Double-inlet double-flue modular afterheat boiler

A waste heat boiler and modular technology, applied in the field of waste heat boiler, can solve the problems of difficult to achieve product optimization, impossible to achieve flue gas mixing, etc., and achieve the effect of optimal design and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

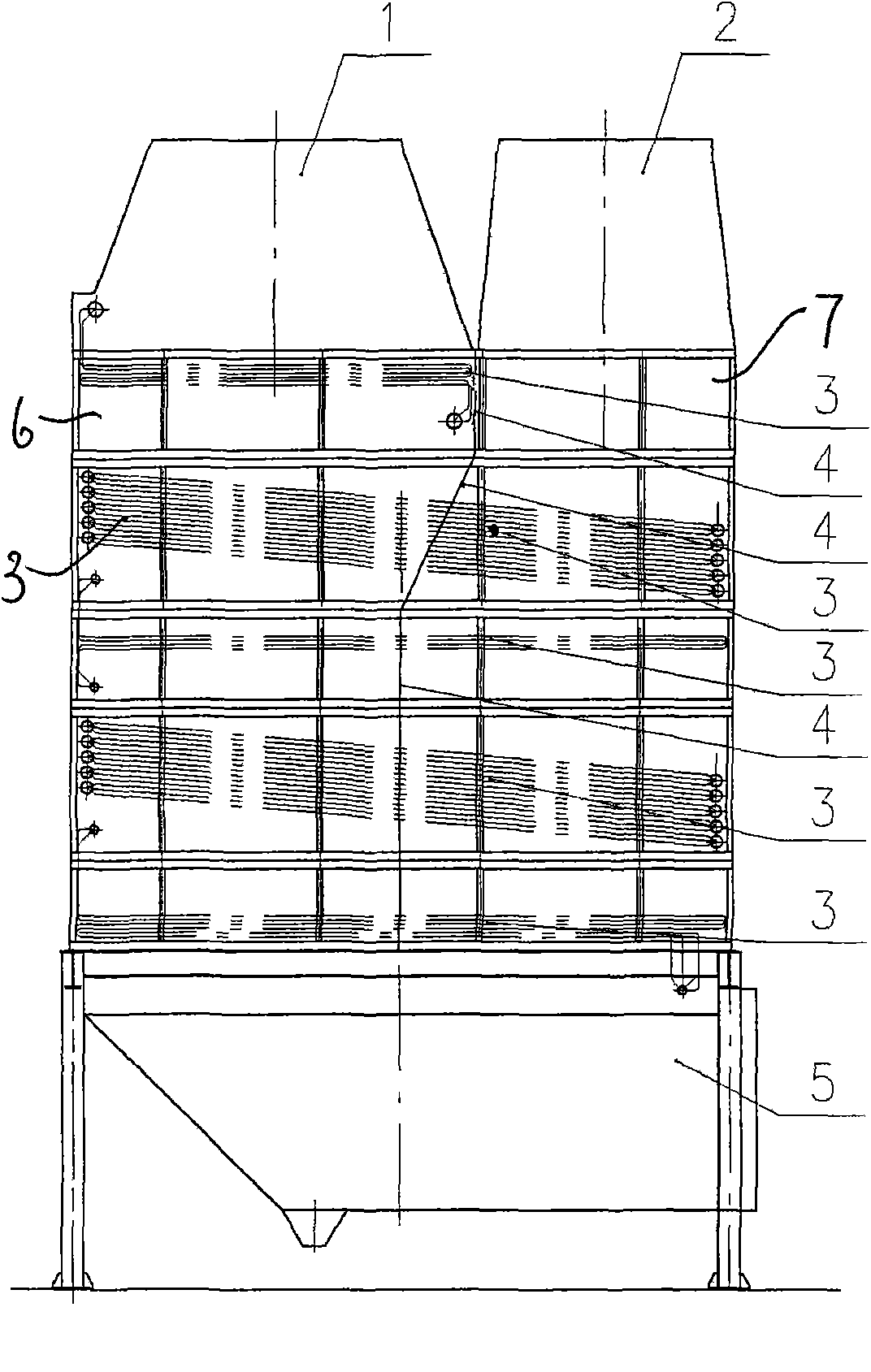

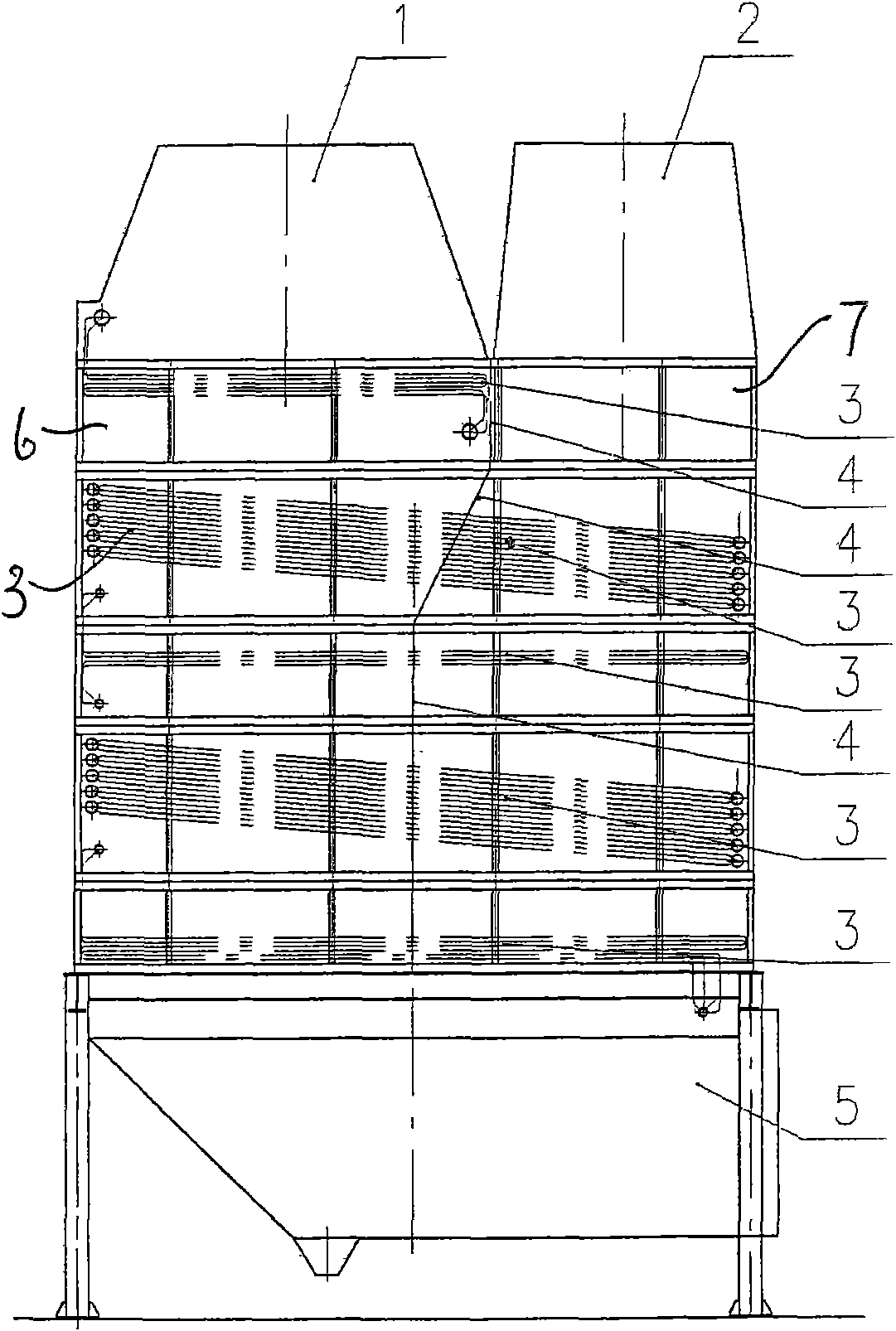

[0011] A dual-intake dual-channel modular waste heat boiler, including a boiler flue, and a middle partition 4 is arranged in the boiler flue to divide the boiler flue into two left and right flues 6 and 7, and the left and right flues are respectively It communicates with the left and right air inlets 1 and 2, and the left and right flues communicate with the same smoke outlet 5. The heating surface of the boiler is arranged in the left and right flues, and the left and right flues share the same heating surface 3.

[0012] The heating surface of the boiler is a modular heating surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com