Repeated bending test equipment of optical cable

A technique of repeated bending and bending test, applied in the direction of applying repetitive force/pulse force to test the strength of materials, measuring devices, instruments, etc. Low heat and the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

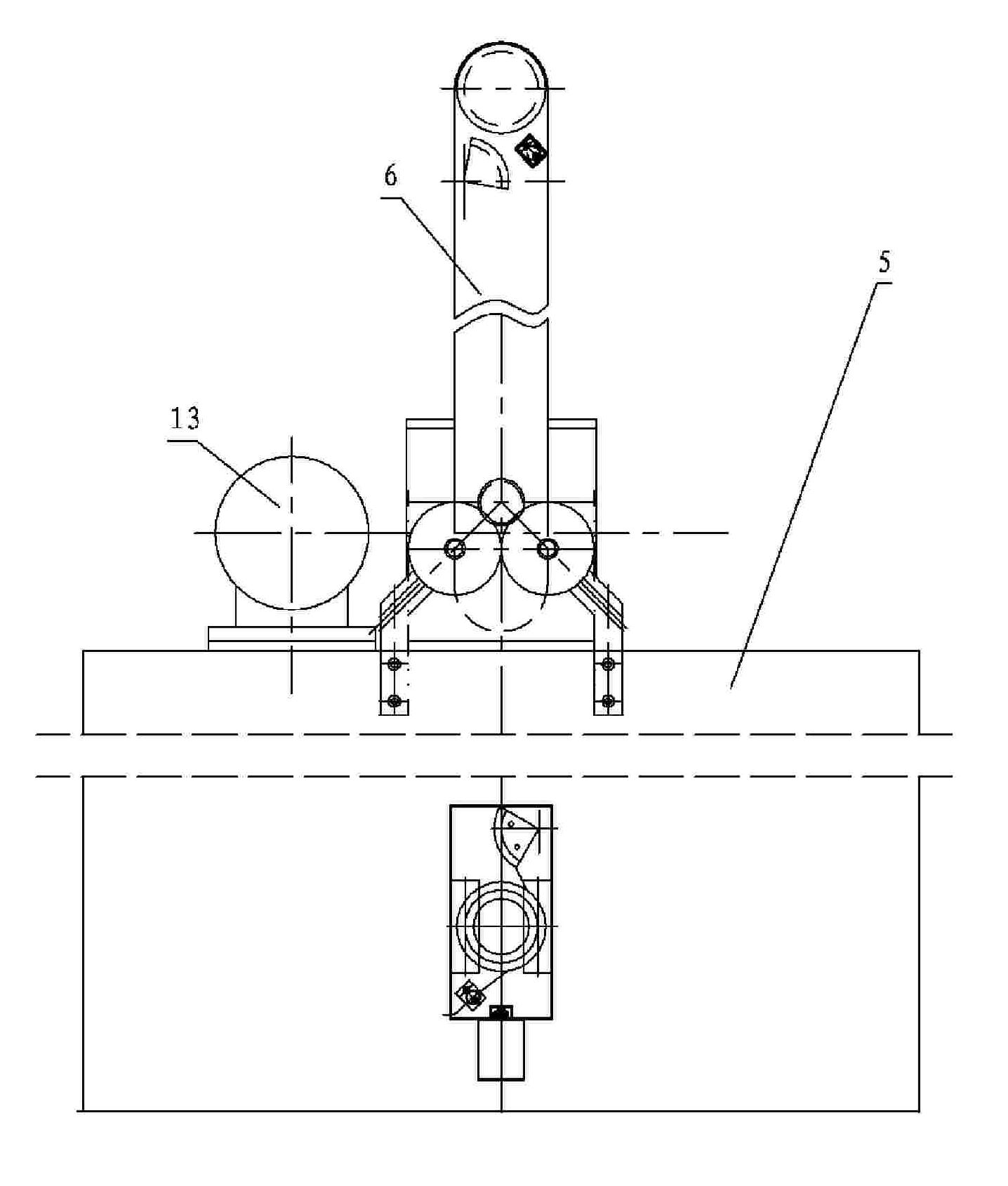

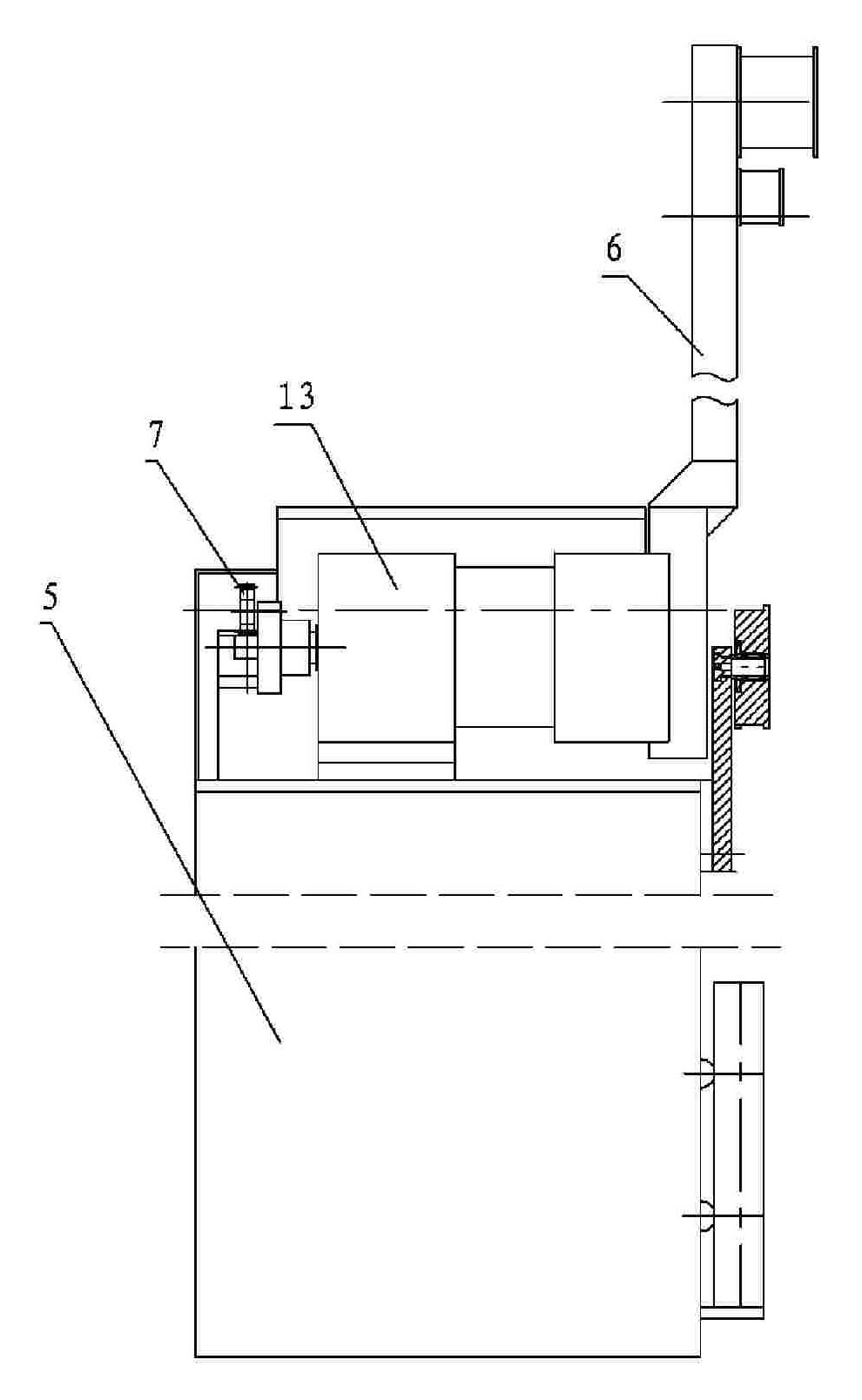

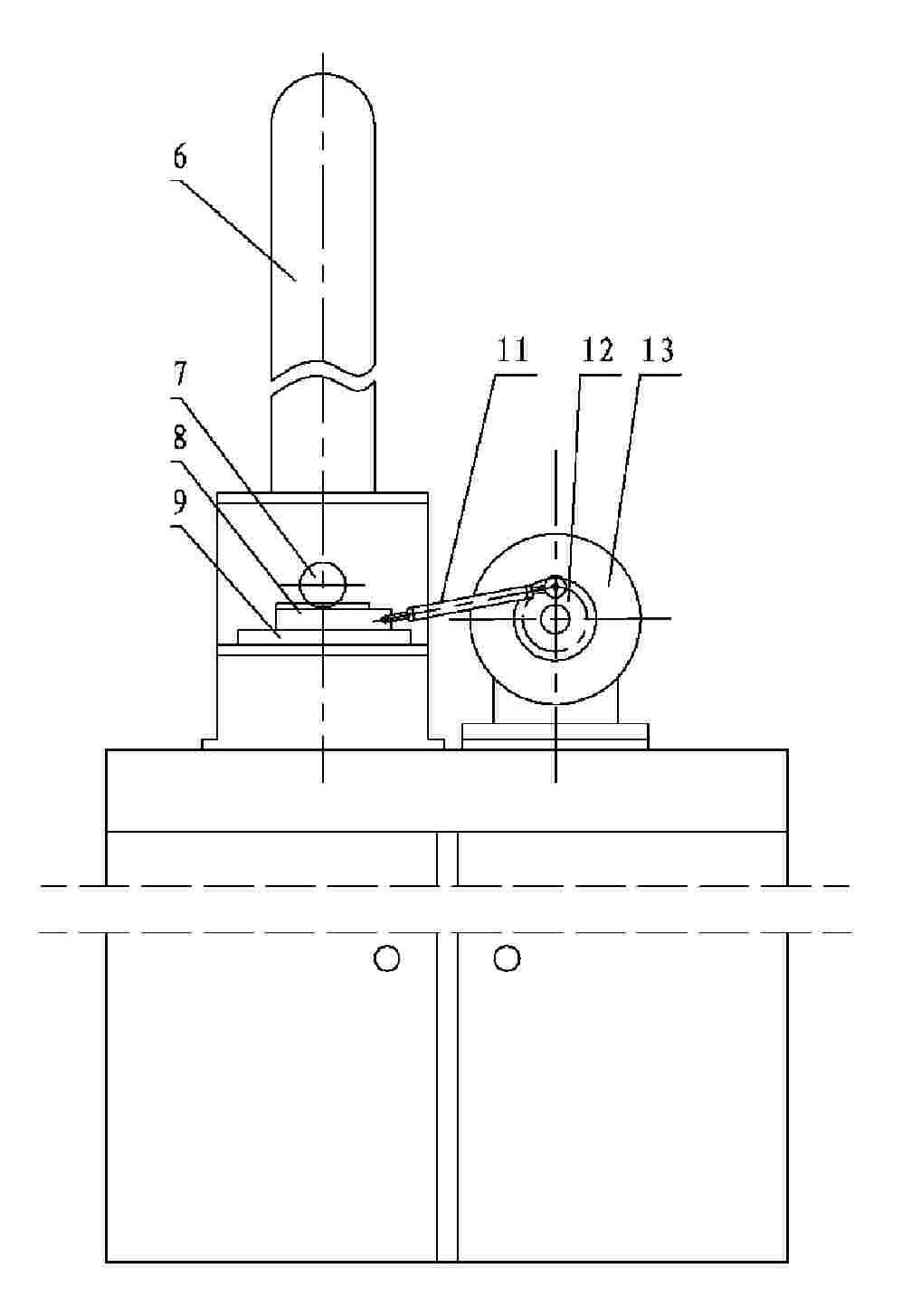

[0024] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Among them, a kind of optical cable repeated bending test equipment, comprises frame 5, is provided with motor 13 on frame 5, is provided with the motor turntable 12 that acts as crank on the output shaft of motor 13, and one end of connecting rod 11 is hinged on the motor turntable 12 On the disk, the other end of the connecting rod 11 is hinged to one end of the toothed slider 8, the toothed slider 8 is slidably installed on the frame 5 through the linear bearing 9, and the gear 7 is assembled on the frame 5 through its rotating shaft. 7 is meshed with the toothed slider 8 for transmission, and one end of the rotating shaft of the gear 7 is fixedly provided with a swing rod 6, and the swing end of the swing rod 6 is fixedly provided with an upper fixture, and the lower part of the frame 5 is provided with a vertical slide rail. The sliding assembly is provided with a counterweight slide block, and a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com