Error-free counting method for rotator revolutions of orthogonally distributed dual sensor

A counting method and dual-sensor technology, applied in the direction of counting mechanisms/items, instruments, etc., can solve problems such as multi-counting, miscounting, "wrong algebraic calculation results, inability to recognize "rotation" and "validity"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

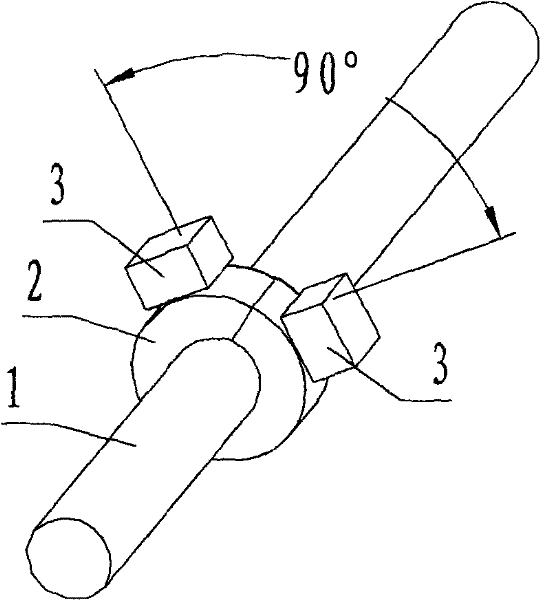

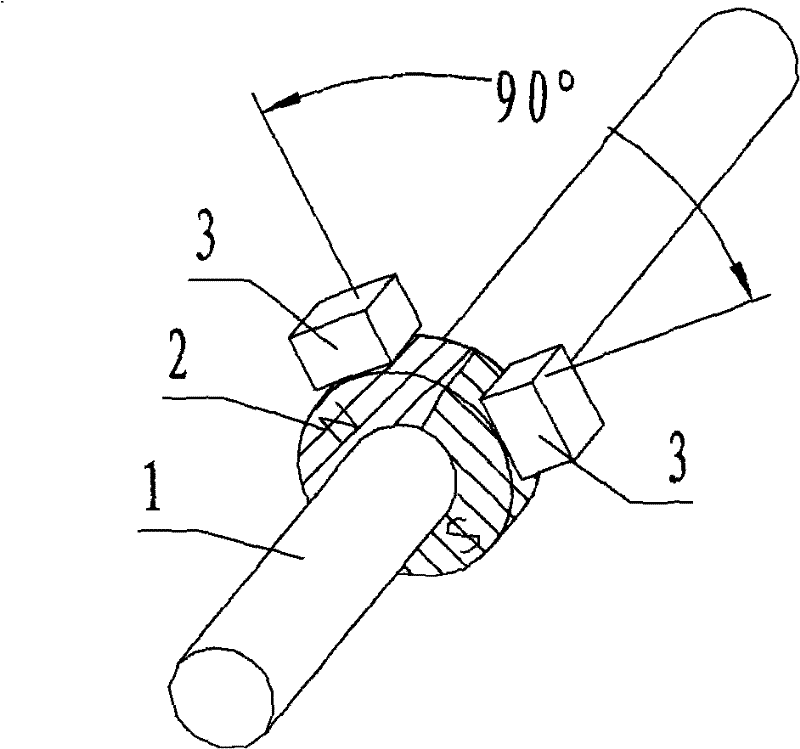

[0025] Embodiment one, refer to figure 1 , figure 2 , Figure 4 ~ Figure 7 ;

[0026] A Hall method, an error-free counting method for the number of revolutions of a rotating body with dual sensors in orthogonal distribution;

[0027] Sensor 3 type: Hall sensor;

[0028]Initiator 2 type: half ring is N pole, half ring is S pole, thin cylindrical ring permanent magnet;

[0029] Judgment record method:

[0030] Facing the output end of the rotating object 1, let the sensor 3 located above the initiator 2 of the rotating object 1 be the upper sensor H 2 , the sensor 3 located on the right side of the initiator 2 of the rotating object 1 is the right sensor H 1 , when the rotating object 1 rotates, the initiator 2 rotates synchronously with the rotating object 1:

[0031] A. The computer performs a subtraction count on the edge of each waveform of the pulse square wave 4 corresponding to the following relationship, that is, it is judged to be counterclockwise and reversely...

Embodiment 2

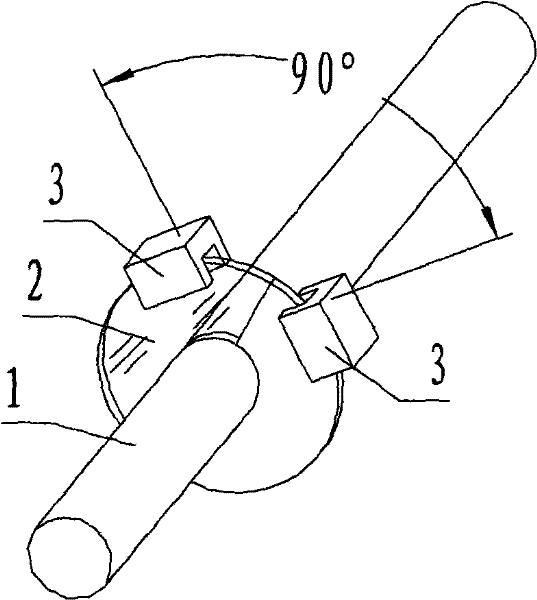

[0037] Embodiment two, refer to figure 1 , image 3 , Figure 4 ~ Figure 7 ;

[0038] A photoelectric method, an error-free counting method for the number of revolutions of a rotating body with dual sensors in orthogonal distribution;

[0039] Sensor 3 type: photoelectric sensor;

[0040] Initiator 2 type: a thin cylindrical ring-shaped shading plate with half light-transmitting and half opaque;

[0041] Judgment record method:

[0042] Same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com