High-power harmonic wave excitation generator

A harmonic excitation and generator technology, applied to the shape/style/structure of winding conductors, can solve the problems of high voltage waveform distortion rate, achieve good voltage quality, small waveform distortion rate, and reduce waveform distortion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

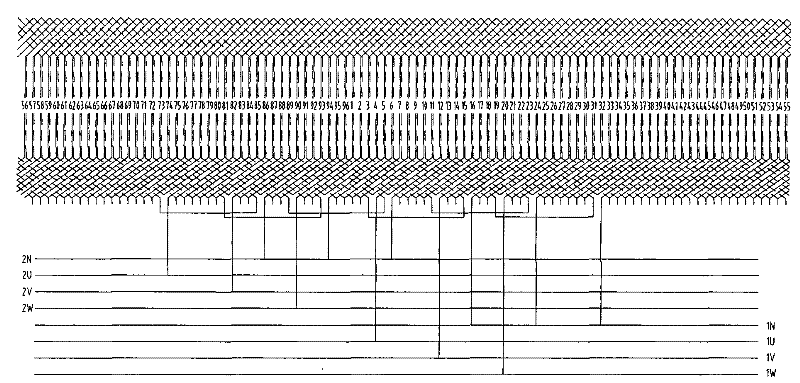

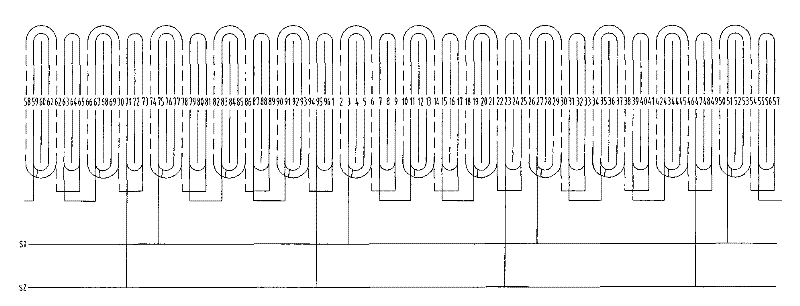

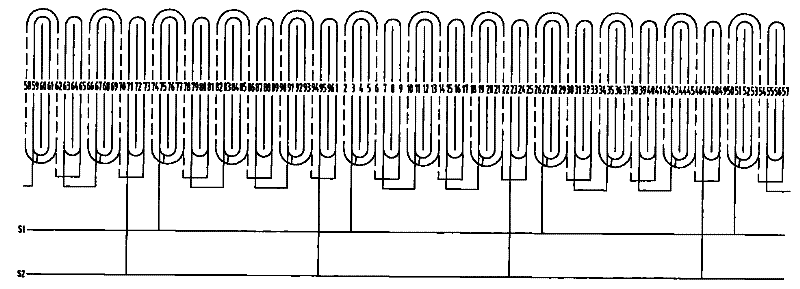

[0009] High-power harmonic excitation generator, including the stator, the main winding embedded in the stator slot and the third harmonic winding, the number of stator slots is 96, the number of poles is 8, the main winding is double-layer wave winding, and the third harmonic winding is unequal turns The single-layer concentric winding, that is, in the 8 slots under each pole pair of the third harmonic winding (the number of third harmonic magnetic field poles is 3 times that of the fundamental wave, then the third harmonic magnetic field pole distance τ 3 =96 / 8×3=4 slots, the pole pair is 8 slots), the number of conductors in the third slot and the seventh slot is zero, the first slot and the fifth slot are embedded with single-layer concentric coils, the second slot and The fourth slot is embedded with single-layer concentric coils in series with the single-layer concentric coils in the first and fifth slots, and the sixth and eighth slots are embedded with single-layer conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com