Double-magnetic mahjong tiles for full-automatic mahjong machine

A mahjong machine and mahjong tile technology, applied in sports accessories, indoor games, etc., can solve the problems of weak magnetic field strength on the bottom surface of the cards, slipping stacks, etc., and achieve the effects of uniform magnetic field strength distribution, increased shuffling speed, and reduced manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

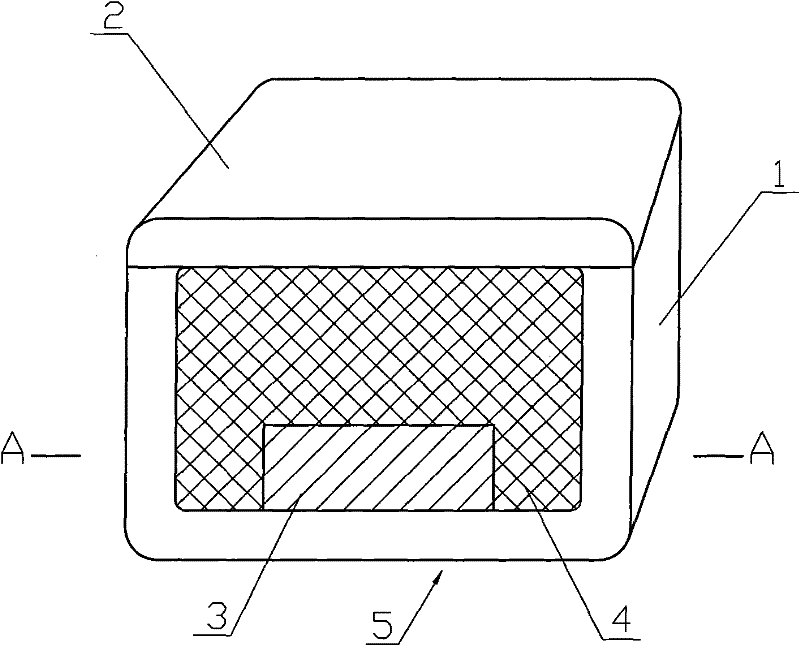

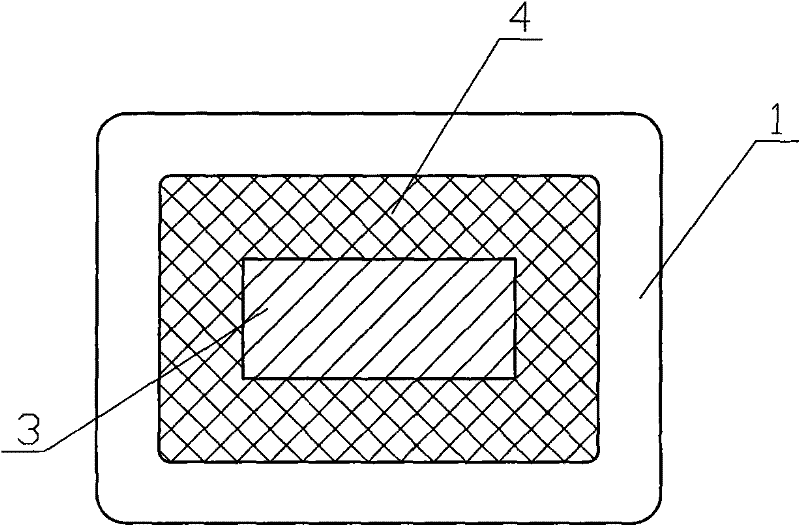

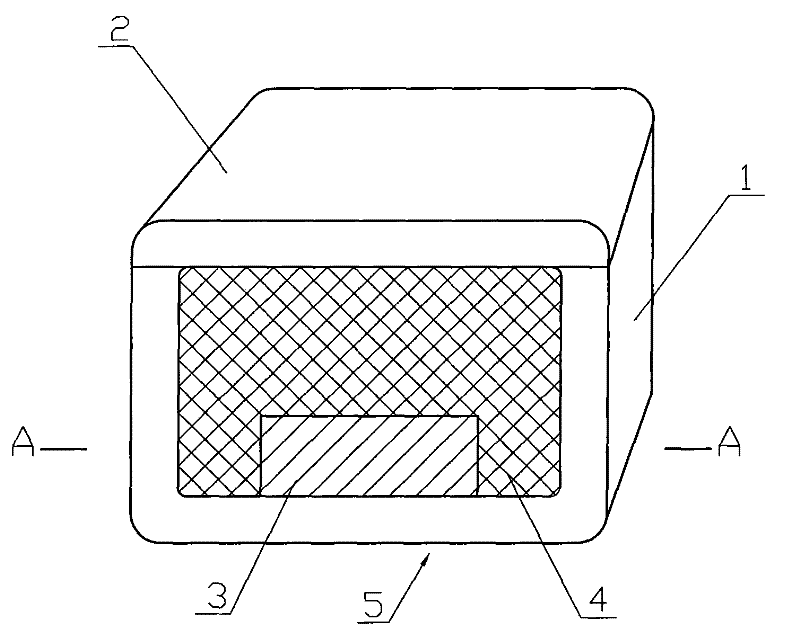

Image

Examples

Embodiment 1

[0026] Magnetic powder, calcium powder, and resin binder are configured and weighed according to 30%, 68%, and 2% of the total weight respectively. The weighed above-mentioned materials were placed in a mixer and mixed for 20 minutes to form a mixture for use.

[0027] Put the high-density magnetic block, that is, the magnetic steel, in the composite magnetic block mold, then pour the above-mentioned mixture into the composite magnetic block mold, press and demould to form a composite magnetic block blank, and place the blank in a low-temperature oven at 65°C , after 10 hours of drying, take it out for use.

[0028] Put the white amino molding resin powder in the shell mold, then press and demould to form a rectangular mahjong tile shell. The housing is placed in a mold with a cover, and the prefabricated composite magnetic block is put into the housing, and finally the blue amino mold resin powder is placed in the mold with a cover for pressing and demoulding to form a blank...

Embodiment 2

[0031] Magnetic powder, calcium powder, and resin binder are configured and weighed according to 45%, 54%, and 1% of the total weight respectively. The weighed above-mentioned materials were placed in a mixer and mixed for 30 minutes to form a mixture for use.

[0032] The magnetic steel is placed in the composite magnetic block mold, and then the composite magnetic block of the above mixture is poured into the composite magnetic block mold, pressed and demolded to form a composite magnetic block blank. The blank was placed in a low-temperature oven at 50°C, dried for 8 hours and taken out for use.

[0033] Put the white amino molding resin powder in the shell mold, then press and demould to form a rectangular mahjong tile shell. The casing is placed in a mold with a cover, and the prefabricated composite magnetic block is put into the casing, and finally the green amino molding resin powder is placed in the mold with a cover for pressing and demolding to form a blank card. ...

Embodiment 3

[0036] Magnetic powder, calcium powder, and resin binder are configured and weighed according to 49%, 50%, and 1% of the total weight respectively. The weighed above-mentioned materials were placed in a blender and mixed for 25 minutes to form a mixture for use.

[0037] The high-density magnetic block is placed in the composite magnetic block mold, and then the composite magnetic block of the above-mentioned mixture is poured into the composite magnetic block mold to be pressed and demolded to form a composite magnetic block blank. The blank was placed in a low-temperature oven at 50°C, dried for 8 hours and taken out for use.

[0038] Put the white amino molding resin powder in the shell mold, then press and demould to form a rectangular mahjong tile shell. The casing is placed in a mold with a cover, and the prefabricated composite magnetic block is put into the casing, and finally the colored amino molding resin powder is placed in the mold with a cover, and then pressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com