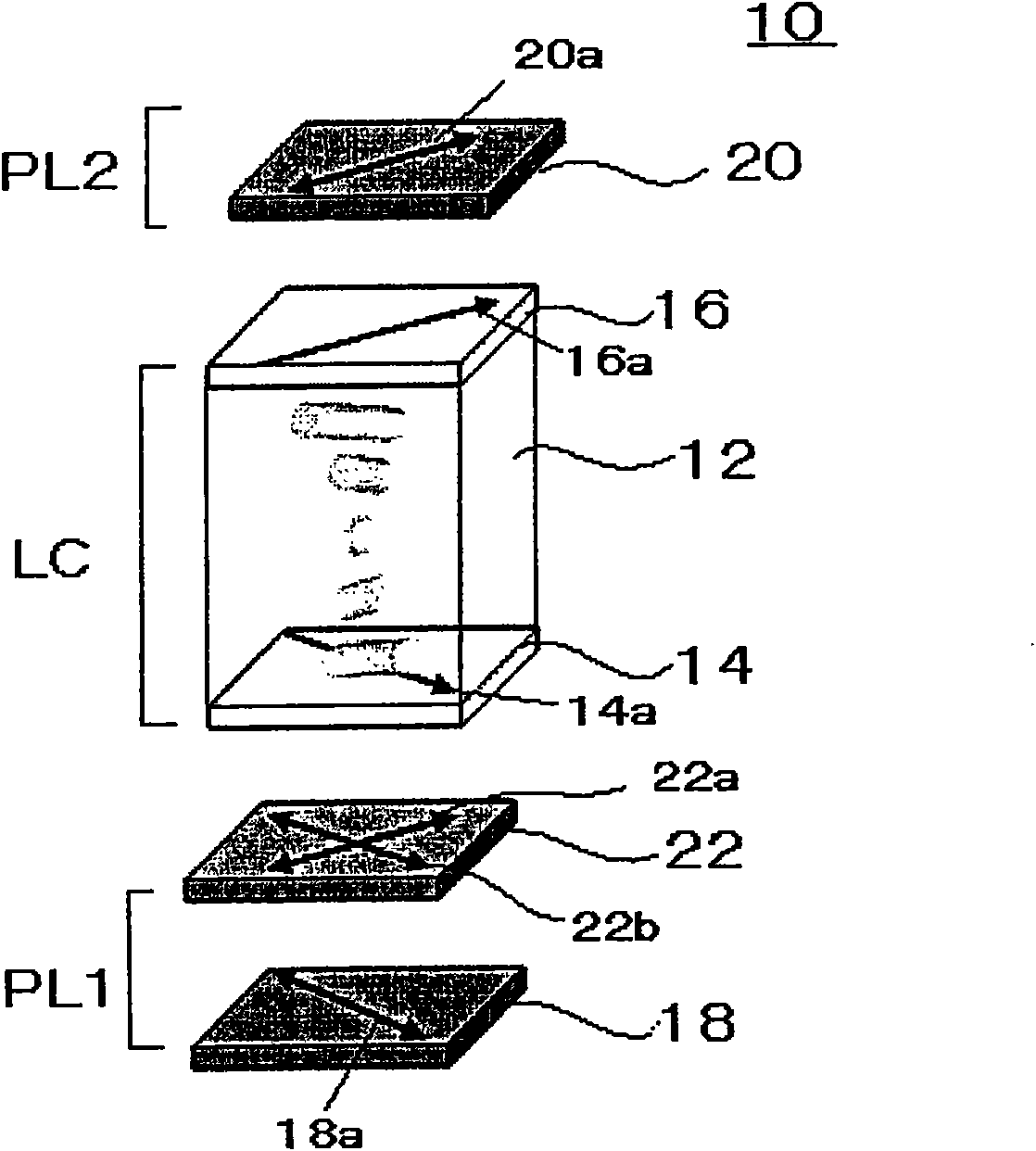

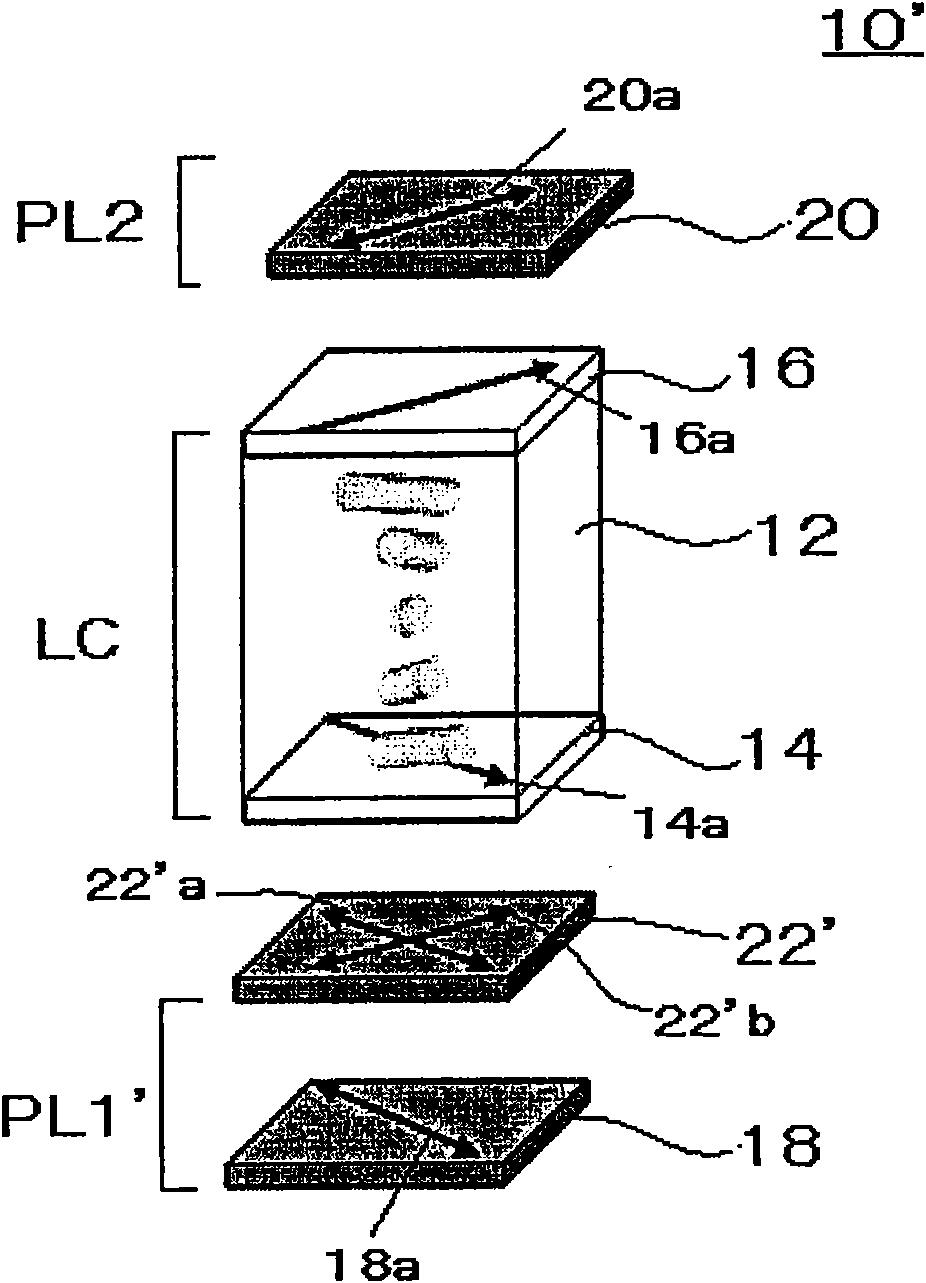

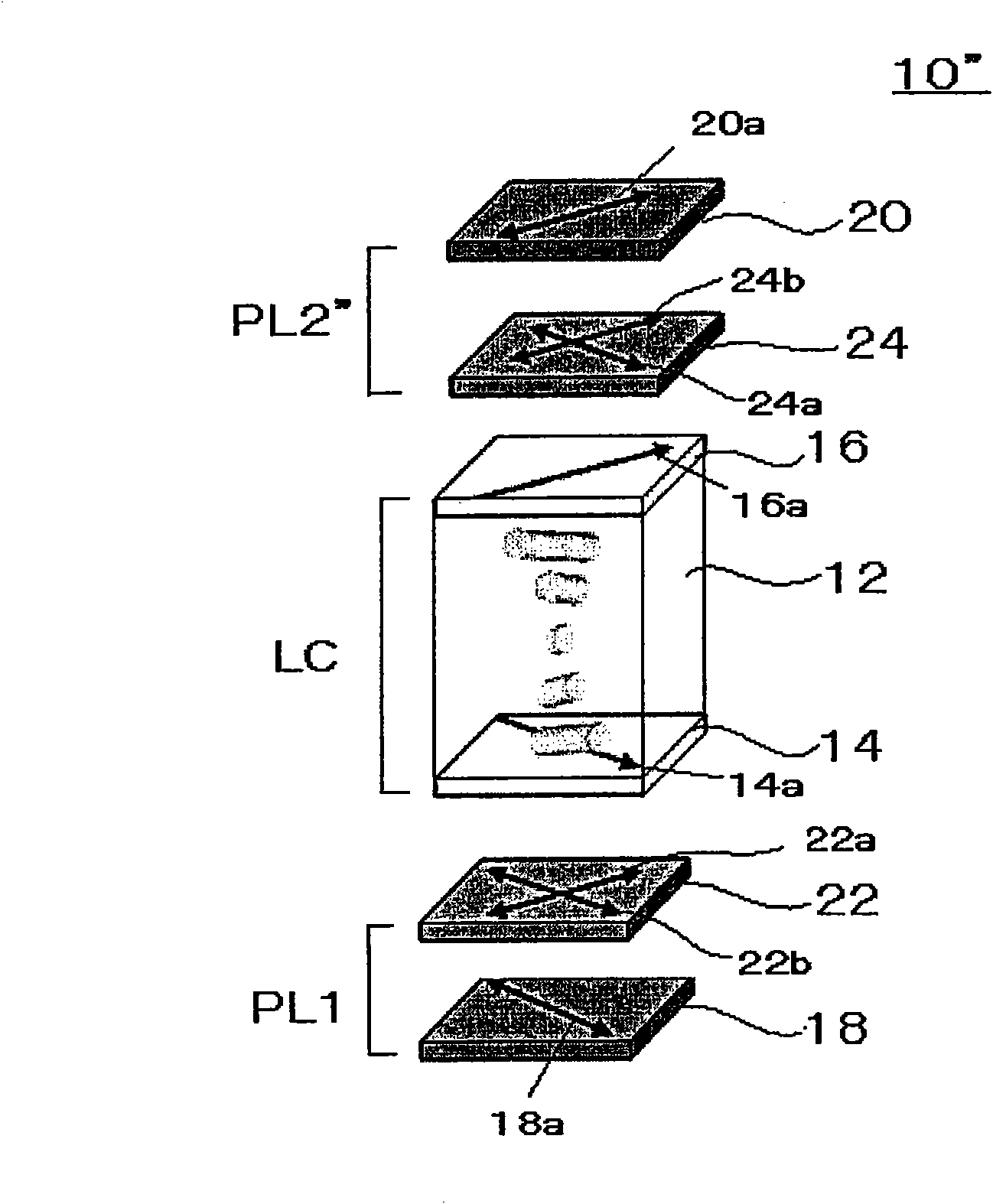

Liquid crystal display device

A technology of liquid crystal display device and liquid crystal layer, which is applied in the direction of instruments, polarizing elements, optics, etc., can solve the problems of large deviation of film optical properties, contact scratches on the film surface, etc., and achieve the effect of improving viewing angle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0232]The present invention will be described in further detail below according to the examples. Materials, usage amounts, ratios, processing contents, processing procedures and the like shown in the following examples can be appropriately changed unless departing from the gist of the present invention. Therefore, the scope of the present invention is not limited to the specific examples shown below.

[0233] 1. Preparation of polymer film for retardation layer

[0234] - As a cycloolefin copolymer, the pellet of "TOPAS#6013" by Polyplastics was used. In addition, it was confirmed by the above method that "TOPAS#6013" has positive intrinsic birefringence and is an amorphous thermoplastic resin. Also, the glass transition temperature of this resin was 136°C.

[0235] ·Cellulose acetate propionate (CAP)

[0236] Cellulose acetate propionate (CAP) was produced according to the method described in Example 1 of JP-A-2006-348123, and granulated by a conventional method. The com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com