Optical disc drive

An optical disc device and optical disc technology, which are applied to optical recording/reproducing, ticketing equipment, instruments, etc., can solve problems such as insufficient strength, and achieve the effect of good convenience in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

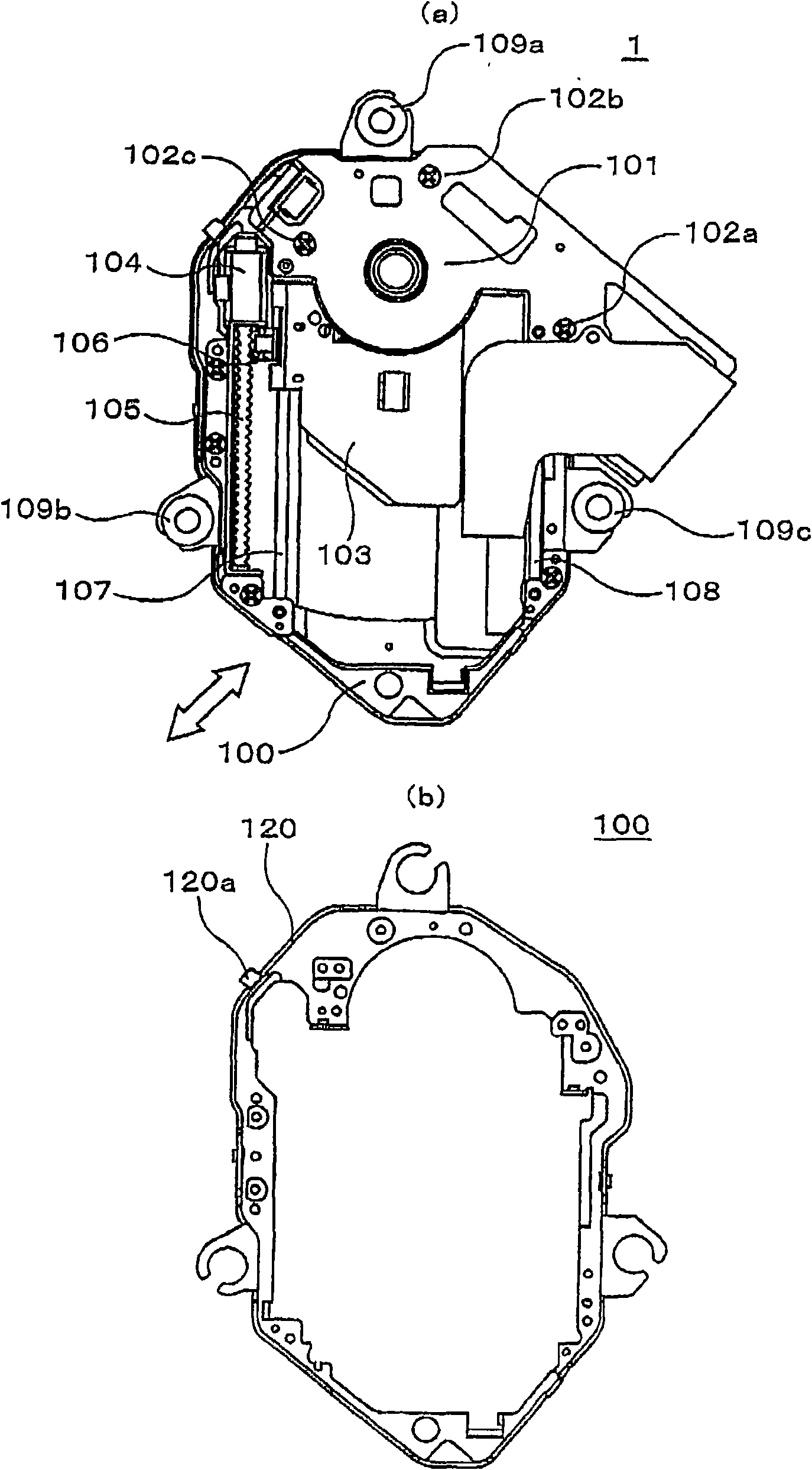

[0031] Below, while using the attached Figure 1 Embodiments of the present invention will be described.

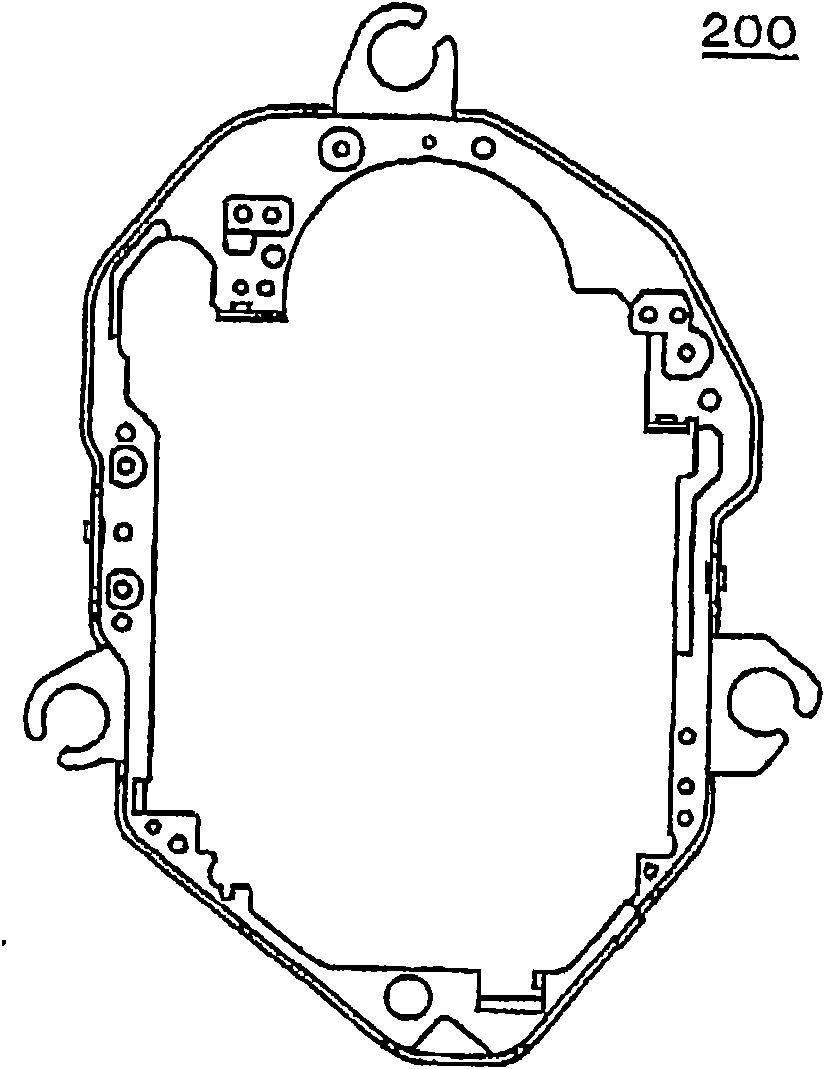

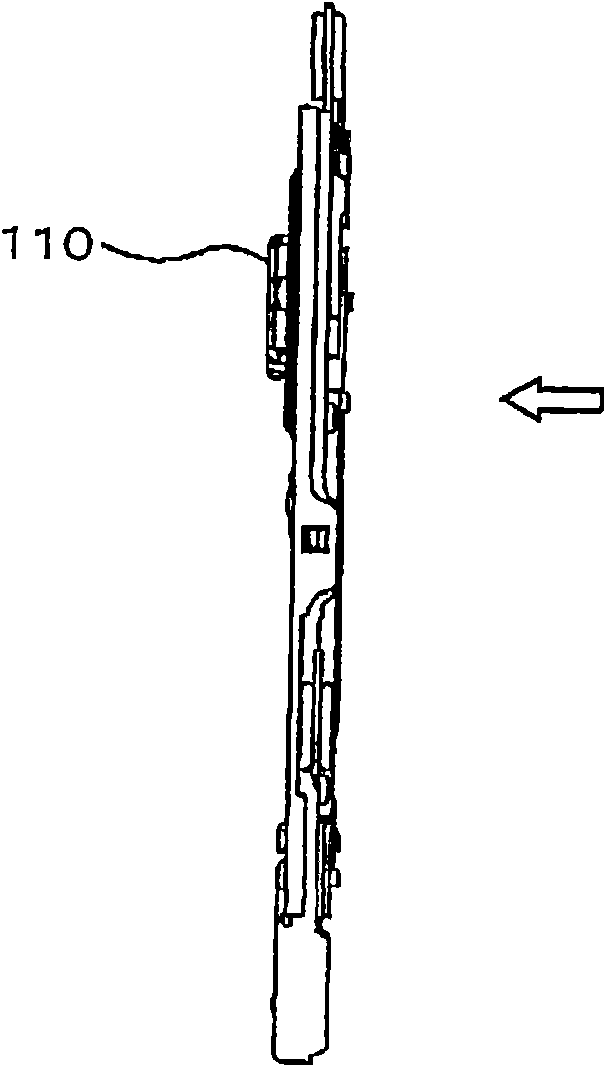

[0032] figure 1 A plan view showing an optical drive core mechanism assembly (hereinafter, abbreviated as TRV mechanism) 1 of the optical disk device of the present invention viewed from the bottom side of the device. The TRV mechanism houses the most important components of the mechanism system related to the recording and reproducing operation of the optical disc device, including a disc motor for rotating the optical disc, an optical pickup unit for recording and reproducing signals, and its moving mechanism. figure 1 (a) represents the whole of the TRV mechanism 1, figure 1 (b) shows the optical drive core 100 as a base portion therein. figure 1 The arrow at the lower left of (a) indicates the direction in which an unillustrated optical disc moves when it is loaded into or ejected from the optical disc device. When loading or ejecting a disc, the disc tray that lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com