Prestress steel strand penetrating device

A technology for prestressed steel strands and steel strands, which is applied in construction, building construction, and processing of building materials, etc., can solve the problems affecting the durability of prestressed concrete structures, long construction period of piercing, and labor of multi-section steel. , to achieve the effect of simple construction, high operation efficiency and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

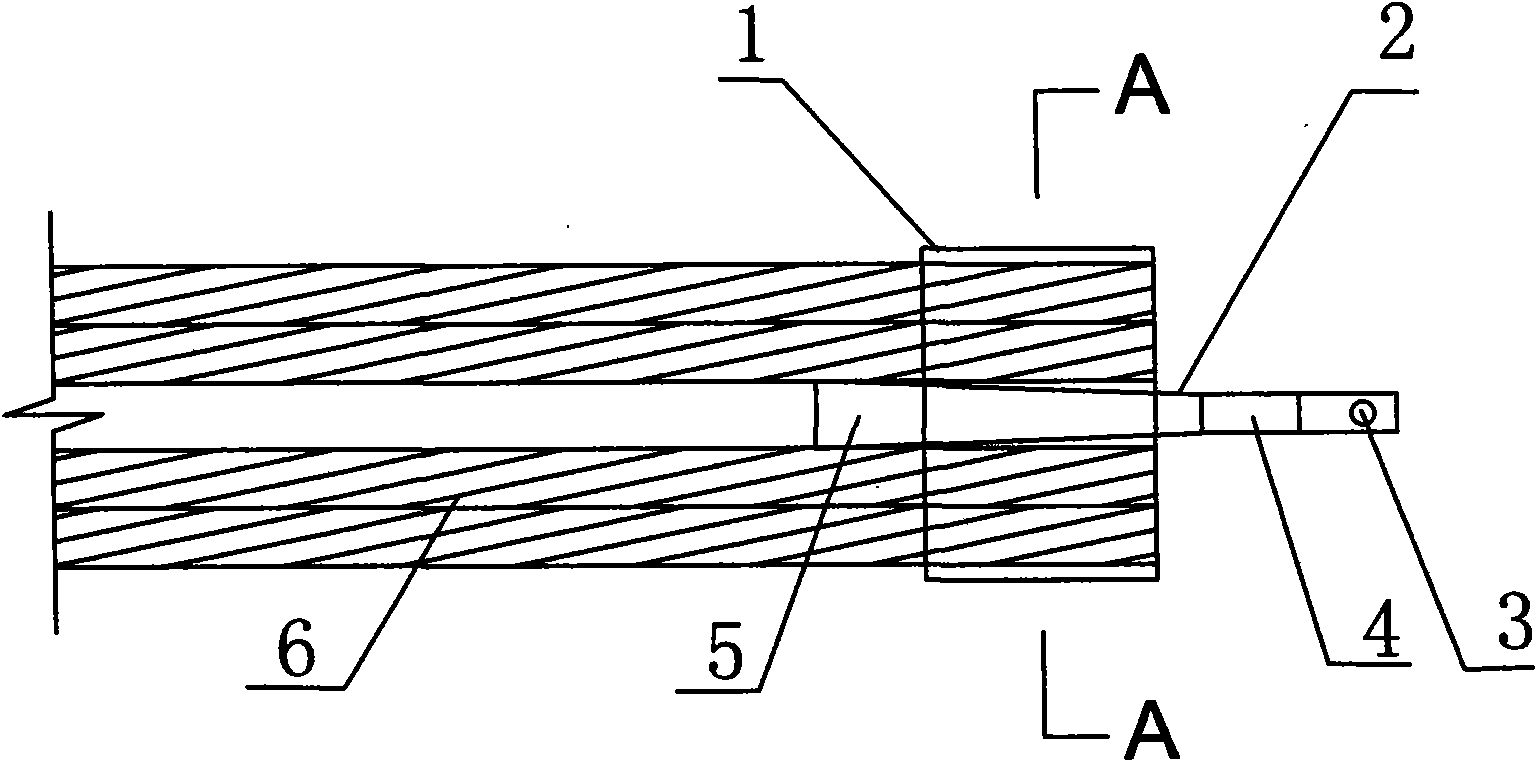

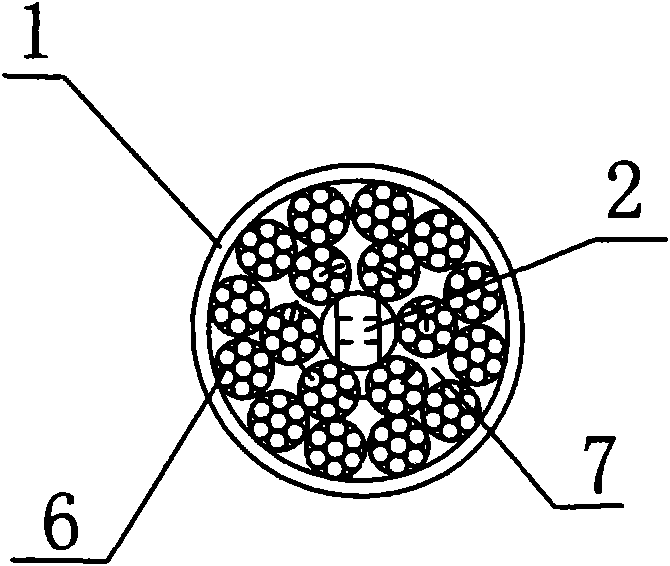

[0017] The present invention will be described in further detail below with reference to the accompanying drawings.

[0018] Lower the hinge and move upward from the root of the steel pipe arch on the Dali Bank

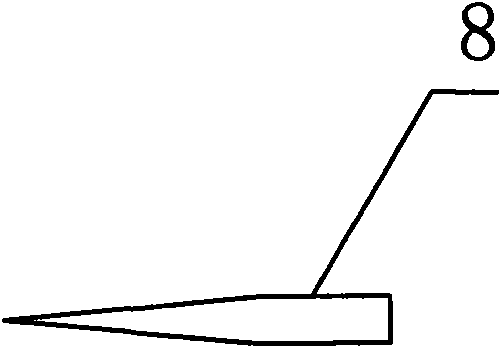

[0019] The present invention comprises circular tubular steel strand restraining ring 1, self-anchor pulling mandrel 2 and anchor piece 8, and self-anchoring pulling mandrel 2 is made up of conical rod 5 and column rod 4 connected as a whole, and The front end is processed with a snap ring installation hole 3 that runs through the side wall, the tapered rod 5 of the self-anchor pulling mandrel 2 is wrapped in the middle of the bundled steel strand 6, and the bundled steel strand 6 of the self-anchor pulling mandrel 2 is wrapped In the steel strand confinement ring 1, a tapered anchor piece 8 is installed at the gap 7 at the front end of the bundled steel strand 6, and the anchor piece 8 is wedged into the gap 7 at the front end of the bundled steel strand 6 to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com