Automobile fuel gas injection valve

A gas injection valve, automobile technology, applied in combustion engines, internal combustion piston engines, oil supply devices, etc., can solve problems such as high failure rate, high energy consumption, poor jet flow, etc., and achieve low cost, low energy consumption, and reduced energy consumption. The effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

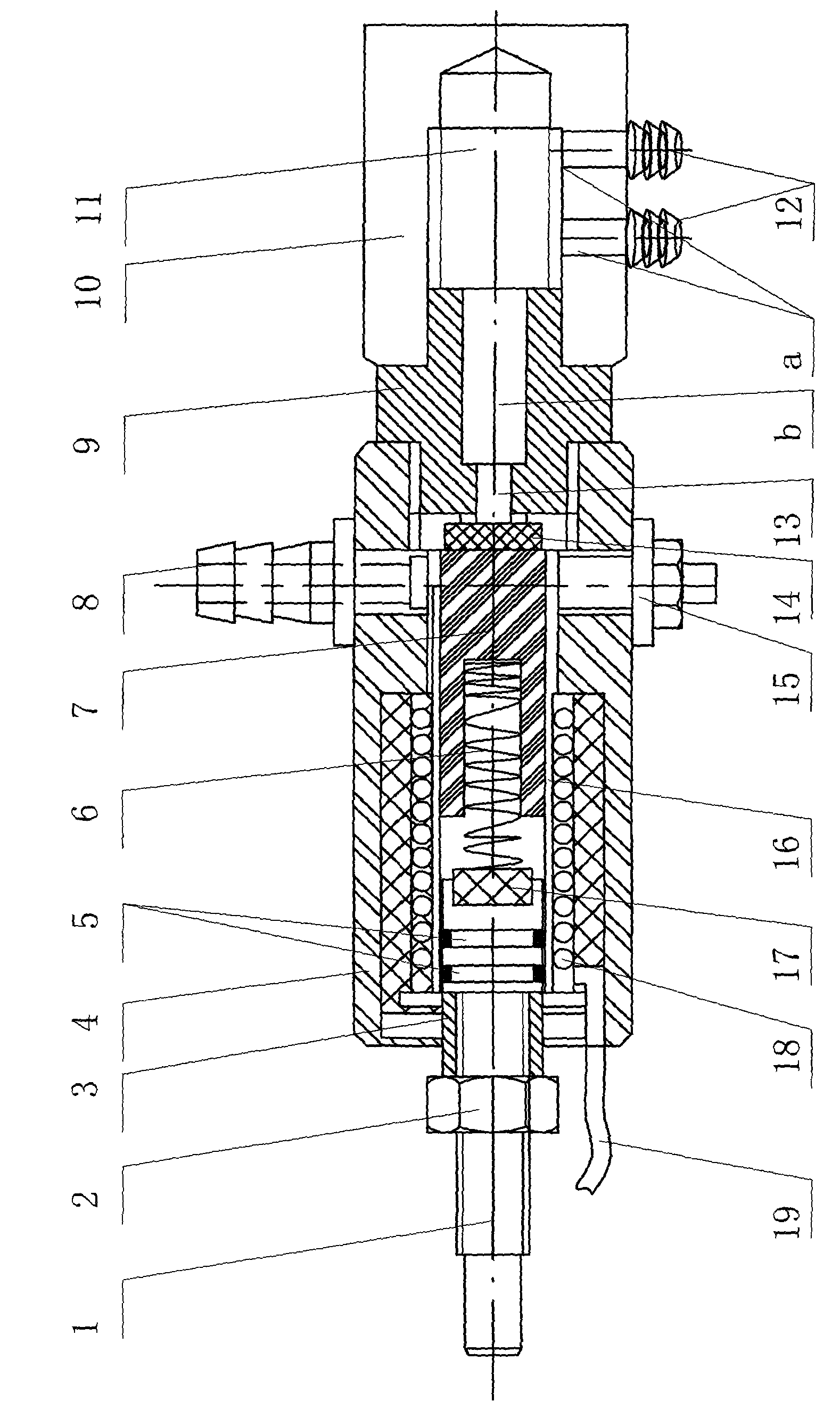

[0018] like figure 1 Shown has shown an embodiment of the automobile gas injection valve of the present invention with a sectional view. This relates to an automobile gas injection valve. One end of the gas outlet 13 of the valve body 4 is provided with an output gas distribution device, which includes a housing 10, a gas distribution chamber 11 arranged in the housing 10 and a There are two discharge passages a below the gas distribution chamber 11 and communicating with it, and each discharge passage a is provided with an output gas joint 12 for connecting with each cylinder of the engine.

[0019] During manufacture, the output gas distribution device and the valve body 4 are connected as a whole through a pair of wire joints 9 , and a gas channel b for connecting the gas outlet 13 and the gas distribution chamber 10 is opened inside the pair of wire joints 9 .

[0020] like figure 1 The shown valve body 4 is provided with a switch device for opening and closing the air o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com