Method for removing impurities from ionic rare-earth ore

An ionic rare earth ore and rare earth technology, applied in the direction of improving process efficiency, can solve problems such as large impurity content, and achieve the effects of safe and simple operation, low energy consumption, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

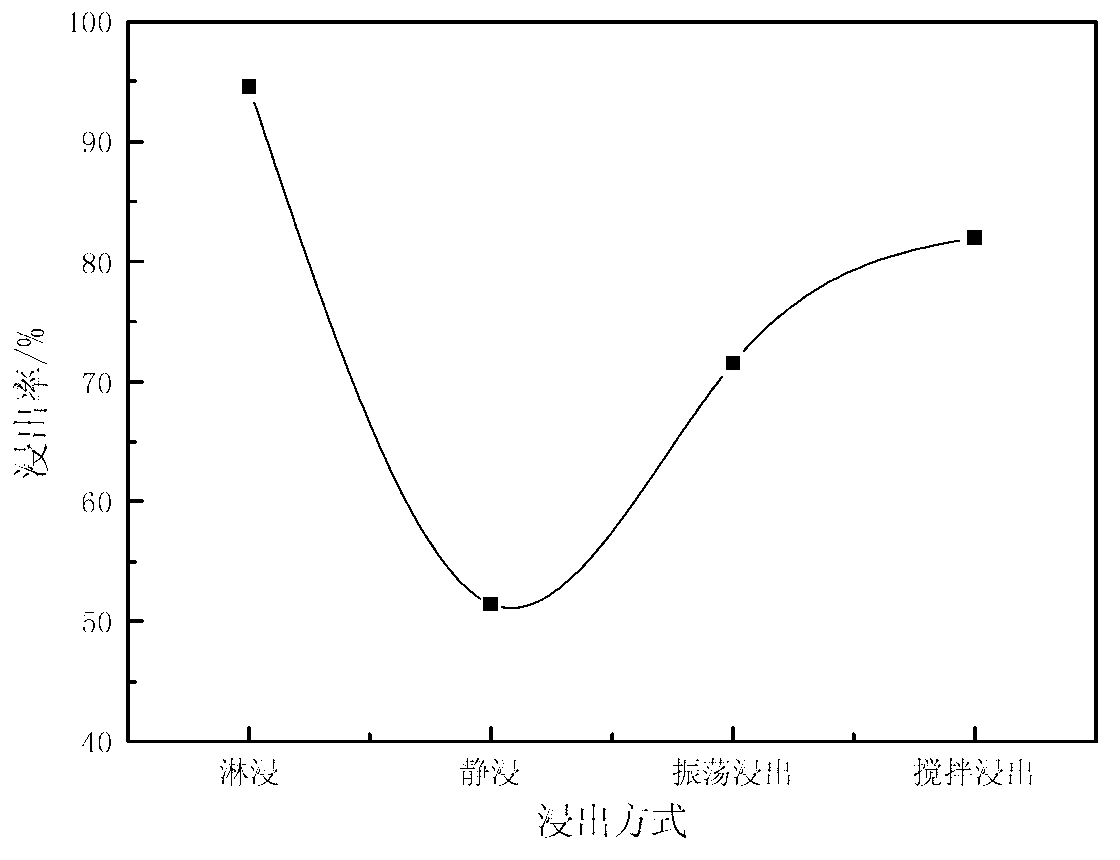

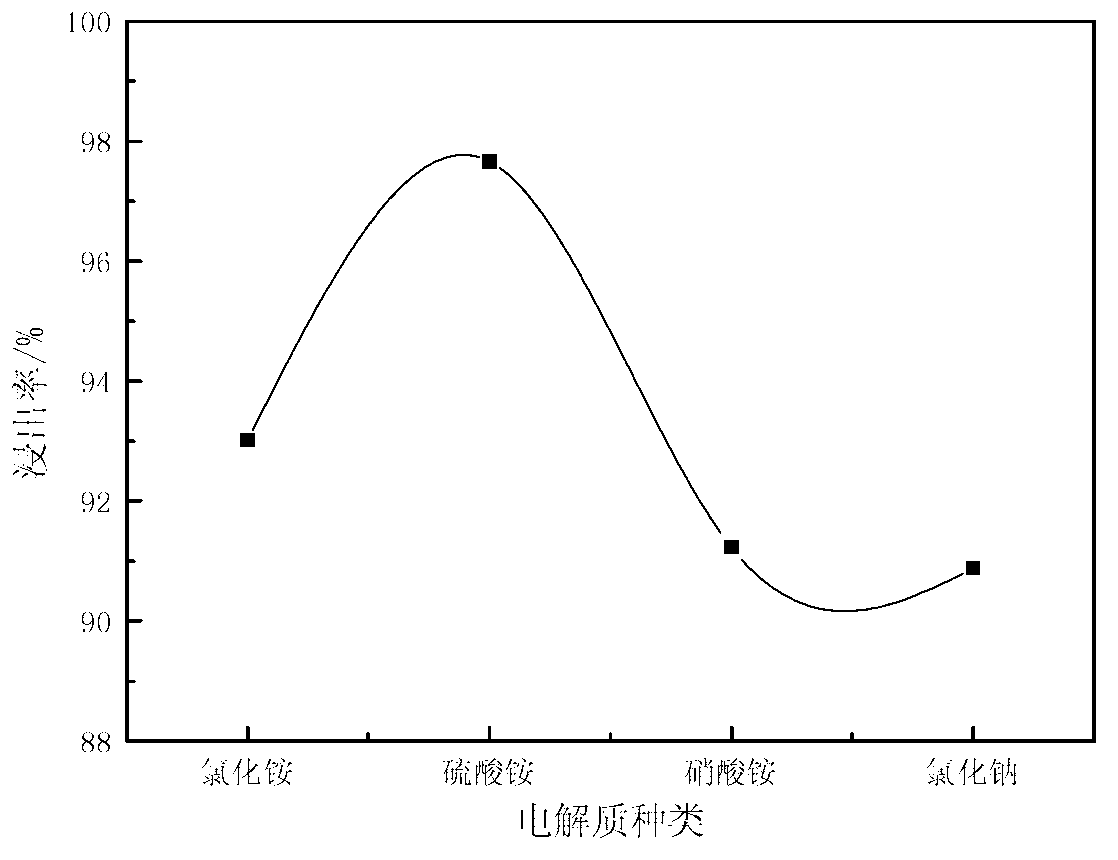

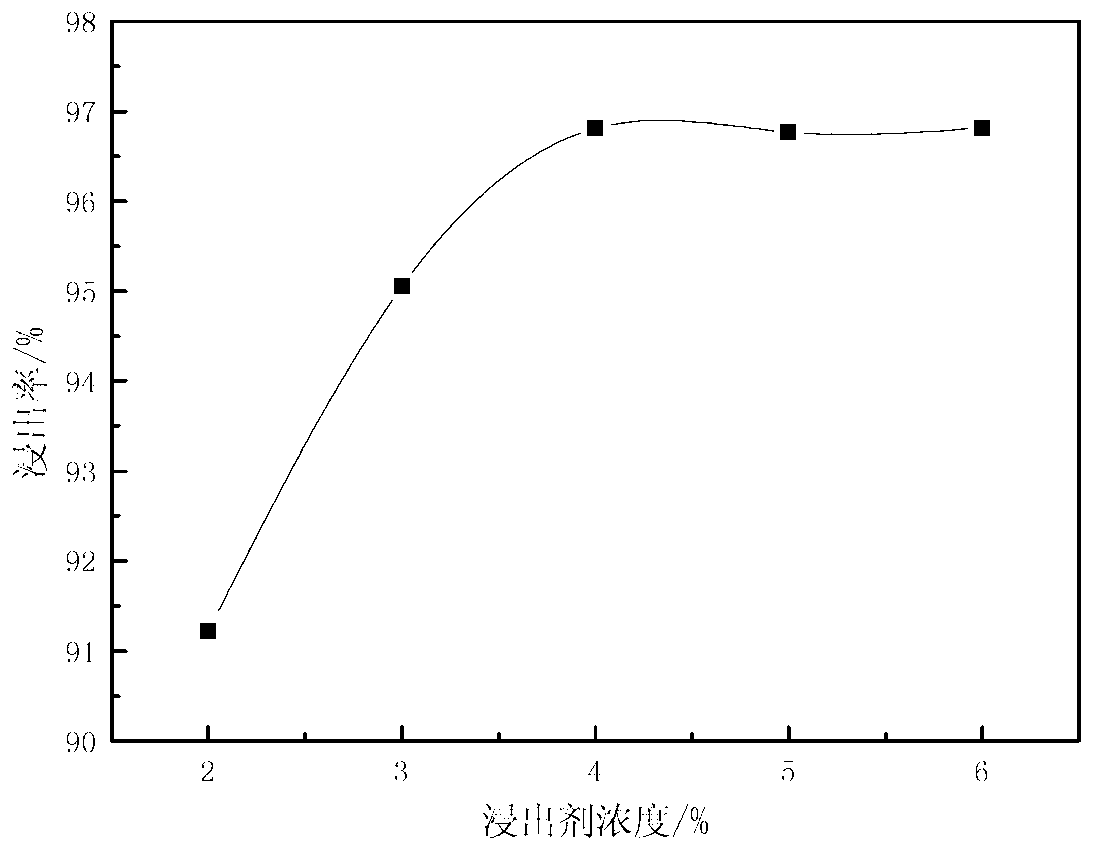

Embodiment 1

[0046] The ionic rare earth ore A is taken from a rare earth mine in Longnan. Weigh 200g of the ionic rare earth ore A and put it into the leaching column, and leaching the rare earth ore A with the prepared mixed leaching stock solution. The test conditions for leaching are raw ore weight: 200g, leaching method: leaching, leaching agent electrolyte: ammonium sulfate, leaching agent concentration: 4%, leaching agent flow rate: 2.5ml / min, raw ore water content: 0%, liquid-solid ratio: 1:1, tartaric acid concentration: 0.2%. Under the above test conditions, the rare earth leaching rate was 96.30%, the removal rate of aluminum ions was 94.48%, and the removal rate of iron ions was 98.04%.

Embodiment 2

[0048] The ionic rare earth ore B was taken from a rare earth mine in Longnan, and 200g of the ionic rare earth ore B was weighed and put into the leaching column, and the rare earth ore A was leached with the prepared mixed leaching stock solution. The test conditions for leaching are raw ore weight: 200g, leaching method: leaching, leaching agent electrolyte: ammonium sulfate, leaching agent concentration: 4%, leaching agent flow rate: 2.5ml / min, raw ore water content: 0%, liquid-solid ratio: 1:1, tartaric acid concentration: 0.2%. Under the above test conditions, the rare earth leaching rate was 97.19%, the removal rate of aluminum ions was 91.05%, and the removal rate of iron ions was 97.52%.

Embodiment 3

[0050] The ionic rare earth ore C was taken from a rare earth mine in Longnan. Weighed 200g of the ionic rare earth ore C and put it into the leaching column, and leached the rare earth ore A with the prepared mixed leaching stock solution. The test conditions for leaching are raw ore weight: 200g, leaching method: leaching, leaching agent electrolyte: ammonium sulfate, leaching agent concentration: 4%, leaching agent flow rate: 2.5ml / min, raw ore water content: 0%, liquid-solid ratio: 1:1, tartaric acid concentration: 0.2%. Under the above test conditions, the rare earth leaching rate was 95.43%, the removal rate of aluminum ions was 90.87%, and the removal rate of iron ions was 98.90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com