The anti-tearing protection device for the belt of the infrared beam coal mine conveyor contains an infrared emitter 7 and an infrared receiver 8, wherein: the infrared emitter 7 and the infrared receiver 8 are respectively installed on the longitudinal sides of the conveyor 1 through the lower fixing frame 6. On the beam, a coal receiving mechanism is arranged between the upper belt and the lower belt of the conveyor 1. The coal receiving mechanism includes two coal receiving plates 5 and a coal receiving chute. spacing, and the lower ends of the two coal receiving plates 5 are respectively connected to the upper ends of the two sides of the coal receiving trough, the coal receiving trough is rectangular and the upper end is open, and the two ends of the two coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com