Method for forming color filter

A color filter, color photoresist technology, applied in the direction of filter, photoengraving process coating equipment, etc., can solve the problems of reducing process efficiency, large number of nozzles, long spraying time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following method for forming a color filter according to the present invention will be described in detail with specific examples in conjunction with the attached drawings. However, the provided examples are not intended to limit the scope of the present invention, and the description of the method flow steps is not intended to The order of execution is limited, and any execution flow recombined from method steps to produce methods with equal efficacy is within the scope of the present invention. The drawings are for illustration purposes only and are not drawn to original scale.

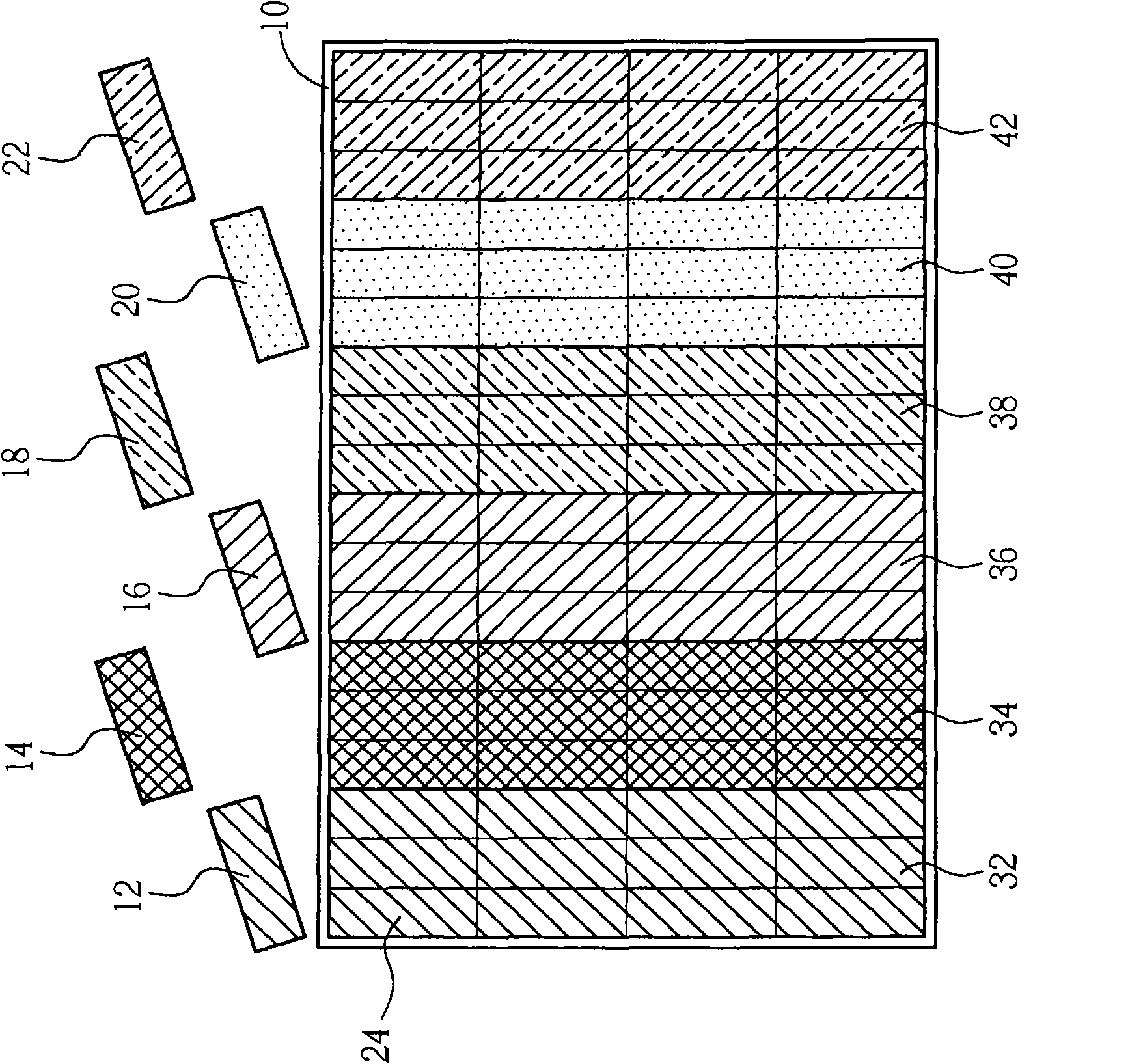

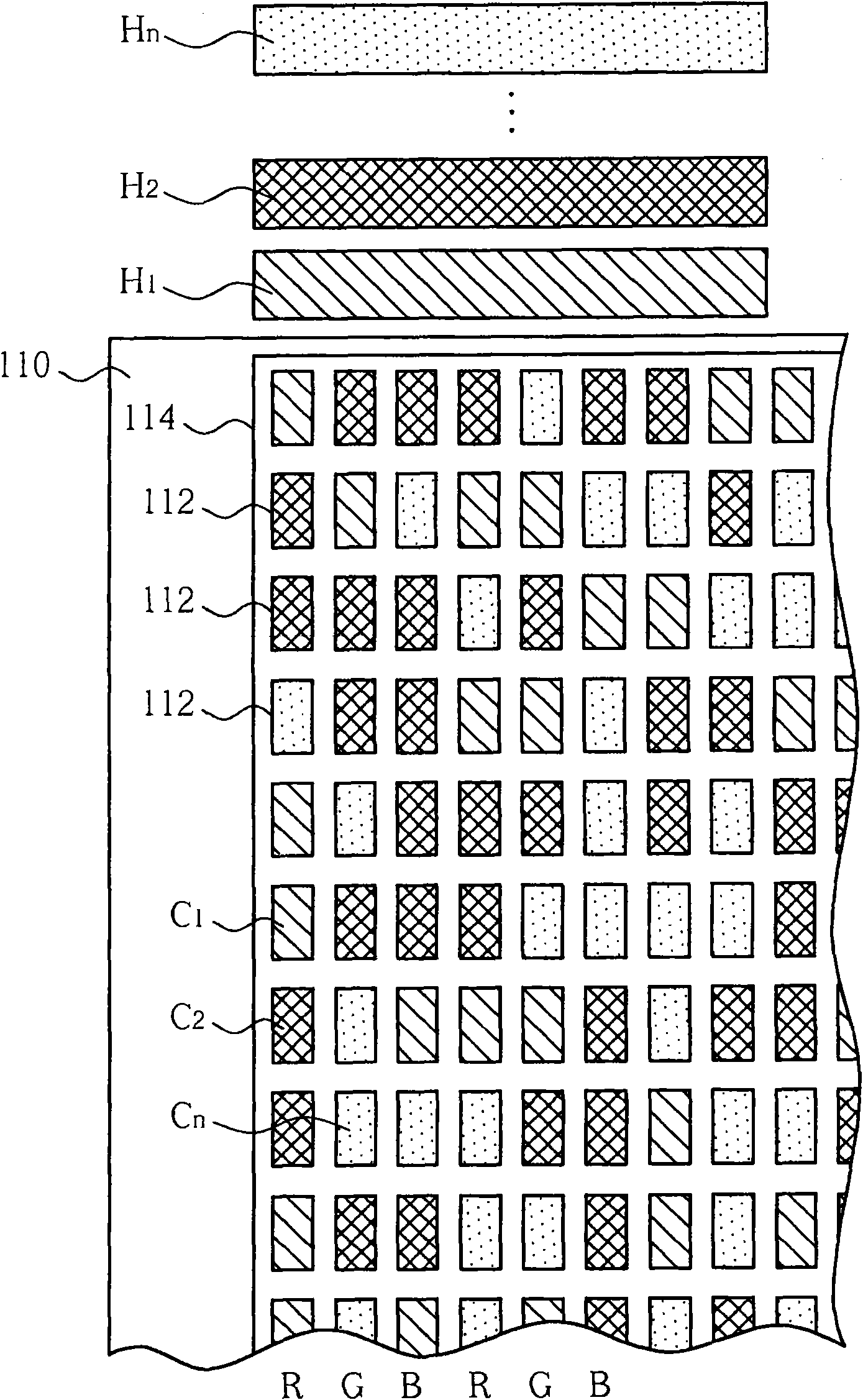

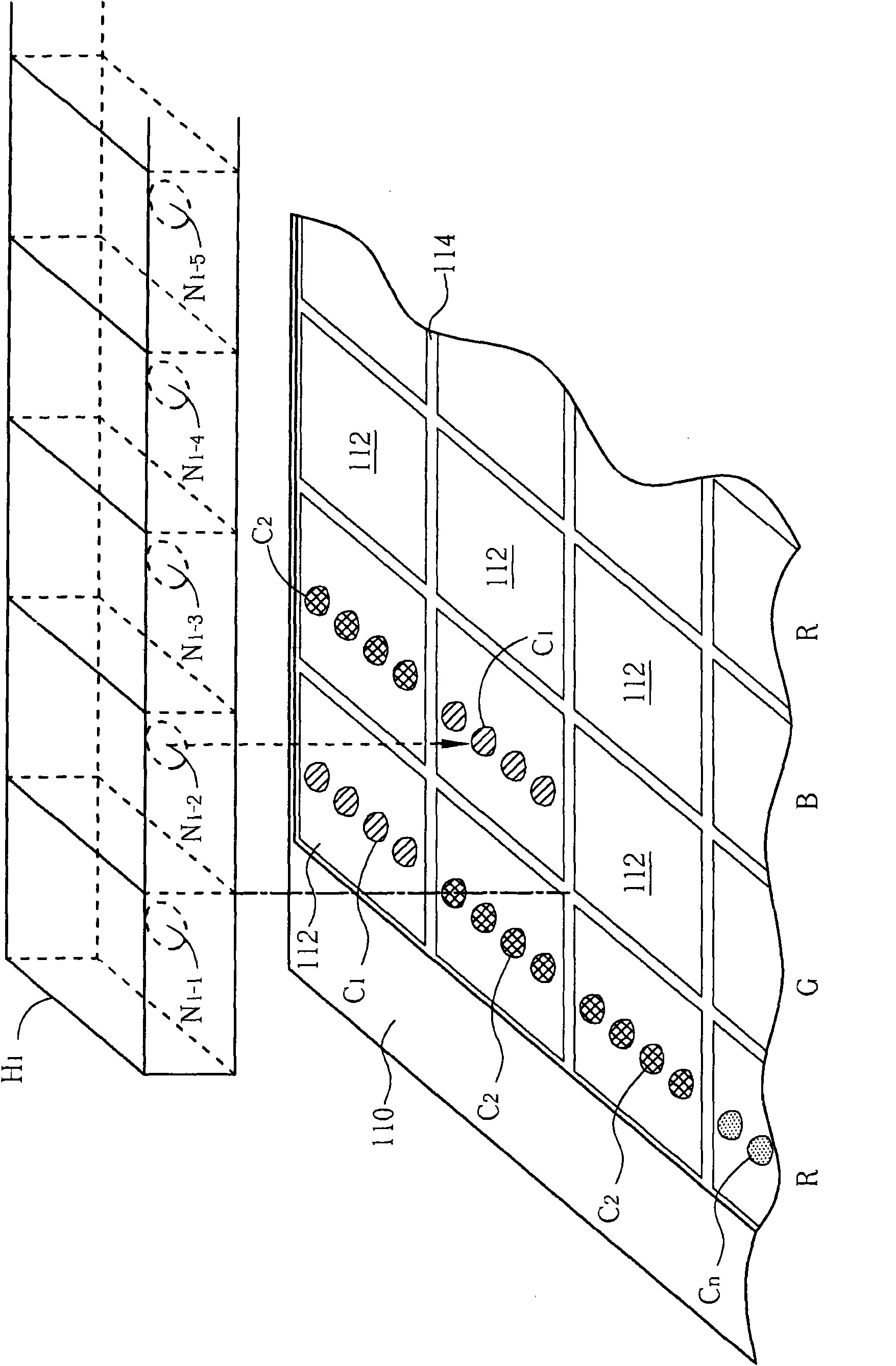

[0020] Figure 2 to Figure 4 It is a schematic diagram of the method for forming a color filter according to the first embodiment of the present invention. like figure 2 As shown, the present invention can provide at least one coating device, such as an inkjet device, and the coating device can include a plurality of shower heads, such as n shower heads H 1 、H 2 ,...,H n , where n i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap